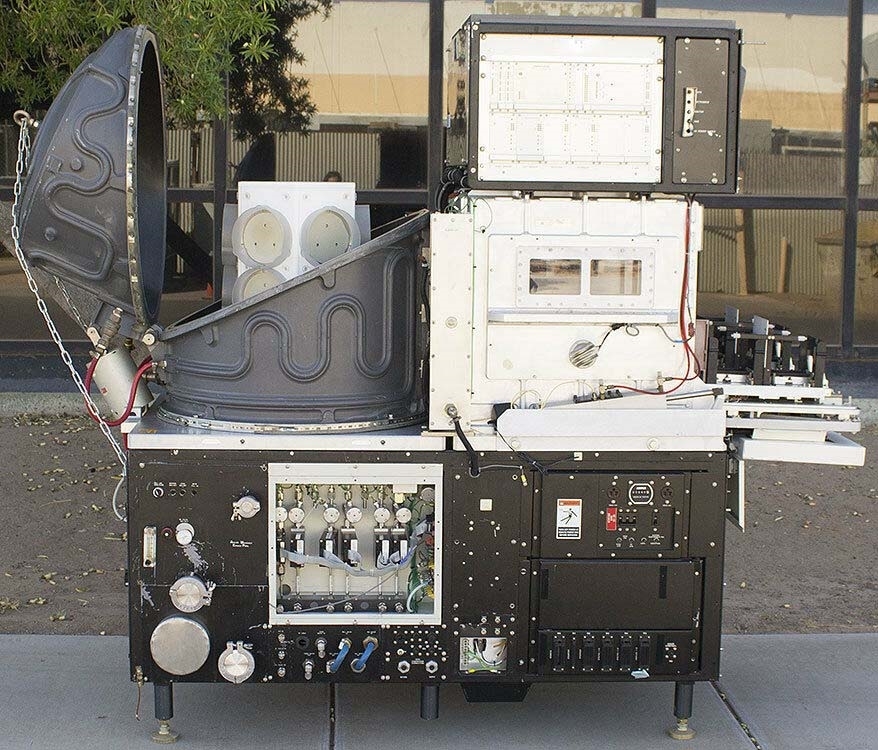

Used AMAT / APPLIED MATERIALS 8330A / 8330 #9276839 for sale

URL successfully copied!

Tap to zoom

ID: 9276839

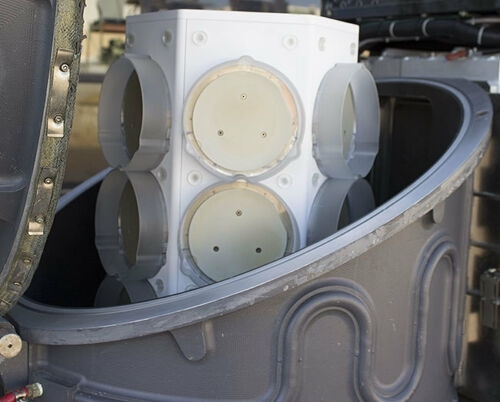

Wafer Size: 6"

