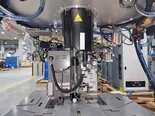

Used AMAT / APPLIED MATERIALS eMax CT+ #9408194 for sale

URL successfully copied!

Tap to zoom

ID: 9408194

Wafer Size: 12"

Oxide etcher, 12"

TM Module

(3) PM Modules

AC Rack

RF Rack

FI (EFEM):

FI Type: 5.3 FI

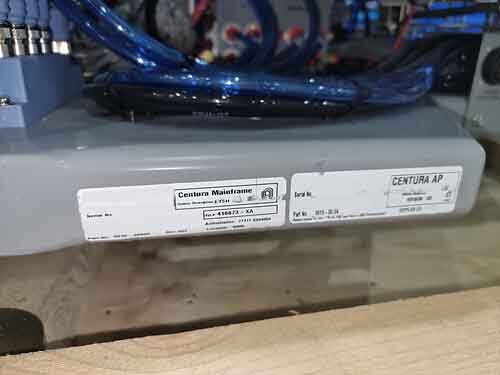

MF Platform type: AP

SUPERMICRO GEN3 0090-06587 Server

SUPERMICRO GEN3 0090-06584 Server

EATON Powerware 5115 UPS, P/N: 0190-26019

MKS MACRONODE 0190-22543 FI Ethernet digital I/O

Keyboard video mouse, P/N: 0190-05111

D-LINK 0190-39904 Ethernet switch hub (24-Ports)

Sealevel, P/N: 0190-22545

Fast Data Gateways (FTG), P/N: 0010-25273

Fast Data Gateways (FTG), P/N: 0010-25274

Short flex controller assy, P/N: 0090-06516

Scanner board short flex controller assy:

SST DNET Scanner board, P/N: 0190-34513

MEI XMP Board, P/N: 0190-24445

SBS Serial board, P/N: 0190-11817

GE SBC Board, P/N: 0090-06299

(2) TAKEX SS20-TR40 Light curtains

(3) TDK TAS300 Load ports

(3) OMRON V640-HAM11-V2-1 RFID

YASKAWA XU-RCM6801 ATM Robot

YASKAWA XU-ACP4860 Aligner, P/N: 0190-14752

YASKAWA XU-ACL4230 Track, P/N: 0190-14739

YASKAWA XU-CN1170A Robot controller, P/N: 0190-23873

YAMATAKE 0190-24680 Gas panel temperature controller

Intake plenum enclosure

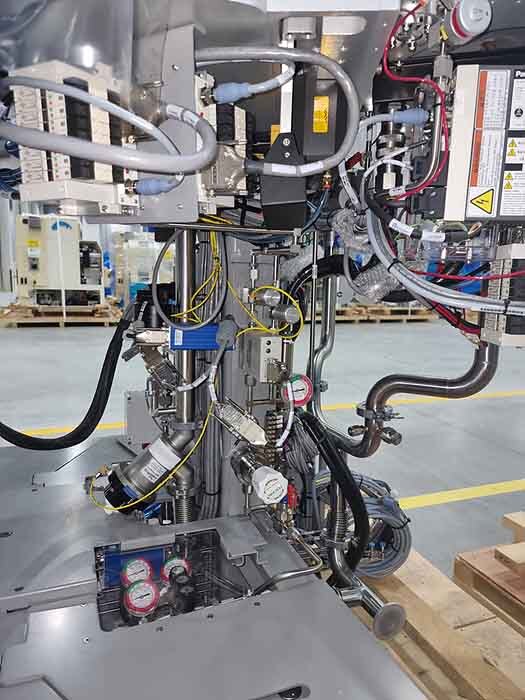

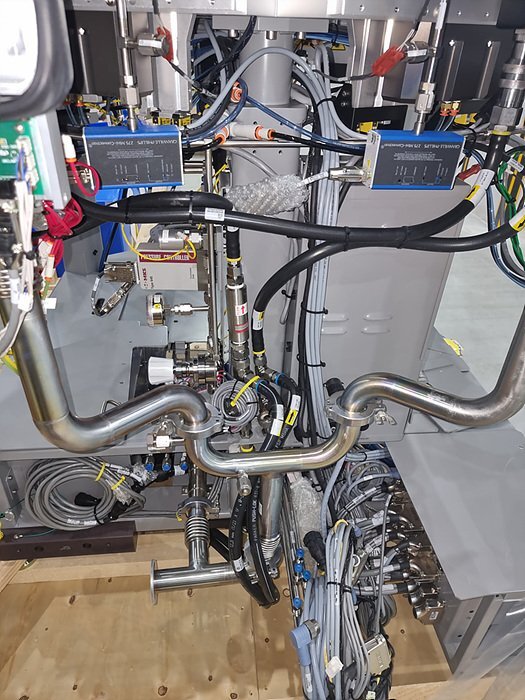

MF Platform:

