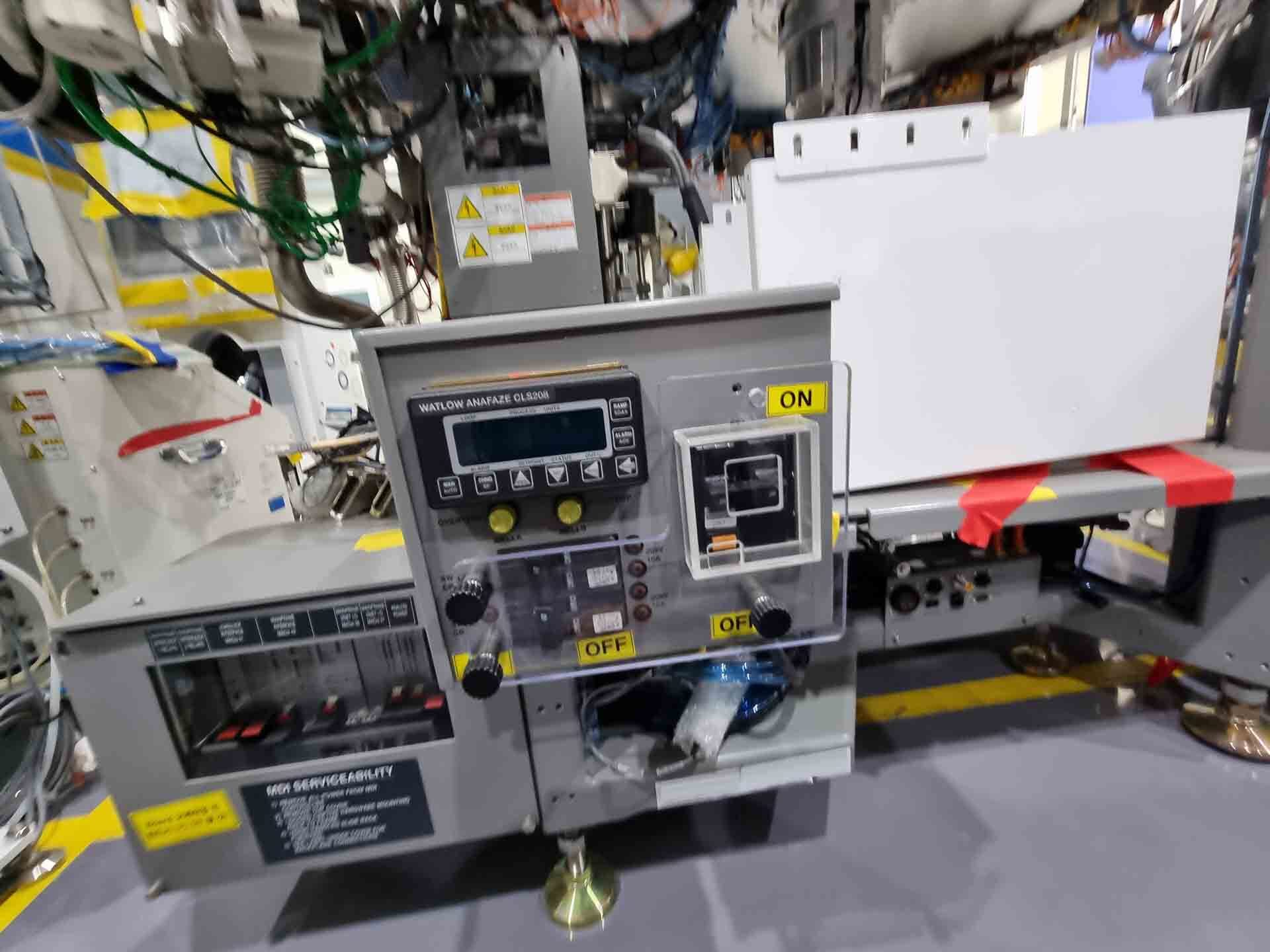

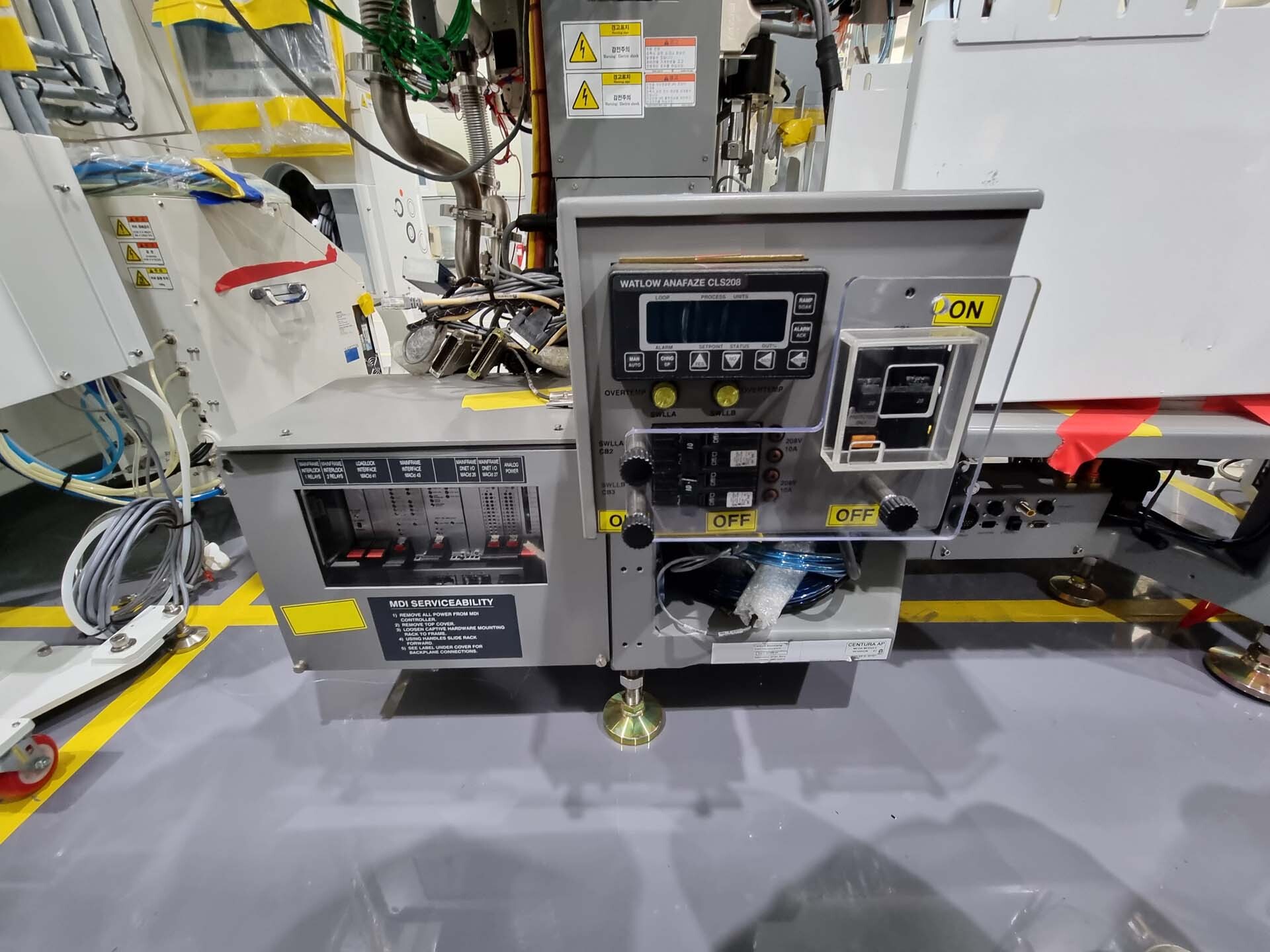

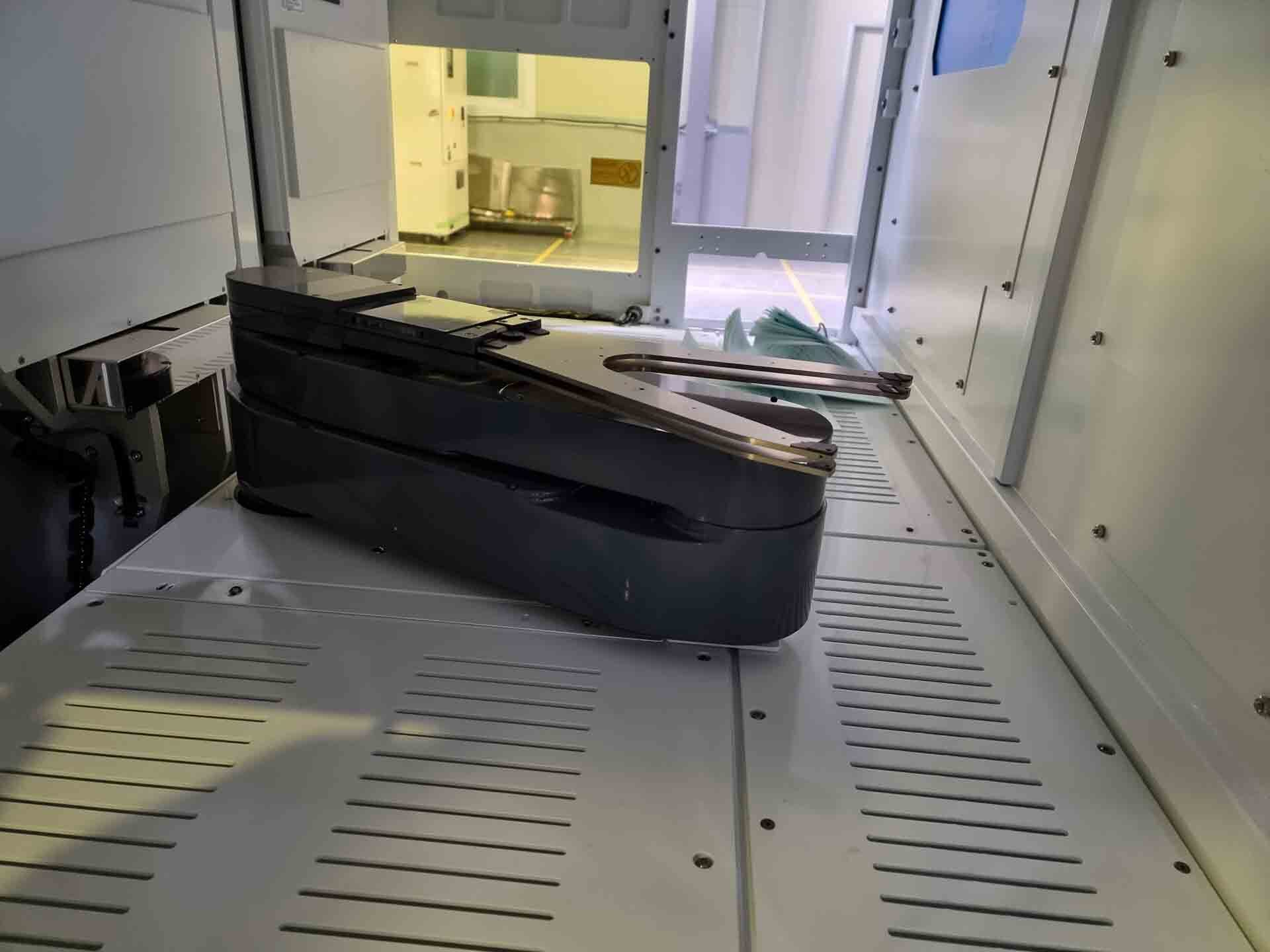

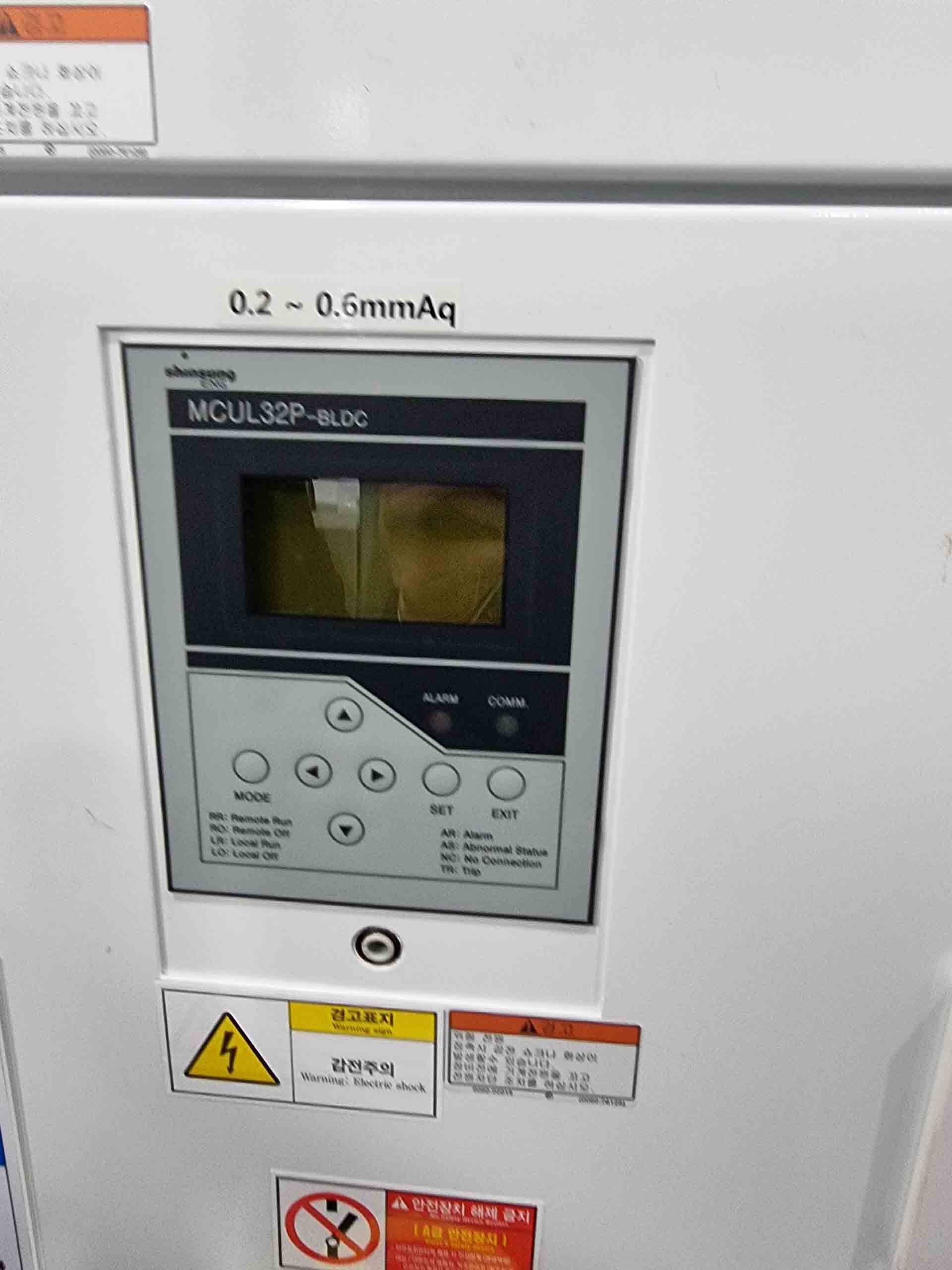

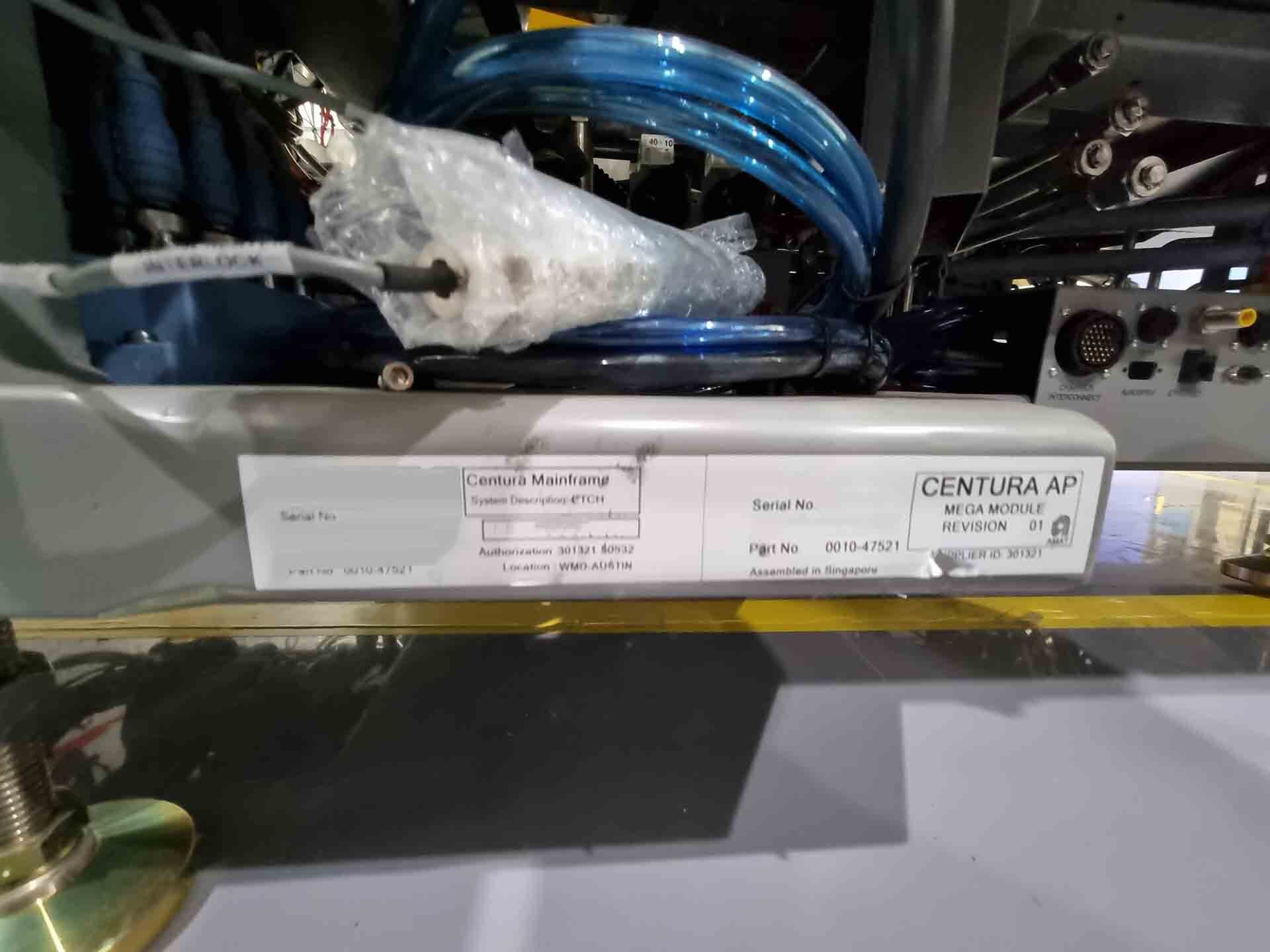

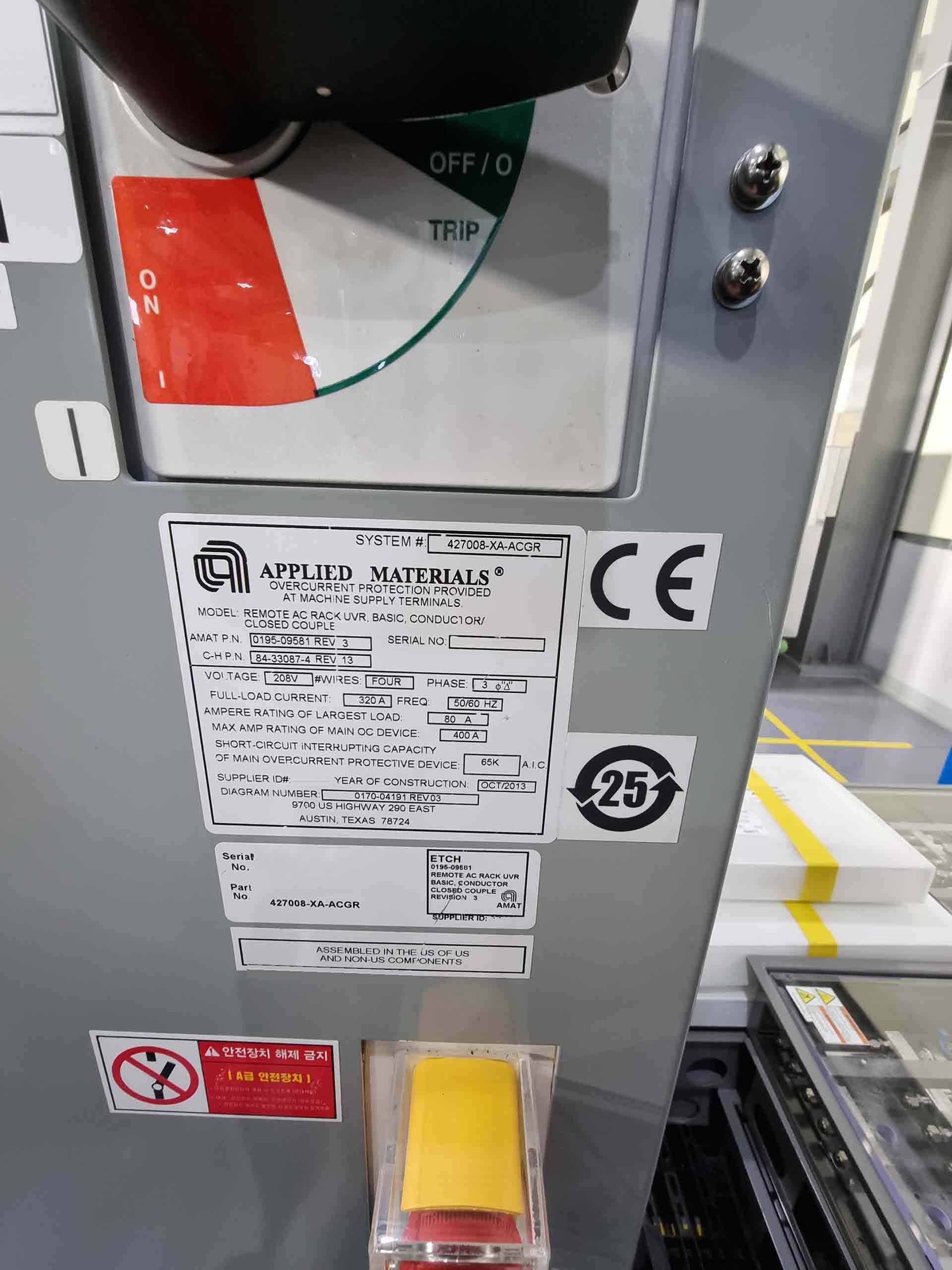

Used AMAT / APPLIED MATERIALS Centura DPS II Mesa #293586295 for sale

URL successfully copied!

