Used AMAT / APPLIED MATERIALS eMax CT+ #9375192 for sale

URL successfully copied!

Tap to zoom

ID: 9375192

Oxide etcher

(3) Chambers

(12) Gas panels

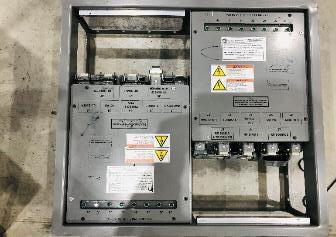

AMAT ETCH Configurable AC Rack

RF Generator rack

FI (EFEM):

UPS

Keyboard Video Mouse (KVM)

Ethernet switch hub: CTRLINK

Fast Data Gateways (FTG)

Long flex controller Assy (Flex 4)

Light curtain

Load port

RFID

ATM Robot

Aligner

Track

Robot controller

Gas panel temperature controller

Light tower

Intake plenum enclosure

MF Platform:

Type: 5.3 FI

TM Robot

TM Robot controller

I-Pump

TM Baratron gauge

Load lock vacuum gauge

Load lock indexer controller

Load lock and TM Diffuser

Load lock vent valve

Auto Pressure Controller (APC)

Slit valve

Modular DNET IO Controllers (MDI)

Chamber A, B and C:

Chamber Control Modules (CCM)

Shower head

Chamber liner

Cathode liner

Slit liner door

MAG Driver

ESC High Voltage Module (HVM)

Throttling gate valve

Embedded endpoint

Ceramic puck

HE Controller

Vacuum gauge

Vacuum switch

Pump

ISO Valve

RF Generator and match box.

AMAT / APPLIED MATERIALS eMax CT+ is an advanced etching/asperging platform designed to provide superior performance for the fabrication of integrated circuitry. It is optimized for 3D/2D etching, featuring high-density, ultra-fine patterning capabilities through a combination of ion beam, inductively-coupled plasma, and magnetically-driven processes. AMAT EMAX_CT+ provides industry-leading etching capability through a combination of high pressure magneto hydrodynamic (MHDF) and low pressure Inductively Coupled Plasma (ICP) technologies. It is capable of creating complex 3D geometries, making it ideal for micro-fabrication of advanced devices, including semiconductor, optoelectronic and MEMS components. APPLIED MATERIALS E-MAX CT+ is highly customizable and can be configured with various plasma and ion beam techniques for the most demanding applications. It is easy to use and ensures a fast and reliable substrate etching process while offering superior spatial resolution, critical for the latest miniaturized device technology. The process chamber of APPLIED MATERIALS EMAX_CT+ has several features which maximize the pressure and temperature uniformity of the substrate during the etching process, ensuring the best possible substrate uniformity and plasma stability. The chamber is also low maintenance, 100% leak-free, and requires a minimal amount of operator involvement. The etching process takes place in a closed environment and specific features like Peltier pump, dual-density wafer handling, and advanced temperature monitoring tools help reduce particulate matter contamination. These features make AMAT eMax CT+ an excellent platform for cost-effectively manufacturing integrated circuitry. E-MAX CT+ utilizes renewable and inert gases to reduce environmental impact and limit hazardous material handling. It features gas delivery systems that ensure precise and efficient delivery of process gases, providing a flexible and reliable etching platform for today's modern manufacturing requirements. AMAT / APPLIED MATERIALS EMAX_CT+ is a reliable and easy-to-use etching/asperging platform, designed to provide accuracy and consistency for circuit fabrication needs. Its superior uniformity and high-density patterning capability make it an excellent choice for high-precision, 3D/2D fabrication.

There are no reviews yet