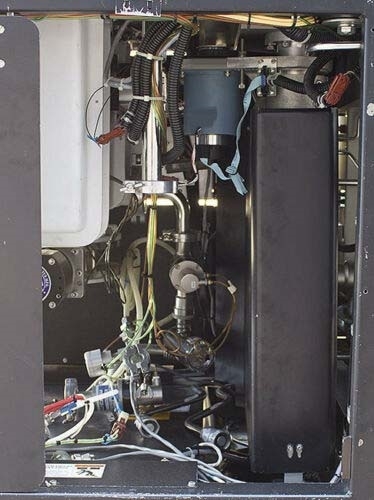

Metal etcher, 6", parts system

Meter reads: 1,542.5 Hours

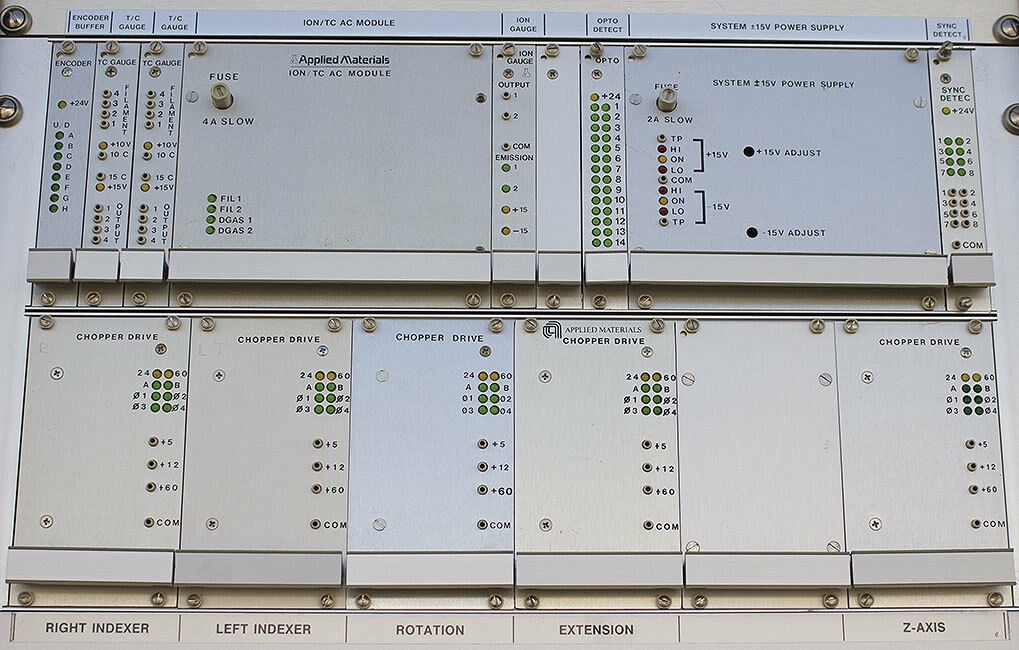

Make / Model / SCCM / Gases

TYLAN / FC-2900M / 200 sccm / BCL3

TYLAN / FC-2900M / 100 sccm / CL2

TYLAN / FC-2900M / 100 sccm / CF4

TYLAN / FC-2900M / 100 sccm / CHF3

TYLAN / FC-2900M / 100 sccm / HE

TYLAN / FC-260V / 50 sccm / N2

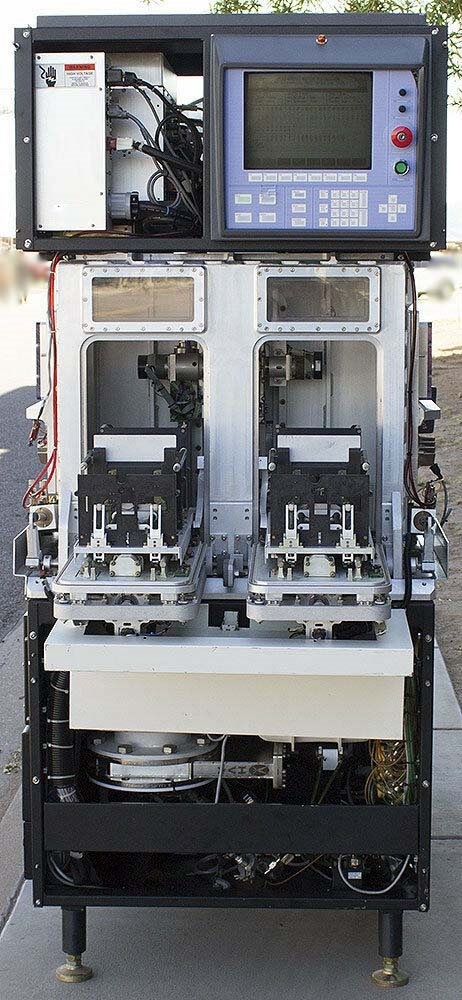

Monitor damaged

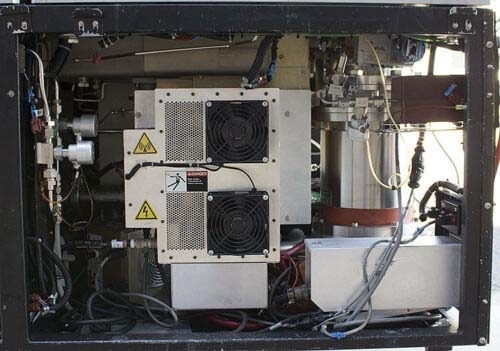

Power supply: 208 VAC, 60 Hz.

