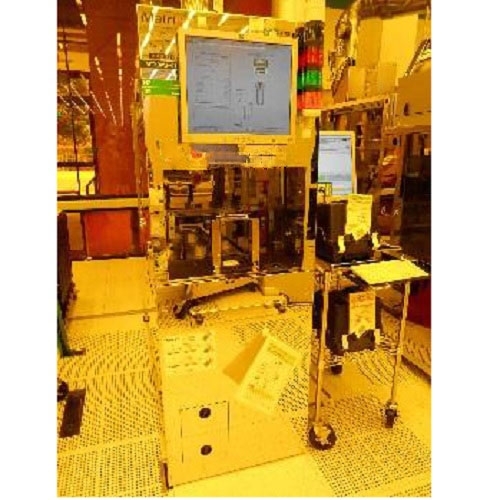

Used AXCELIS / FUSION / MATRIX Bobcat 209S #9201805 for sale

URL successfully copied!

Tap to zoom

ID: 9201805

Wafer Size: 8"

Vintage: 2001

Single chamber asher

2001 vintage

Power:

208VAC

3 Phase

50 / 60 HZ

Installed in wafer fab

Fully operational

Manuals (CD) available with tool

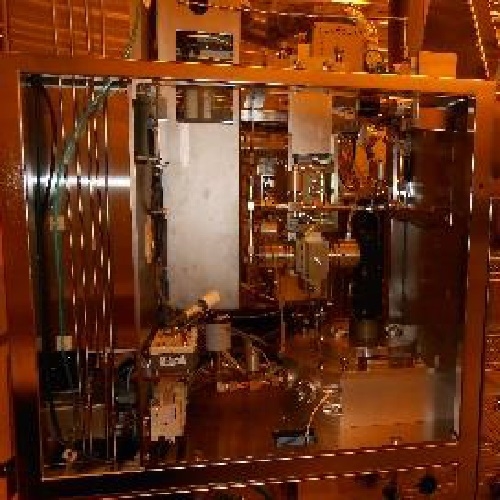

Asher component details

Mainframe:

Type Standalone

Model Matrix Bobcat 209S asher

Chamber:

How Many? 1

Type RIE

Process ASH

Load locks / Load plate:

Open cassette or SMI Open cassette

How Many? 1

Robot:

How Many? 1

Method of Transport Transfer Unit

Make / Models: Rorze, RR701

RF Generators:

How Many? 2

Make/Models: Comdel FR-111R2, Microwave generator 3kw

Gas box:

Gases used per chamber: 3

Identify gases: N2-1000, N2 -300, N2- 1000 (Gases run O2,N2, none)

MFC’s used (Make /Model): MKS

Control system:

PC or Control Rack? PC

Software ype and Version: Windows nt.

AXCELIS / FUSION / MATRIX Bobcat 209S is an etcher/asher designed for the production of integrated circuits such as microprocessors and DRAMs. FUSION Bobcat 209S is highly reliable, accurate, and efficient, offering excellent performance when etching or ashing applications. It has the ability to process substrates up to 8 inch in diameter, offering both single and double sided processes. The systems electrical components are designed to operate at a nominal voltage of 200V and can handle up to 600V, resulting in greater control over the etching and ashing processes. The system also features a patented swing door chamber, allowing for quick and easy substrate loading/unloading. The swing door also aides in maintaining a consistent temperature for the entire process, reducing exposure to substrate temperature variations. MATRIX Bobcat 209S also offers a unique integrated Computer Monitor VGA/Video Camera. This allows to the user to visually inspect each substrate to monitor process consistency. An Automatic Endpoint Detection system also monitors process conditions in order to ensure the etching and ashing process ends correctly. In addition, AXCELIS Bobcat 209S is RF-capable and features a temperature controlled platform for improved density, uniformity, and etch rate stability. It also features a mass flow controller that provides precise axial deposition control throughout the process. The system also supports multiple recipe programs allowing the user to program the etching and ashing recipe and store recipes for future reference. Bobcat 209S is designed for maximum capability and efficiency, allowing for accurate, high-quality etching and ashing processes within a short period of time. It is well-suited for manufacturers seeking increased performance and improved production speed. It is reliable and user-friendly for those seeking a reliable etcher/asher for their integrated circuit needs.

There are no reviews yet