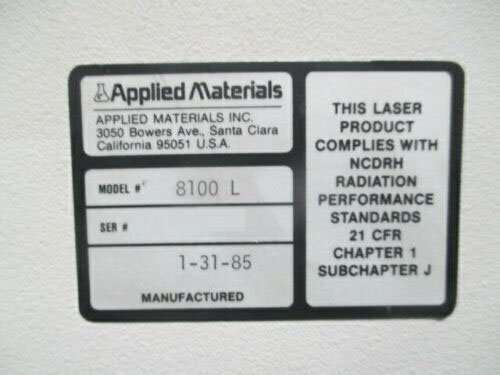

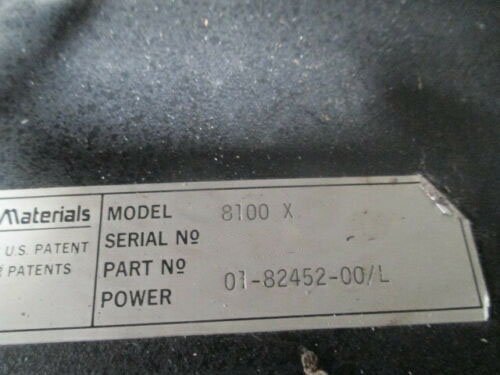

Used AMAT / APPLIED MATERIALS 8100 #9356903 for sale

URL successfully copied!

Tap to zoom

ID: 9356903

Oxide etcher

CTI-CRYOGENICS Cryo-Torr Vacuum pump

LEYBOLD-HERAEUS Turbotronik NT 450 Vacuum pump controller

LEYBOLD-HERAEUS Turbo pump

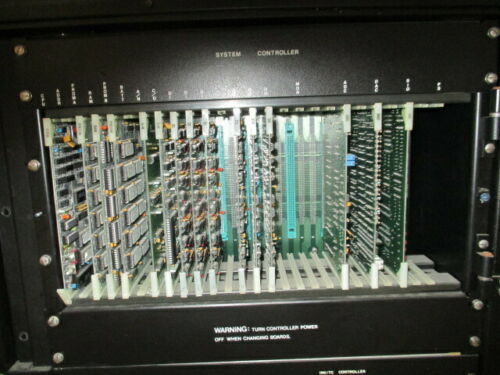

Boards: CPU, PROMA, RAM, PROMB, A/N, C/D, (3) DI, (3) DO, ADC, DAC, SIO

Mass Flow Controller (MFC):

Make / Model / Gas / Range

TYLAN / FC-260V / N2 / 100 SCCM

TYLAN / FC-260 / N2 / 100 SCCM

TYLAN / FC-260 / N2 / 50 SCCM

TYLAN / FC260KZ / BCL3 / 200 SCCM.

AMAT / APPLIED MATERIALS 8100 is a high-precision etcher/asher equipment designed for advanced semiconductor manufacturing processes. This system has been designed using advanced lithography technology to deliver precise and consistent results for etching/ashing applications. It uses physical vapor deposition (PVD) and reactive ion etching (RIE) techniques for advanced patterning and micron layer etching/ashing. AMAT 8100 offers outstanding precision with its CompuShape software, which allows for precise formation of shapes and patterns on the substrate surface. With its advanced control unit, APPLIED MATERIALS 8100 ensures consistency and accuracy of the process. The computer-controlled chamber temperature, pressure, and flow can all be monitored and adjusted to maximize process performance. The machine is also capable of performing tests to validate process parameters and stability. 8100 also offers an impressive feature set that lives beyond its predictable performance. The tool comes equipped with an in-house gas asset that features 100 gases, allowing access to up to 30 processes with minimal effort. Its photomask and auto-alignment capabilities ensure that the desired pattern is in perfect alignment with the substrate. Further, the user-friendly interface and self-diagnostics features make AMAT / APPLIED MATERIALS 8100 an ideal choice for most etching/ashing processes. In terms of safety, AMAT 8100 is equipped with industry-standard safety features that reduce potential risks and prevent operational errors. Its in-vacuum auto-filter model provides additional particle control to ensure a clean-room grade etching/ashing environment. APPLIED MATERIALS 8100 also has both equipment and user lockout capabilities that ensure there won't be any unauthorized changes to the system. 8100 is a powerful etcher/asher unit that is suitable for a wide variety of application and process requirements. With its precision control features and advanced lithography technology, sophisticated patterns and shapes can be etched or ashed with the highest level of accuracy and repeatability. Its robust feature set, safety features, and user-friendly interface make it a reliable and cost-efficient choice for the most demanding semiconductor fabrication processes.

There are no reviews yet