Tap to zoom

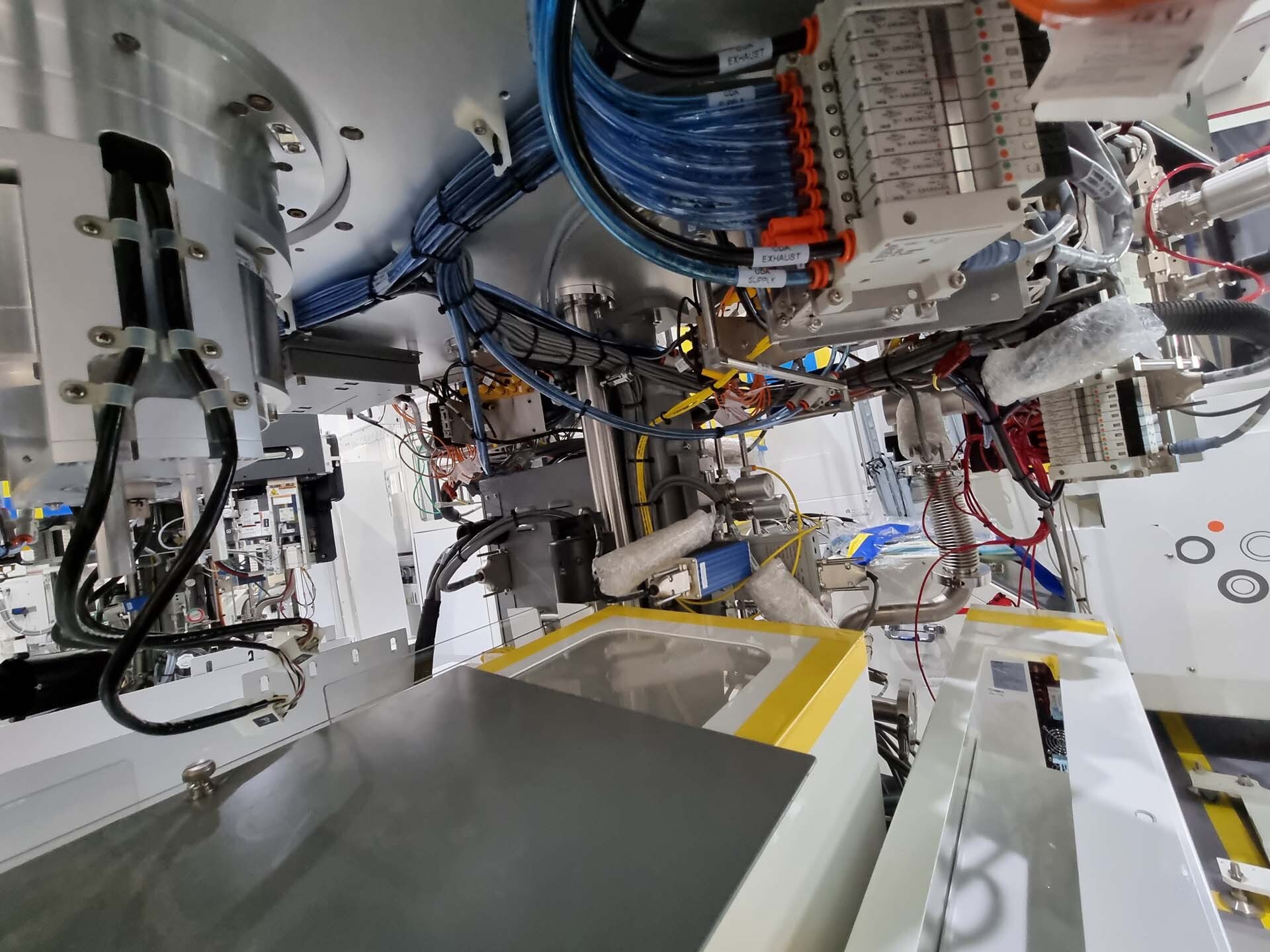

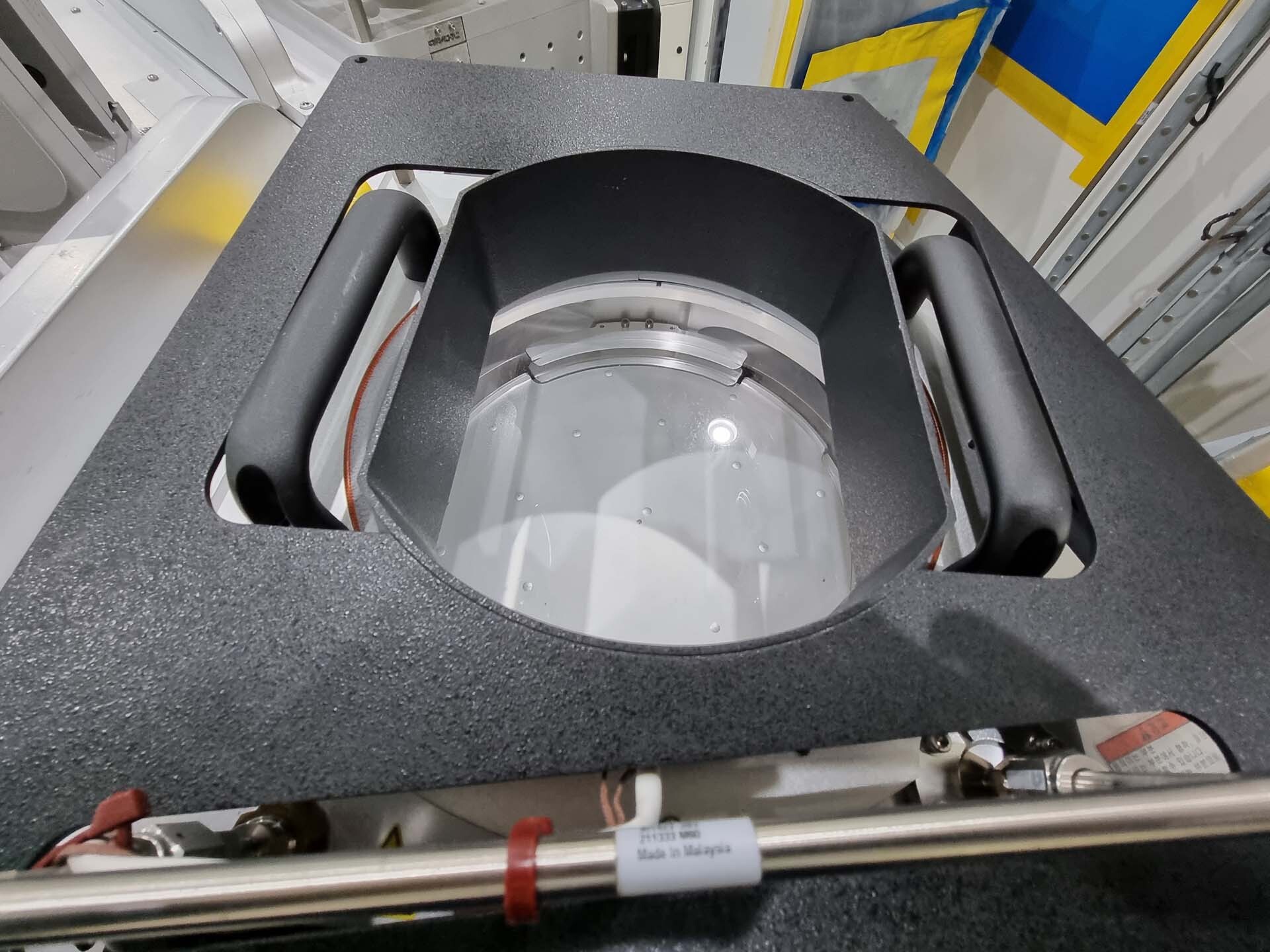

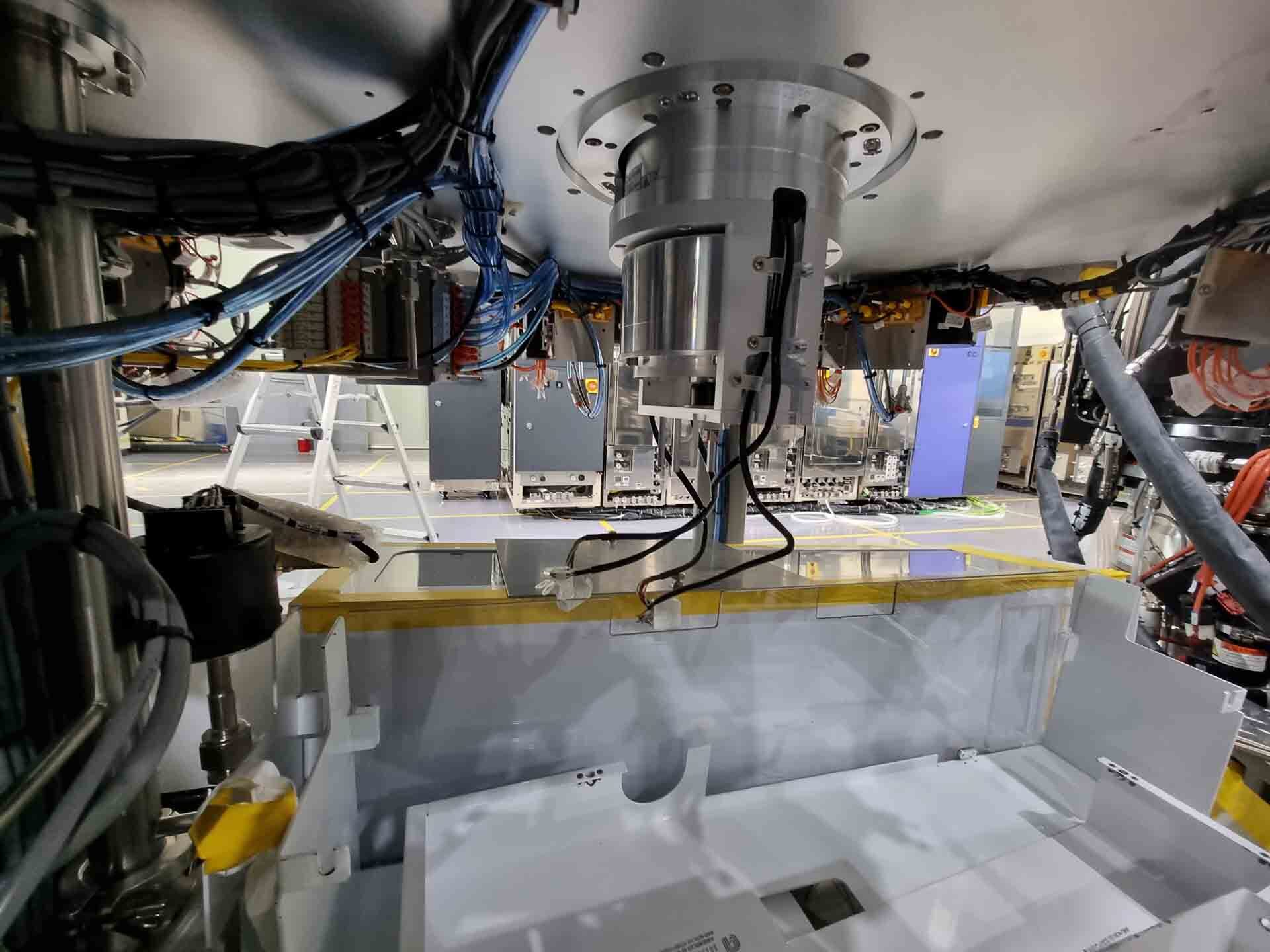

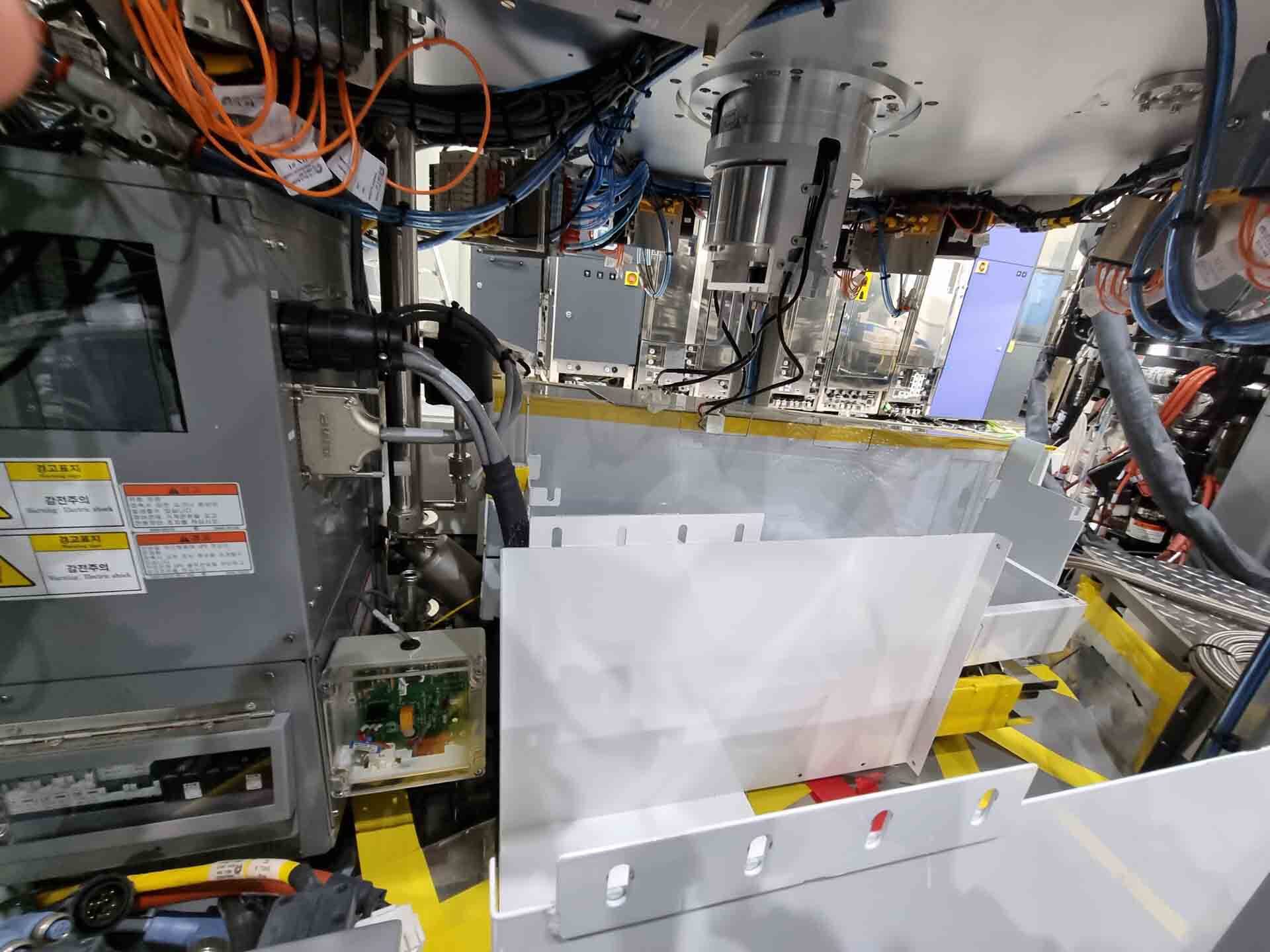

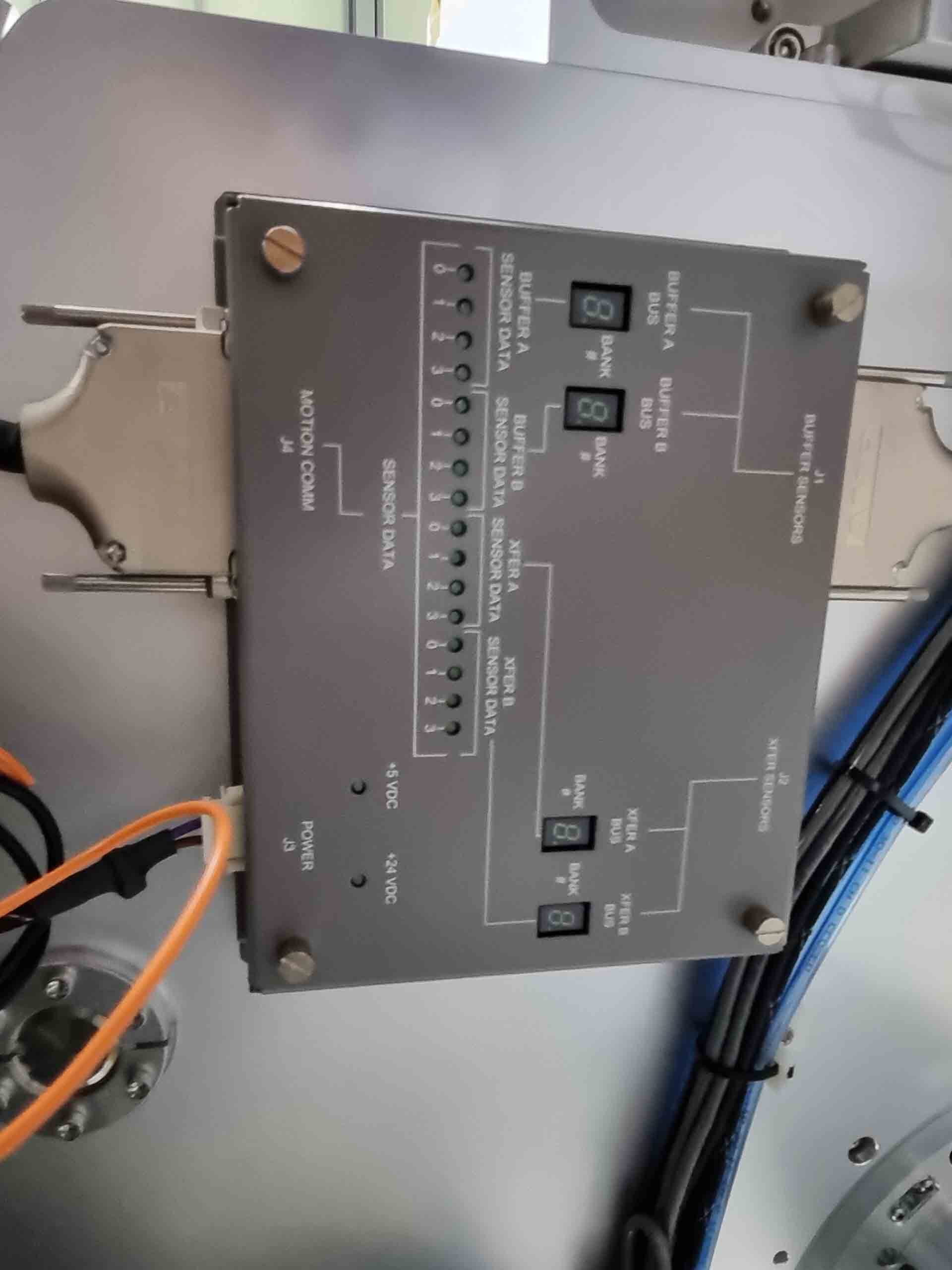

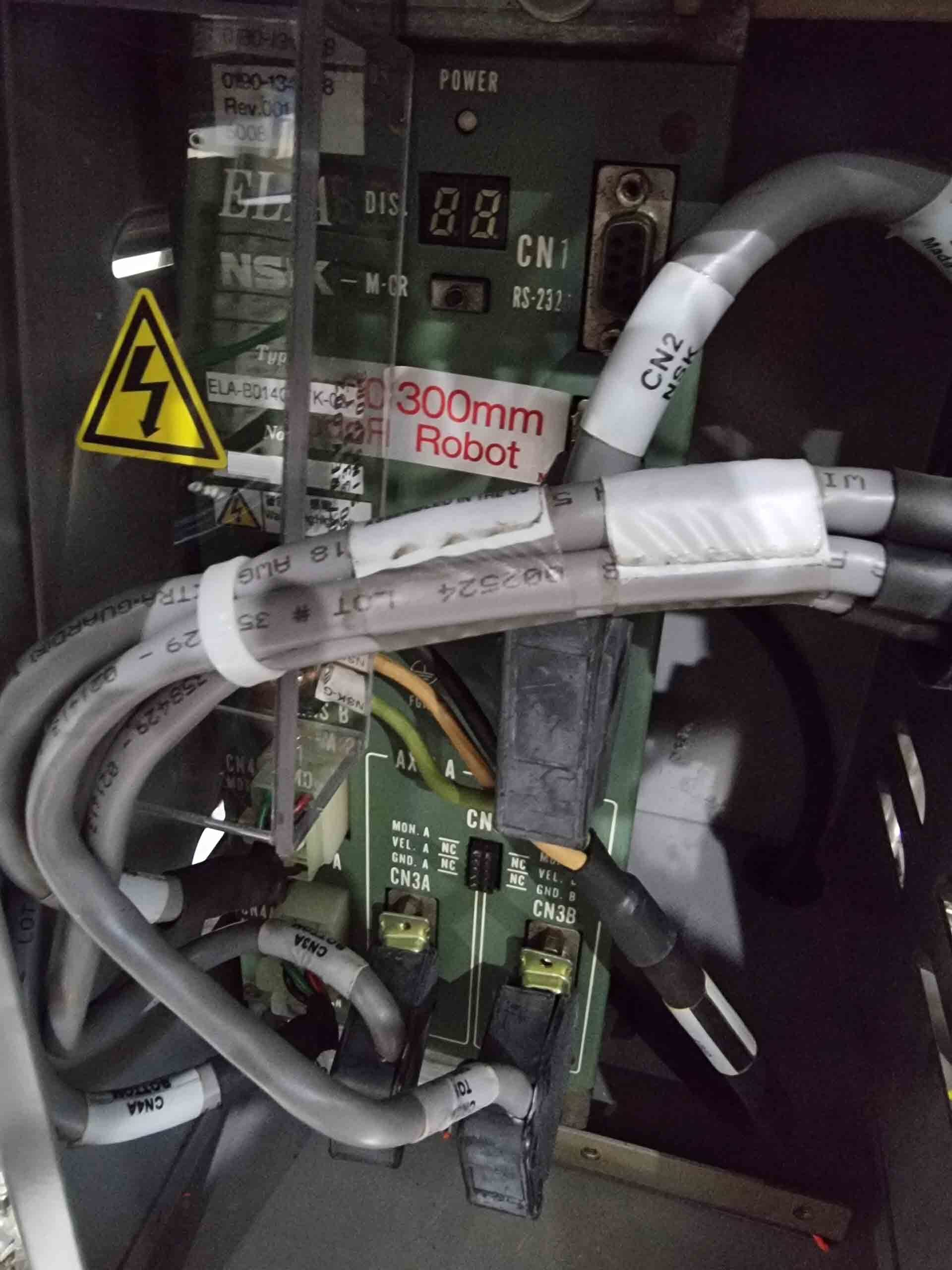

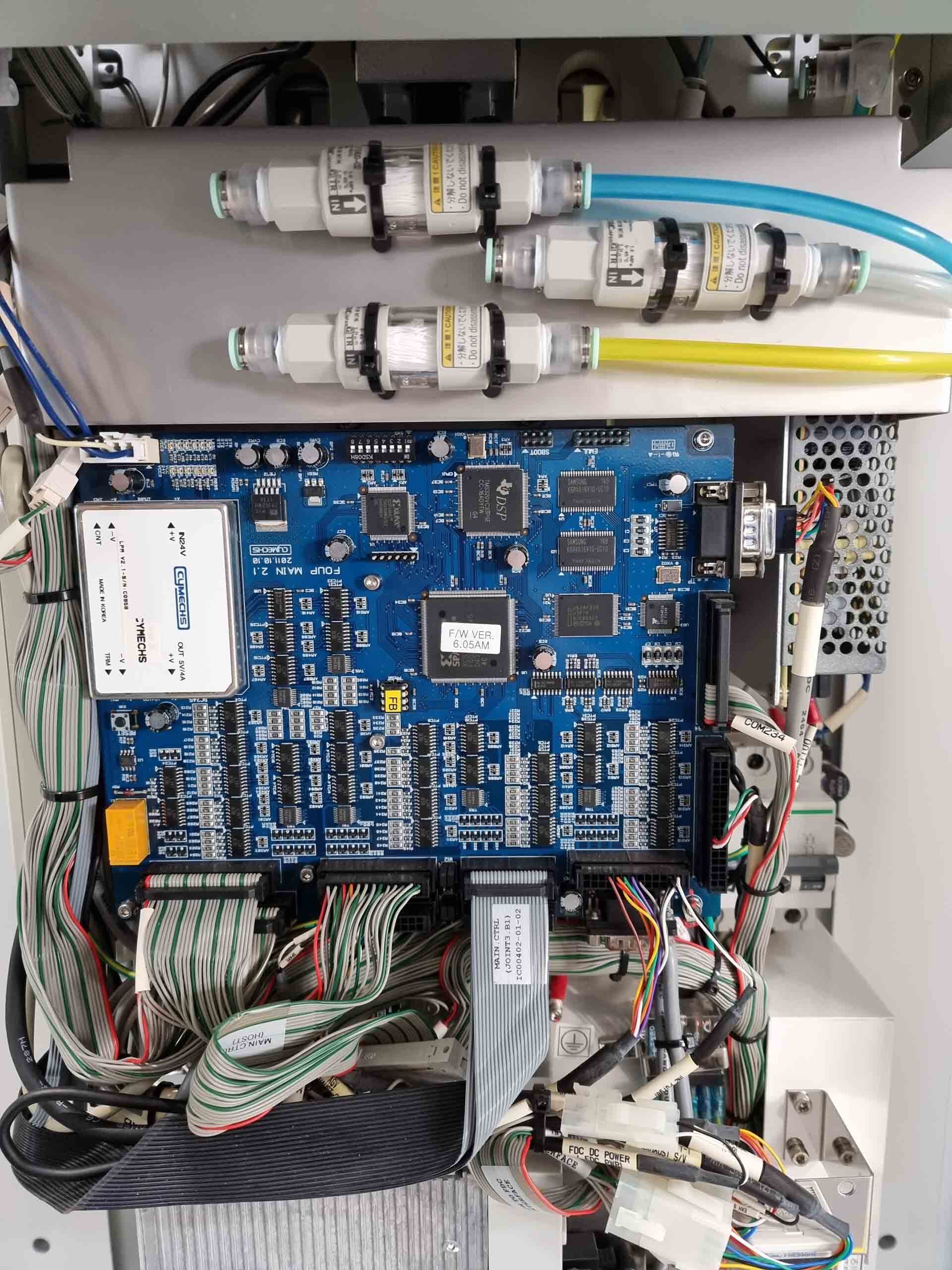

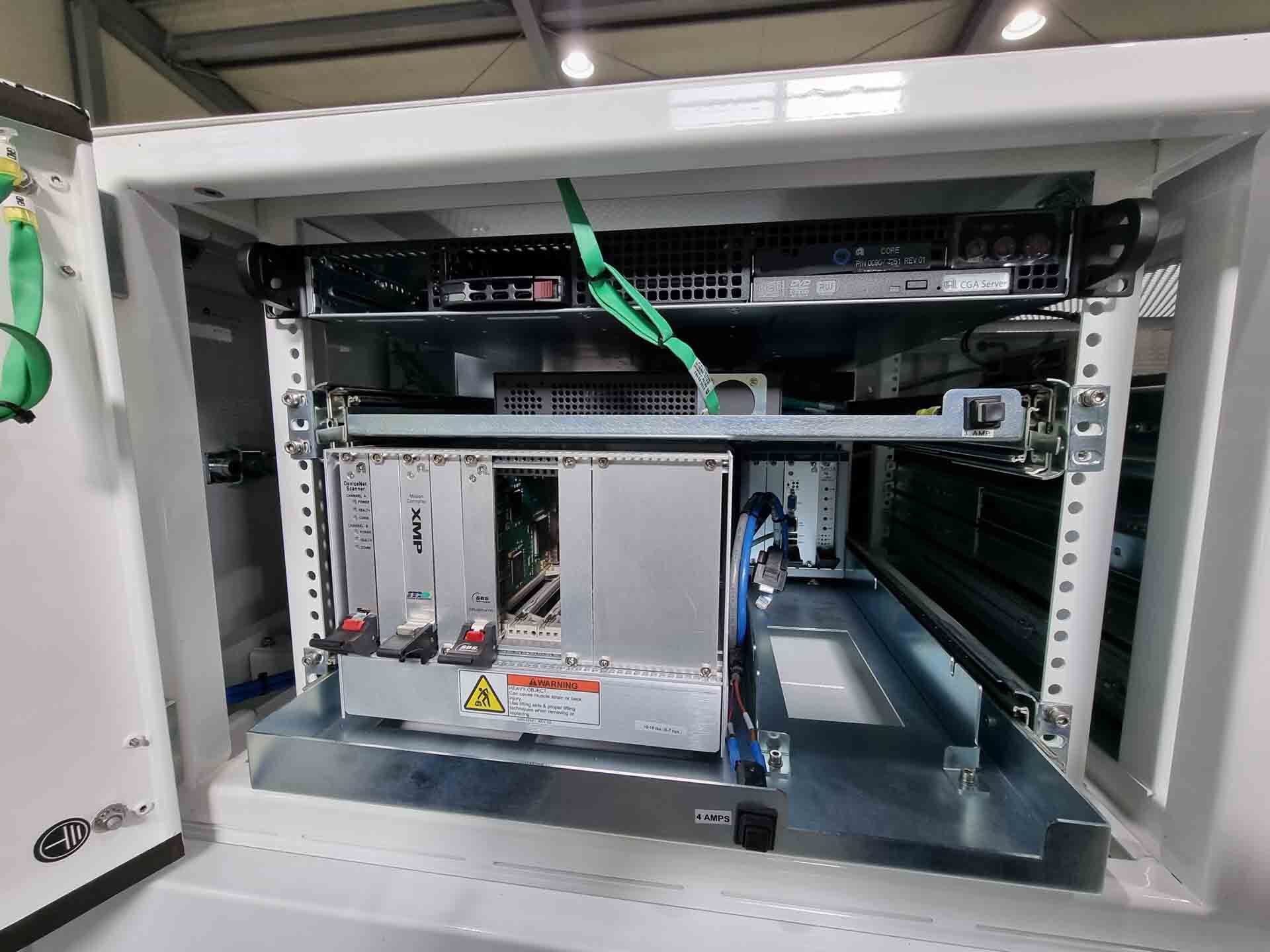

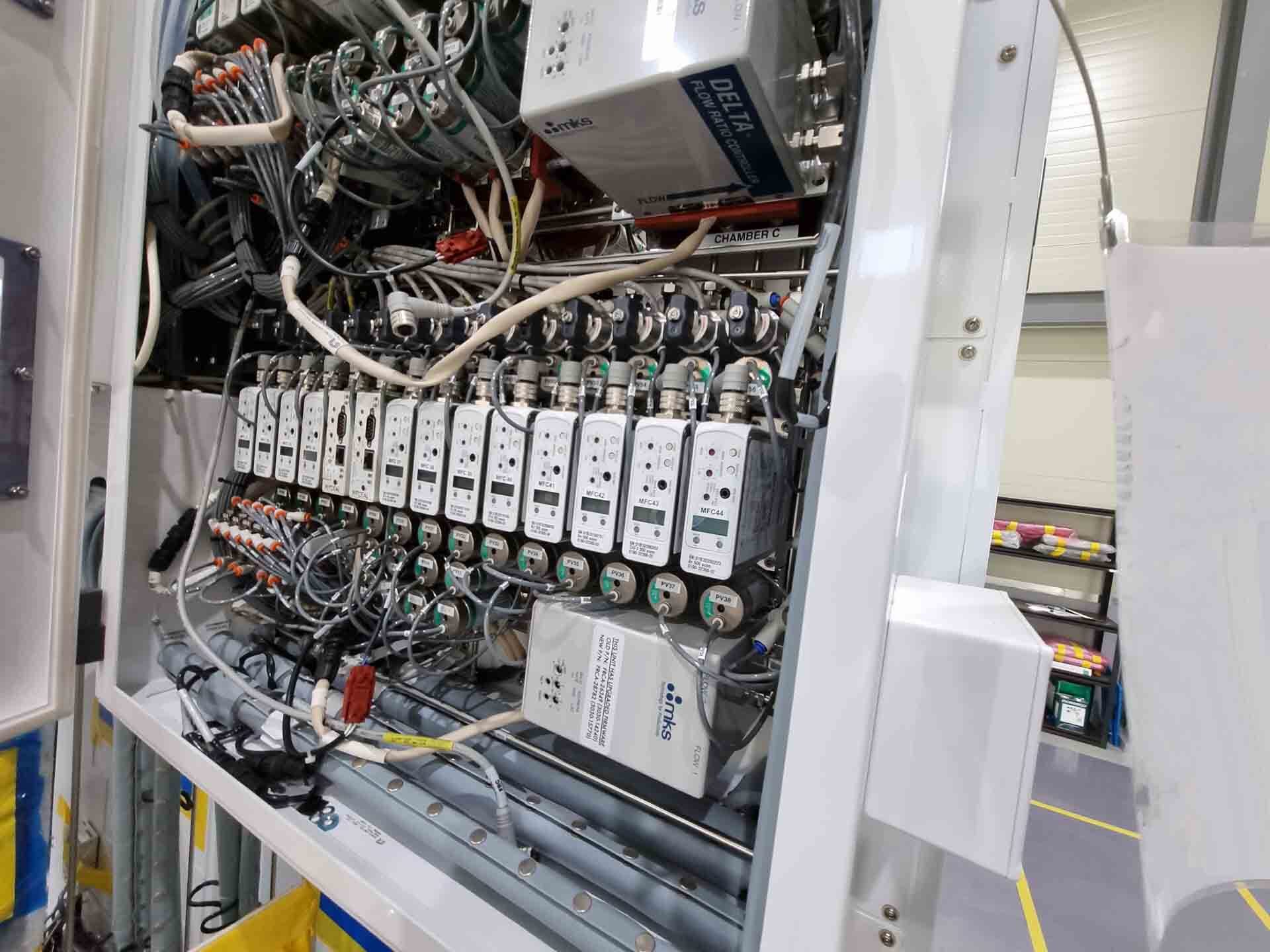

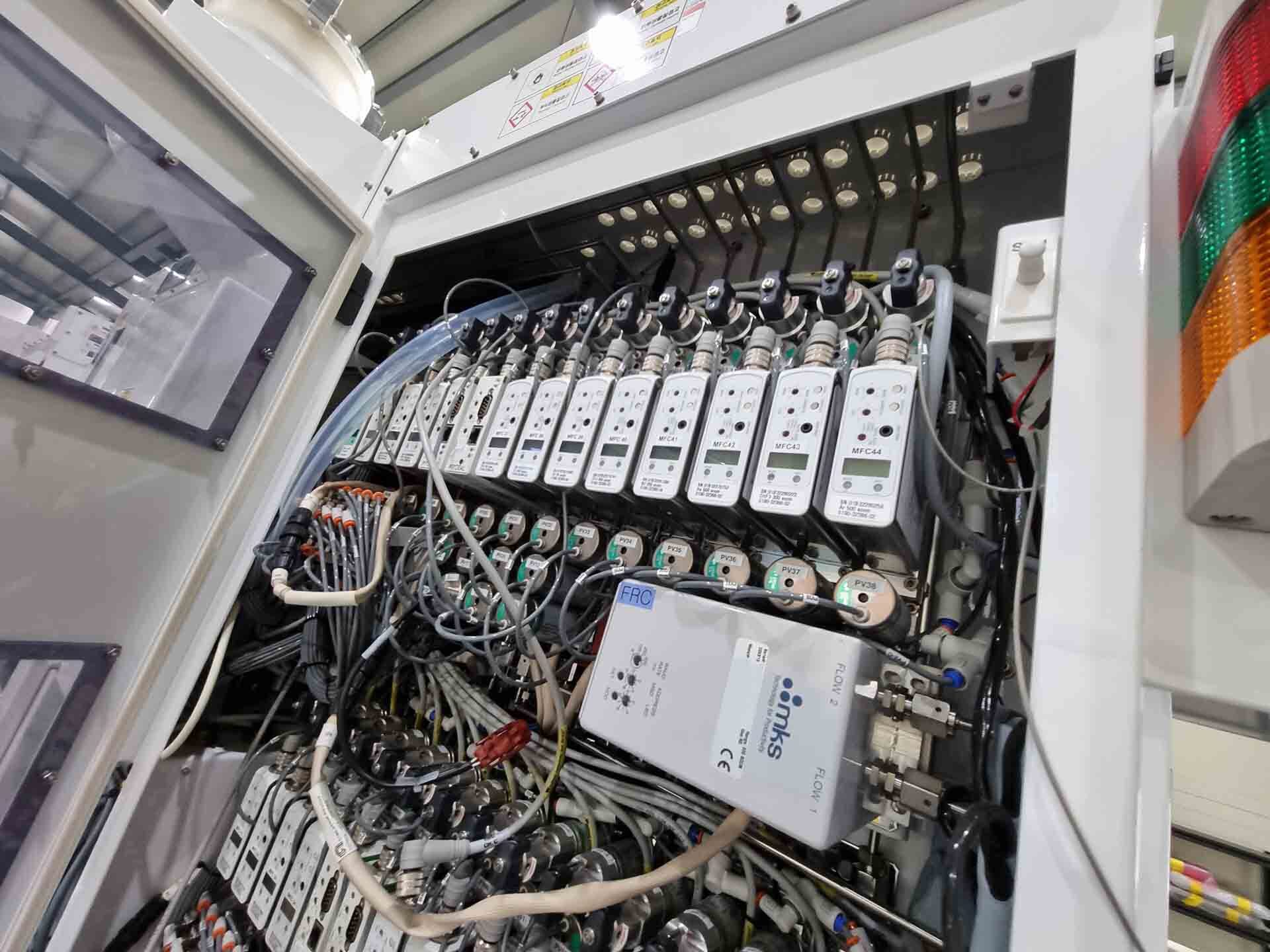

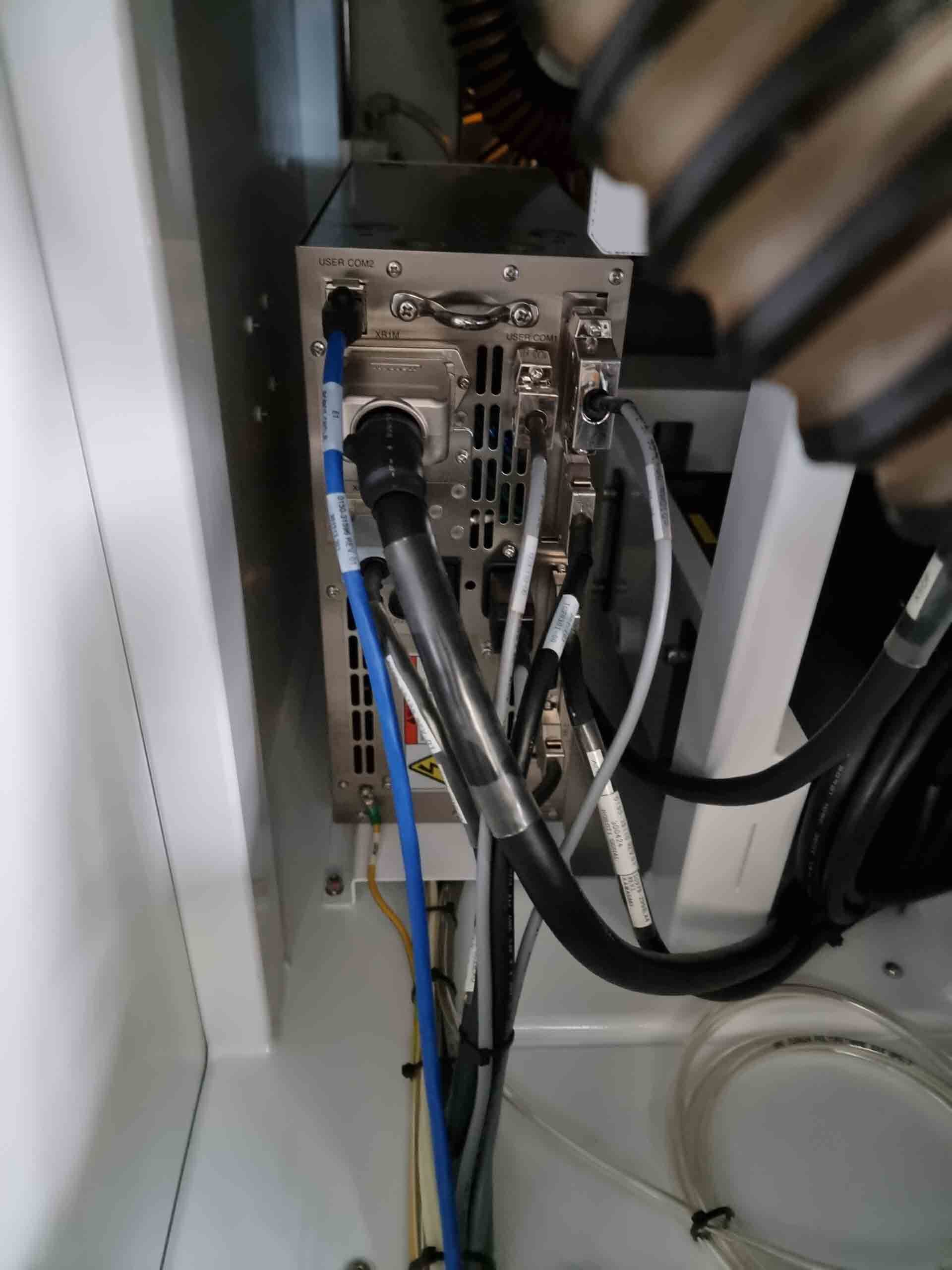

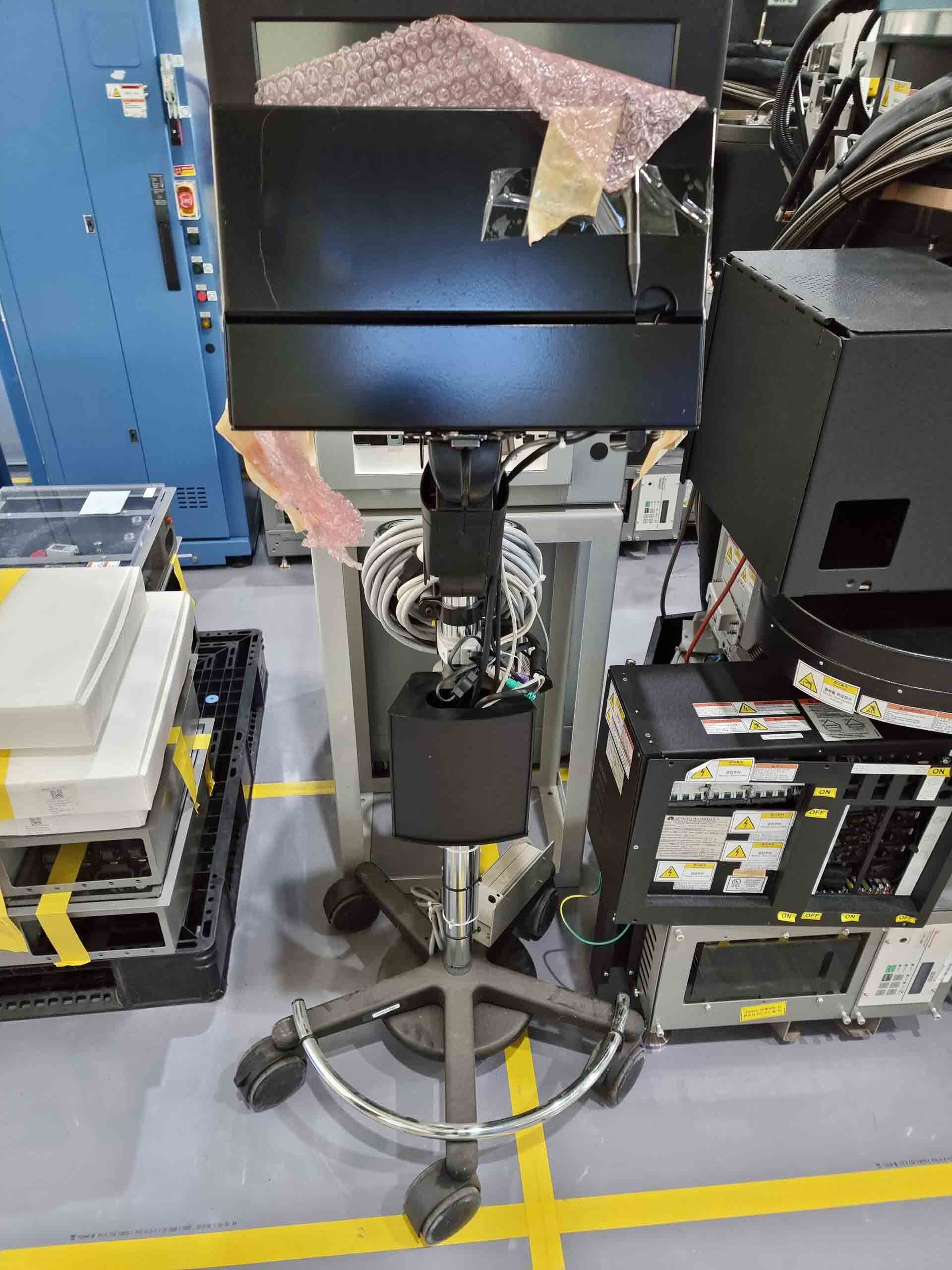