NSK VHP TM Robot

NSK ELA-B014CG1-04 TM Robot controller

(2) Cermic dual blades: Low shoe type

ALCATEL A100L Single I-pump

MKS 124AA-00010BB TM Baratron gauge: 10TORR

GRANVILLE-PHILLIPS 275 Mini-convectron TM vacuum gauge: 10TORR

(2) GRANVILLE-PHILLIPS 275 Mini-convectron load lock vacuum gauges: 10TORR

(2) PANASONIC MQDB011AAD03 Load lock indexer controllers, P/N: 0190-19214

(2) Load lock diffusers

STM Diffuser

(2) Load lock vent valves

MKS 640 Auto Pressure Controller (APC): 10TORR

VAT 0190-03234 Slit valve

GME Chamber port assy

Lid, P/N: 0242-23452

Modular DNET IO controller (MDI):

Modular, P/N: 0190-01898

MF Interlock relay, P/N: 0190-02362

MF Interlock relay, P/N: 0190-02363

Loadlock interface, P/N: 0090-01809

Mainframe interface, P/N: 0090-01810

CDN494 IO, P/N: 0190-04745

Analog power, P/N: 0190-01971

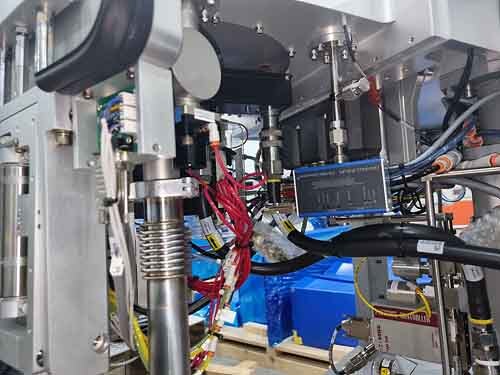

Process chamber: A, B and C:

Chamber Control Modules (CCM):

TENTA 0190-02076 Water leak detector board

Interlock board, P/N: 0190-07052

(2) MKS 0190-23509 Quad serial boards

(2) TENTA 0190-07450 Digital I/O boards

MKS 0190-22967 Analog I/O board

SBS 0190-22255 IP Carrier board

SST 0190-16926 Devicenet scanner board

TENTA 0190-24007 SBC Board, 400 Mhz

TENTA 0190-07502 Power supply board

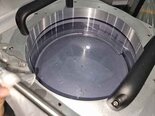

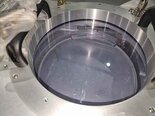

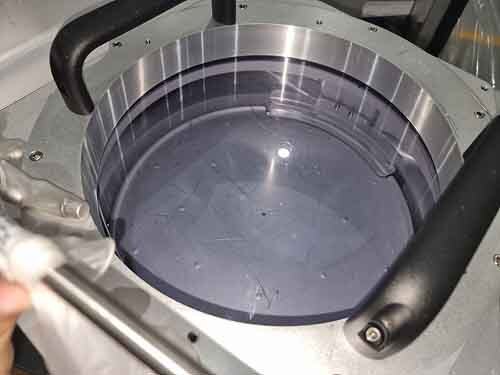

Shower head, 16"

Chamber liner

Cathode liner

Slit liner door

KOLLMORGEN MAG Driver, P/N: 0190-17272

ESC High Voltage Module (HVM), P/N: 0010-16690

NORCAL TPV200 Throttling gate valve, P/N: 0190-25400

NORCAL TPV200 Throttling gate valve, P/N: 0190-25401

Embedded endpoint, P/N: 0010-10663

Ceramic puck, P/N: 0040-63474

MKS DPC HE Controller, P/N: 0010-29436

Vacuum gauges:

MKS Dual range process manometer, P/N: 1350-00201

GRANVILLE-PHILLIPS 275 Mini-convectron foreline vacuum gauge, P/N: 3310-01200

Vacuum switches:

