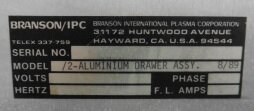

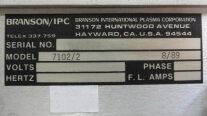

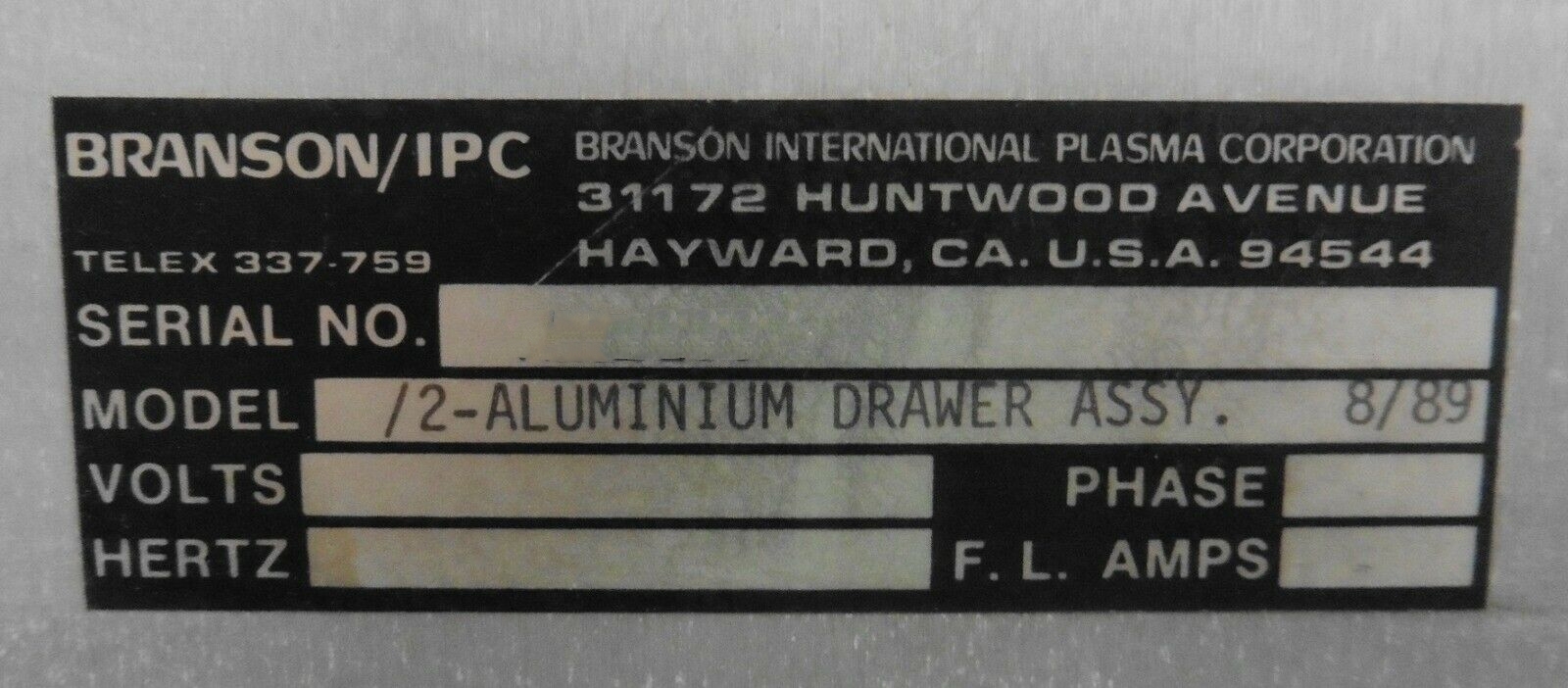

