Used AMAT / APPLIED MATERIALS 8300E #9177298 for sale

URL successfully copied!

Tap to zoom

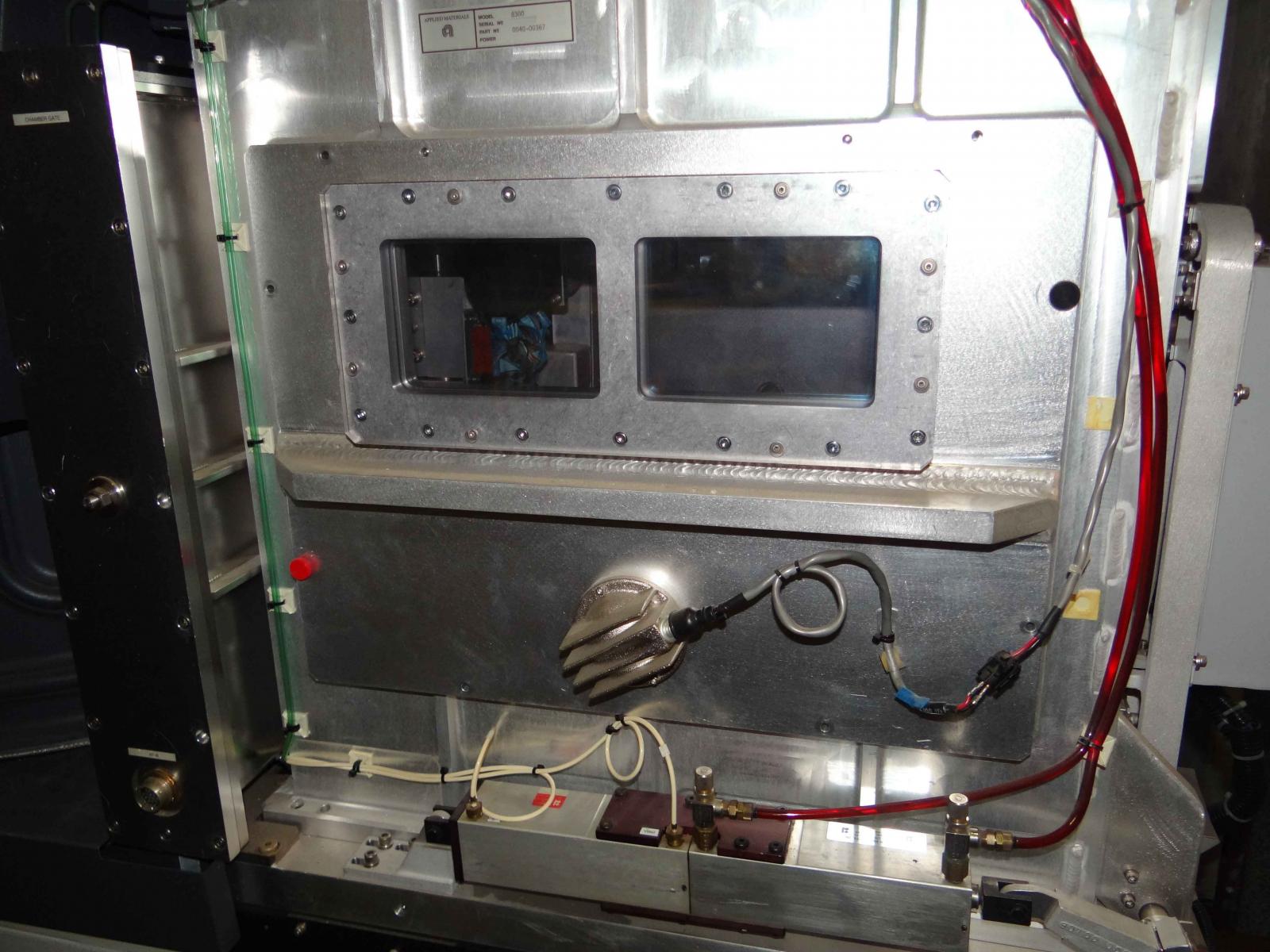

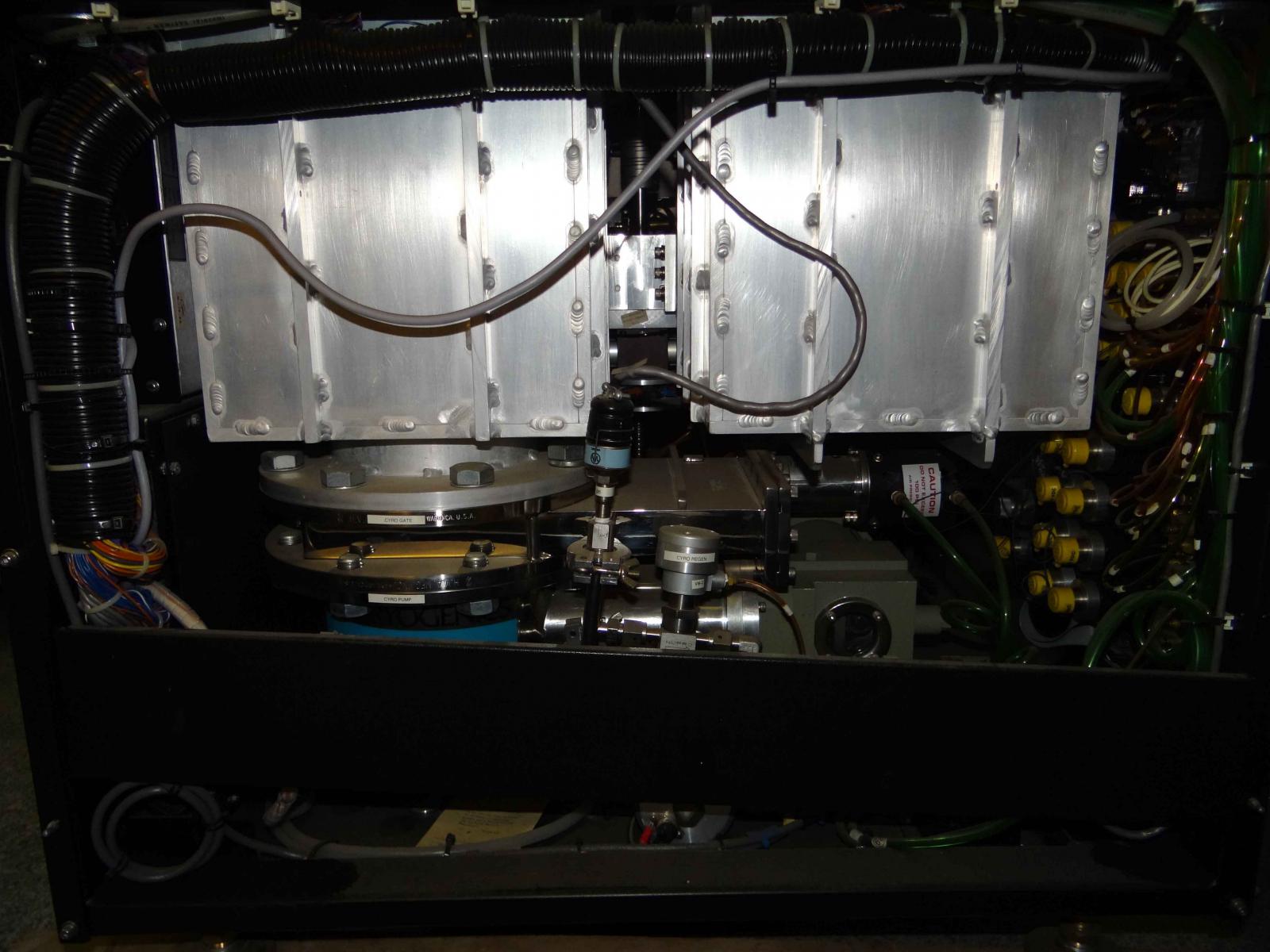

AMAT / APPLIED MATERIALS 8300E etcher/asher is an essential tool for surface-micromachining and semiconductor applications. It is a high-performance equipment designed for advanced etching and ashing operations. AMAT 8300E offers precise control of etching parameters and provides a wide range of selectable process gas and recipe setups to meet the needs of the modern microelectronics fabrication facility. APPLIED MATERIALS 8300 E is equipped with a Hybrid Rapid Thermal Oxidation/Diffusion (HRTOD) process chamber featuring precise control of process parameters such as temperature, pressure, time, and flow. The unique ability to employ both rapid thermal processing (RTP) and chemical dissociation processes in the same chamber provides the highest quality plasma etch and ash processes available. It also includes a main chamber temperature range of 25° to 850°C, a quartz view window, and a process environment of up to 20 mTorr. This system is also equipped with an Oxide Removal Unit (ORS) for the safe removal of mineral residues found on aluminosilicate substrates and other residues left from previous processing procedures. The ORS features an integrated gas injector to quickly break down and remove oxides, nitrides, and metals from film surfaces. AMAT 8300 E provides a high-efficiency RF generator for Optimal Etching Control (OEC) enabling precision in etching parameters and improved process results. This machine also features independent gas injection, enabling the user to select the ideal parameters for various etching processes and optimize them for the desired results. In addition to etching and ashing, APPLIED MATERIALS 8300E offers a range of after-etch operations for a variety of materials, including post plasma cleaning using either a plasmafied hydrogen-based process or an O2-based process. AMAT / APPLIED MATERIALS 8300 E also provides a spin-clean operation for removal of residual particles from processed substrates without the need for manual wiping. 8300E is a highly-maneuverable tool, offering easy integration into existing fabrication environments and is capable of meeting the most stringent requirements of today's latest advanced semiconductor processing technologies.

There are no reviews yet