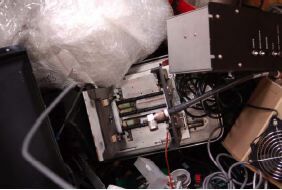

Used AMAT / APPLIED MATERIALS 8300 #101449 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 8300 Asher/Etcher is a two-stage, high throughput, lithography compatible, thermal chemical processing equipment designed for etching or ashing of a wide variety of materials, including silica, quartz, silicon, germanium and other semiconductors. The system is capable of operating with high speed (over 90 wafers per hour) and with high uniformity. AMAT 8300 unit is equipped with a high-vacuum, multi-step asher platform and a high-performance, low-vacuum asher/etching chamber, allowing for easy throughput of processes. The high-vacuum machine can achieve pressures of up to 1.2E-7 torr, allowing for uniformity across the process. The through-the-wafer processing chamber is optimized for low-vacuum operations. The high throughput etching/ashing chamber includes a process gas selection, a gas-flow controller, and a temperature controller. All of these components are sensitively temperature monitored and/or processed to ensure optimal control of the process. The end result is an excellent edge definition, low sheet resistance, and minimal loading effects with typical refinements seen in different types of ashers or etchers. APPLIED MATERIALS 8300 features a patented, electrode-less plasma source loaded with noble gases, which provides high predictability of process parameters. This ensures a uniformity across the process. The tool is also equipped with an upstream gas box and gas mixing asset, which enable process gases to be accurately and precisely measured and monitored along with temperature control. 8300 is designed for excellent throughput. The high-vacuum model can process up to 90 wafers per hour and the low-vacuum equipment can process 45 wafers per hour. This means that it is able to rapidly process a large number of wafers of different sizes and thicknesses. AMAT / APPLIED MATERIALS 8300 also offers great ease of use, with an intuitive User Interface (UI) that allows users to easily set up and run processes. The UI includes advanced tools such as a recipe library, process monitor, and history log. This allows users to quickly analyze the performance of their process and adjust it accordingly. Overall, AMAT 8300 Asher/Etcher is an extremely robust and reliable system for etching/ashing of a wide variety of materials for advanced processes. It is designed for high throughput and uniformity, and provides a user-friendly interface to quickly and easily set up and run processes. APPLIED MATERIALS 8300 offers excellent process results and a great degree of flexibility and scalability.

There are no reviews yet