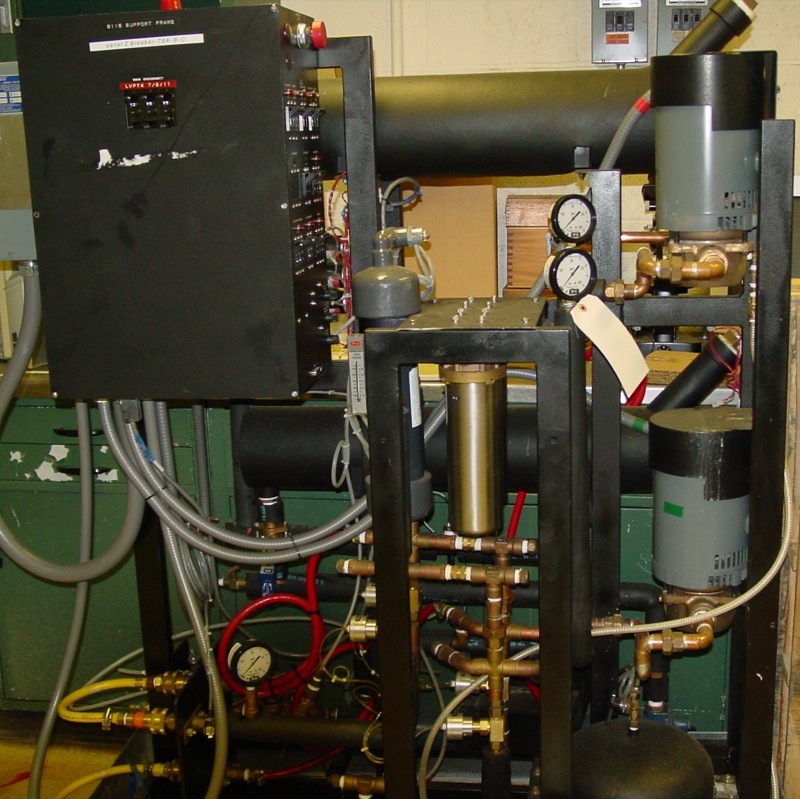

Used AMAT / APPLIED MATERIALS 8115 #78336 for sale

URL successfully copied!

Tap to zoom

ID: 78336

Wafer Size: 5"

Plasma Etcher for 5" wafers

System includes:

25 x 25 SS water cooled bell jar

Power hoist

AMAT PLC controller

Auto valve control

2Kw RF power supply with matching network

Multi MFC gas inlet & pressure controller

Heat & cool exchanger pump assembly

Three gas manifold

Leybold TMP1000 L/S Turbo pump

D60 Mechanical pump

Quartzware and Spares

Manuals

Not included:

RF power supply

Turbo pump and controller

Gas and vacuum manifold

Mechanical pump

Gate valve

O-rings

Seals

Gaskets

Currently stored in a warehouse.

AMAT / APPLIED MATERIALS 8115 etcher / asher is an advanced dry etching equipment designed to process round or rectangular wafers up to 8" in size. It is used in a variety of industries, such as semi-conductor manufacturing, flat panel display, and MEMS fabrication. Its etching capabilities make it ideal for similarly sized substrates. This system features a sophisticated control unit, which allows for precise process control and repeatability. The machine's precision two-axis motion motion control enables high performance, repeatable etching results. An additional feature of AMAT 8115 is its capability to handle a wide range of process gases including O2, Cl2, SF6, NH3, etc. This gas flexibility makes it adaptable for a variety of etching needs. APPLIED MATERIALS 8115 utilizes a hard-cathode, open-field component, which is designed to provide more uniform etching compared to magnetron systems. Additionally, the integrated RF generator can deliver a high power output of up to 300 W. This tool operates within a compact footprint and is composed of a transfer module, reaction chamber, robotics and exhaust asset. The model is designed to facilitate automated loading and unloading of wafers. The equipment is also equipped with gas-monitoring capability to ensure the process is running at optimal levels. 8115 Etcher / Asher is built to offer high performance etching with extreme accuracy, repeatability, and long-term reliability. It is a convenient and cost-effective tool for semi-conductor manufacturers and other industries utilizing micro-fabrication processes.

There are no reviews yet