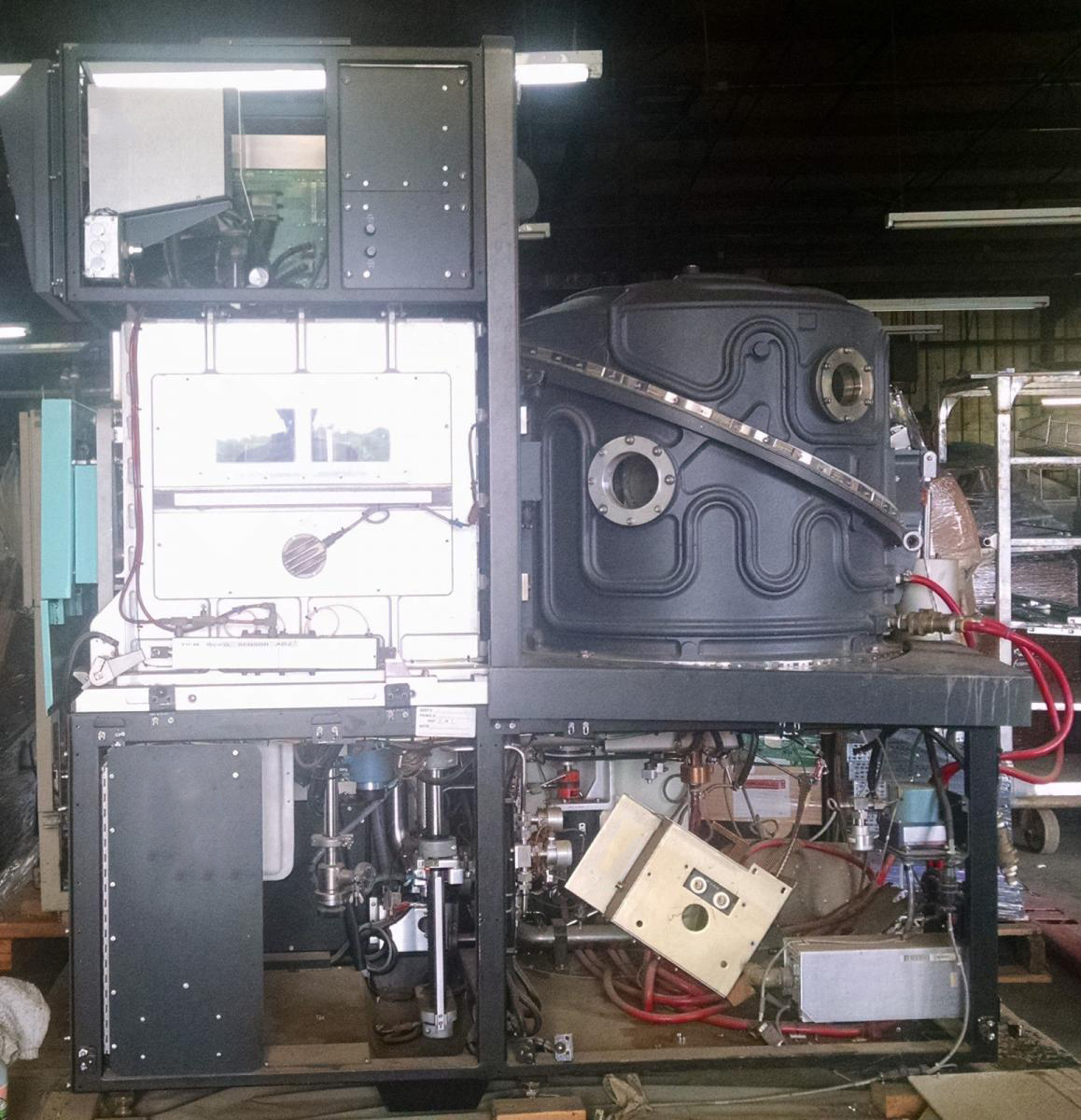

Used AMAT / APPLIED MATERIALS 8310 #9122949 for sale

URL successfully copied!

