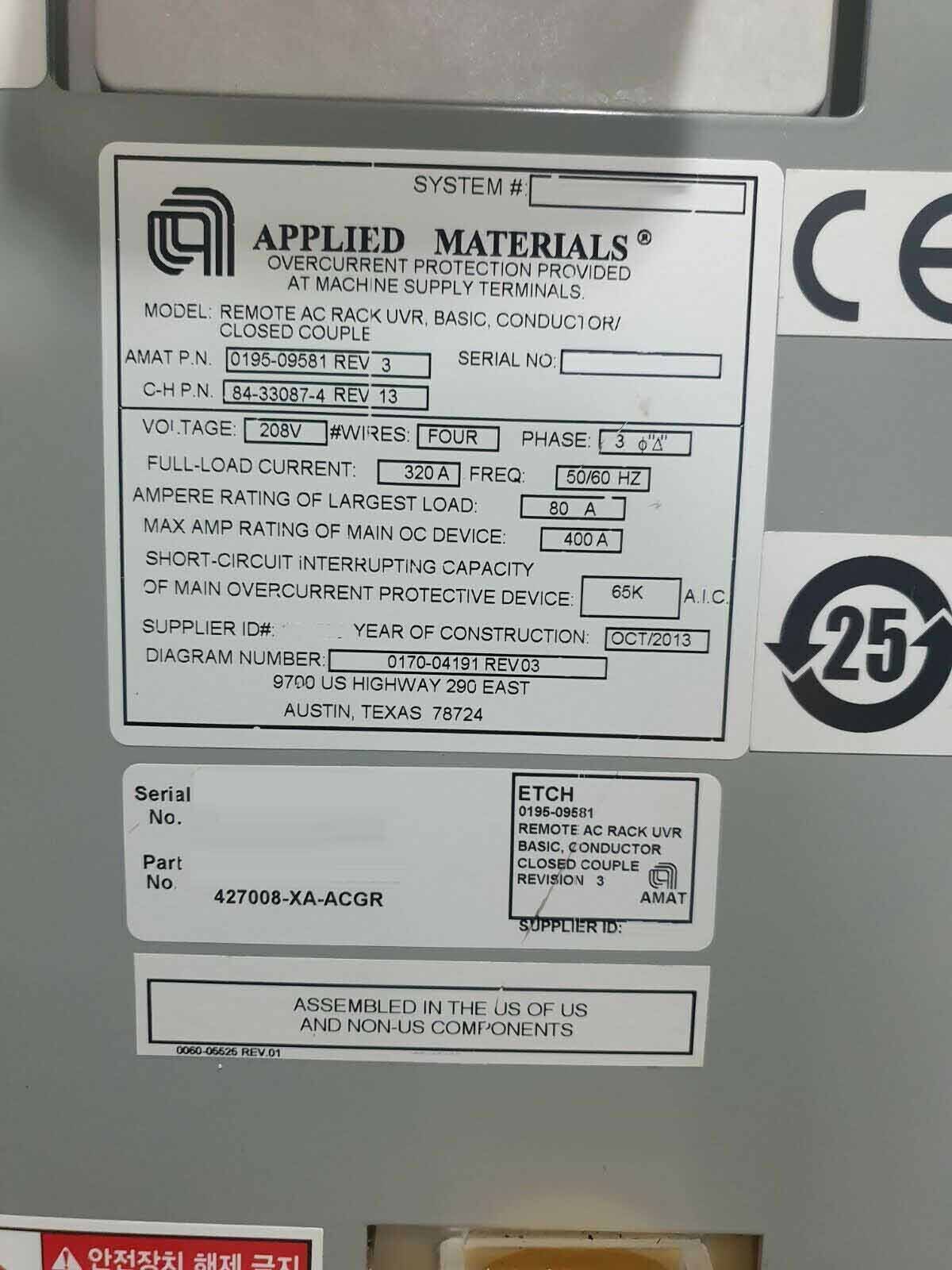

Used AMAT / APPLIED MATERIALS DPS G5 MESA T2 #9395535 for sale

URL successfully copied!