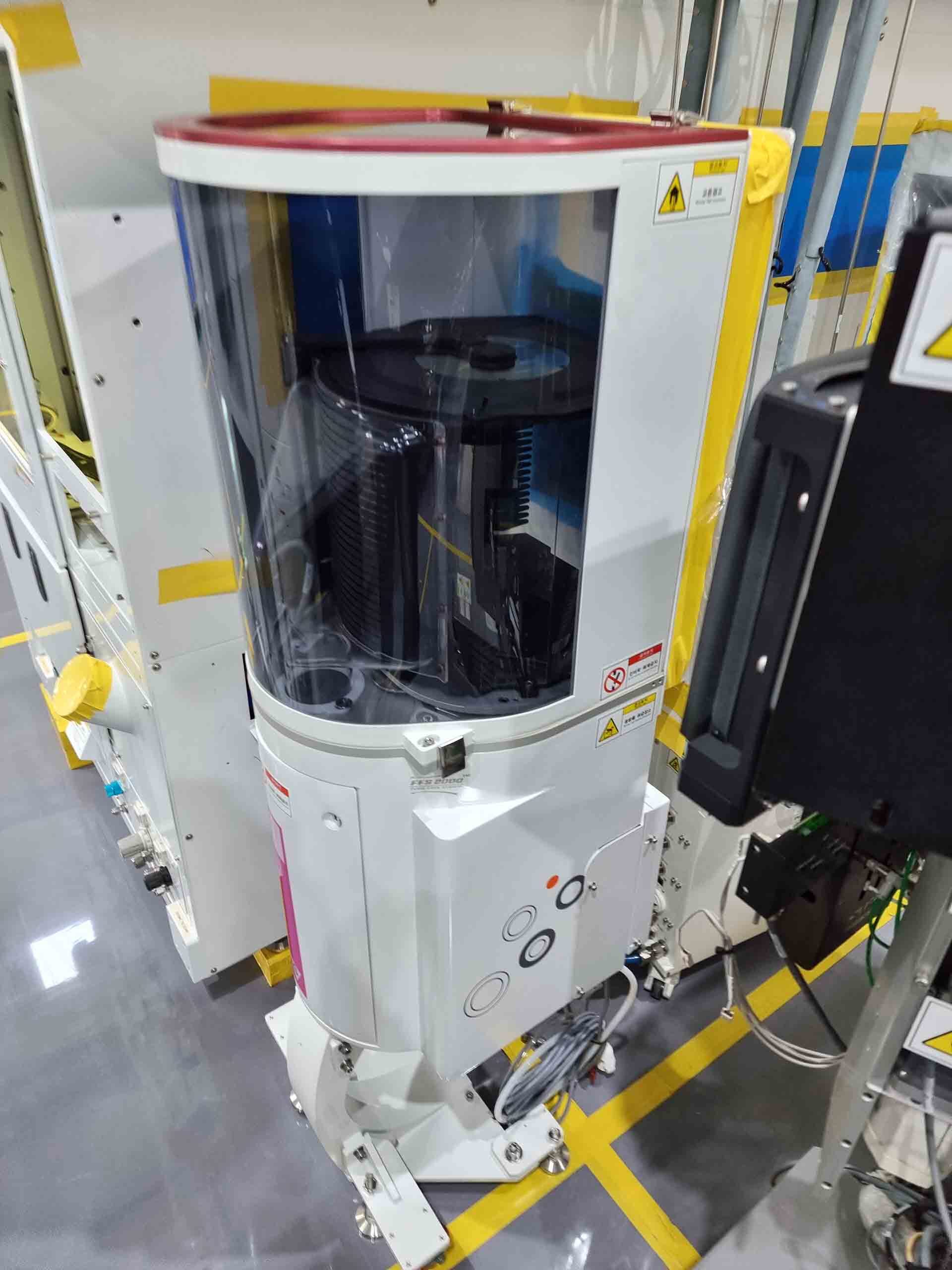

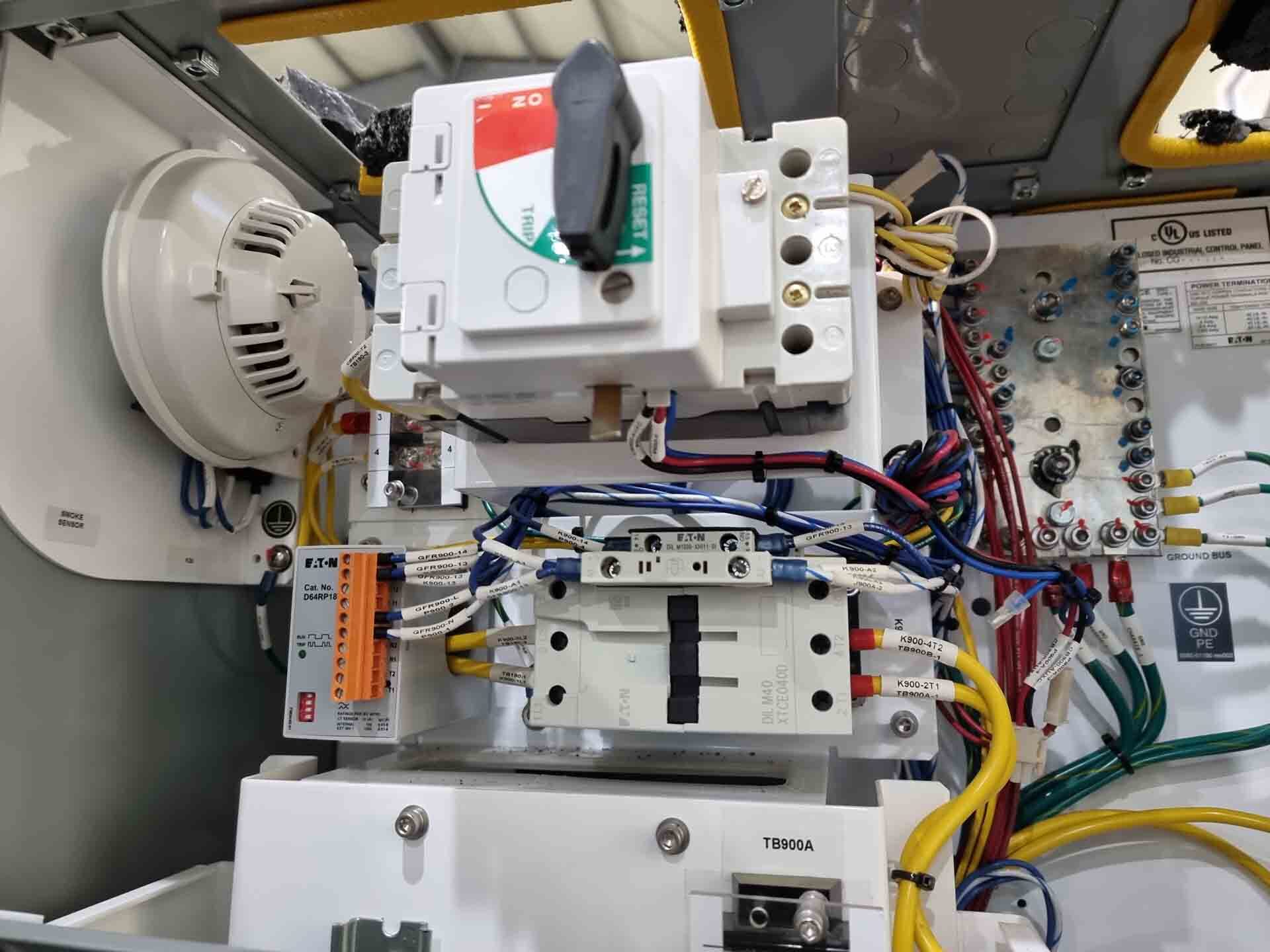

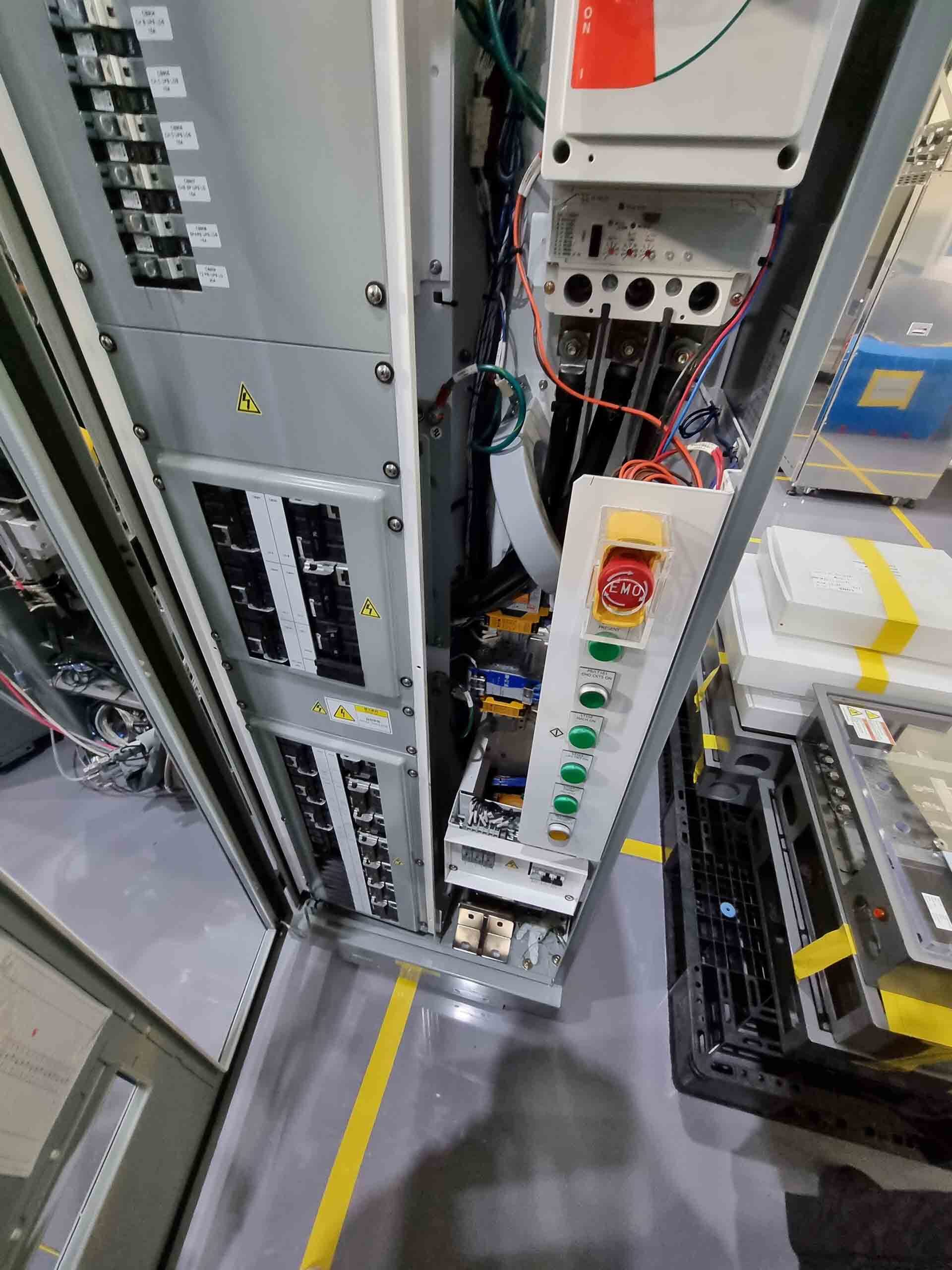

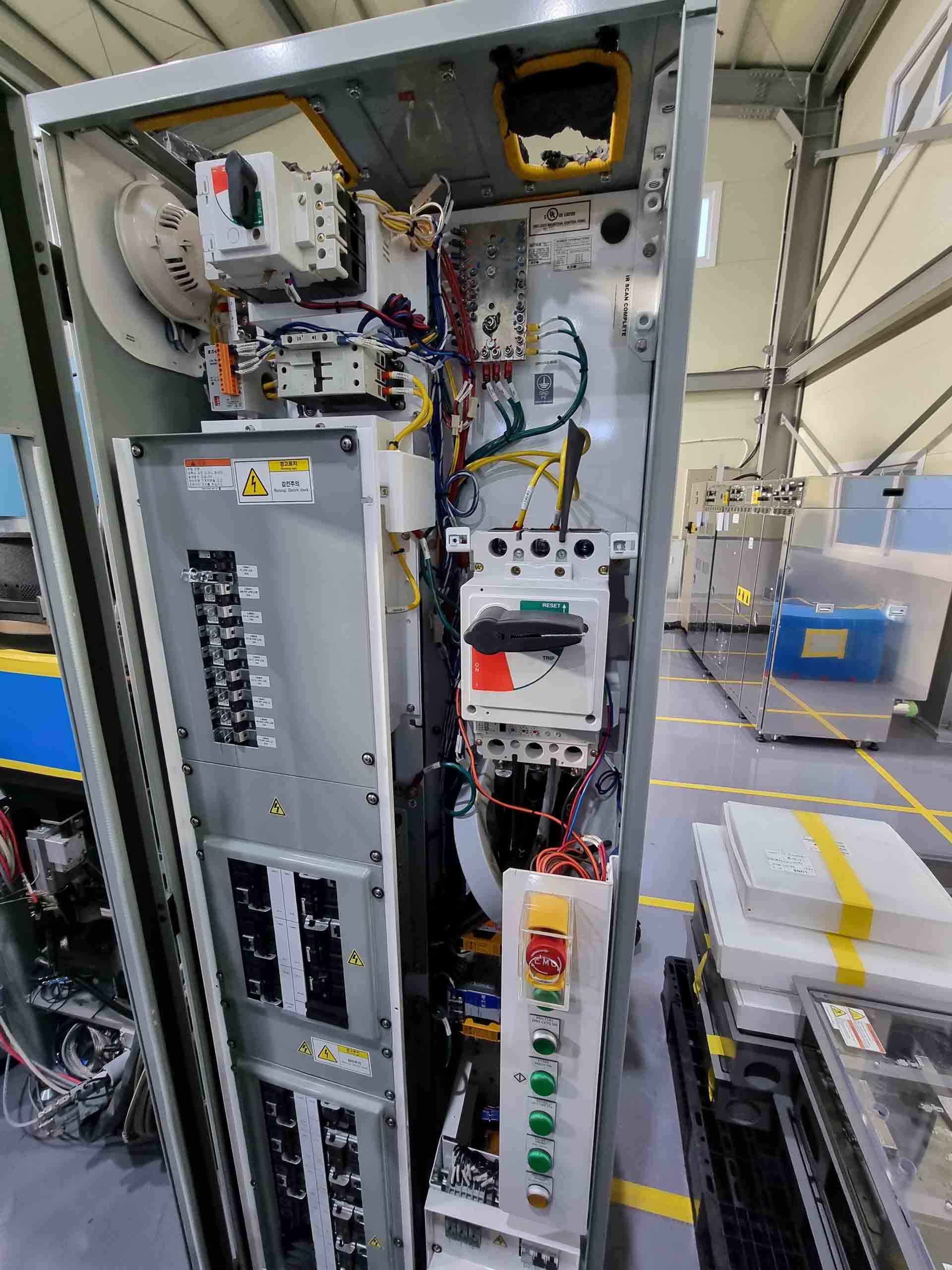

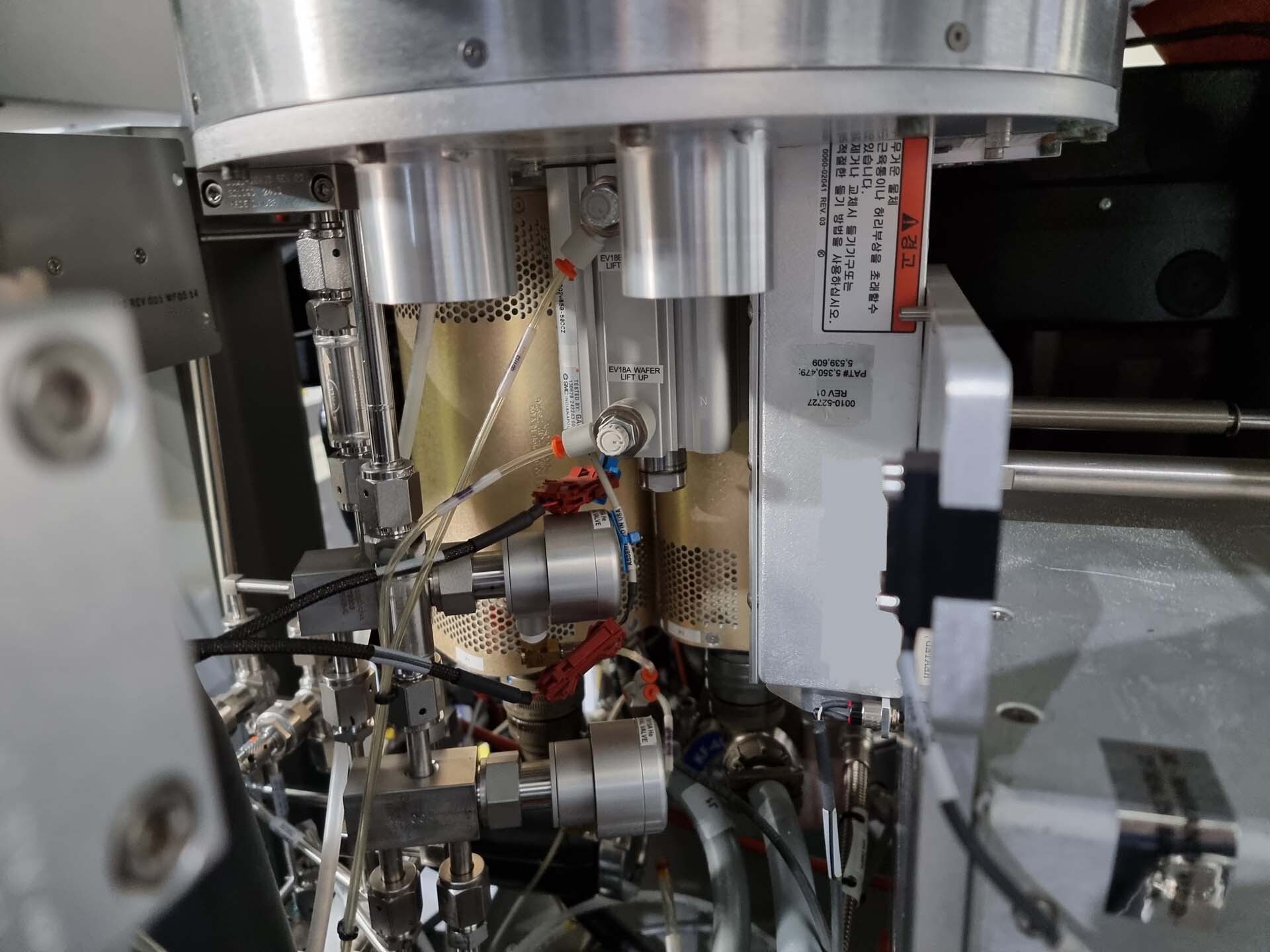

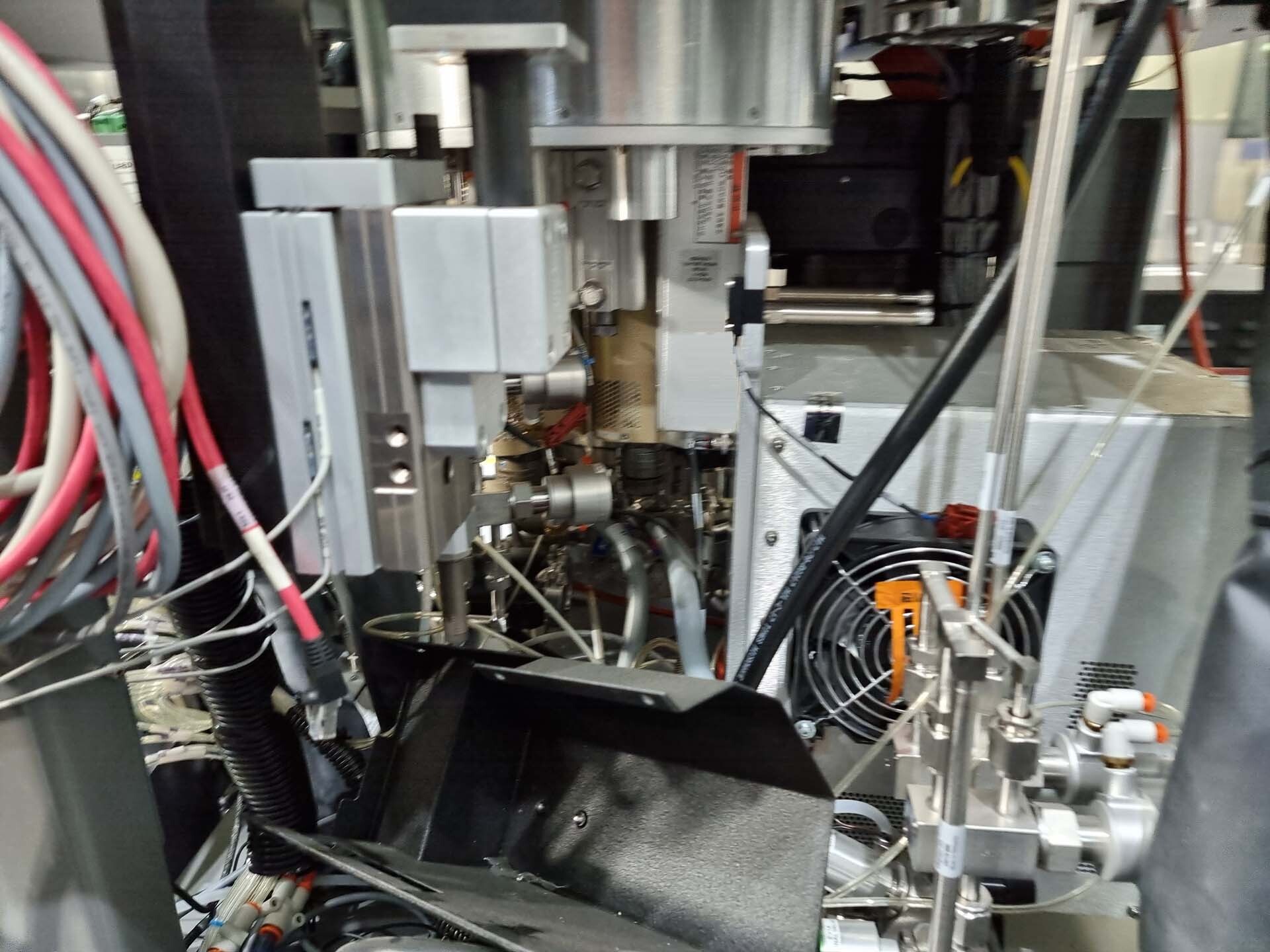

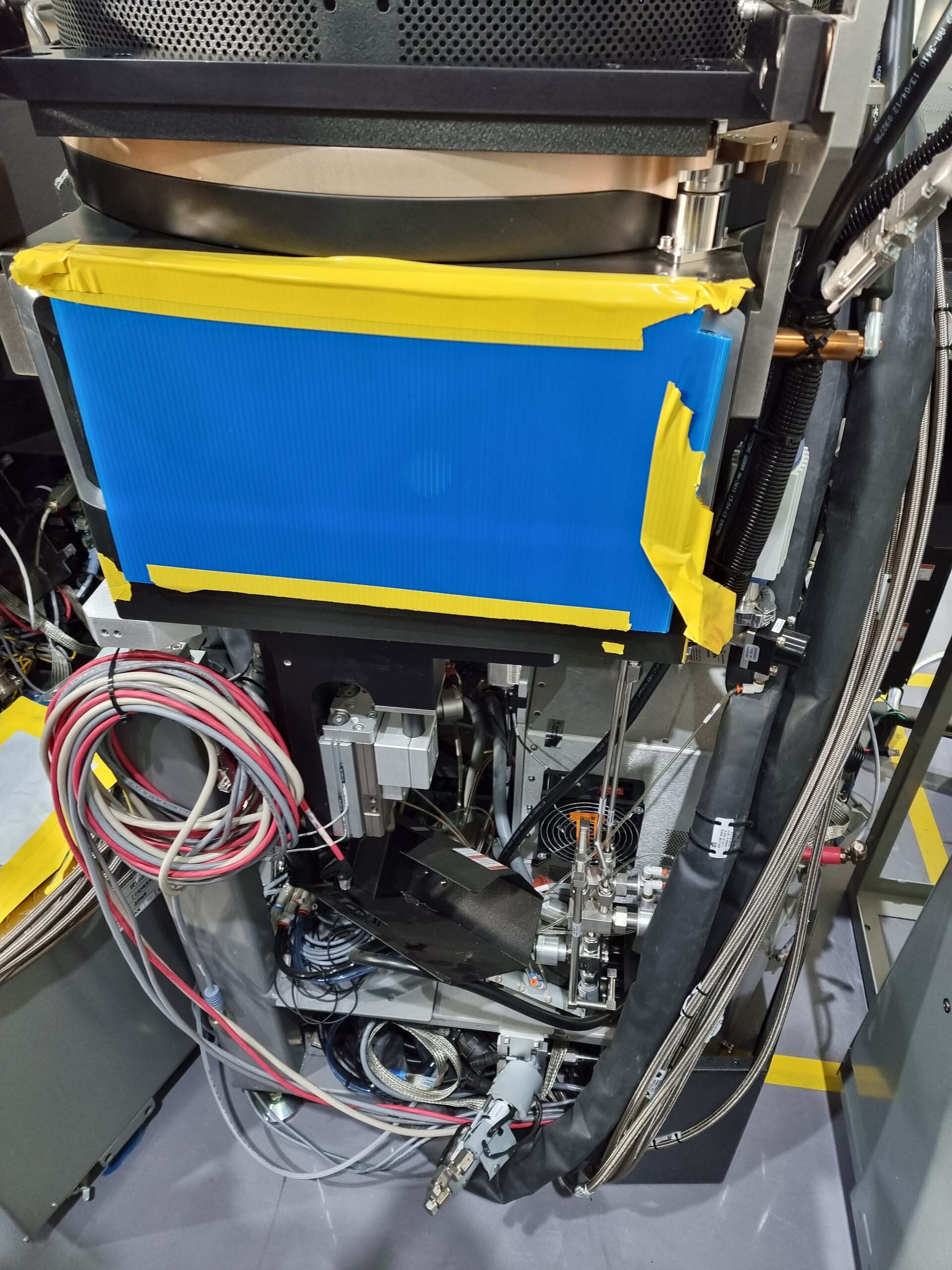

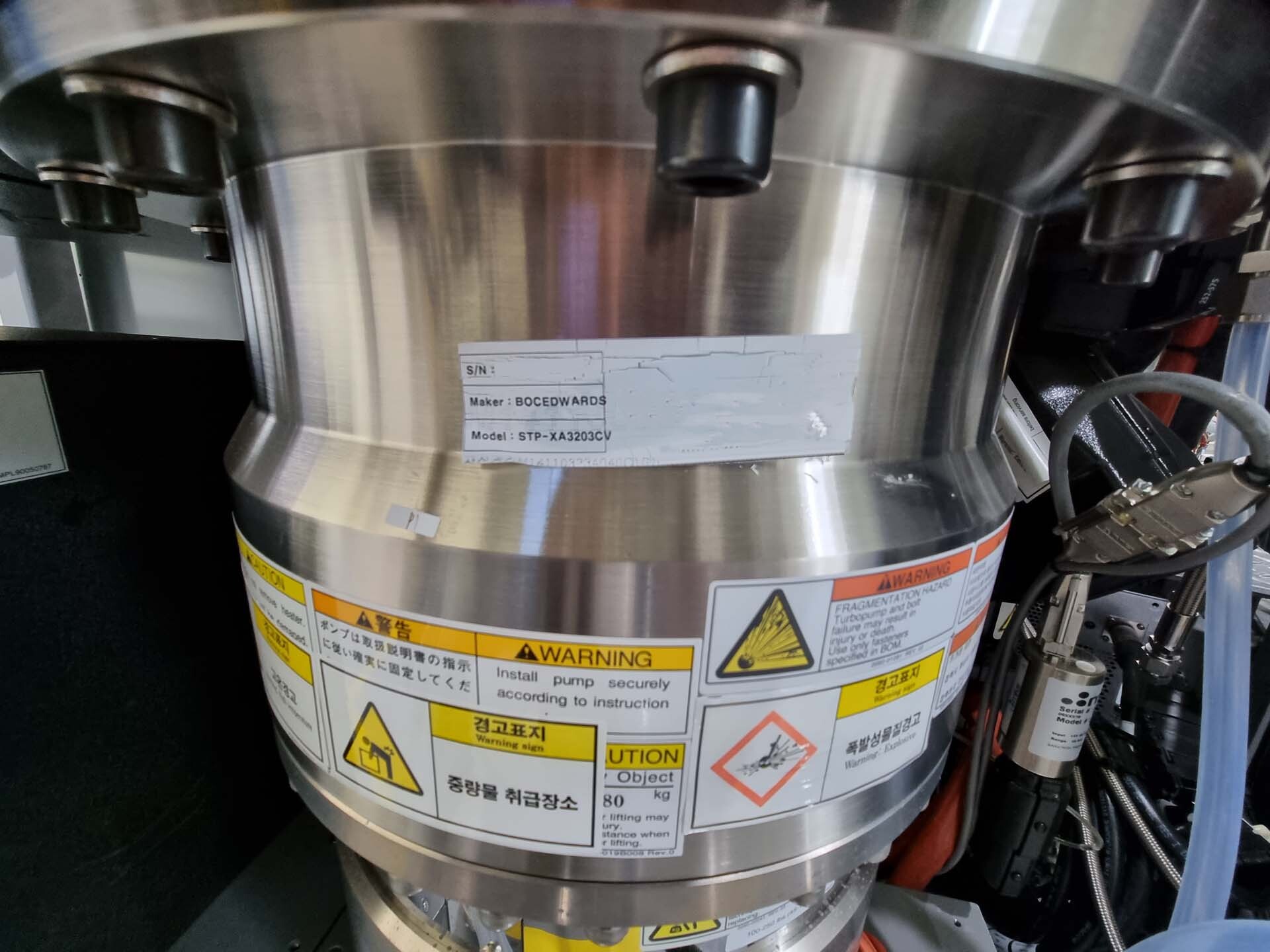

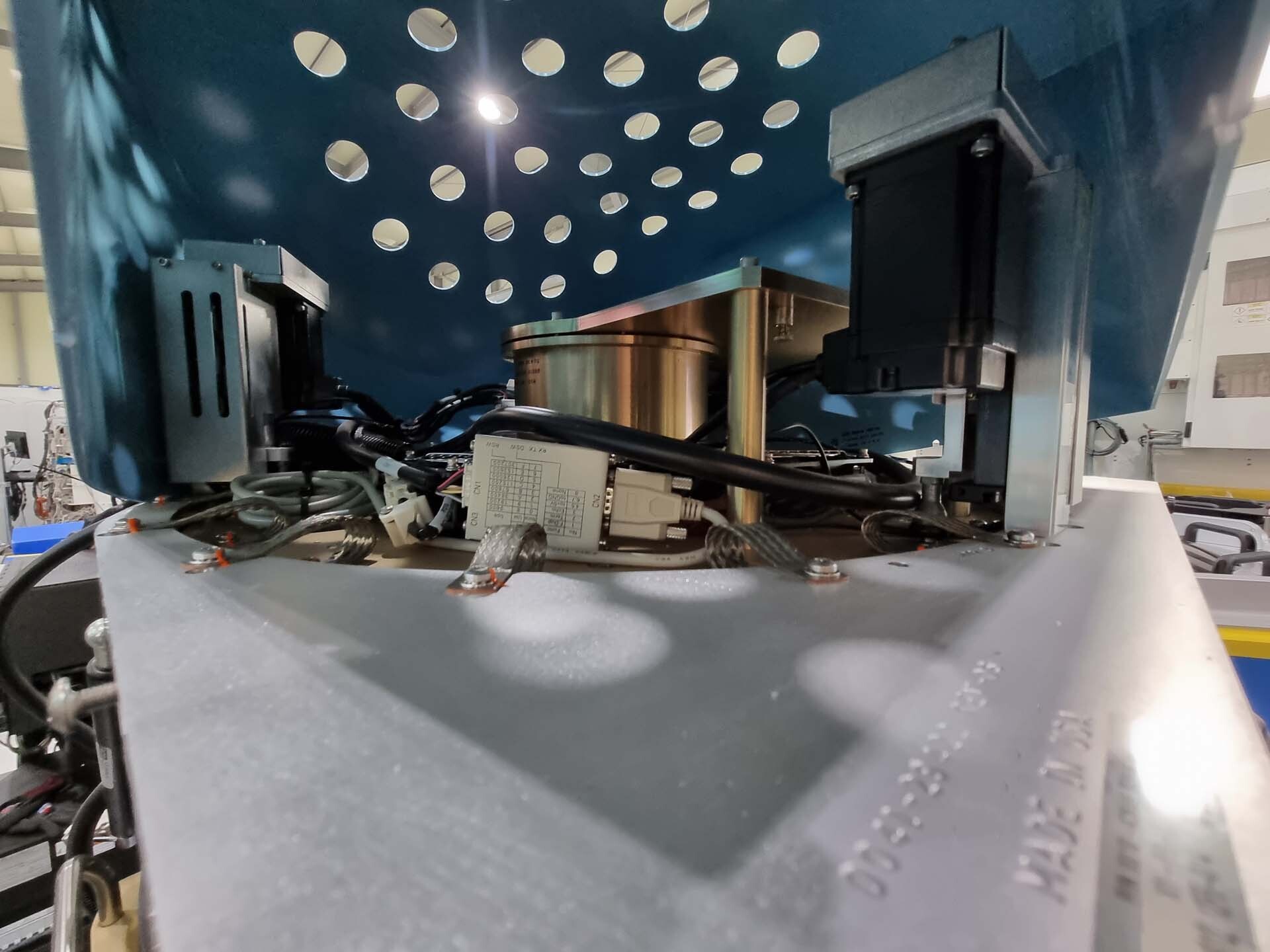

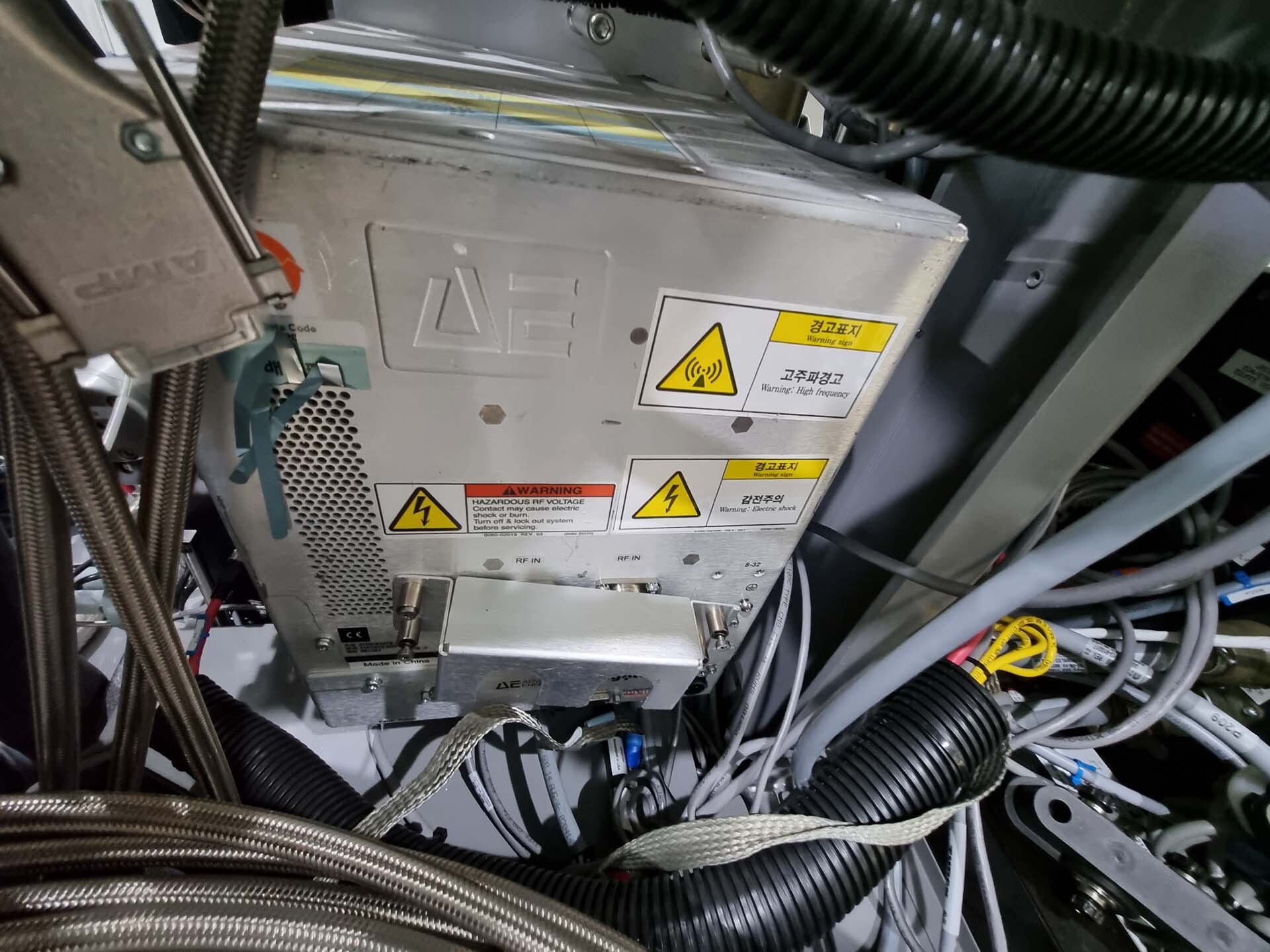

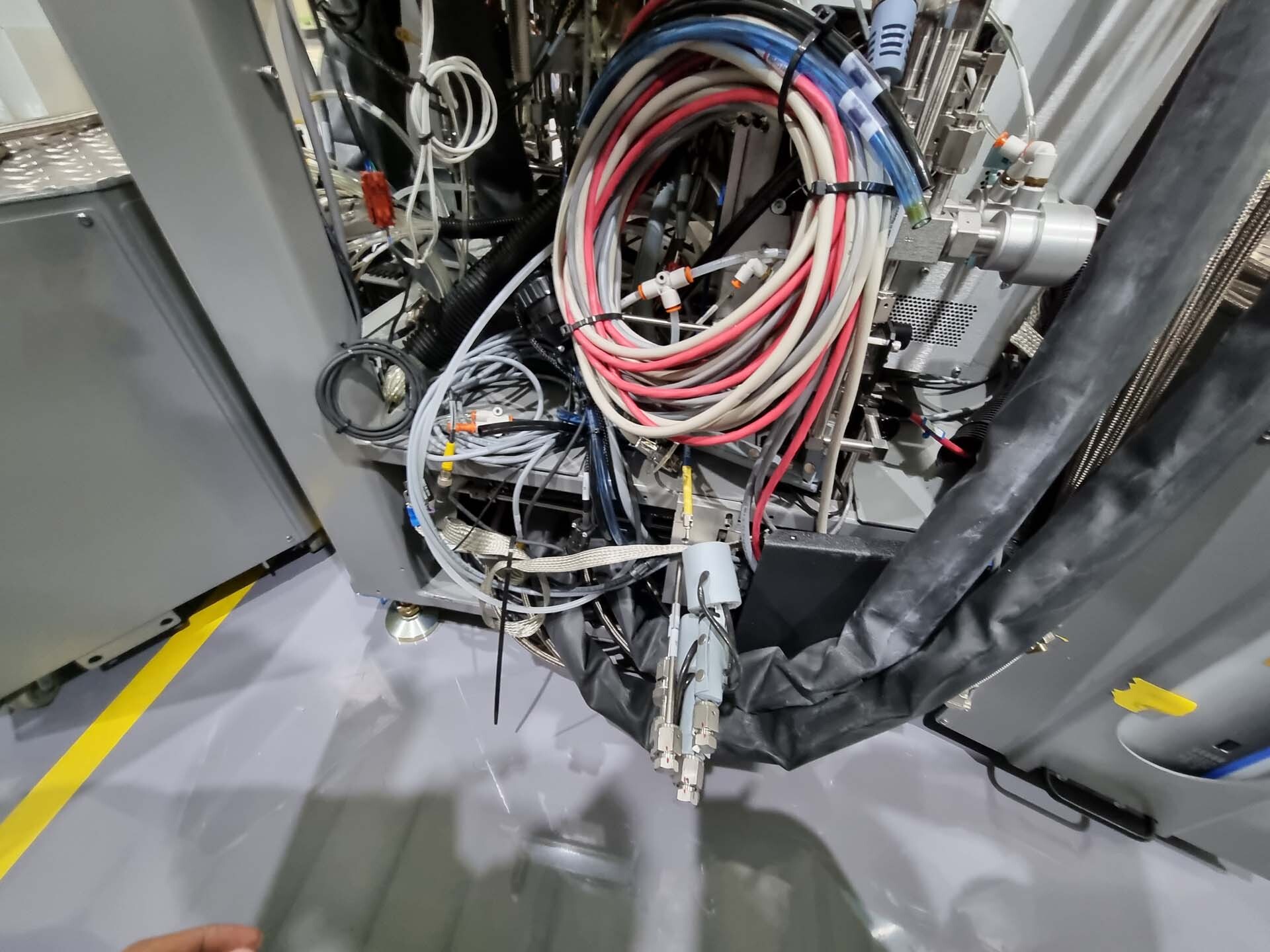

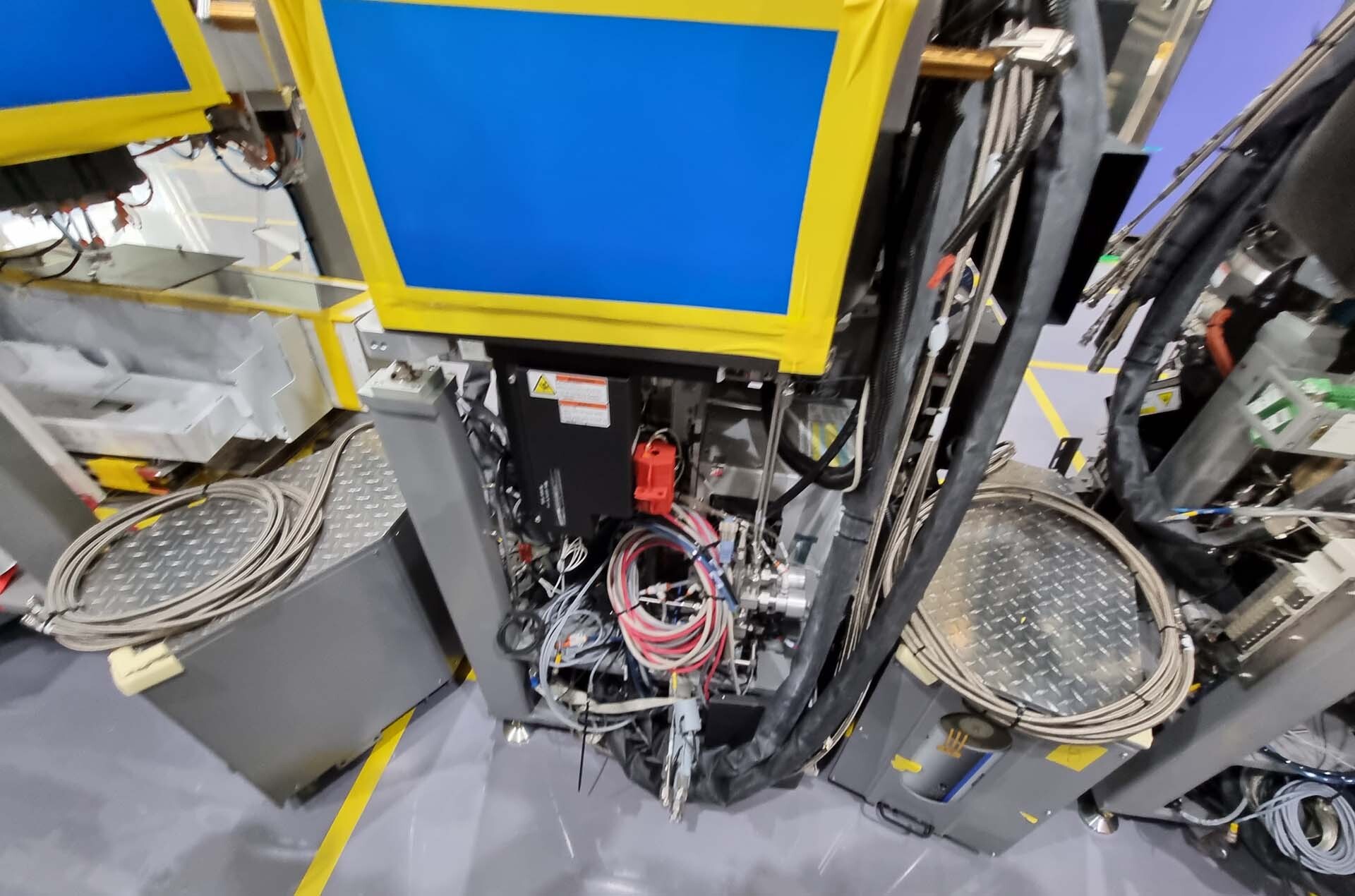

