Used ALCATEL / ADIXEN / PFEIFFER AMS 4200 #9285833 for sale

URL successfully copied!

Tap to zoom

ID: 9285833

Vintage: 2008

Plasma DRIE etcher

Dual load locks

Robot transfer module

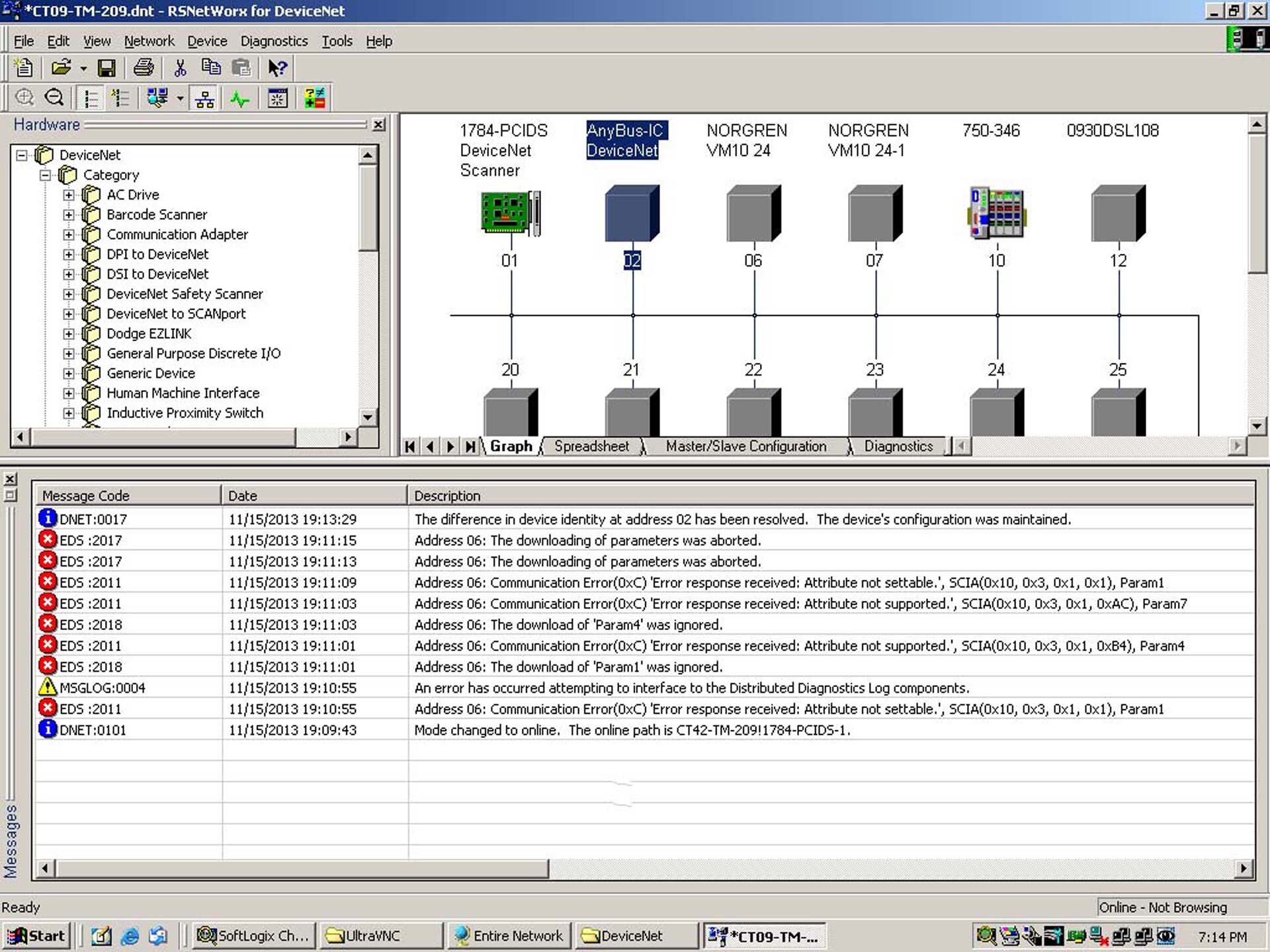

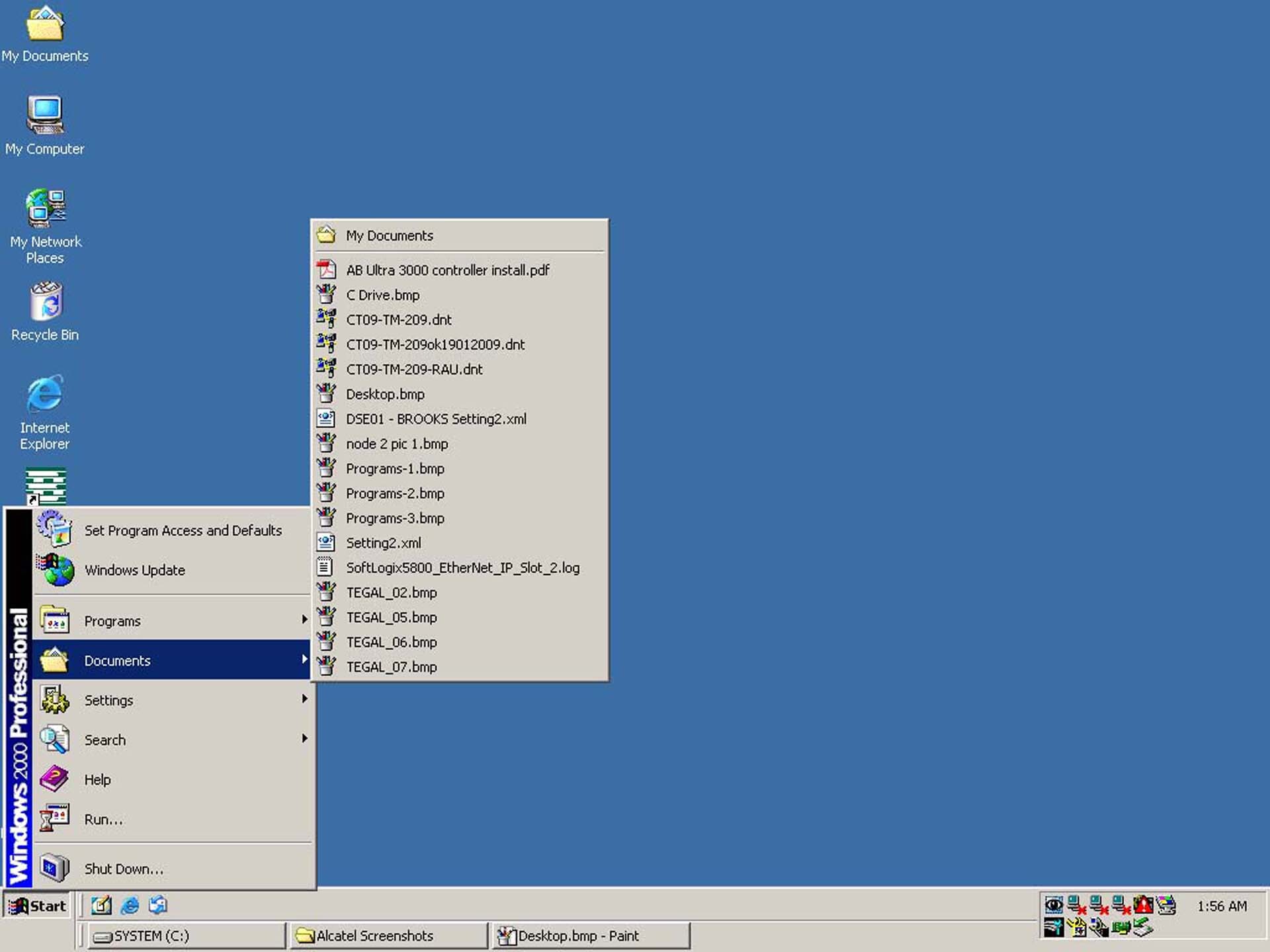

Controller rack

RF Generator rack

Front and rear monitor

BROOKS AUTOMATION Platform

Magnatron 7 Robot

ACT 600M TMP Turbo pump

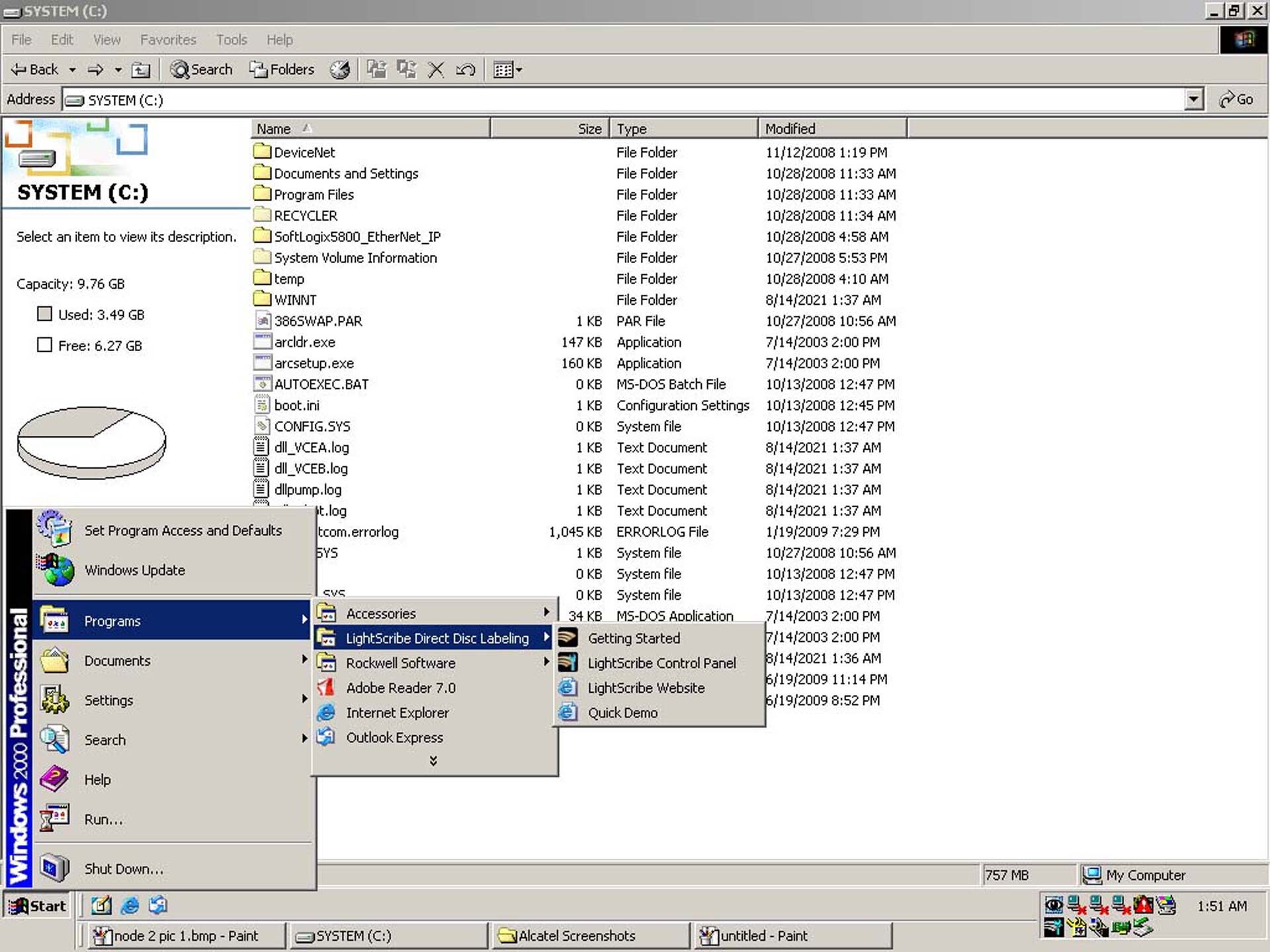

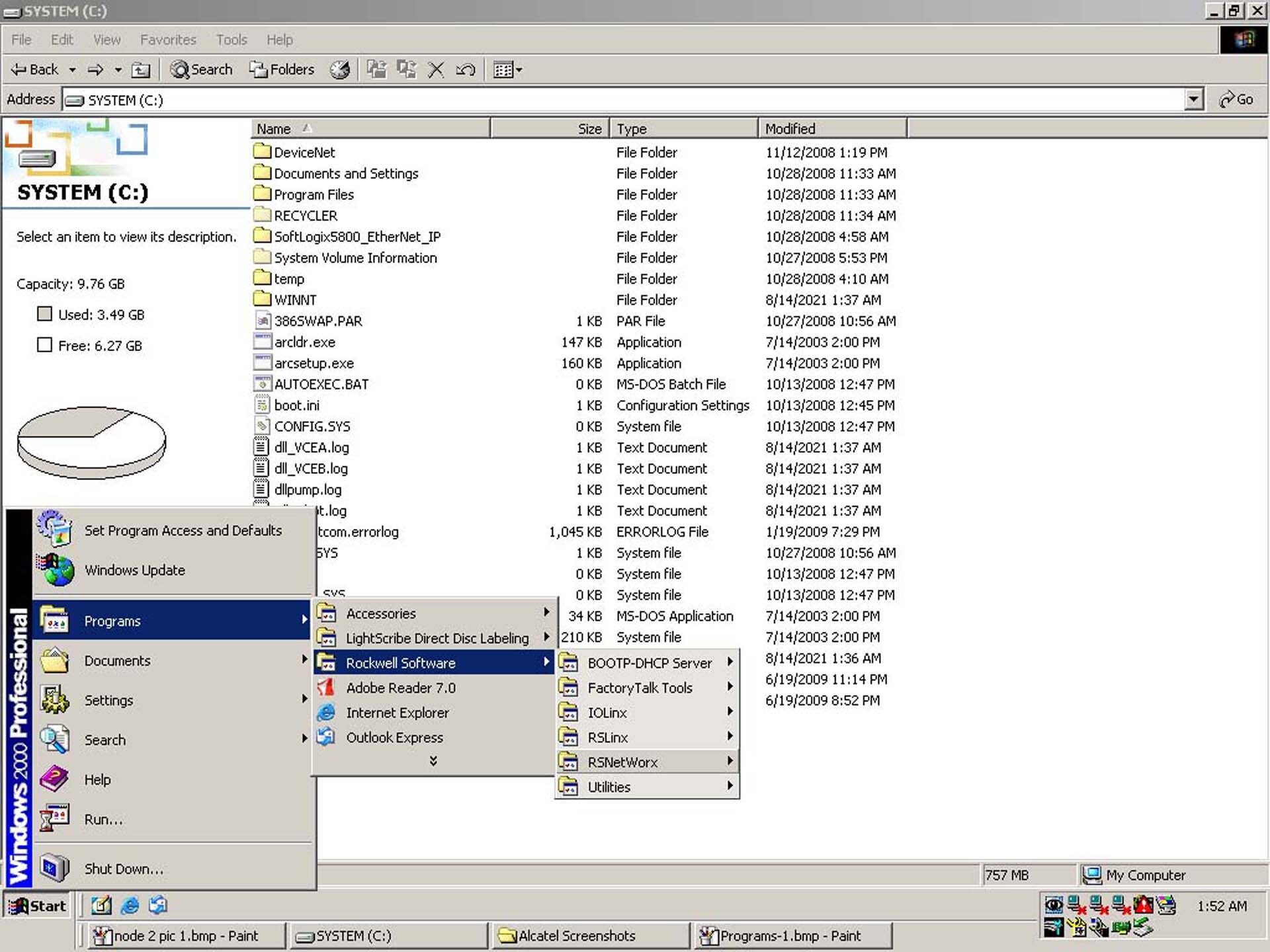

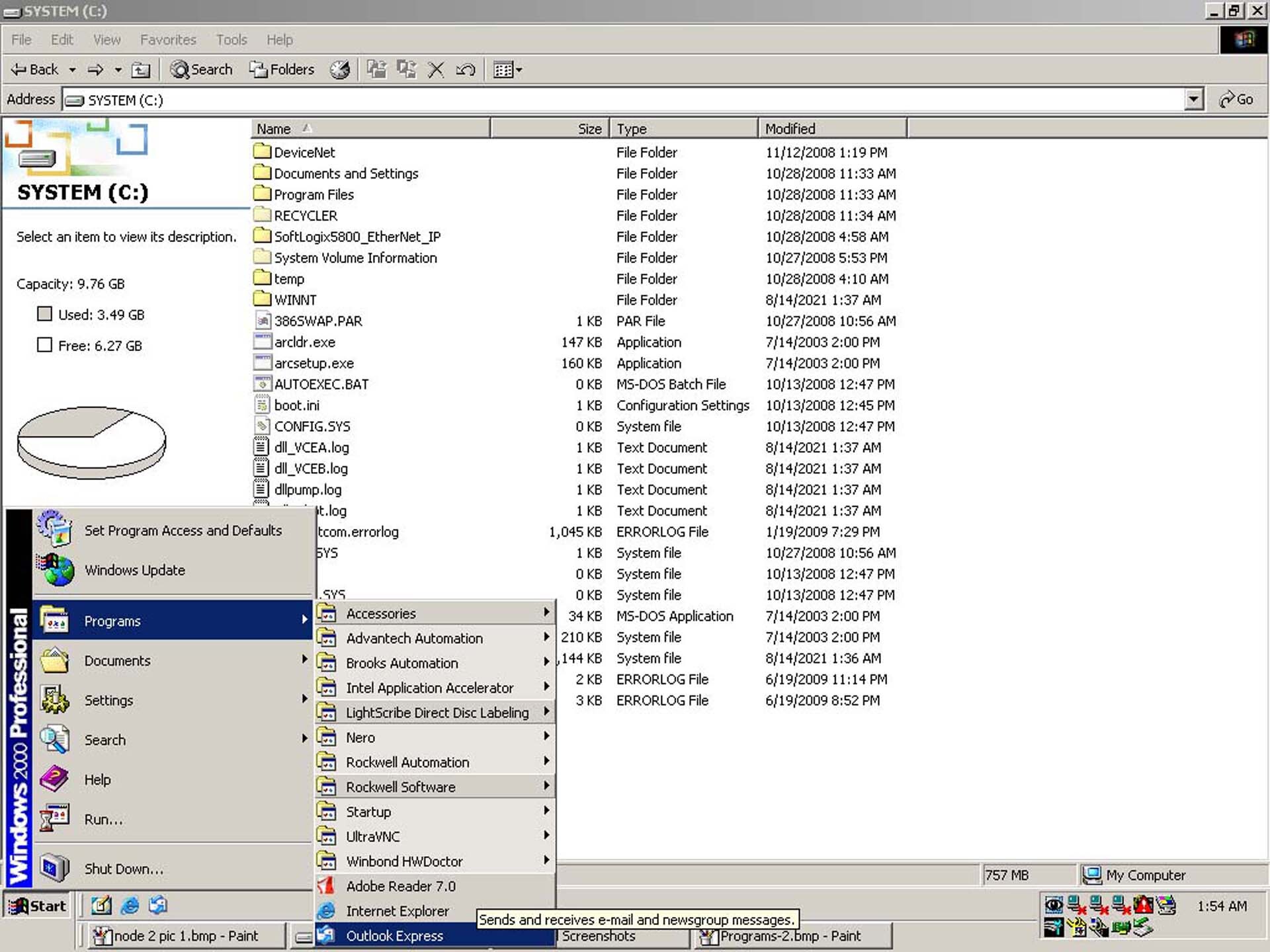

