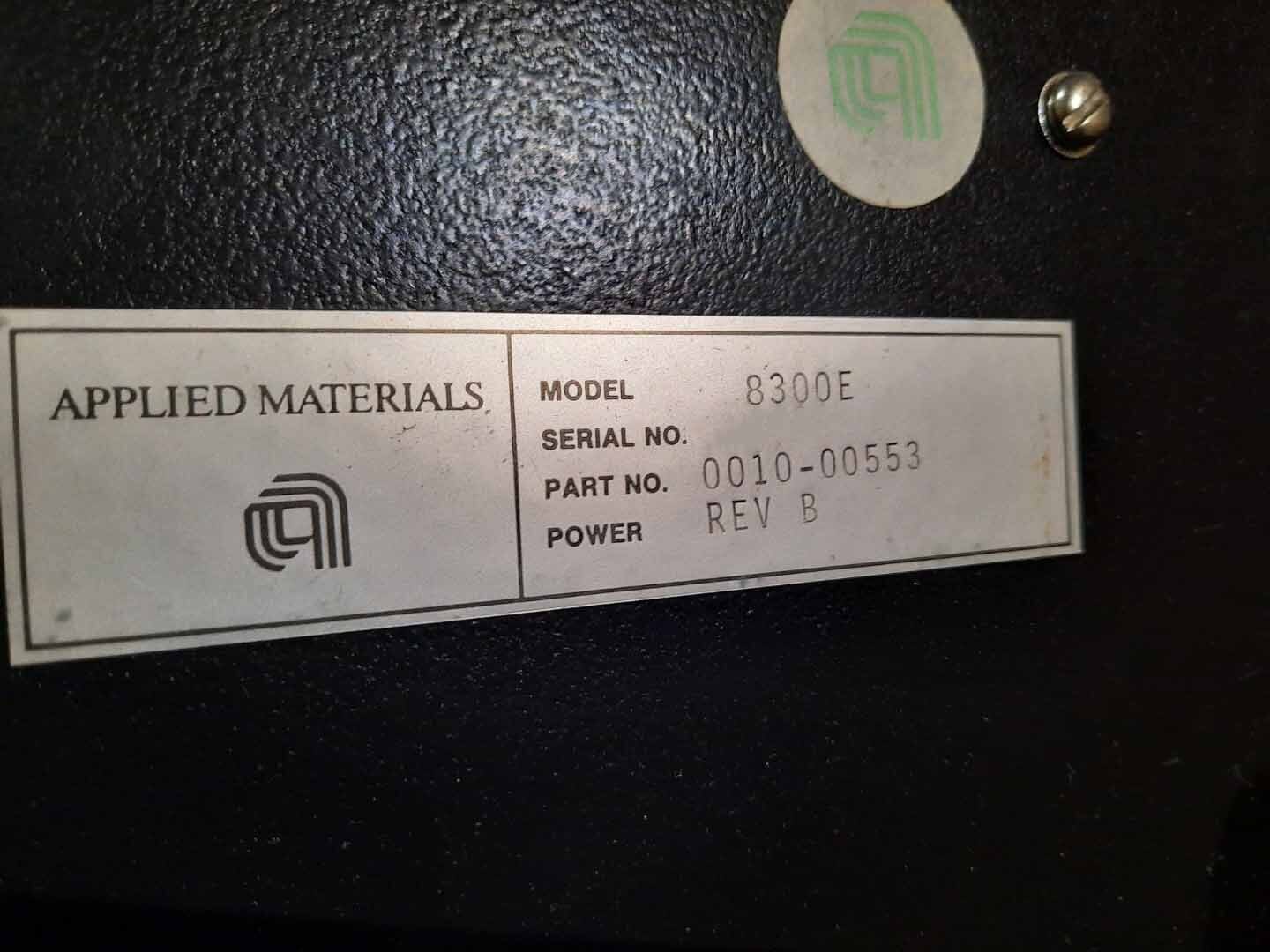

Used AMAT / APPLIED MATERIALS 8300E #9244442 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS 8300E Etcher / Asher uses next-generation 10KW ICP etching technology in order to quickly and accurately etch high aspect-ratio structures in advanced process nodes. This system is specifically designed to etch a variety of different materials, such as Silicon, Polysilicon, Tungsten, Copper, Ni/V/Ti, III-V compounds, and other difficult to etch materials. Additionally, AMAT 8300E is temperature dependent, allowing it to fine tune etch parameters for high variation processes. APPLIED MATERIALS 8300 E is capable of scaling down to high aspect-ratio structures, enabling fabrication of innovative components for 5nm and below process nodes. It also incorporates several non-line-of-sight features such as multi-point dosing, in situ dual-direction cleaning to boost purity across device vitalizing supports, and the use of dielectrics for profile modification. This increases the quality of the etch process significantly. AMAT / APPLIED MATERIALS 8300 E also features advanced monitoring and control; its integrated process monitoring combined with back-end support, custom diffusion exit-control, and advanced yield management helps minimize costs and decrease downtime. It is also equipped with efficient software algorithms to accurately adjust the flow rate, pressure, and temperature for the process chamber. 8300E delivers higher reliability and improved performance, lowering cost of ownership and increasing productivity. APPLIED MATERIALS 8300E also supports for multi-plant operation across multiple sites. Its multi-zone capability enables its users to configure different etching parameters, maximizing its process capabilities. 8300 E Etcher/Asher is a state-of-the-art etching solution, providing high levels of flexibility, productivity, and reliability in the advanced process nodes.

There are no reviews yet