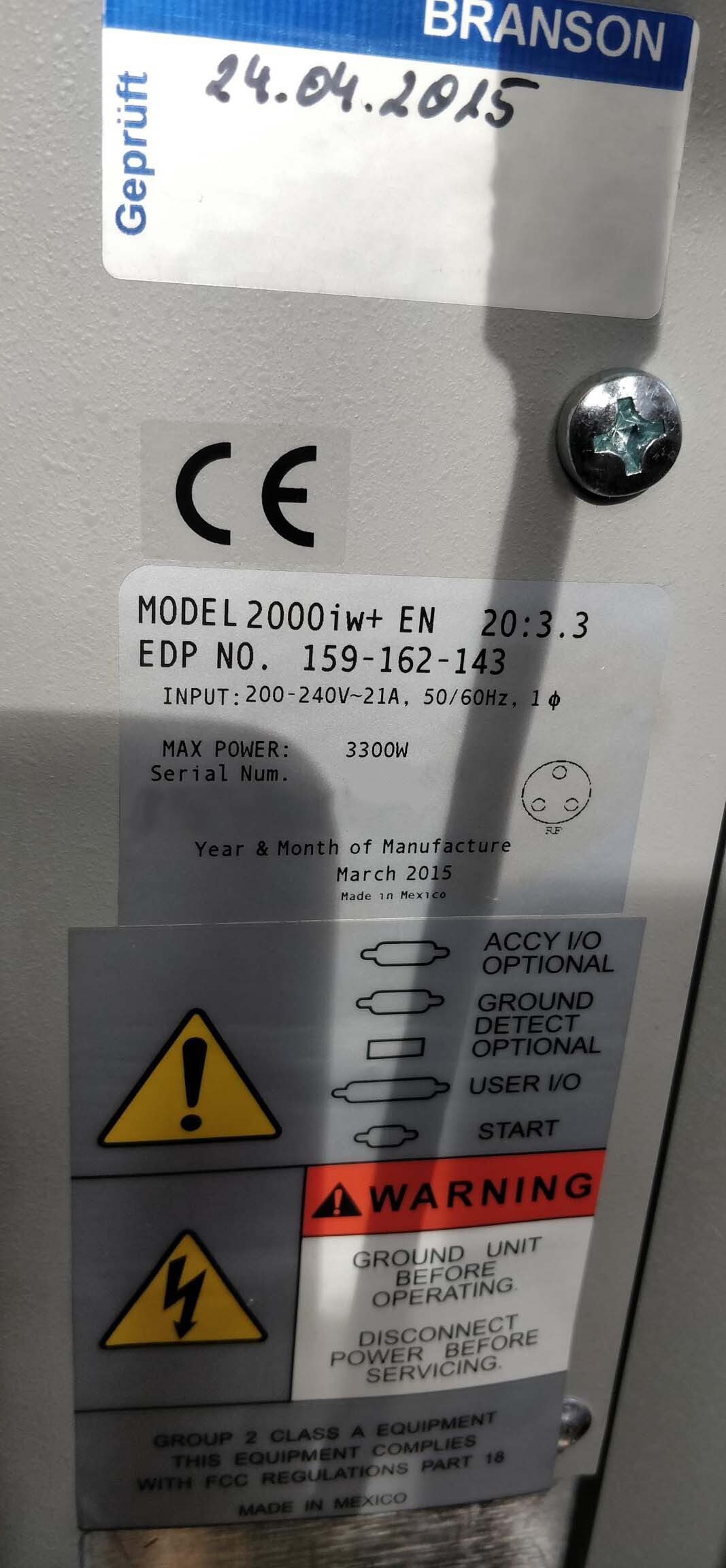

Used BRANSON / IPC 2000iw+ #9307711 for sale

URL successfully copied!