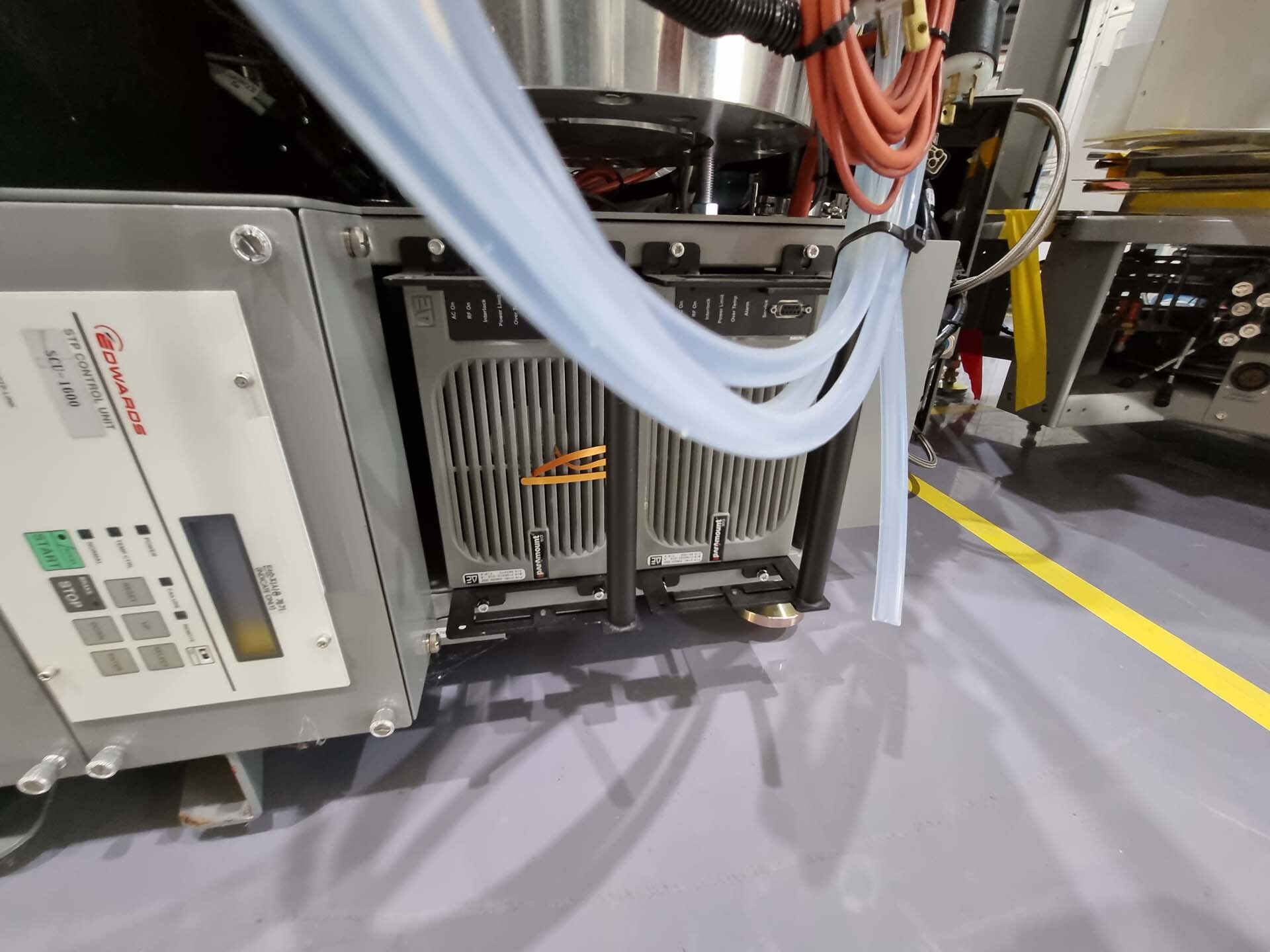

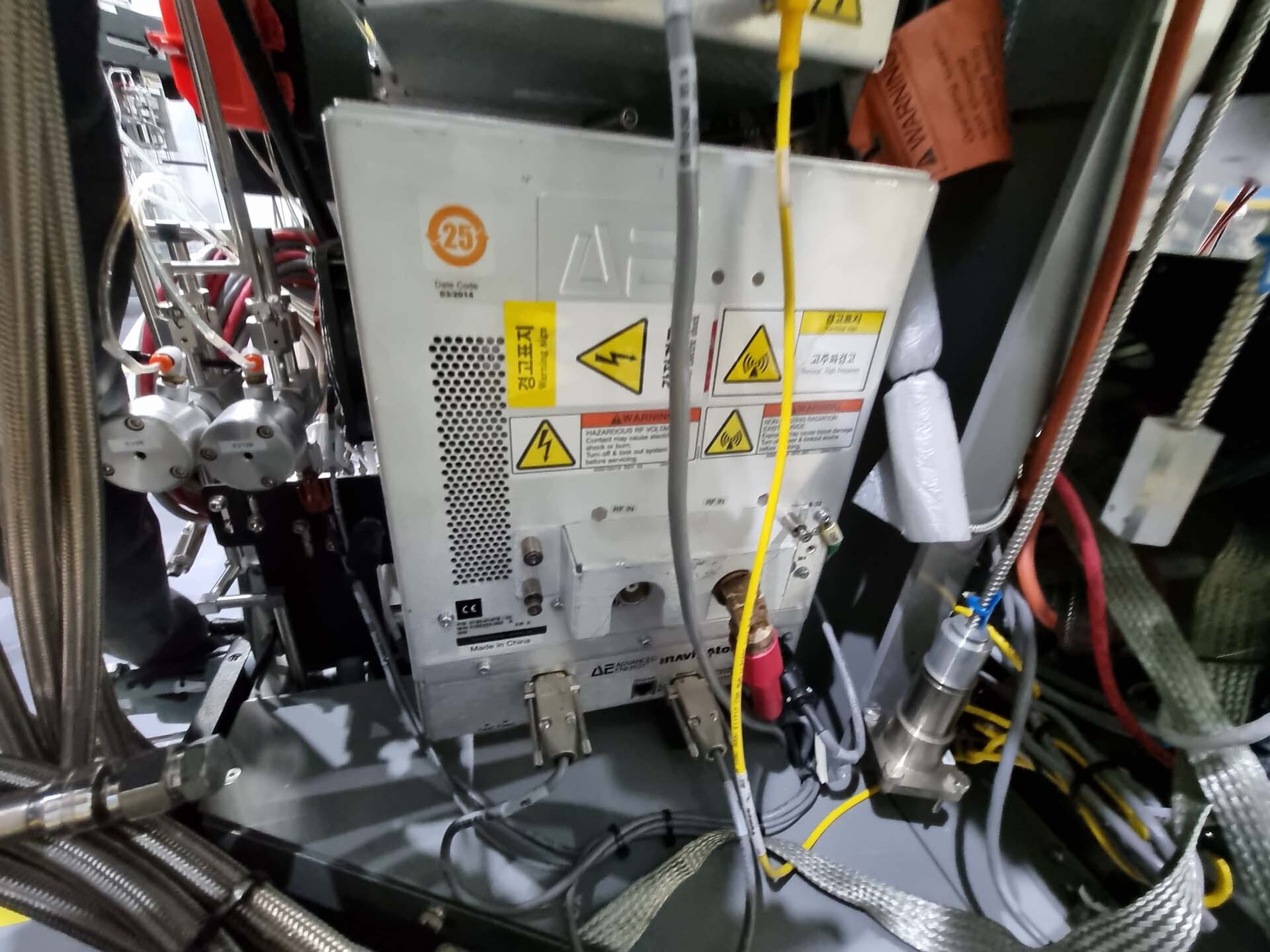

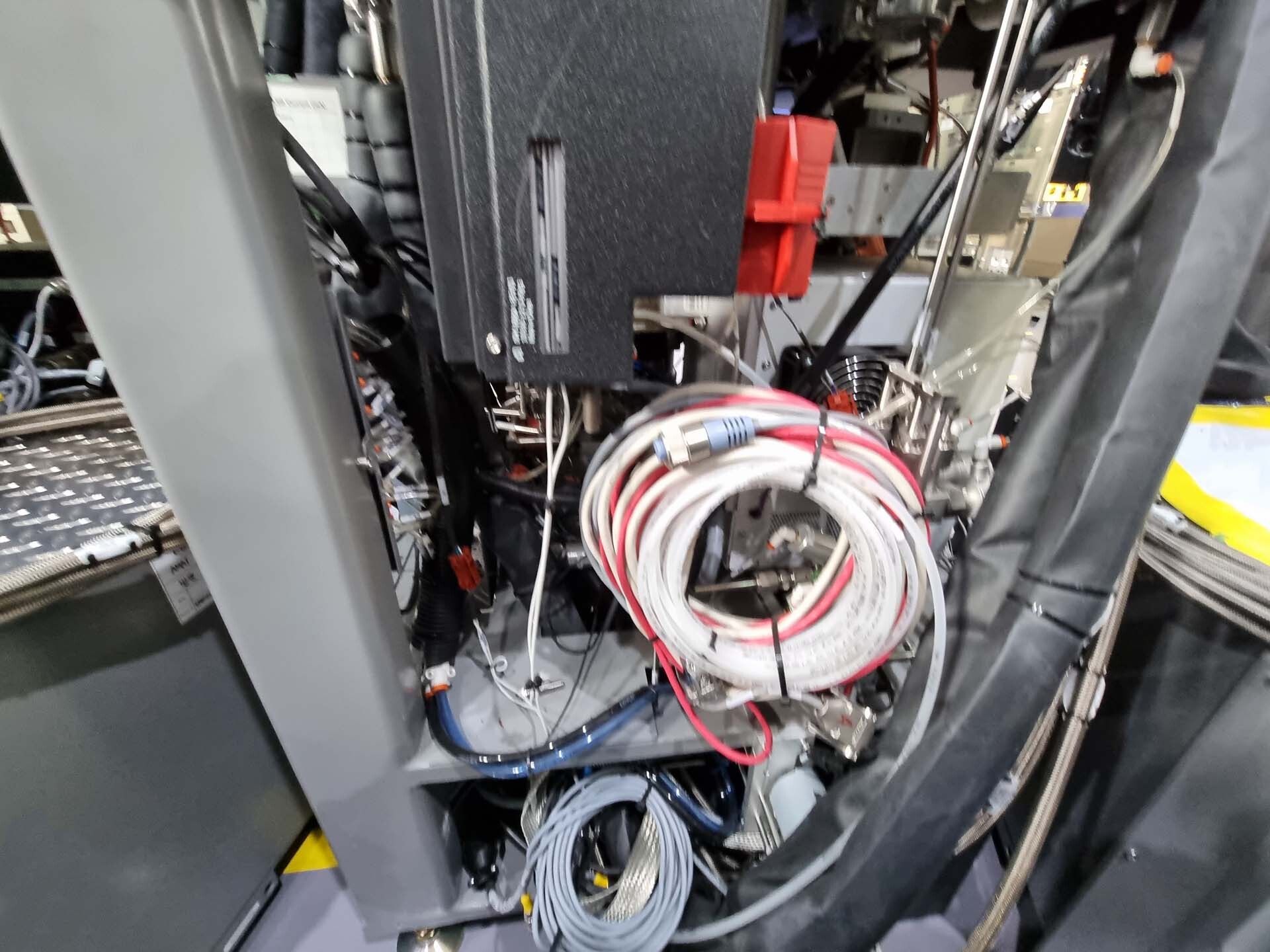

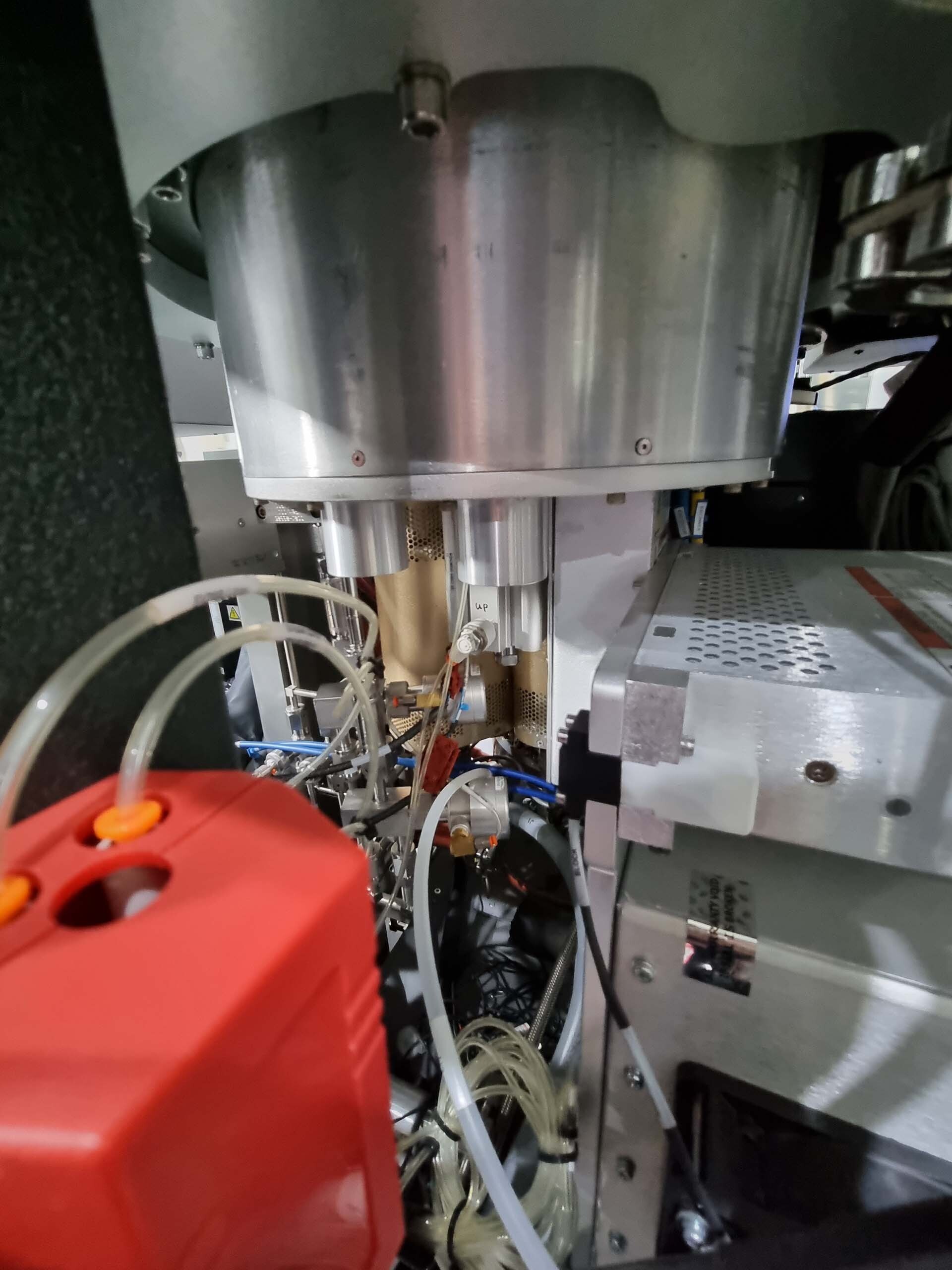

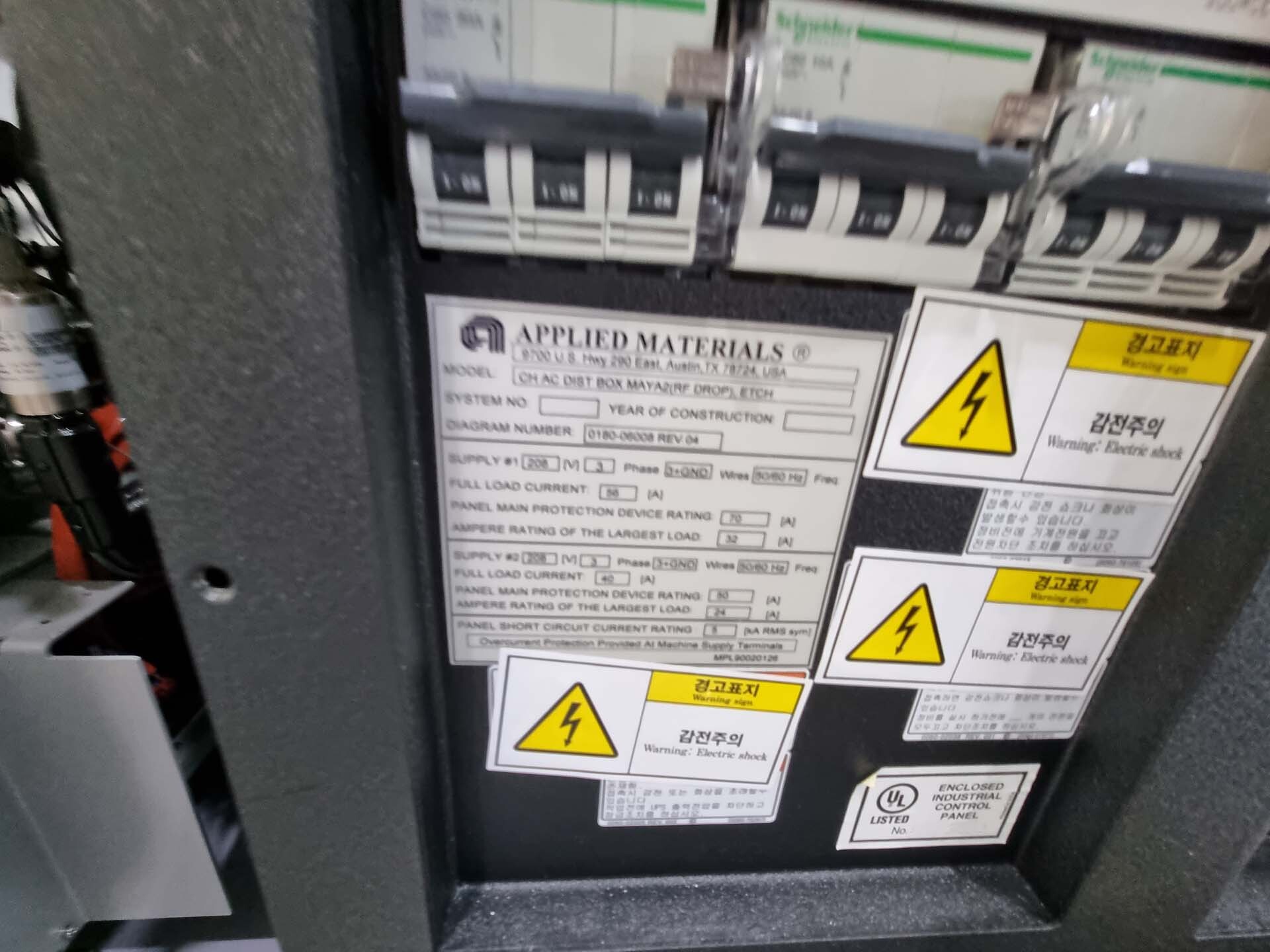

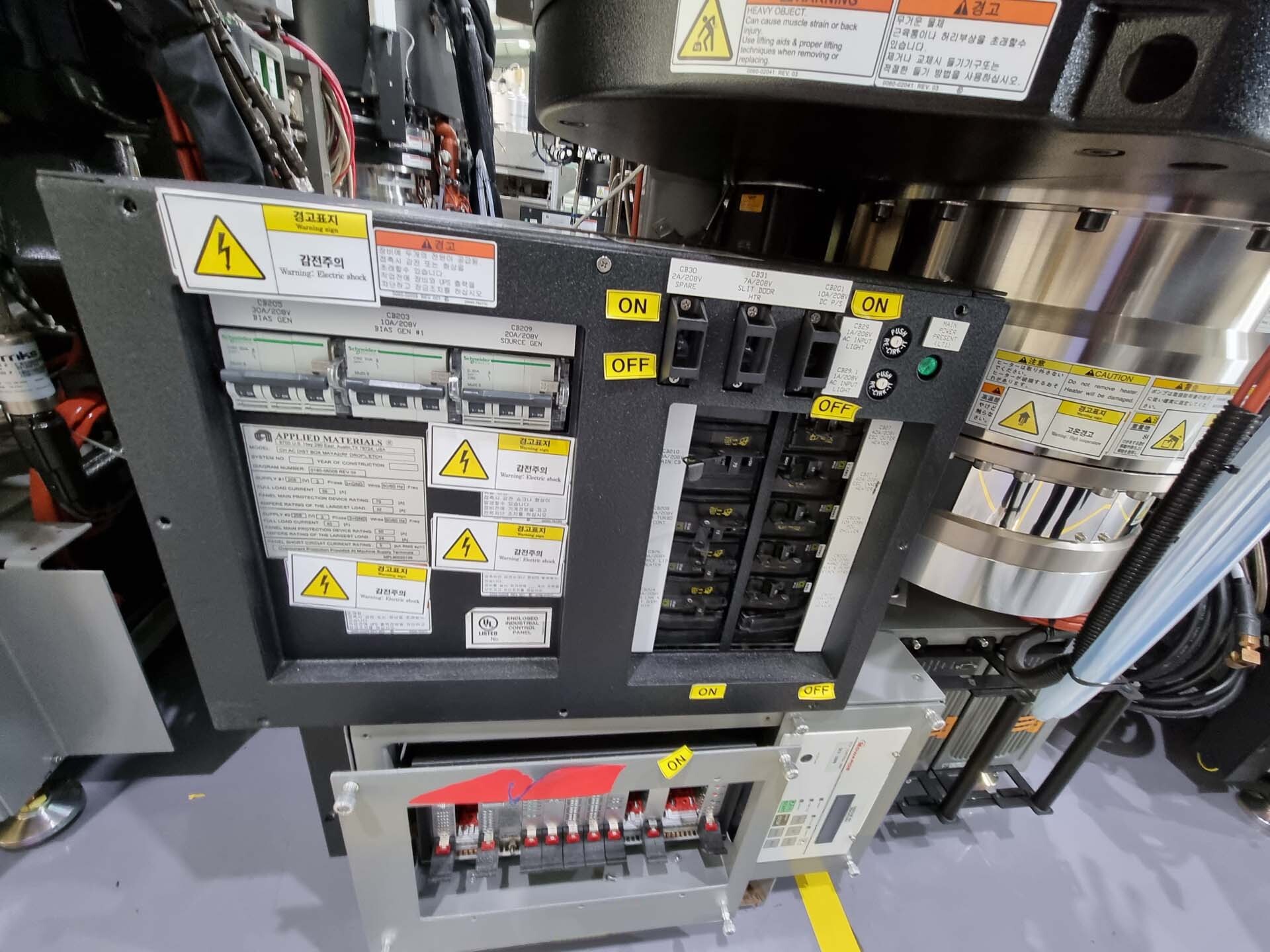

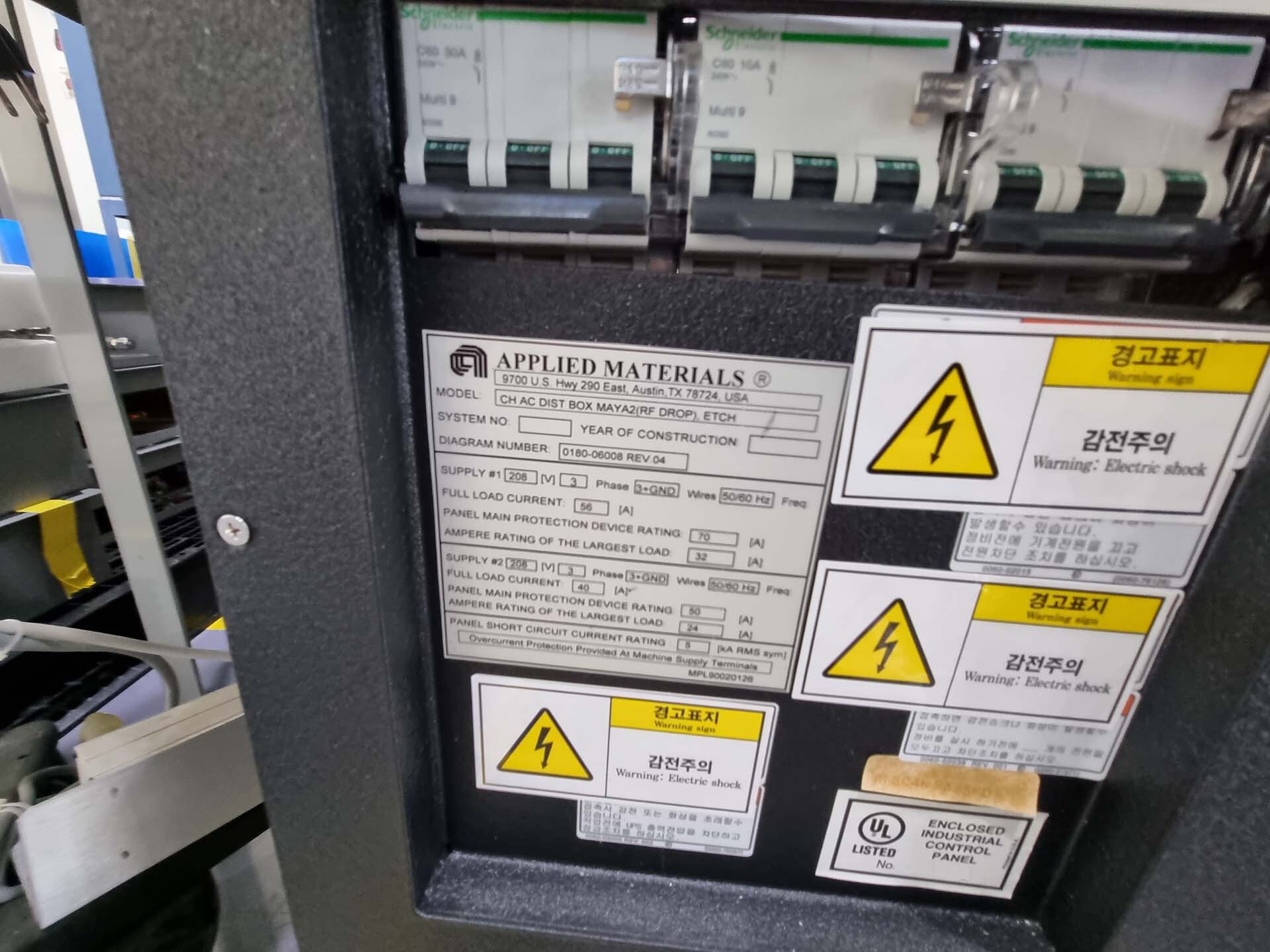

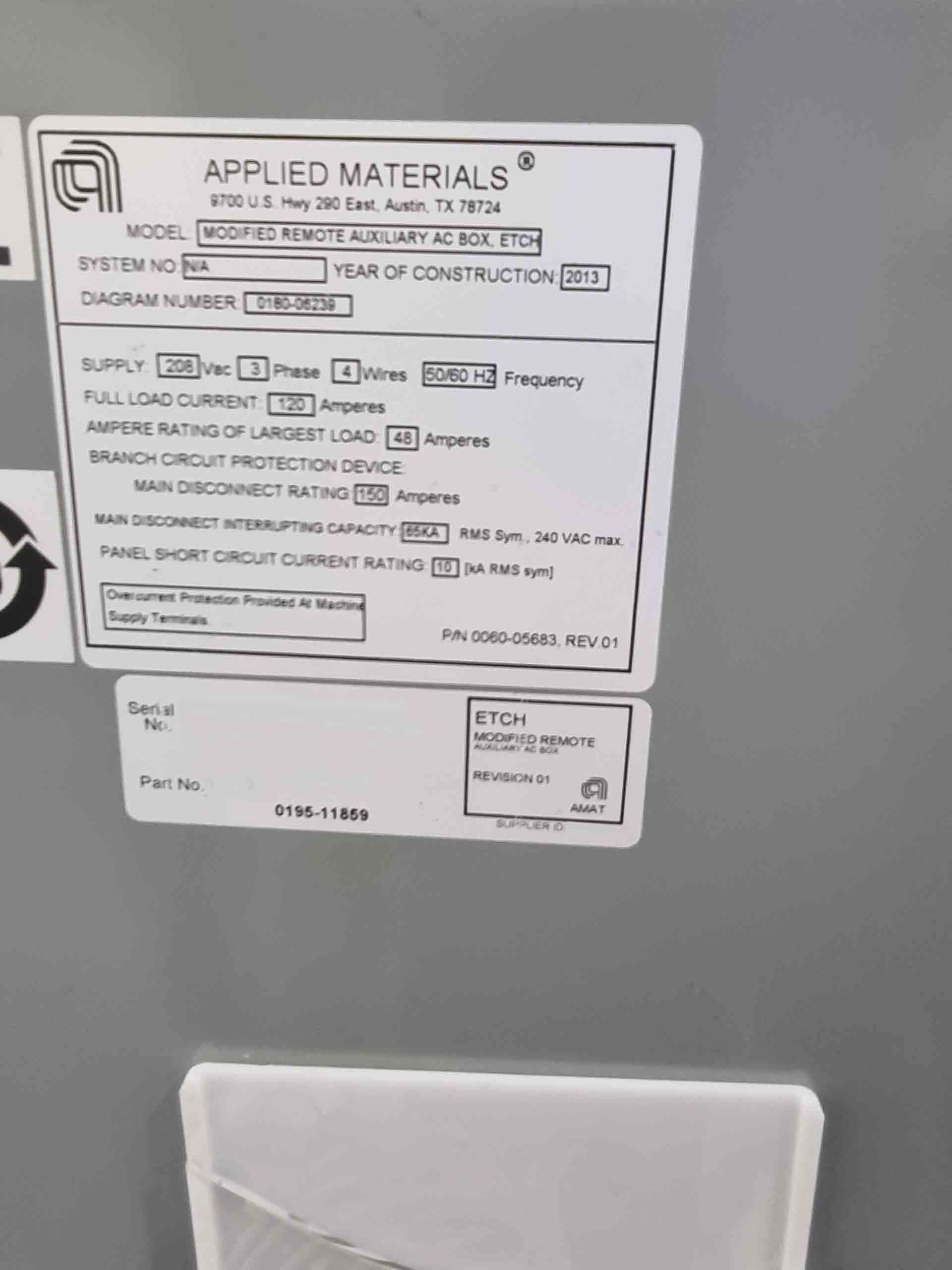

AMAT / APPLIED MATERIALS Centura DPS II Mesa Asher/Etcher is a high-capacity etching and ashing equipment designed for the deposition of thin films and