Used AMAT / APPLIED MATERIALS DPS G5 #9375195 for sale

URL successfully copied!

Tap to zoom

ID: 9375195

Poly etcher, 12"

AC Remote power rack

CHX Chiller

EDWARDS IXM 1800 Dry pump

Chambers:

(3) DPS (A, B, C)

AXION (D)

FI (EFEM):

UPS

MKS Macronode

Keyboard Video Mouse (KVM)

Ethernet switch hub

Fast Data Gateway (FDG)

Short flex controller assy

Light curtain

Load port

RFID

Aligner

Robot controller

Ionizer controller

Light tower

Intake plenum enclosure

MF:

Type: AP

TM Robot

TM Robot controller

TM Robot blade

Integrated point of use pump (I-PUP)

TM Baratron gauge

TM Vacuum gauge

Load lock vacuum gauge

Load lock indexer controller

TM Diffuser

Load lock vent valve

Load lock heater controller

Load lock door

Auto Pressure Controller (APC)

Slit valve

GME Chamber port Assy

Lid

Bulk gas delivery

Modular DNET IO Controllers (MDI)

Process chamber:

Chamber Control Module (CCM)

Source coil

Source ceramic lid

Source lid heater

Upper liner

Lower liner

Cathode liner

Flow equalizer

Slit liner door

Cathode assy

ESC RF Filter box

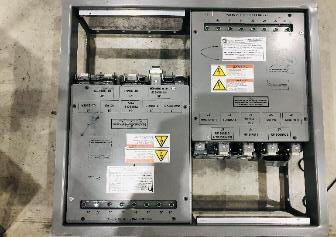

AC Distribution box

Temperature controller

Throttling gate valve

Eyed OES Spectrograph

Electrostatic Chuck (ESC)

HE Controller

Ion gauge

Pumpstack

Chamber lift assy

TGN Gas delivery

Vacuum gauge

Vacuum switch

Pump

Foreline ISO Valve

RF Match box and generator

Strip chamber:

Chamber Control Module (CCM)

Pedestal assy

Throttling gate valve

Foreline ISO Valve

AC Distribution box

Temperature controller

Vacuum gauge

Vacuum switch

Remote plasma source

Gas panel:

Type: NEXTGEN (16) Sticks

Gas weldment type: Single line drop

Mass Flow Controller (MFC)

Flow Ratio Controller (FRC).

AMAT / APPLIED MATERIALS DPS G5 is a Deep Reactive Ion Etch (DRIE) and Asher equipment with an extensive list of features and capabilities. It works by using ions to etch or asher a material, usually a semiconductor, to create desired patterns. It is comprised of several components, such as a source chamber and pressure chamber, to support its specialty functions. The source chamber includes a vapor injection system, as well as a modular, removable manifold design. This chamber is held under vacuum conditions for reliable material etching. Tests have proven its reliability and repeatability. The pressure chamber houses the process gases. This is where the bulk of the etching occurs, and is kept precisely at a requested pressure. The chamber also comes equipped with a safety pressure interlock unit, remote pressure monitoring, and pressure regulation. AMAT DPS G5 is designed to be user-friendly and was built for repeatability of results. It is equipped with two 50 MHz RF generators to ionize the process gas to etch the material. The machine also features a high voltage DC bias technol- ogy, as well as a plasma oxidation tool to ensure that the etch rates are consistent. The range of materials that the asset can etch is quite extensive, including Silicon, Silicon Nitride, and other semiconductors. The model is capable of producing a controlled etch profile, even on softer materials like Gold. The plasma etching and ashing processes are both quite fast and can be completed in a relatively short amount of time. The built-in temperature control and safety feature, as well as the adjustable parameters and process time, make the equipment easily adjustable to a variety of projects and applications. Overall, APPLIED MATERIALS DPS G5 is an excellent etcher and asher to tackle many different projects. With its reliable components, easy user-interface, and adjustable features, it ensures that projects are performed with accuracy and precision. The system has proven its worth in many industries, and its vast range of materials and capabilities make it an unbeatable option.

There are no reviews yet