Tap to zoom

ID: 9307711

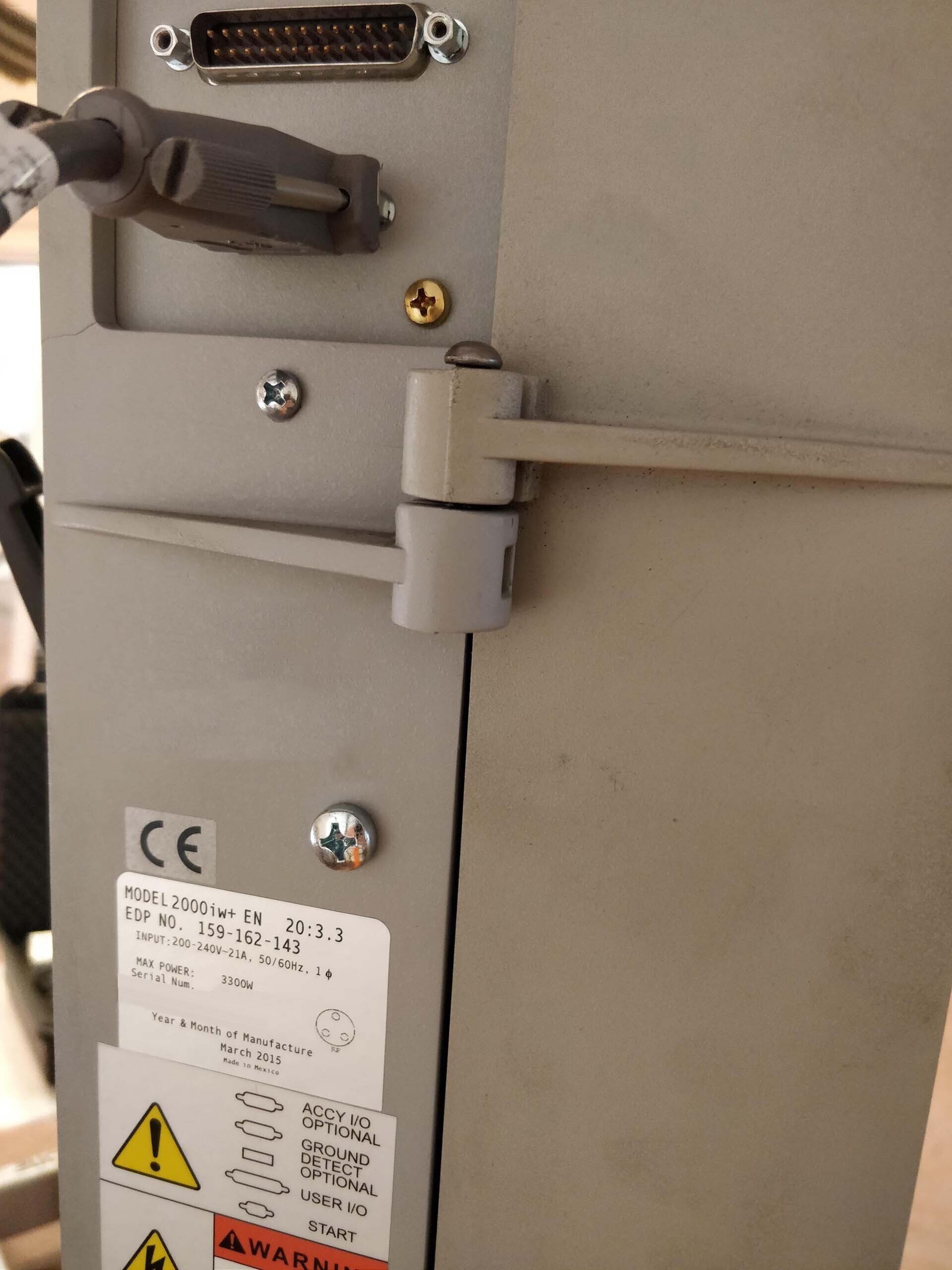

Vintage: 2015

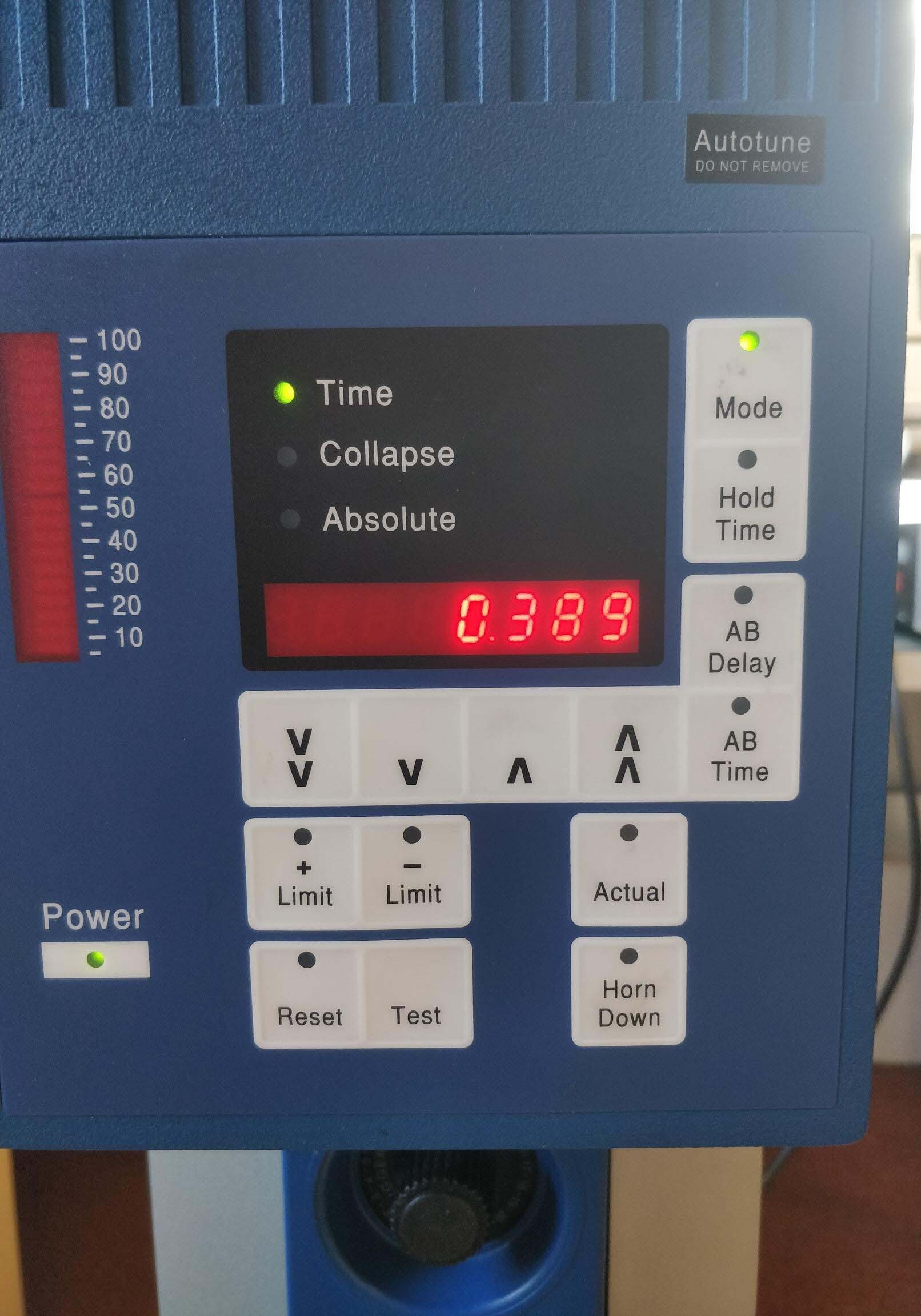

Ultrasonic welder

With CJ20 Converter

Booster

Frequency: 20 kHz

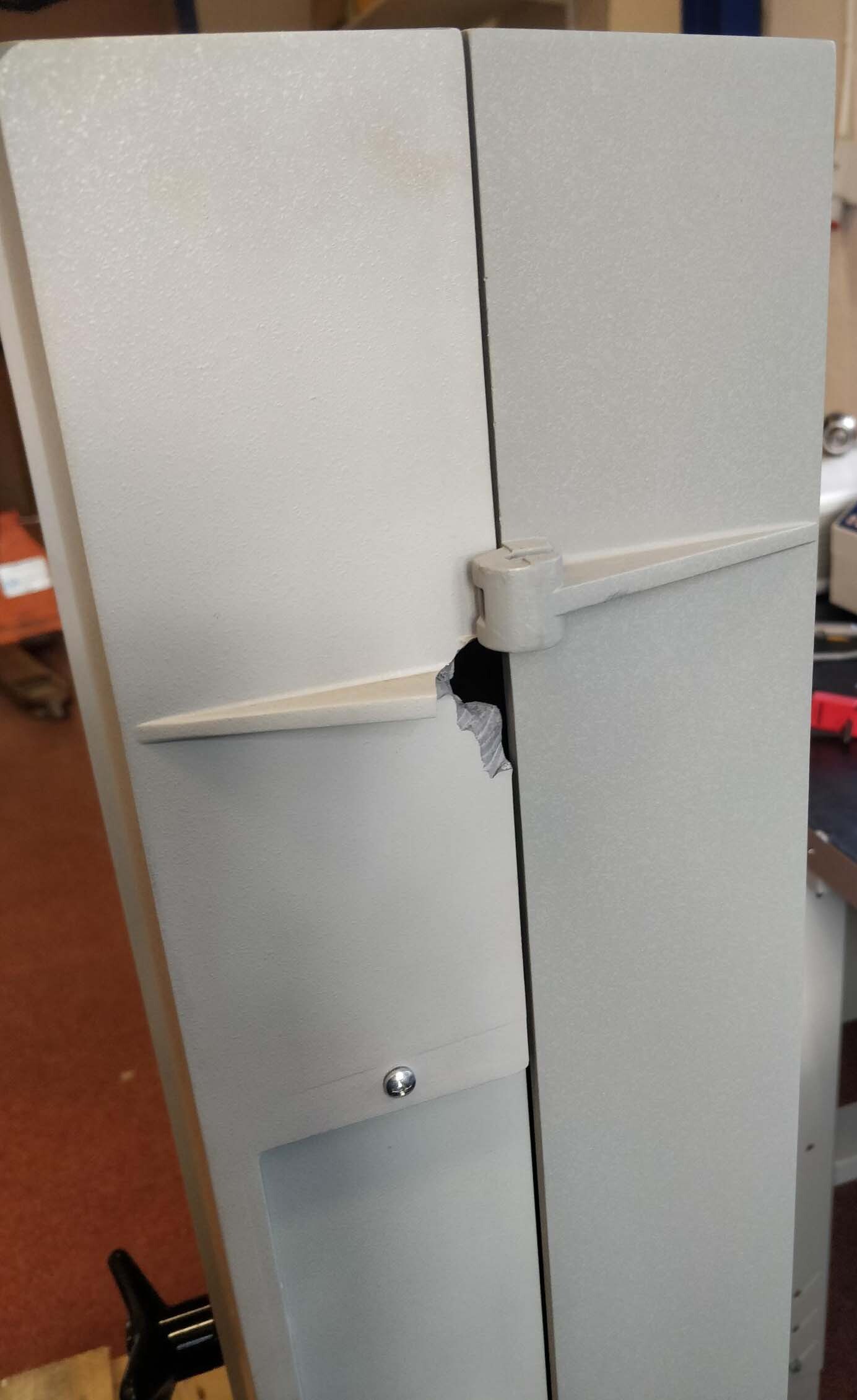

Cover damaged

Hinge missing

Power: 3300 Watt

2015 vintage.

BRANSON / IPC 2000iw+ is an automated, multi-application etcher / asher equipment designed to provide superior quality results for research and production applications. The machine is a five-step system utilizing a "cohesive" ensemble of processes for precision etching or ashing with high-throughput. The interchangeable process stages include etching/ashing/vapor deposition/ablating, deep etching/ differential etching, and other applications like surface analysis, testing, and critical dimension measurement. The advanced user interface offers a comprehensive unit for data input, collection, and storage in a variety of formats. Features of the machine include easy-to-use touchscreen technology, digital temperature and pressure sensors with up to 16 different channels, software-controlled quartz tools, and dual quartz casting chambers with max temperatures up to 3,572°F (1,980°C). The robust construction of IPC 2000iw+ ensures accurate, repeatable etching or ashing of intricate patterns and wiring layers on a variety of substrates, including wafers, plates, and bumps. The built-in fail-check feature preserves user data and product integrity during etching or ashing processes, while the tool's precise processes can be integrated to existing equipment or upgraded to accommodate specific needs. A remote ashing/etching chamber is available with BRANSON 2000iw+, allowing operators to remotely control the ashing or etching process from a connecting PC, laptop, or mobile device. In addition, integration of this asset into an existing process line is possible, allowing users to control, monitor, and optimize the model from a single point of control. The innovative design of 2000iw+ gives it flexibility for both laboratory and manufacturing applications. The equipment can be customized to meet specific requirements, including total process control, user access control, and the management of sequences and recipes. This flexibility is further enhanced by IPC exceptional customer support and training services.

There are no reviews yet