Used TEL / TOKYO ELECTRON Alpha 8SE #9253985 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9253985

Wafer Size: 8"

Vertical furnace, 8"

Process: Nitride

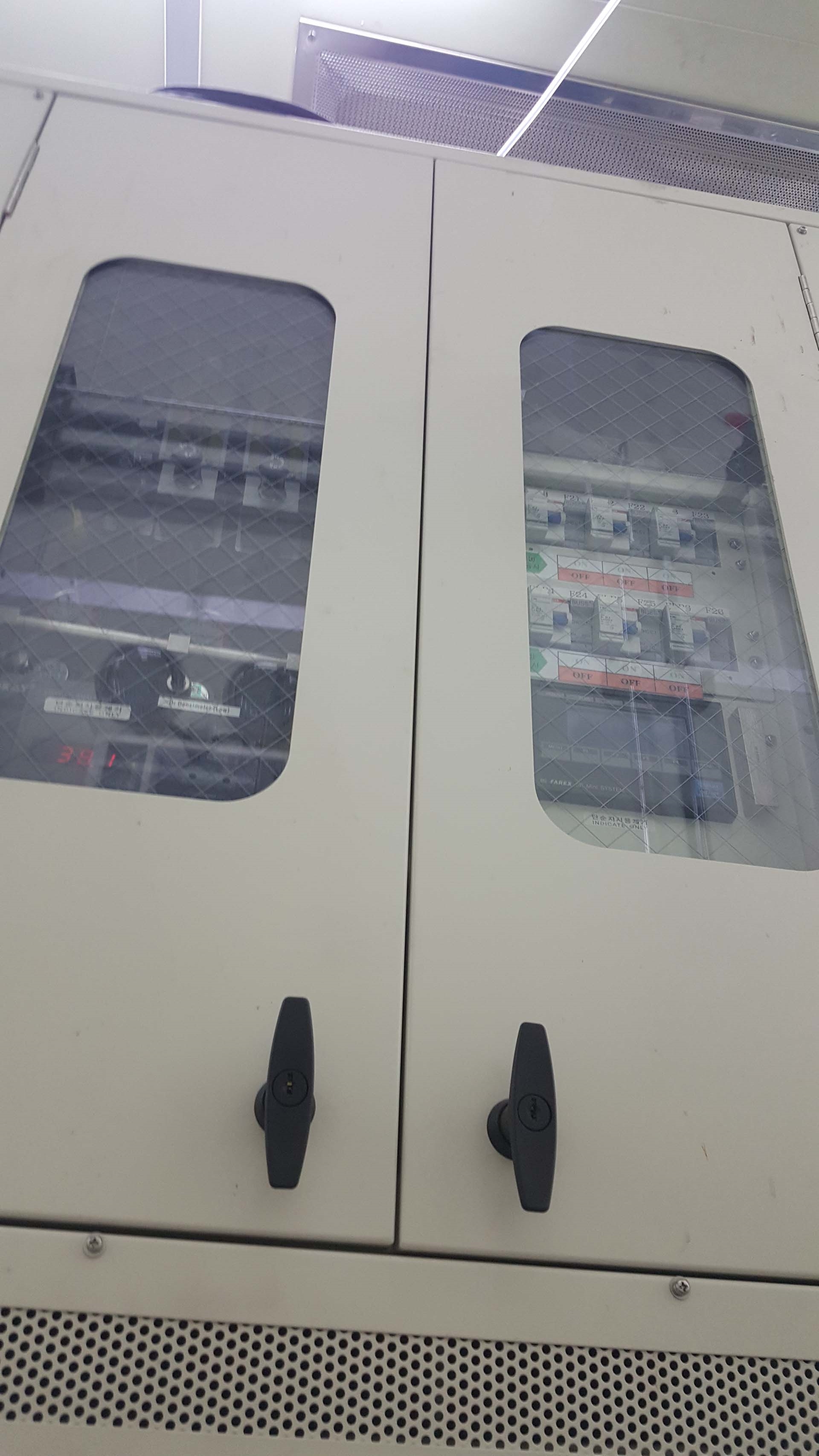

WAVES Display for PDU unit

Furnace:

WAVES 3.11 Controller

CKD Pressure controller

M560 Temp controller

VMM-40-101 Heater

(5) Control zones

IGS Gas pattern panel

PDU Unit

R-Axis

NOMARL ETC

AERA MFC

MKS Baratron Pressure controller:

MKS Baratron Sensor BS1

MKS Baratron Sensor BS2

N.C Pressure gauge

N.C Pressure gauge controller

CKD Pressure control

N.C Main valve

Loading system:

Transfer fork: 4+1

(21) Upper stages

(2) Transfer stages

Flat zone aligner

Wafer counter sensor

Power supply:

Heater power: 440 V

Control power: 208 V.

TEL / TOKYO ELECTRON Alpha 8SE is a semiconductor device diffusion furnace and accessories designed to provide production solutions for linked devices. TEL ALPHA-8SE is an incredibly durable and versatile furnace that is capable of performing a variety of complex fabrication and assembly processes. As such, it can be used in variety of industrial applications, most prominently in the semiconductor components and device assembly industries. TOKYO ELECTRON ALPHA-8 SE features a stainless steel chamber with ceramic liners, allowing for precise temperature control with uniformity and repeatability. This helps eliminate temperature variation for the precise fabrication and fabrication of temperature-sensitive components. The temperature range of ALPHA-8 SE is from 200°C to 1,000°C and is designed for accurate temperature control and precise oxidation control. The furnace also presents excellent internal uniformity, delivering consistent temperatures throughout its chamber. This is achieved with its circular showerhead design and precise amount of gas flux. Inside ALPHA-8SE, a precise 12-zone gas system ensures uniformity and repeatability in all processes through the proper blend of gases. This furnace is capable of many processes associated with the assembly of semiconductor components. ALPHA 8 S E can be used in anneal processes, both oxidation and reduction, as well as etching and dopant diffusion processes. It also supports processes like low-pressure Chemical Vapor Deposition (CVD), diffusion of oxygen, sulfurous oxide and nitrogen oxide, as well as wet etch, thermal oxidation and nitridation. TEL ALPHA 8S-E operates using its proprietary process control software, allowing for precise and consistent control of various parameters. This program provides for easy setup and adjustment of all process parameters and control values with expert modes that allow operators to conduct up to four processes in a single cycle. Designed with the utmost attention to safety and reliability, TEL ALPHA 8 SE is an intuitive and efficient diffusion furnace for the fabrication and assembly of semiconductor components. With its precise temperature uniformity, repeatability, and diverse process capabilities, this furnace can help to ensure the fast and accurate production of linked devices.

There are no reviews yet