Tap to zoom

ID: 9395535

Vintage: 2013

Poly etcher

AP Frame

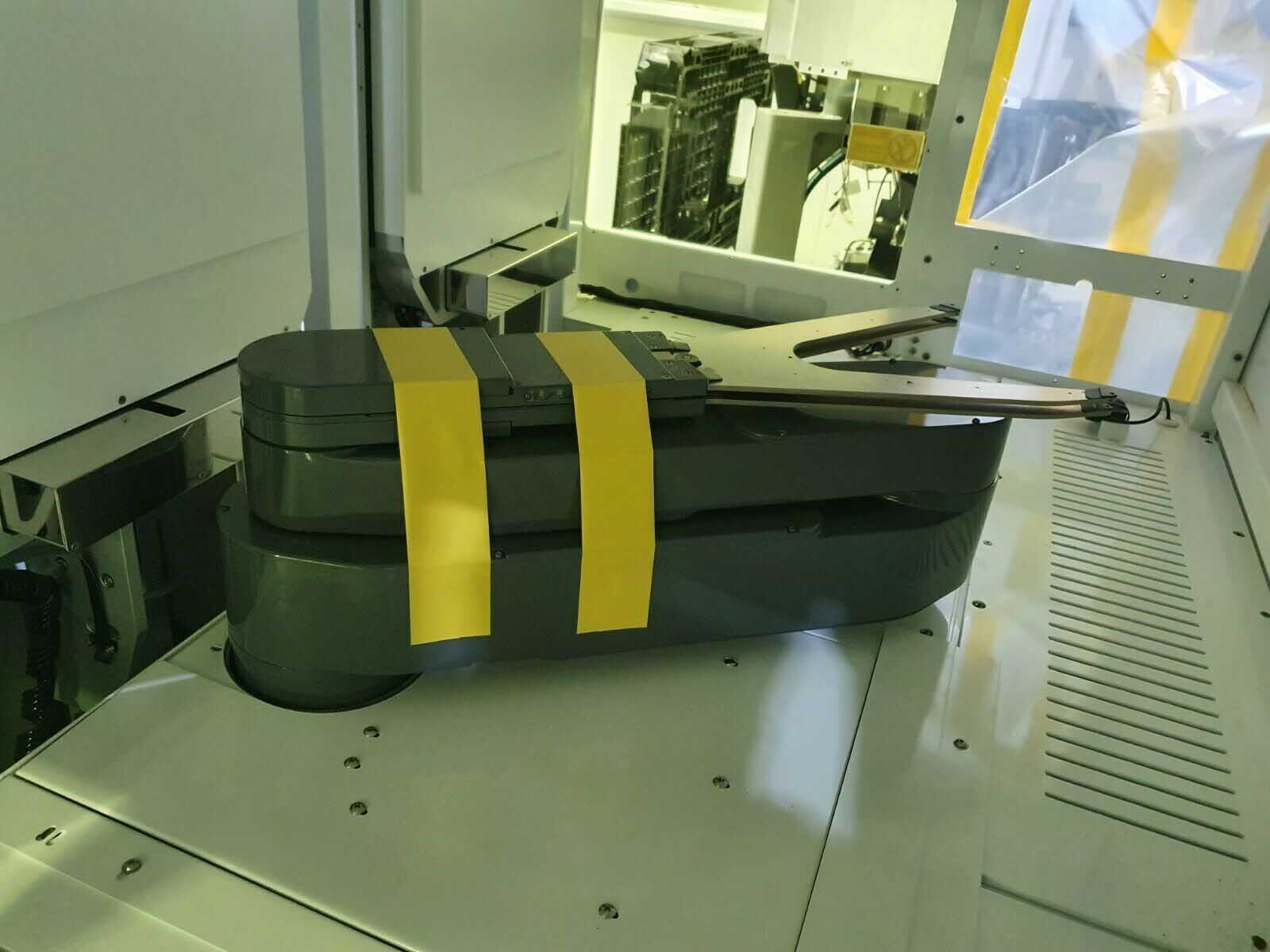

TM Robot: VHP

Process module: (3) MESA T2/RF (Etcher)