Tap to zoom

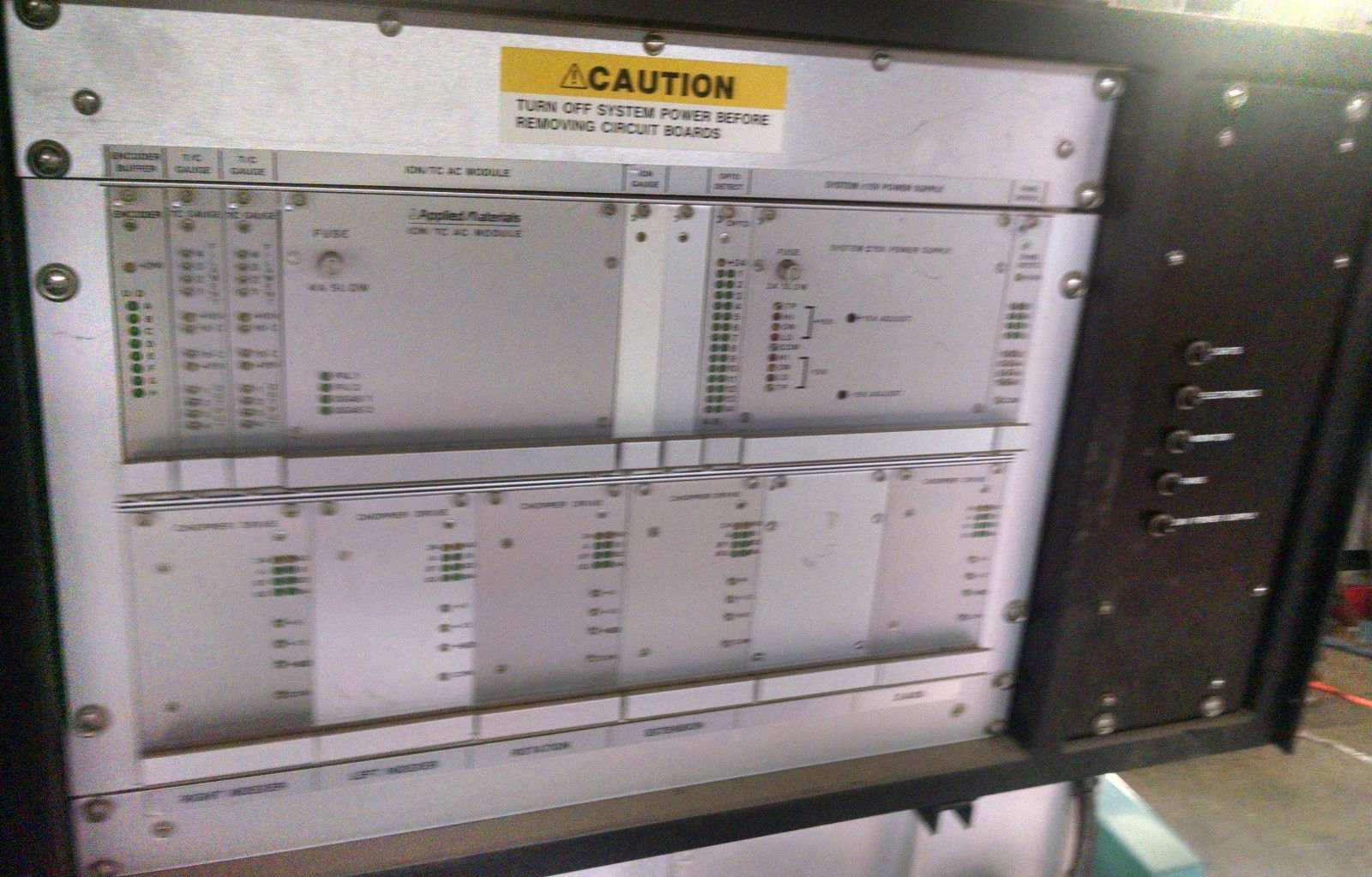

AMAT / APPLIED MATERIALS 8310 is an etcher and asher commonly used in the semiconductor industry. It is the perfect solution for ion implantation and deposition processes. As a multi-functional etcher, it can be used to deposit, etch, asher, and clean a variety of semiconductor films. AMAT 8310 offers superior uniformity, repeatability and process control, making it the ideal choice for small wafer and low-volume applications. APPLIED MATERIALS 8310 is designed to operate with a variety of energy sources and supports both RF and N2 etching capabilities. It is equipped with a range of features including advanced axial stages for several processmodules, a large chamber, and a load lock chamber that work with a nebulizer for deposition. The PM2 process module is equipped with an optimized ion mill and anode centrifuge for process fine-tuning. 8310 offers high precision asher capability at high speed, as well as high-volume processes capability. It is integrated with a user-friendly interface and a built-in EGA Auto Remote Interface (ERI) system for convenient operation. Its two-piece system, which allows for both RF and N2 etch processes, is ideal for both low and higher production volumes. AMAT / APPLIED MATERIALS 8310 also comes with a Hot Gas System and a Fine Tuner, which provide optimal deposition processes with high yields at low thermal stress. It has a non-contact eddy current sensor that allows for precise deposition measurements over a wide range of temperatures. AMAT 8310 is designed for reliable performance and is backed by a 24-month warranty, making it a great choice for industrial and research applications. With its robust design and high process control, APPLIED MATERIALS 8310 gives users superior control over parameters that they can manipulate for the highest-quality results.

There are no reviews yet