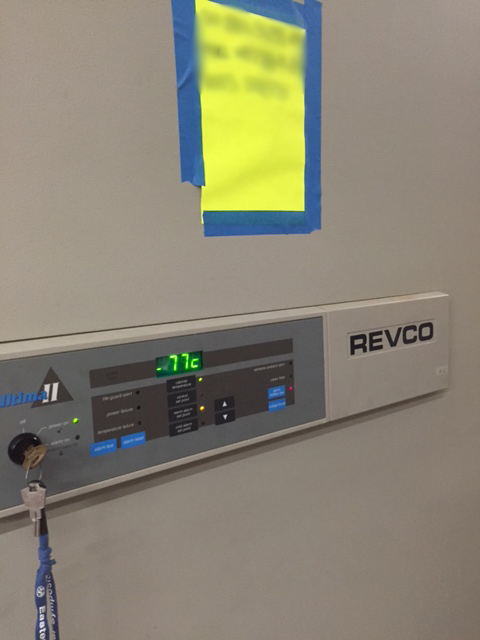

Used REVCO ULT 2586-9D35 #9062368 for sale

URL successfully copied!

Tap to zoom

REVCO ULT 2586-9D35 is an environmental chamber ideal for a range of different applications, such as the conditioning and testing of materials in a range of temperatures and humidities. The unit features a temperature range of -85°C to +85°C, with a relative humidity range of 10-95%. It is also capable of achieving extremely low temperatures, capable of reaching -79°C due to the use of liquid nitrogen monitor wells. ULT 2586-9D35 has a stainless steel interior chamber, and features a series of shelves that are heated from below. The shelves can be moved up and down within the chamber to extend or contract the height of the chamber. It has a main control panel located on the exterior making it easy to control the internal conditions. The chamber also contains a door interlock equipment to ensure that the chamber has stabilized before the chamber door can be opened. REVCO ULT 2586-9D35 is capable of reaching rapid temperature changes, thanks to its individual test wells which allow for specific product testing. It features an absolute pressure safety system that monitors pressure, allowing for quick temperature changes in the chamber. It also contains a built-in hydraulic lift unit allowing for the easy removable of the test wells, shelves, and other components within the unit. The chamber is constructed with a thermally insulated copper cryogenic shield to prevent heat transfer. The shield also works to reduce temperature gradients within the chamber. ULT 2586-9D35 is also equipped with temperature sensors and controllers, allowing for precise control of the chamber environment. The unit uses Boron Silicate to help prevent contamination and provide a sterile environment. The chamber also includes a series of valve controllers for supplying gas to the chamber. Overall, REVCO ULT 2586-9D35 is an ideal environmental chamber for a variety of industrial and research applications. Its precise temperature and humidity control enable a wide range of testing scenarios, while its construction materials provide added insulation and reduce contamination risks. The unit's built-in safety features help to guard against outside temperature changes, pressure build-ups, and contamination, and its built-in lift machine makes replacing internal components easy.

There are no reviews yet