Used AMAT / APPLIED MATERIALS 8100 #9356906 for sale

URL successfully copied!

Tap to zoom

ID: 9356906

Oxide etcher

Pump power rack

Heat exchanger

Electrical power rack

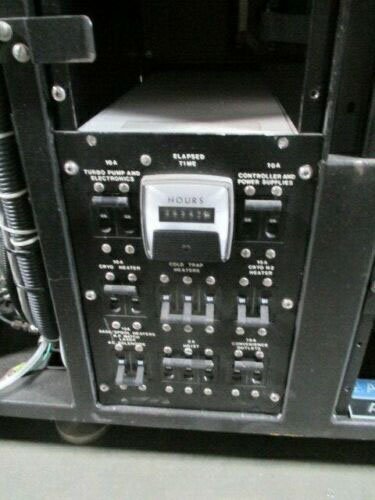

8100E Circuit breaker box, P/N: 01-81914-00

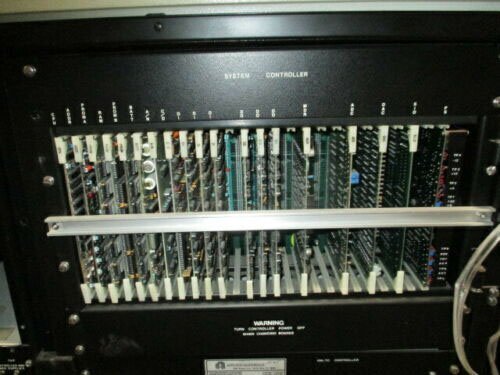

Boards: CPU, ADDR, PROMA, RAM, PROMB, BATT, A/N, C/D, (3) DI, (3) DO, MDR, ADC, DAC, SIO, PS.

AMAT / APPLIED MATERIALS 8100 is an etcher/asher for semiconductor device production. Its compact design, versatility in etch capabilities, and high throughput rate make it an ideal solution for both low and high volume production and engineering applications. AMAT 8100 offers an integrated microwave generator that provides a higher source power than manual methods to allow for the precise control and processing of complex film structures. This generator is also paired with an in-situ pressure controller to ensure accurate etch uniformity and reduced susceptibility to drift. APPLIED MATERIALS 8100 plates feature an innovative multi-point load-lock equipment designed to provide close contact between the workpiece and the process fluids for optimum uniformity of process results. 8100 is equipped with an array of welded, interlocked components that ensure the safety, reliability, and accuracy of the process. This system uses an autofeed lock-in feature to ensure that all safety components remain securely engaged during the process. Additionally, AMAT / APPLIED MATERIALS 8100 boasts an integrated cassette-to-wafer lift and transfer unit that optimizes loading time, reduces loading errors, and ensures uniformity of process results. AMAT 8100's advanced automation and process control systems provide users with the ability to monitor etch processes in real-time and make adjustments on the fly. This includes a wide range of process measurements and alarms, along with full data display and control, and multiple-recipe memory and storage for repeatable etch processes. APPLIED MATERIALS 8100 also incorporates an advanced advanced fluid management machine that allows users to configure the best temperature and flow distribution for their desired etch process. 8100 has multiple on-board lines that can be used to bring in a variety of fluids, including corrosives, photoresists, and dielectrics. AMAT / APPLIED MATERIALS 8100 further supports efficient management of consumable materials, such as gas delivery, operator signature, and user-defined data logging. Given its combination of features, AMAT 8100 etcher/asher is a highly capable and reliable solution for semiconductor device production. APPLIED MATERIALS 8100's added safety, precision, and automation systems make it a suitable choice for both low and high-volume production and engineering applications.

There are no reviews yet