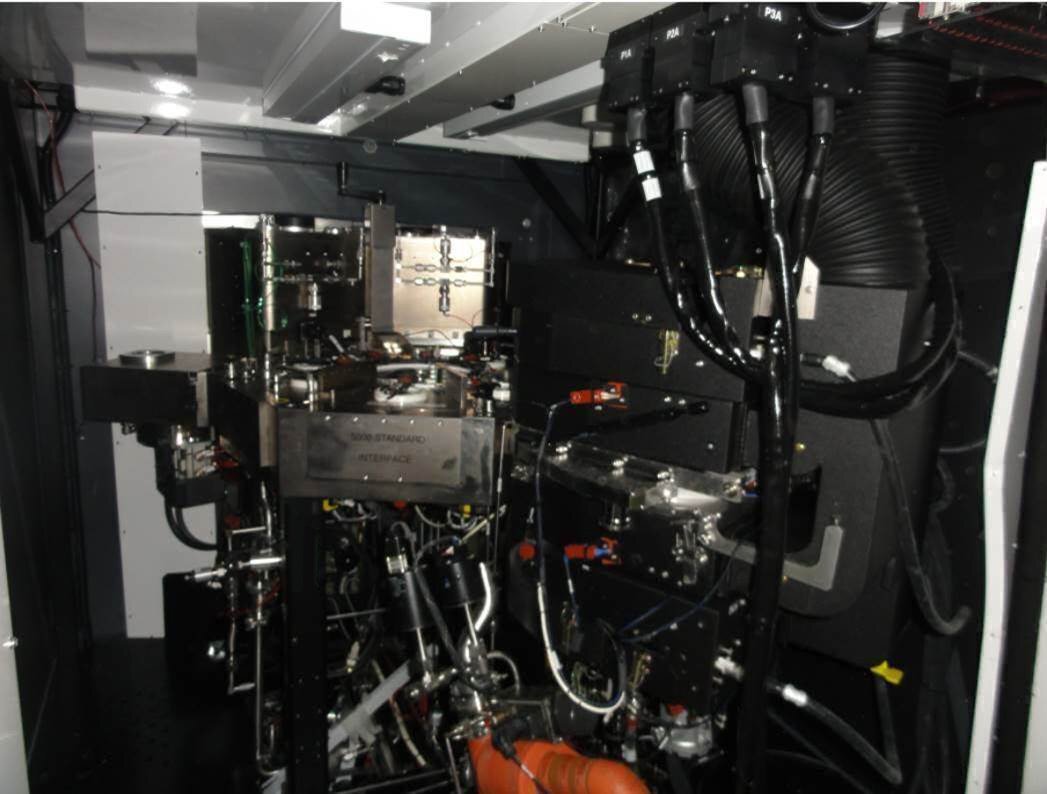

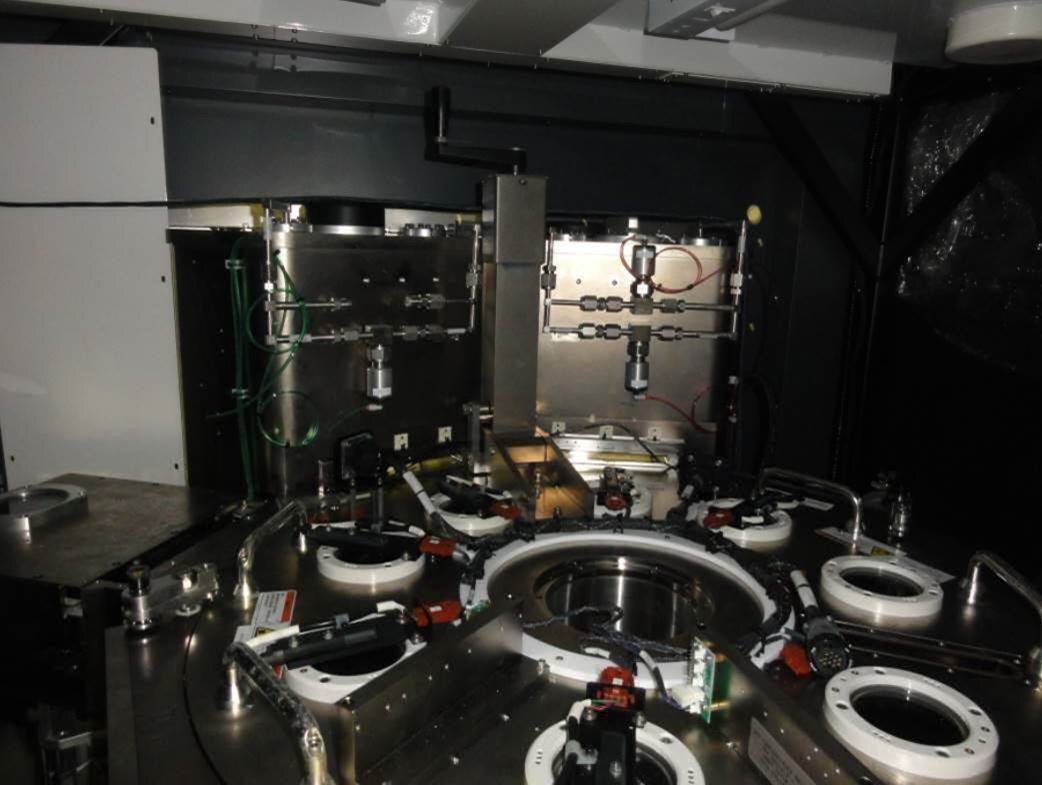

Used AMAT / APPLIED MATERIALS Centura XT ISD #293595648 for sale

URL successfully copied!

Tap to zoom

AMAT / APPLIED MATERIALS Centura XT ISD is an advanced etcher/asher that leverages the latest in semiconductor technology in order to provide superior process control and repeatability. This system combines single wafer loading with high precision etching and ashing capabilities to support advanced process development and production processes. AMAT Centura XT ISD features an automated process control platform that allows for repeatable results. The system also features a uniform gas distribution design that aids in maintaining uniform etch rates and uniform processing orientation. This ensures consistent etch results over a large number of wafers. APPLIED MATERIALS Centura XT ISD also features a high vacuum capability, which can reach a throughput of 150 wafers per hour, making it well-suited for production processes. The high resolution of Centura XT ISD's plasma sensor supports the user in achieving their desired etch rates. This sensor is also capable of monitoring the etch rates of multiple sites in both runs and processes. Additionally, a real-time current feed capability is featured in AMAT / APPLIED MATERIALS Centura XT ISD and can be used to achieve enhanced etching results by providing an adjustable etch rate. AMAT Centura XT ISD also offers support for a range of wafer sizes and feature various metal lift-off processes that enable the user to achieve a wide array of etching and metal deposition processes. This helps to support a variety of advanced materials processing applications, from simple etch-leveling and packaging to metal liftoff, Bulk Substrate Removal (BSR), and Undercut/Thinning applications. APPLIED MATERIALS Centura XT ISD is designed to be a flexible and efficient tool with a low maintenance cost. Its features make it capable of handling both small and high-volume etch and ashing jobs with ease. As a result, Centura XT ISD is well-suited for all types of etching and ashing operations, from research and development to high-volume production processing.

There are no reviews yet