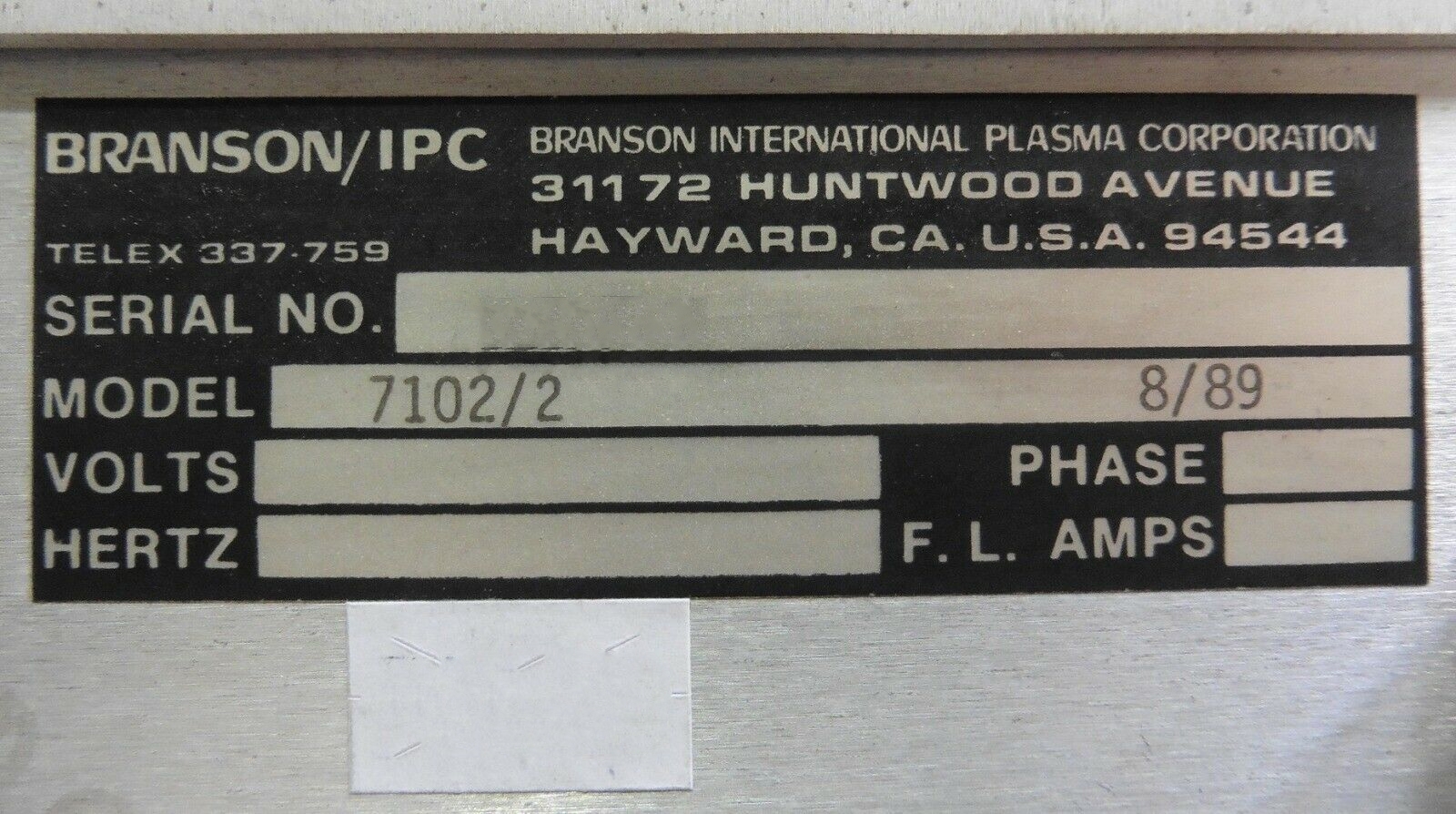

Used BRANSON / IPC 7102 #9291949 for sale

URL successfully copied!