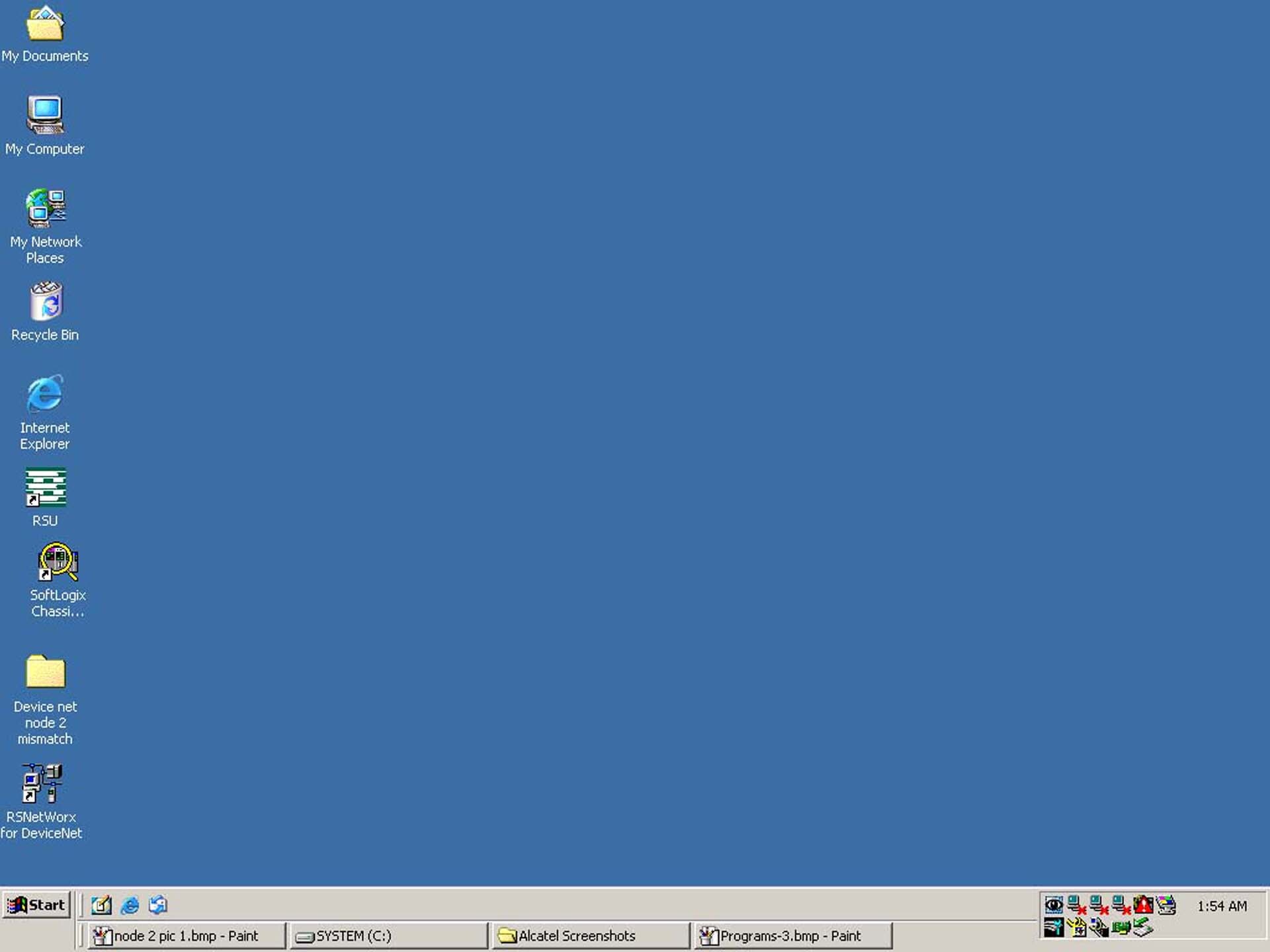

Interface computer

Transfer computer process chamber: AMS X200

ACT 1300M TMP Turbo pump

(2) SEMCO HV52000C SEREN L301 RF Power supplies

ADVANCED ENERGY Dressler cesar RF

ENI Spectrum B-3013 RF Generator

Process gases:

Gas / Range

SF6 / 1000 SCCM

C4F8 / 400 SCCM

O2 / 100 SCCM

O2 / 800 SCCM

Ar / 200 SCCM

N2 / 1000 SCCM

Ar / -

CHF3 EDM / -

CE Marked

Power supply: 200/208 VAC, 3 Phase, 50/60 Hz

2008 vintage.

ALCATEL / ADIXEN / PFEIFFER AMS 4200 is a dedicated plasma etcher / asher specifically designed for