MKS 41A-21439 ATM Switch, P/N: 0190-01901

MKS 51A-21440 ATM Switch, P/N: 0190-01902

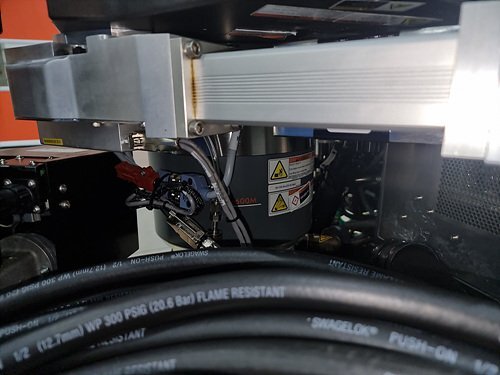

ALCATEL ATH1600M Master turbo pump

ALCATEL ATH1600M Slave turbo pump

ALCATEL ACT1300M Master turbo pump controller

ALCATEL ACT1300M Slave turbo pump controller

NORCAL 3870-01455 ISO Valve

NORCAL ESVP-1503T-NWB-CR ISO Valve, P/N: 3870-03304

ADVANCED ENERGY Ovation 2760 Source RF generator, 0190-17779

DAIHEN RMN-50N1 RF Bias match box, P/N: 0190-15322

DAIHEN AMN-30H RF Source match box, P/N: 0190-15323

Gas panel for chamber A, B and C:

Mass Flow Controllers (MFC):

Size / Make / Model

200 SCCM / CELERITY / AASGD40W1

200 SCCM / SAM / 2480G1

100 SCCM / CELERITY / AASGD40W1

300 SCCM / BROOKS AUTOMATION / GF-125C

20 SCCM / CELERITY / AASGD40W1

20 SCCM / CELERITY / AASGD40W1

20 SCCM / CELERITY / AASGD40W1

100 SCCM / CELERITY / AASGD40W1

1000 SCCM / BROOKS AUTOMATION / GF-125C

200 SCCM / CELERITY / AASGD40W1

1000 SCCM / BROOKS AUTOMATION / GF-125C

200 SCCM / CELERITY / AASGD40W1

Mass Flow Controller (MFC) for chamber A and C:

Size / Make / Model

200 SCCM / CELERITY / AASGD40W1

MKS FRCA-29015 Flow Ratio Controller (FRC):

Size: 1000 SCCM

Type: NEXTGEN 14-Sticks

Weldment type: Single line drop

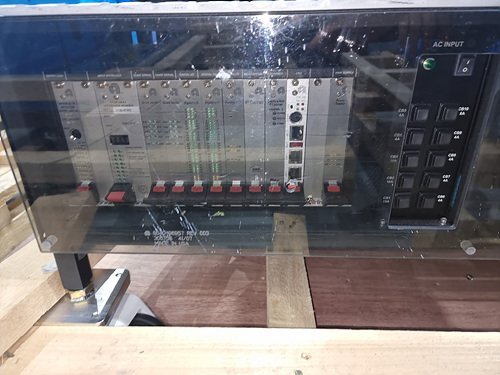

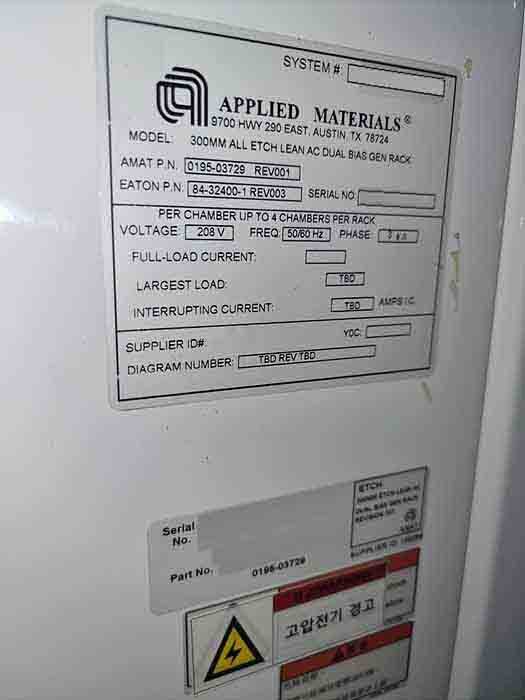

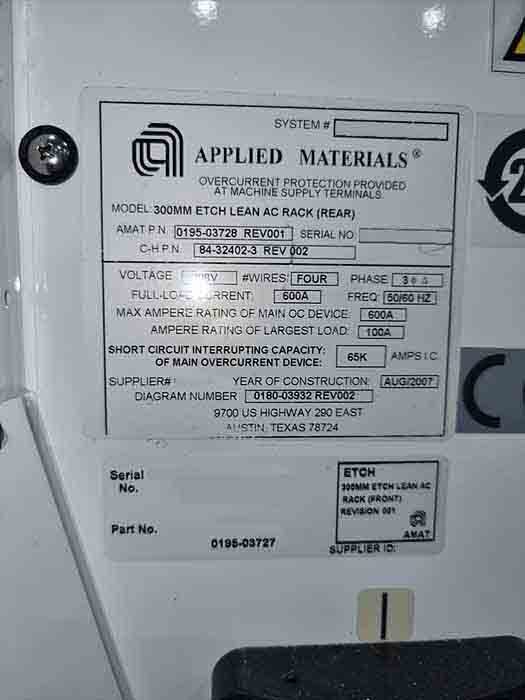

Etch lean AC power rack, 12"

