Used THERMCO 5200 #9076495 for sale

URL successfully copied!

Tap to zoom

ID: 9076495

Wafer Size: 6"

Vintage: 1995

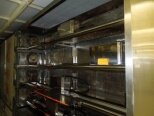

Diffusion furnace / LPCVD, 6"

(2) Tubes: Gate oxide

(1) Tube: Oxide

(1) Tube: poly LPCVD

Four tubes with semi-auto boat loader

Laminar flow and gas cabinet

High temperature element with 40’’ flat zone

Tube1: Poly (SiH4,N2O HCL,N2)

Tube2: Poly (SiH4,N2O HCL,N2)

Tube3: Poly (SiH4,N2O HCL,N2)

Tube4: Poly (SiH4,N2O HCL,N2)

1995 vintage.

THERMCO 5200 Diffusion Furnace is a powerful and reliable solution to providing thermal processing of semiconductor substrates. This batch-type furnace is specifically designed for thermal processing such as doping, nitridation, oxidation, thermal oxidation, and annealing. The furnace includes a drive system, temperature controller and heating elements. The furnace has a maximum temperature of 1200 °C and can operate up to a pressure of 200 millibar. It offers an impressive rate of heating and cooling with a uniform temperature profile over the substrate area. The furnace's structure is designed with high-grade and thermal resistant materials, while the outer casing is made with epoxy coated steel designed to survive even under high temperature and pressure exposure. The high temperature-resistant insulation along with anodized aluminum seals on the chamber doors and other hardware ensure maximum heat retention and safety. The heating elements are made of graphite with a molybdenum/tungsten alloy wrap, ensuring uniformity and strength. The vacuum system of 5200 consists of a rotary vacuum pump and a diffusion pump with a pre-vacuum pump. The rotary vacuum pump evacuates the chamber from atmospheric pressure down to 1 mbar. The pre-vacuum pump evacuates the chamber from atmospheric pressure to 20 mbar. The diffusion pump evacuates the chamber from 20 mbar down to 10-8 mbar, while the getter pump maintains the vacuum even when the chamber is shut off. The advanced furnace control system ensures accurate temperature control and is designed with an LCD display and programmable controls for various batch processes. THERMCO 5200 offers a host of accessories for customized operations specific to the processing needs of the user. These include quartzwafers, manual and automatic loading platforms, inert gas flow control systems, temperature sensors, and a variety of protection options. It also comes with a touch panel controller, which allows for hands-free chamber control and monitoring during the processing cycle. To sum up, 5200 Diffusion Furnace is a robust and reliable solution for thermal processing of substrates. Its design allows for uniform temperature distribution and high accuracy of temperature control, while the chamber door and other hardware ensure maximum heat retention. It is suitable for a wide range of thermal processing operations and its configuration can be tailored to the specific needs of the user.

There are no reviews yet