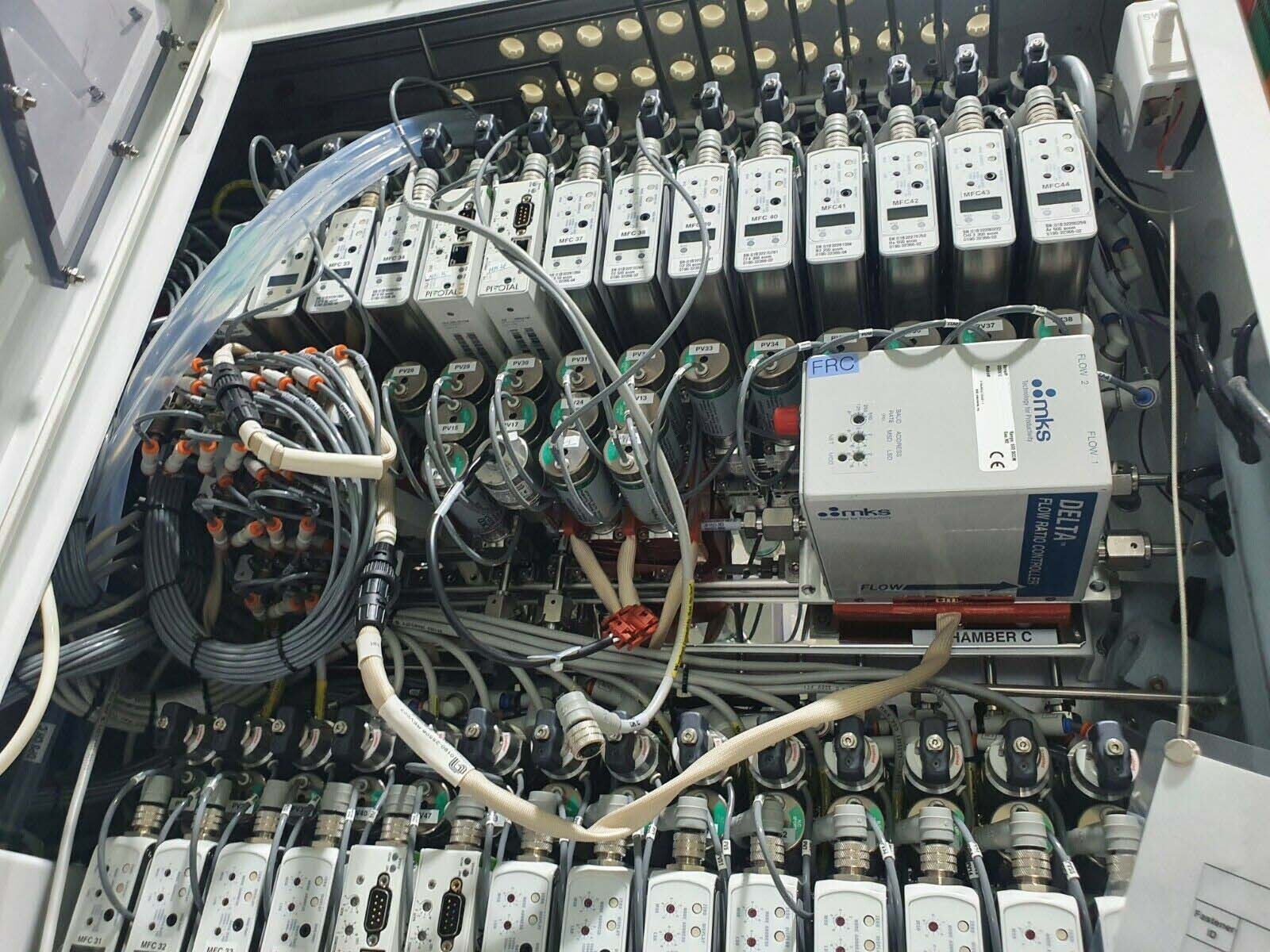

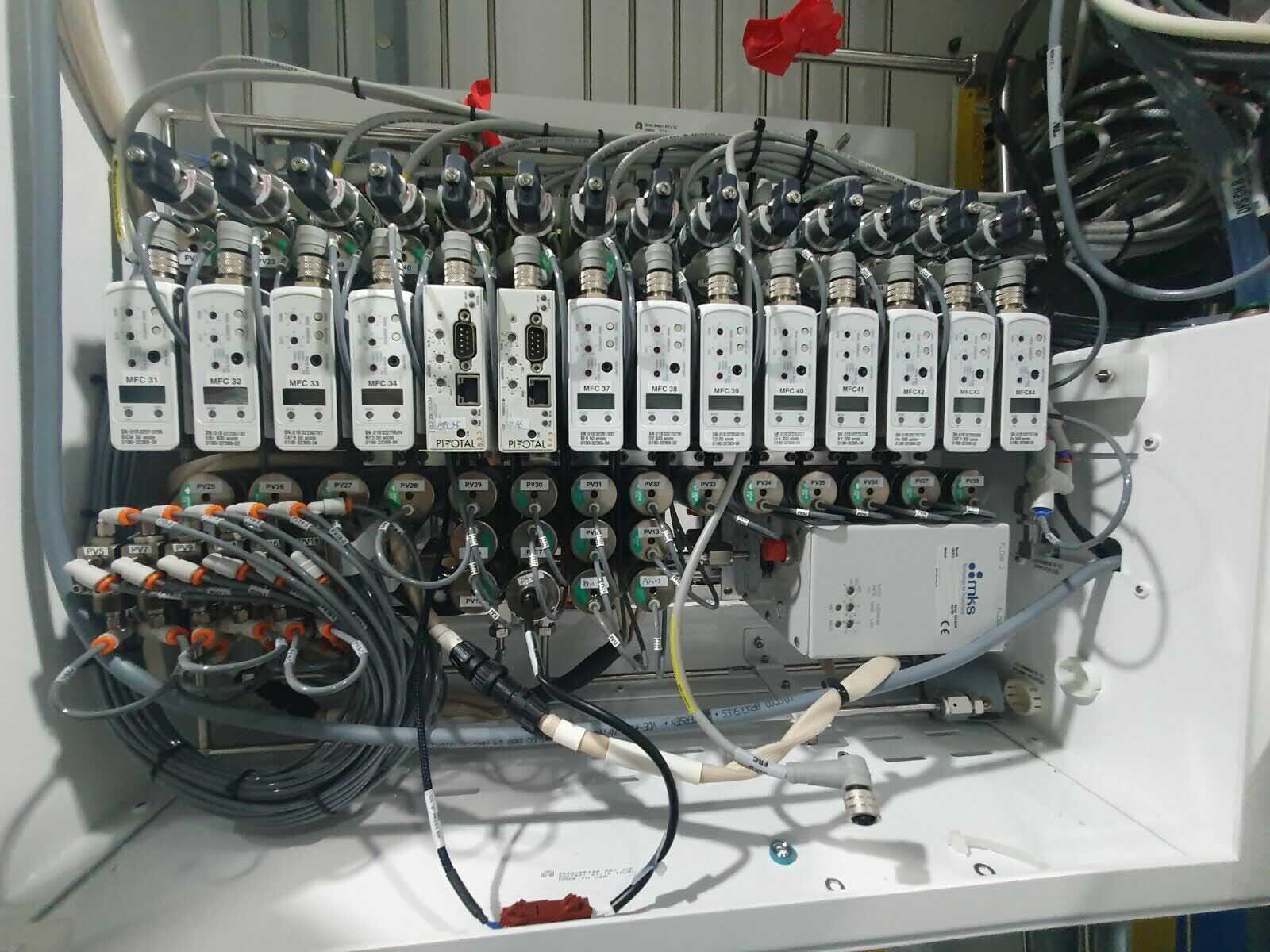

Process gases: SiCL4, HBR, C4F8, NF3, SF6, CL2, CF4, CHF3, O2, N2, Ar, He

EFEM:

(3) FOUPs CYMEHCS Duraport-DE2

KAWASAKI 3NT520B-A006 Controller

PIPER VAC A100L

TMP:

(3) EDWARD STP-XA3203CV

(3) IH1000C

RF Generators:

AE APEX1513

AE APEX3103

2013 vintage.

AMAT / APPLIED MATERIALS DPS G5 MESA T2 is an etcher/asher which is used to carry out a variety of processes, such as etching, ashing, ashing selective and simultaneous etching-ashing of media. This equipment is specifically ideal for semiconductor and microelectronics fabrication. It features a two-module operation that uses an integrated processing chamber to provide fast and efficient transfers of the substrate between the plasma etch and ashing chambers. AMAT DPS G5 MESA T2 asher-etcher also features a built-in robotic transfer system, allowing equipment operators to quickly move substrates from one chamber to the other. This unit also includes a temperature controller that can be programmed to maintain precise temperatures for multiple substrates at once. Additionally, the controller also provides optimized pressure and temperature settings for optimum process control and uniformity. In the etch chamber of APPLIED MATERIALS DPS G5 MESA T2, the machine utilizes advanced, advanced Etch reactor technologies to enable precise etching of media. These reactor technologies include direct current technology, pulsed grid technology, ion cyclotron resonance technology, and electron cyclotron resonance technology. These technologies incorporate the use of high-power RF waveforms and frequencies to make sure that substrates can be etched with the highest precision and speed. DPS G5 MESA T2 asher-etcher also features an advanced Asher reactor technology. This Asher reactor technology utilizes a combination of temperature and pressure to provide a uniform and consistent environment for efficient ashing of substrates. The Asher reactor also utilizes slit nozzles for precise delivery of inert and reactive gases that are used in the process. This technology also ensures that no dead zones occur due to gas flow, thereby providing a uniform ashing of the substrate. Overall, AMAT / APPLIED MATERIALS DPS G5 MESA T2 tool provides a comprehensive solution for etching and ashing technology. It utilizes a combination of advanced plasma etcher and asher reactor technologies to ensure the highest precision and speed for etching and ashing processes. Its advanced controller also makes it possible to program and maintain exact temperatures and pressures to ensure uniform and consistent results across a wide range of substrates. Additionally, its automated robotic transfer asset ensures efficient transportation of substrates between the etch and ashing chambers. This model is an ideal choice for semiconductor and microelectronics fabrication processes.

There are no reviews yet