Used AMAT / APPLIED MATERIALS WC MCA #179308 for sale

URL successfully copied!

Tap to zoom

ID: 179308

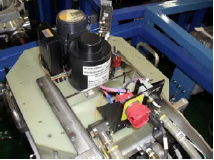

Chamber

Watercooled Chamber body

Adapter: 0040-02428

G12 Source Assy

AC Box: 0010-22242

2 Position Gate Valve

2 Phase Cryo Pump

Motorized Lift: 0010-13235

Magnet: 0010-01198.

AMAT / APPLIED MATERIALS WC MCA is a combination etcher/asher designed specifically for wafer fabrication. It is designed to quickly etch and asher selected materials, removing specific areas and leaving the rest of the chip intact. Equipped with an integrated vacuum equipment, the MCA is capable of removing particles or unwanted residues during the etching process, further increasing the accuracy and speed of the process. Furthermore, the MCA is also equipped with a robust power management system to control and regulate etching times, minimizing energy consumption and maximizing throughput. The MCA has a variety of etching applications, from deep etches requiring dry etching solutions, to shallow etching solutions that cut specific material layers and shallow trenches. This allows for precise control of the process, providing end users with efficient and highly precise etching results. The MCA also has a temperature control function, allowing for precise temperature control over the etching solutions, eliminating the effects of liquid evaporation and supports consistent etch rates. Power rated at 200 - 300 Watts, this etching/acher unit has a footprint of 24 inches by 24 inches and a height of 32 inches. The MCA is designed to be easily integrated into automated wafer fabrication systems and can be used in serial or parallel process configuraitons. The MCA's small footprint makes it perfect for use in smaller fabrication facilities and its small form factor means it can be installed in tight spaces. The MCA also features two wafer cassettes, meaning it can etch up to 30 wafers per batch, allowing for high-volume production. The control machine for the MCA enables precise control of the etching process, preventing "etching overshoot" caused by inconsistent etching parameters. Furthermore, the tool offers advanced process monitoring and data collection capabilities, allowing users to store recipes for repeatable processes or store debug information for analysis when things go wrong. It's all about accuracy and throughput, and AMAT WC MCA delivers. With reliable and precise etching and ashing solutions, low energy consumption and high-volume throughput, the MCA is ideal for wafer fabrication facilities looking to improve production efficiency and overall cost-effectiveness.

There are no reviews yet