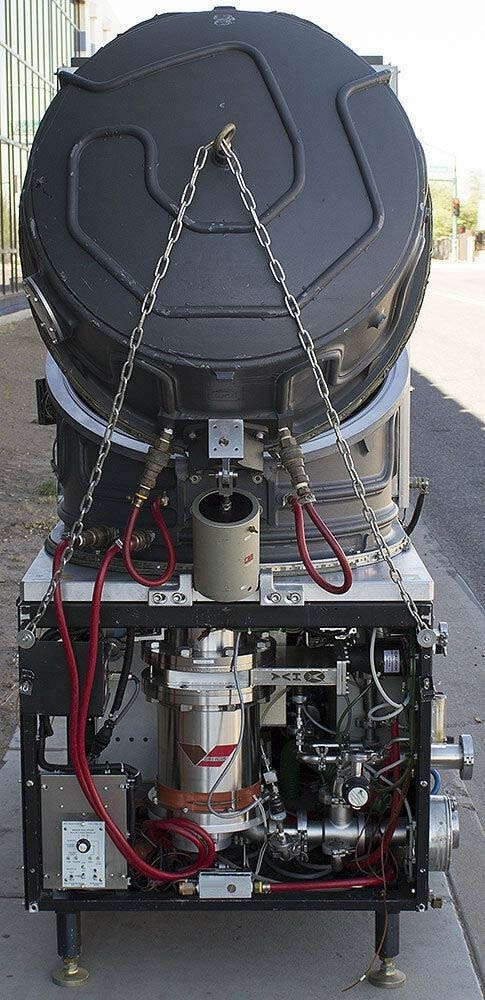

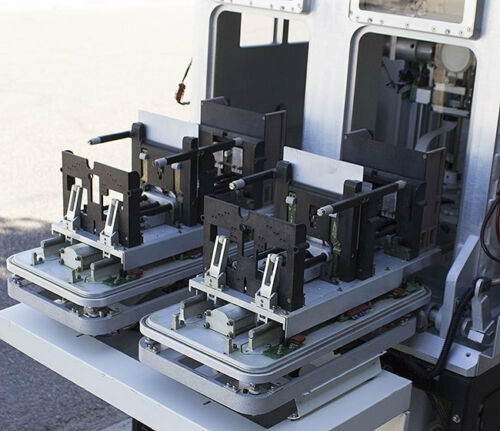

AMAT (APPLIED MATERIALS) AMAT / APPLIED MATERIALS 8330A / 8330 is an etcher / asher used in manufacturing operations. It is a cost-effective, high-throughput equipment that offers superior performance when it comes to etching and ashing processes. The system is designed to process multiple applications simultaneously, allowing for an up to 8 wafer capacity with a single operation. The machine is equipped with an advanced vacuum unit that enables precise temperature and process control for all etch and ashing process tasks. As an etching machine, AMAT 8330A / 8330 has two main chambers - one for metal and another for insulation etching. The metal etch chamber provides excellent anisotropic etching results utilizing reactive ion etching (RIE) capabilities. Additionally, precision control of chamber pressure, temperature, gas flow and RF power is achievable due to the built-in automated temperature controllers. The insulation etching chamber consists of an inductively coupled plasma (ICP) source, which enables the etching of thermally stabilized substrates. Automated thermal controllers provide precise temperature and process control over all etching operations. Furthermore, the tool is equipped with an advanced class-1000 wafer handling asset, offering fast wafer loading, unloading and manipulation, and time-saving wafer alignment. In terms of ashing capabilities, APPLIED MATERIALS 8330A / 8330 model features a single chamber configuration, enabling fast and efficient ashing processes. The chamber is equipped with a quartz boat and a built-in automated temperature controller, which provides precise temperature control over the ashing process. This contributes to improved process uniformity, repeatability and yields. The equipment also includes process failure diagnostics that allow for quick troubleshooting of any malfunctions. Overall, 8330A / 8330 is a powerful, high-throughput etching and ashing system. With its advanced features, the unit provides precise temperature and process control for achieving the best possible results in all etching and ashing procedures. It is an ideal solution for advanced ashing and etching applications in a variety of industries.

There are no reviews yet