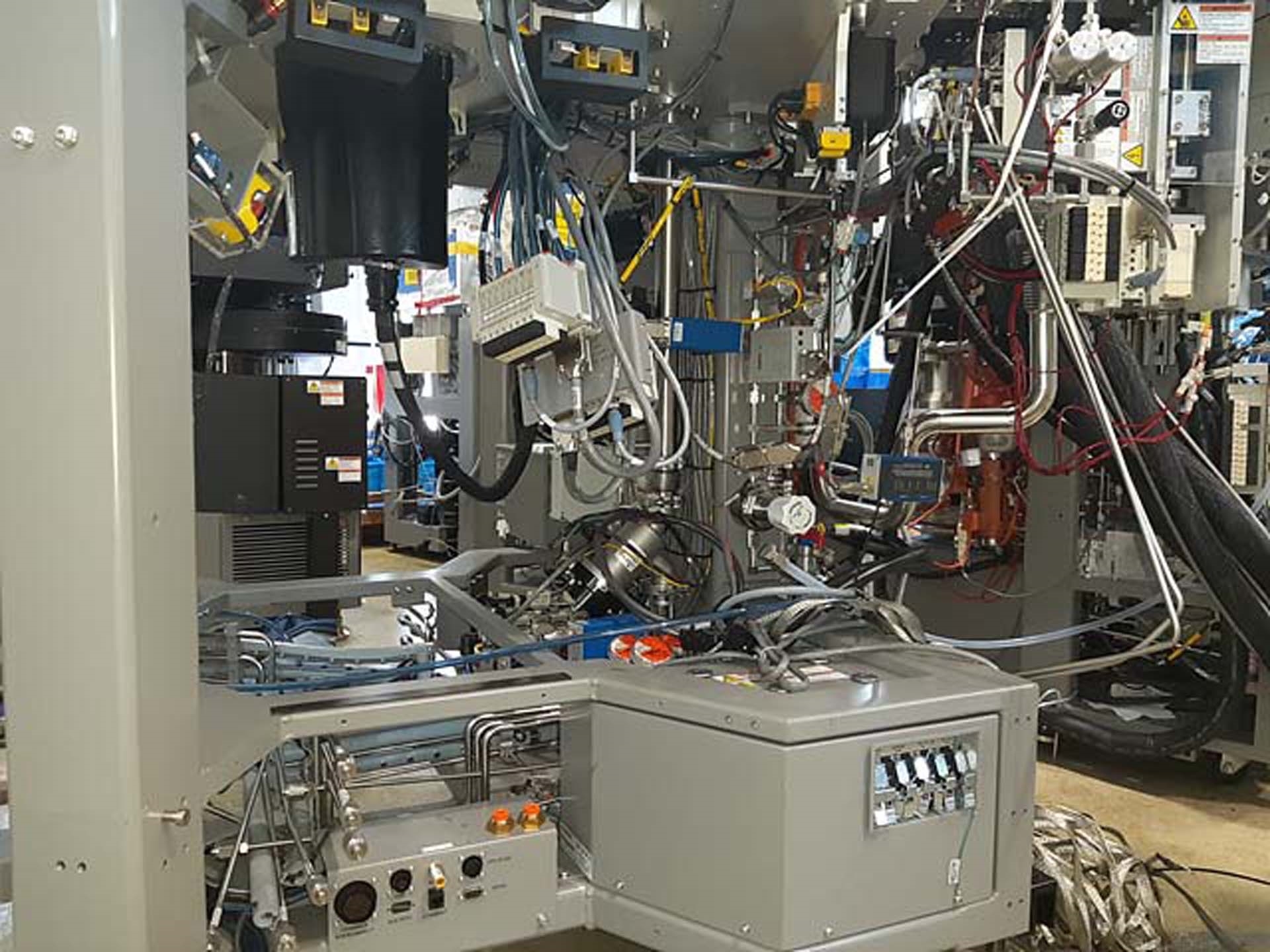

Used AMAT / APPLIED MATERIALS DPS II #9255366 for sale

URL successfully copied!

Tap to zoom

ID: 9255366

Wafer Size: 12"

Poly etcher, 12"

ADVANCED ENERGY Navigator 3013 Source matcher, 3155132-004

ADVANCED ENERGY Navigator 1513 Bias matcher, 3155126-020

ADVANCED ENERGY APEX 3013 Source generator, 3156113-006

ADVANCED ENERGY APEX 1513 Bias generator, 3156110-005

ALCATEL / ADIXEN / PFEIFFER A100L Load lock pump

PC: Pentium 4

Chamber A, B and C:

ESC, 0041-26723

Ceramic lid, 0200-06404

Hub, 0200-04969

Gas nozzle, 0050-88146

Quartz single ring, 0200-04619

Insulator, Quartz, 0200-36034

Lower chamber liner, 0040-43977

Upper chamber liner, 0040-81156

Cathode liner, 0021-26273

Plasma screen, 0021-26274

Lift pin, 0200-04593

Plasma screen screw cover, 0200-00933

SLD Door, 0020-89739

TGV, 0190-29611

High voltage module, 0190-23905

Lid heater, 0090-04235

FE-ICP, 0010-37963

Source outer coil capacitor, 0630-00665

TGN Gas line, 0050-88146

Gas nozzle lower clamp, 0041-10491

Gas nozzle upper clamp, 0041-10490

PCB Water leak detector, 0190-02076

Interlock module, 0190-17964

CPCI 3U Quad serial communication, 0190-23509

CPCI48 Digital 48 I/O, 0190-07450

CPCI 32/16 Analog 32/16 I/O, 0190-22967

Dnet BUS scanner, SST CPCI, 0190-16926

SBC C400MHZ 3U 4HP 64M RAM Vx works, 0190-24007

One slot 3U Power supply, 0190-07502

Helium controller (IHC) assy, 0010-07061

Heater controller, 0190-26495

EyeD SRM, 0190-28658

EyD Fiber optic cable, 0190-19764

EPD Window point, 0200-02160

Manometer window port, 0200-39135

Chamber D:

Throttle valve, 3870-03335

SLD Door, 0040-47461

Temperature controller, 0010-19317

Interlock module axiom, 12", 0190-15733

DIP Board, 0190-07450

AIO Board, 0190-22967

D-Net scanner board, 0190-16926

SBC Board, 0190-24007

Power supply board, 0190-07502

Serial communication board, 0190-23509

Pedestal, 0010-34860

Lift pin, 0021-43884

Top cap, GDP, Axiom HT, 0200-02980

Liner, side GDP, Axiom HT, 0200-02981

Lower GDP, HT2, Axiom, 0200-02272

Insert quartz glass, 3350-00048

Single ring, 0020-47977

Gas configuration:

Chamber A:

Gas / Name / Size

Gas01 / BCL3 / 200

Gas02 / HBR / 500

Gas03 / CHF3 / 200

Gas04 / CL2 / 200

Gas05 / NF3 / 70

Gas06 / O2 / 200

Gas07 / O2_S / 20

Gas08 / SF6 / 50

Gas09 / CF4 / 300

Gas10 / N2 / 200

Gas11 / HE / 500

Gas12 / AR / 500

Chamber B:

Gas / Name / Size

Gas01 / BCL3 / 200

Gas02 / HBR / 500

Gas03 / CHF3 / 200

Gas04 / CL2 / 200

Gas05 / NF3 / 100

Gas06 / O2 / 200

Gas07 / O2_S / 20

Gas08 / SF6 / 50

Gas09 / CF4 / 300

Gas10 / N2 / 200

Gas11 / HE / 500

Gas12 / AR / 500

Chamber C:

Gas / Name / Size

Gas01 / BCL3 / 200

Gas02 / HBR / 500

Gas03 / CHF3 / 200

Gas04 / CL2 / 200

Gas05 / NF3 / 100

Gas06 / O2 / 1000

Gas07 / O2_S / 20

Gas08 / SF6 / 100

Gas09 / CF4 / 300

Gas10 / N2 / 200

Gas11 / HE / 500

Gas12 / AR / 500.

AMAT / APPLIED MATERIALS DPS II is an advanced etch/ash equipment designed to produce superior surface results in microelectronic applications. The system is composed of a multi-chamber ultra-high vacuum processing chamber, a unique ablation technology, and sophisticated sensor package. AMAT DPS II is ideal for tight process control in wet and dry etching, ashing and deposition processes. APPLIED MATERIALS DPS II was specifically designed for etching, ashing and deposition of dielectrics and semiconductor materials. Its ultra-high vacuum chamber is capable of achieving a pressure of less than 10-8 Torr and carbon-laced wall liners which minimize outgassing. An advanced ablation technology further improves unit performance, allowing for precise control of process parameters and reliable process repeatability. DPS II's advanced sensor package ensures precise control of the process parameters. It consists of two independent controllers and four pyrometers for temperature, pressure, and RF power monitoring. Additionally, three thermocouples and four digitally-controlled mass flow controllers ensure repeatable, stable process control. Furthermore, the machine features an edge machine that provides superior wafer orientation detection, precision wafer manipulation, and wafer-directional cooling. The unique sensor package of AMAT / APPLIED MATERIALS DPS II provides a variety of benefits including superior temperature uniformity and stability of the chamber, increased throughput, and enhanced surface quality. Additionally, the advanced ablation technology allows for precise, repeatable etching, ashing and deposition process control. Furthermore, its multi-chamber design allows for the integration of multiple etch/ash processes in a single tool, saving time and money. Overall, AMAT DPS II is an advanced etch/ash asset designed to provide superior surface results in microelectronics applications. Its ultra-high vacuum chamber, unique ablation technology, and advanced sensor package ensure precise, repeatable process control. Additionally, its multi-chamber model design allows for the integration of multiple etch/ash processes in a single equipment, increasing throughput while minimizing costs.

There are no reviews yet