Power: 600A

Front: 0195-03727

Rear: 0195-03728

(3) ENI GHW-50 RF Bias generators

P/N: 0190-15319

Frequency: 13.56 MHz

(3) MKS B-5002 RF Bias generators

P/N: 0190-15320

Frequency: 2 MHz

Spare parts:

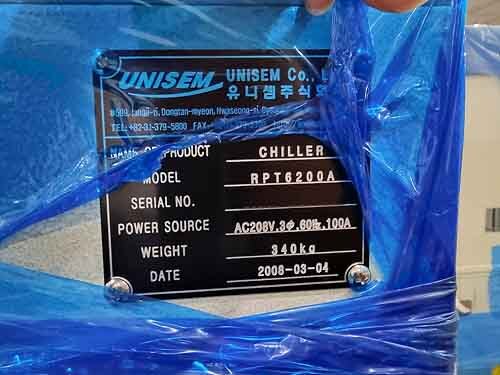

(3) UNISEM RPT6200A Chillers

(3) 13.56 Mhz RF Coaxial cables (79FT), P/N: 0620-02935

(3) 2 Mhz RF Coaxial cables (79FT), P/N: 0620-03165

CHX 485 Communication cable

(3) MAG Driver contactor cables, P/N: 0150-11950

EMO Interconnect 50FT cable, P/N: 0150-02438

(3) RGJP, P/N: 0150-15149

(3) Pump umbilicals, 75FT cable, P/N: 0150-35744

(3) Chamber cooling manifolds, P/N: 0190-22819

(3) E-FIB Insert, P/N: 0190-23662

Monitor rack

Gas panel SLD

Bottom cover

Gas panel exhaust duct

FI Intake plenum

Enclosure

IPUP

Mobile worksation

(3) SUS Pads.

AMAT/APPPLIED MATERIALS AMAT / APPLIED MATERIALS eMax CT+ is a high-performance plasma etcher/asher equipment designed to handle a variety of applications. The system offers multiple process modules to meet the demands of each application. AMAT EMAX_CT+ operates with a patented high density DC (direct current) plasma source to ensure low etch rates and consistent process results. The unit also features a multi-stage RF (radio frequency) bias power supply for increased selectivity and process control. APPLIED MATERIALS E-MAX CT+ also features dual-chamber process chambers to provide faster throughput and improved process yields. The high density DC plasma source of eMax CT+ can generate plasma sources from 10 - 400 watts, while the RF bias power supply has a maximum output power of up to 25 kilowatts. The source can also be configured to meet a variety of needs, with a variety of gas mixes including Bas, BrF2, F2 and more. The process chamber of AMAT / APPLIED MATERIALS EMAX_CT+ is equipped with a variable-area metal perforated gas showerhead to ensure precise gas distribution, along with an automated proportional valve for precise control of the gas flow rate. AMAT eMax CT+ utilizes advanced process control technology, featuring pulse control, pulse height analysis and advanced control algorithms. These features allow precise control of etch process parameters such as bias power, pressure, DC and RF power as well as EMAX_CT+ process chamber pressure. The machine can also be used for wafer uniformity measurements, as it is equipped with an Absolute Standard Pressure Chamber for calibration purposes. APPLIED MATERIALS eMax CT+ features an advanced user interface that provides a comprehensive and intuitive set of integrated controls to ensure maximum tool performance. In addition, an embedded Web server allows easy access and control of E-MAX CT+ over network connections. The asset also feaures an automatic self-diagnosis feature that can help reduce downtime when errors occur. Overall, AMAT / APPLIED MATERIALS E-MAX CT+ is a reliable plasma etcher/aser model designed to provide precise control and high throughput. The equipment alsofeautures high density DC and RF power sources, dual-chamber process chambers and an advanced user interface. With its advanced control algorithms and comprehensive set of controls, AMAT E-MAX CT+ is an ideal and cost-effective solution for etching and ashing applications.

There are no reviews yet