demanding aluminum etching and ashing requirements. ADIXEN AMS 4200 has a touchscreen HMI controller with a wide range of etching and ashing capabilities. It's designed with a 700 watt Plasma Source, allowing for increased repeatability and increased yield in the etching / ashing process. It has a unique double-wall stainless steel design, which creates and maintains a vacuum chamber, ensuring proper processing when etching / ashing aluminum components. It also comes with a variety of safety features, such as a timer-controlled gas valve, a gas-overflow valve, and a dual speed vacuum regulator, for increased safety. ALCATEL AMS 4200 also has many customizable settings, such as adjustable DC and RF frequencies, width modulation, and current profiles, allowing the operator to tailor the etching process and ensure the desired results. The built-in RF generator offers a wide range of power levels, from 50 W to 700 W, which allows the etching process to be fine-tuned for each specific application. In addition, the integrated chamber pressure control and built-in pressure gauge allow for precise chamber pressure control when etching or ashing aluminum components. PFEIFFER AMS 4200 comes with an array of features that increases efficiency and reproducibility while minimizing maintenance costs. A customizable software package with recipe storage and alarm logging allows the operator to easily configure and store processing recipes and troubleshoot operations. Additionally, automatic gas regulators and an optional programmable lift-off system ensure repeatable productivity. An effective and reliable two-source supply system is also available, reducing set-up times and improving process repeatability. Lastly, AMS 4200 can be combined with a variety of modules, such as an in-situ vacuum leak detect module, that can further reduce setup costs and improve process repeatability. Overall, ALCATEL / ADIXEN / PFEIFFER AMS 4200 is a reliable and efficient etcher / asher. Its features improve process repeatability and minimize maintenance costs, while its customizable settings allow for precise control of the etching/ashing process, ensuring optimal results.

There are no reviews yet