Used AMAT / APPLIED MATERIALS eMax CT+ #9390469 for sale

URL successfully copied!

Tap to zoom

ID: 9390469

Wafer Size: 12"

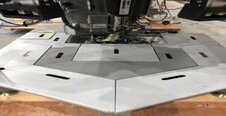

Oxide etcher, 12"

(3) Chambers (A, B, C)

MF Platform type: AP

FI (EFEM):

SUPERMICRO GEN3 0090-06587 Servers

EATON Powerware 5115 UPS

MKS MACRONODE 0190-22543 (FI Ethernet digital I/O)

AMAT / APPLIED MATERIALS 0190-05111 Keyboard Video Mouse (KVM)

D-LINK 0190-39904 Ethernet switch hub

AMAT / APPLIED MATERIALS 0190-22545 Sealevel

AMAT / APPLIED MATERIALS 0010-25273 Fast Data Gateways (FTG)

AMAT / APPLIED MATERIALS 0010-25274 Fast Data Gateways (FTG)

AMAT / APPLIED MATERIALS 0090-06516 Short flex controller assy

SST DNET Scanner B/D Short flex controller assy

MEI XMP B/D

SBS Serial B/D

GE SBC B/D

(2) TAKEX SS20-TR40 Light curtains

(3) TDK TAS300 Load ports

(3) HERMOS TLG-RS232 RFIDs

YASKAWA XU-RCM6841 ATM Robot

YASKAWA XU-ACP4860 Aligner

YASKAWA XU-ACL4230 Track

YASKAWA XU-CN1170A Robot controller

WATLOW 96 Gas panel temperature controller

AMAT / APPLIED MATERIALS Light tower

AMAT / APPLIED MATERIALS 0040-81205 Intake plenum enclosure

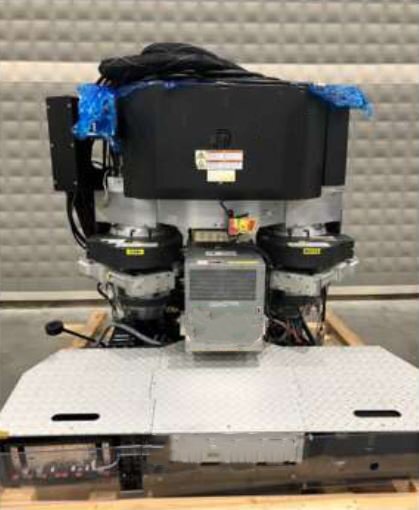

MF Platform:

Type: 5.3 FI

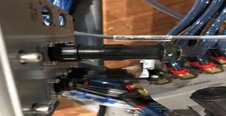

NSK VHP TM Robot

NSK ELA-B014CFL-03 TM Robot controller

ALCATEL A100L I-Pump

MKS 124AA-00010BB TM Baratron gauge

GRANVILLE-PHILLIPS 275 Mini-Convectron TM Vacuum gauge

(2) GRANVILLE-PHILLIPS 275 Mini-Convectron Load lock vacuum gauges

(2) PANASONIC MQDB011AAD03 Load lock indexer controllers

(2) Load lock diffusers

TM Diffuser

(2) Load lock vent valves

MKS 640 Auto Pressure Controller (APC)

Slit valve

Modular DNET IO Controllers (MDI)

Chamber A, B and C:

(3) TENTA Water leak detector B/D Chamber Control Modules (CCM)

(3) AMAT Interlock B/D Chamber Control Modules (CCM)

(6) MKS Quad serial B/D Chamber Control Modules (CCM)

(6) TENTA Digital I/O B/D Chamber Control Modules (CCM)

(3) MKS Analog I/O B/D Chamber Control Modules (CCM)

(3) SBS IP Carrier B/D Chamber Control Modules (CCM)

(3) SST Devicenet scanner B/D Chamber Control Modules (CCM)

(3) TENTA SBC B/D Chamber Control Modules (CCM)

(3) TENTA Power supply B/D Chamber Control Modules (CCM)

(3) Shower heads

(3) Chamber liners

(3) Cathode liners

(3) Slit liner doors

(3) MAG Drivers

(3) ESC High Voltage Modules (HVM)

(3) Throttling gate valves

(3) Embedded endpoints

(3) Ceramic pucks

(6) HE Controllers

(3) Vacuum gauges

(3) Vacuum switches

(3) Pumps

(3) ISO Valves

(3) RF Generators and match box.

AMAT / APPLIED MATERIALS eMax CT+ is a powerful and modern etcher / asher for various materials in semiconductor device fabrication. It is designed to provide cost-effective, versatile, and reliable processing for wafer etching and wafer ashing processes. The equipment consists of a control unit containing all the necessary components to manage processing recipes, scanning, and wafer handling, and a process chamber with an enclosed vacuum environment. The system also features a high-performance robotic arm to transfer the wafers in and out of the high-purity, ultra-cryo environment. AMAT EMAX_CT+ is employed in numerous process steps in the manufacturing of semiconductor devices and is capable of handling various chamber configurations for etching and ashing. The unit can reach high etch rates and has superior uniformity. Additionally, the machine has a process chamber with adjustable pressure for etching, and a quartz process tube with purge gas for ashing. It is also equipped with a temperature controller, allowing for precise and uniform temperature control during processing. APPLIED MATERIALS E-MAX CT+ tool is capable of handling single wafer etching and ashing processes, allowing it to simultaneously etch and ashing multiple wafers with minimal maintenance. Moreover, the asset uses an oxygen dielectric etching process to reduce the number of particles generated by the process and minimize surface damage. In addition, it is equipped with high-level safety features for protecting the process environment and operators from potentially hazardous chemicals or particles. AMAT eMax CT+ also offers a comprehensive software package for controlling, managing, and monitoring the model's operations. It features an intuitive and easy-to-use touch screen interface, as well as an integrated recipe editor for fast recipe creation. The software package also includes advanced diagnostics, empowering users to troubleshoot issues quickly. In conclusion, EMAX_CT+ is a highly reliable and efficient etcher / asher equipment for the fabrication of semiconductor devices. It is capable of handling multiple etch and ashing processes in a single run, with superior throughput and uniformity. The integrated software package offers easy recipe management and advanced diagnostics, allowing quick troubleshooting.

There are no reviews yet