ultra-shallow junctions in semiconductor processing. This system uses two separate, independently controllable process chambers to enable etching of multiple layers with different parameters. The DPS II Mesa Asher/Etcher is equipped with two independent aluminum reaction and diffusion chambers that enable the simultaneous etching of two separate layers with different etch parameters. The chambers are loaded with substrates, with both an upstream and a downstream chamber being used for etching. A heated transfer unit is used to move the wafers between the separate chambers. The machine is designed for applications in the area of advanced semiconductor technologies, including the formation of devices such as stacked poly-crystalline SiON and ultra-shallow junctions, back-end of line (BEOL) dielectric etching, Cu/low-K, and other applications. The tool offers ultra-precise, high-speed etching of up to 50 mm wafers in one sequential run. It also offers optimal uniformity of up to ±0.2 % over a wide range of conditions. The DPS II Mesa Asher/Etcher is equipped with several technologies including ActiveProcess™ control, which monitors and maintains real-time process control of in situ etch depth and uniformity. This technology enables the asset to maintain recipe accuracy and wafer-to-wafer uniformity ratios better than 1%. The model is also equipped with OptiFlo Plus™, which supplies process gases to both chambers using a combination of high pressure, low pressure, remote, and direct gas injection. The gas delivery equipment is flame-resistant and low-noise, which reduces emissions and therefore increases safety in the working environment. Overall, AMAT Centura DPS II Mesa Asher/Etcher provides a reliable, accurate, and high-throughput solution for semiconductor etching and ashing applications. Utilizing optically-controlled process parameters, versatile substrate handling, and in situ depth mapping, the system is well suited for advanced device processing and fabrication.

There are no reviews yet