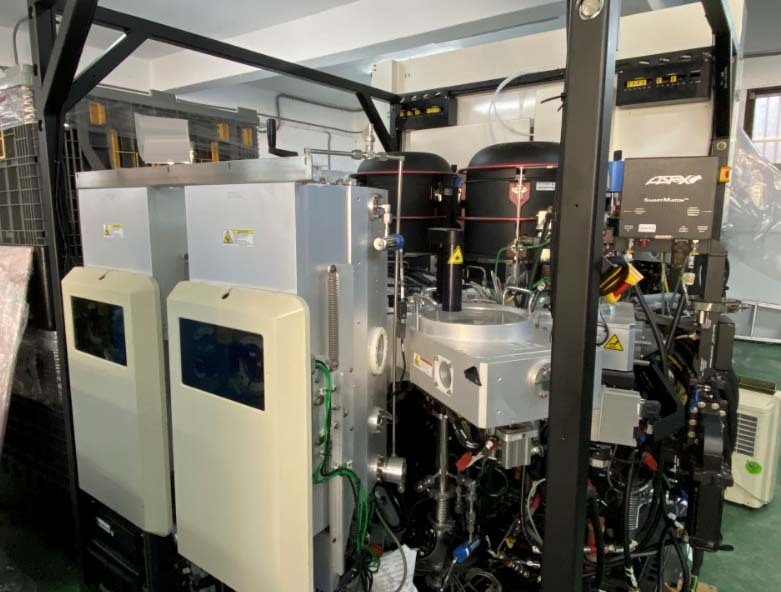

Used AMAT / APPLIED MATERIALS Centura DPS Metal #9247622 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9247622

Wafer Size: 8"

Vintage: 2000

DPS Etcher, 8"

Wafer shape: SNNF

EMO Type

Chamber:

Chamber A, B: DPS Metal DTCU chamber

Chamber C, D: ASP+ Chamber

Chamber E: Cool down chamber

Chamber F: Orient chamber

Load lock:

Load lock type: Narrow body

Auto rotation

Cassette type, 8"

Mapping function: FWM

Fast vent option

Vent type: Variable speed

Mainframe:

Platform type: Centura II Etcher

Buffer robot type: VHP

Buffer robot blade: Standard metal

Status light tower

Remote monitor: Table mount

AGILENT / HP / HEWLETT-PACKARD / KEYSIGHT Buffer robot

No SMIF

(2) Chillers: HX-150 and Steelhead0

Gas panel configuration: VME1

EBARA ET800WS-A Turbo pump

NESLAB System II Heat exchanger

Front panel

Control rack

Local AC rack

Accessories

Cables

DPS R1 DTCU:

OEM-12B3 RF Generator type

GMW-25 RF Generator type

Gas panel configuration: VME1

EBARA ET800WS-A Turbo pump

Throttle valve

Endpoint: Monochromators

ASP+

Process control: Manometer

Microwave

Smart match

Magnetron head

Applicator

VDS Assembly

Sub-system:

(2) AMAT1 Chillers

(2) HX-150 Chillers

Electrical configuration:

Line voltage: 208 V

Full load current: 320 A

Frequency: 50/60 Hz

CE Marked

2000 vintage.

AMAT AMAT / APPLIED MATERIALS Centura DPS Metal is an advanced etcher/asher equipment that provides the highest levels of process control and throughput for precision applications such as MEMS and semiconductor devices. The system relies on a multi-frequency ICP source and an advanced dual-mode plasma-enhanced-chemical-vapor-deposition (PECVD) chamber to optimize the etching process. By providing consistently high yields, high reliability, and high throughput, AMAT Centura DPS Metal achieves excellent yields under a wide range of variables. APPLIED MATERIALS Centura DPS Metal is equipped with a range of features that allow users to achieve optimal process results. These features include automated pressure and temperature control, an effective plasma source, and a multistream delivery unit. Automated pressure and temperature control enables precise process control, which can be used to adjust process parameters for particular applications. In addition, the effective plasma source increases etching uniformity and improves etch selectivity. The multistream delivery machine ensures that the right gases and chemicals reach the chamber at the right concentrations. The tool can also perform a wide range of etch processes, such as selective wafer etching, dielectric etching, post CMP cleaning, and advanced photolithography. Each process is designed to take advantage of the asset's advanced plasma etching processes. Moreover, the model is able to etch all types of materials such as aluminum, carbon, silicon, and others. This wide range of process ability makes the equipment suitable for a variety of applications including micro cavities, MEMS, and semiconductor devices. Centura DPS Metal also offers excellent process uniformity. This uniformity ensures that all wafers are etched in a consistent manner, leading to consistent yields across the lot. Additionally, the system includes advanced process monitoring capabilities such as real-time visual monitoring and process gas flow control. This allows the user to view and monitor the process in detail, as well as providing control over the process. Overall, AMAT / APPLIED MATERIALS Centura DPS Metal provides an exceptional level of process control, allowing users to achieve high precision results no matter the circumstances. By providing advanced plasma etching, process uniformity, and control, the unit enables consistent and reliable results, making it the ideal etching solution for advanced and precision applications.

There are no reviews yet