Used AMAT / APPLIED MATERIALS 8300 #9087521 for sale

URL successfully copied!

Tap to zoom

ID: 9087521

Wafer Size: 8"

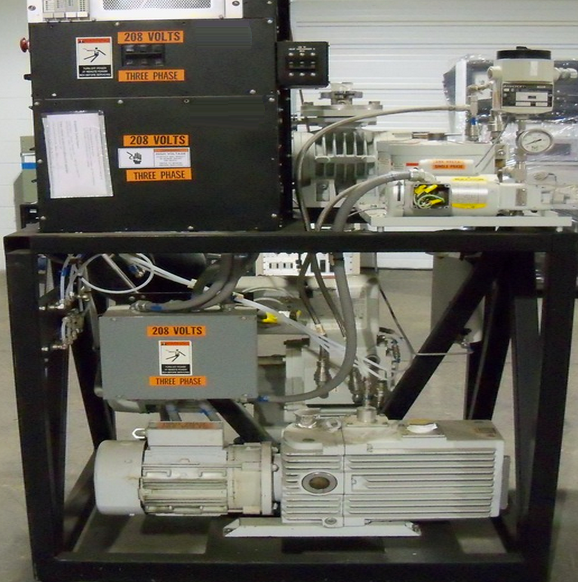

Oxide etchers, 8"

NESLAB Heat exchanger

LEYBOLD Wet pump.

AMAT / APPLIED MATERIALS 8300 is a highly advanced etching/asher platform designed to process wafers of various substrates. AMAT 8300 enables manufacturers to create high-density products for advanced technologies including transistors, microchips, integrated circuits, and photovoltaic solar cells. This equipment is capable of achieving precise etching results, making it ideal for volume production requirements. APPLIED MATERIALS 8300 provides superior process control, allowing it to match the desired etch characteristics. The platform includes multiple hardware units working in tandem, including a plasma source, power utilization system, source controller, gas delivery unit, match network, and chamber. These hardware components work together to provide clean and efficient etching on the wafer surface. The plasma source uses radio frequency (RF) accelerators to create argon plasmas that provide a non-eroding etch surface. This is because the RF accelerators do not require direct contact with the wafer surface, thus enabling the process to proceed quickly and cleanly. The power utilization machine then adjusts the applied power, so that the user only pays for the power used in the etching process. The source controller uses pressure-regulated, programmable assist gases and the match network uses frequency tunable circuits to configure the plasmas for exact etching requirements. 8300 is well suited for various applications, ranging from shallow trench isolation to contact etching of copper and optical alignment. It is also ideal for a broad range of applications, including photomask, embedding, plasma enhanced chemical vapor deposition, and surface treatments. Furthermore, it is capable of handling up to 4 inch substrates with excellent repeatability. With its capability to deliver precise and uniform etchings, AMAT / APPLIED MATERIALS 8300 tool is an ideal choice for manufacturers looking to produce quality and cost-effective products. It is highly reliable, making it cost-effective and highly productive. By leveraging a wide range of process control options along with the latest technologies, this asset provides customers with exceptional value.

There are no reviews yet