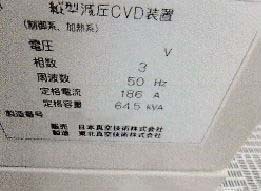

Used ULVAC V10-100LC #9350452 for sale

URL successfully copied!

Tap to zoom

ID: 9350452

Wafer Size: 6"

Vintage: 2009

Vertical furnace, 6"

Process: Sin / HTO

Main body

Control unit

Heater

JIG

Duct unit

Top cover

(6) Quartz tubes

UPS

2009 vintage.

ULVAC V10-100LC is a diffusion furnace and accessory that is used in a variety of chemical processes. It provides a precise, low-temperature environment for the diffusion of materials in a process known as Low-Pressure Chemical Vapor Deposition (LPCVD). This type of furnace is used primarily to grow thin films of material, used in the semiconductor industry for the production of active and passive components. V10-100LC features a unique design that utilizes a low-vacuum environment to provide a temperature range of -50°C to 800°C and a low thermal gradient of 0.1 to 0.2°C/min. The system includes an advanced digital controller, capable of accurate temperature, power, and pressure monitoring and control. In addition, the furnace includes two thermocouples, one for temperature measurement and one for pressure measurement. The unique design of ULVAC V10-100LC features a multiple-sheathed quartz tube, allowing the deposition to occur in a low-vacuum environment that is physically isolated from other parts of the system. This ensures uniform temperature control throughout the furnace and a more consistent process. Additionally, the furnace utilizes a quartz heating element, high-efficiency thermal insulation, and a CAD/CAM optimized bell-shaped cover to provide excellent temperature uniformity. Additional features of V10-100LC include rapid cooling capability, high emissivity, and the ability to perform automatic shut-off at the end of a process cycle. ULVAC V10-100LC's small footprint, lightweight, and rugged design make it a great choice for industrial applications. Further, the system has been designed with flexibility in mind and can be easily adapted to a variety of different production processes. V10-100LC is an economical and versatile solution for low-temperature diffusion of a variety of materials. Its low-temperature operation, high-precision control, and compact design make it a great choice for producing thin films of material in the semiconductor industry and a multitude of other applications.

There are no reviews yet