Tap to zoom

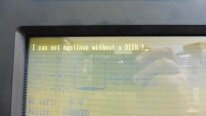

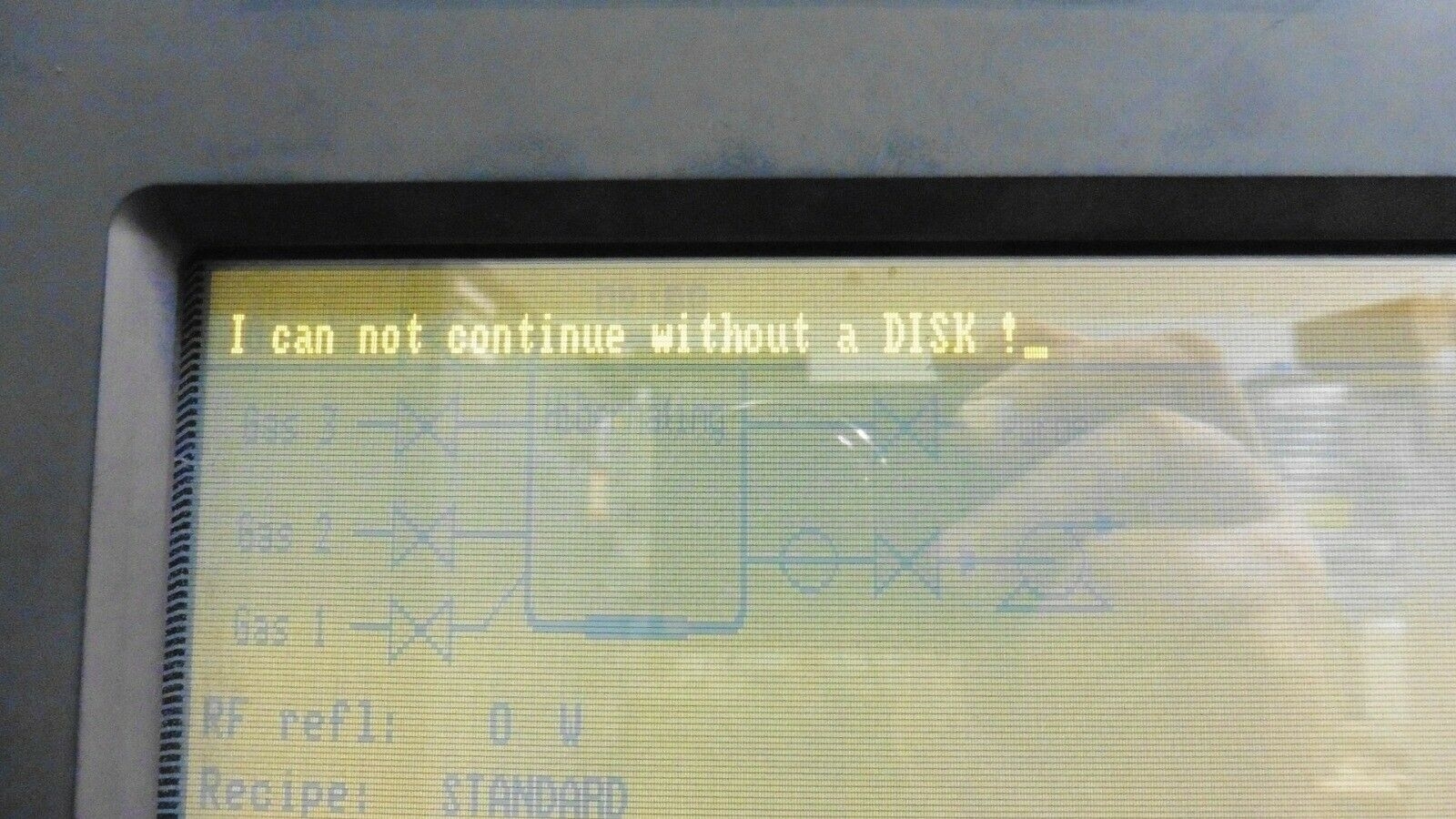

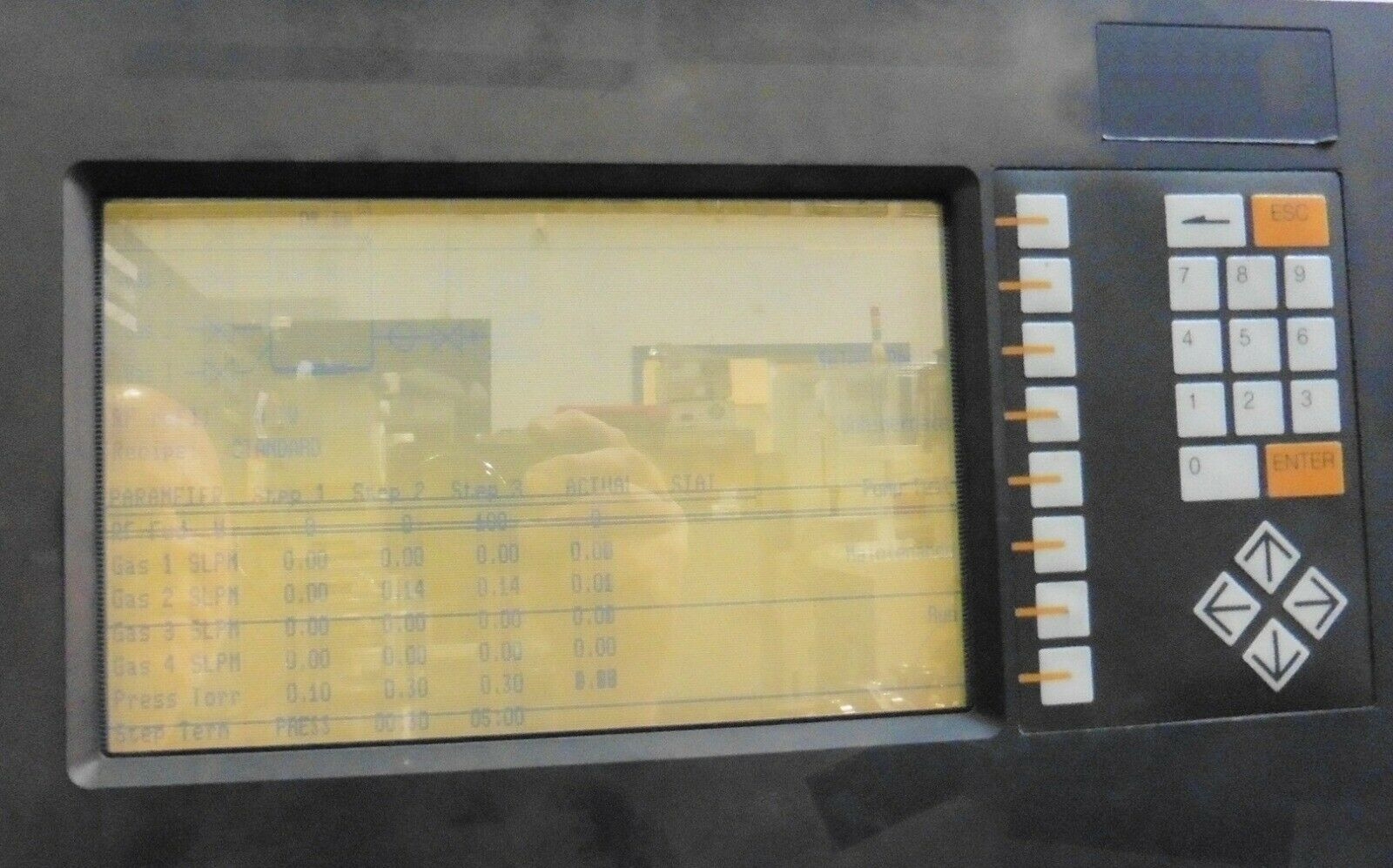

BRANSON / IPC 7102 etcher / asher is a standalone equipment designed for single-sided or dual-sided boards common in prototyping and small to medium-sized production runs. This versatile and compact solution provides users with the capability to quickly and accurately etch a wide variety of metal and other specialty substrates through batch processing or continuous production. Constructed of stainless steel and thermally insulated with a clear polypropylene cover, IPC 7102 is built for long-term, reliable performance. This state-of-the-art etcher / asher utilizes four independently adjustable, hermetically sealed pressure tanks and two parallel enclosed tanks for laminar fluid flow. The flexible design allows the tanks to be configured in one tank per type, two tanks for mixed execution, or one in-line tank. The system also features an integrated dual gas unit that permits precise, repeatable and independent control of both argon and oxygen across a wide adjustment range for precision etching. For optimal safety, the machine is equipped with a built-in liquid level sensor and a sophisticated PLC based control logic. Users can configure the number of pressure tanks, etching gases, times, and temperatures, as well as set etch and rinse timers for consistency and quality. All together the tool can accommodate up to eight different etch chemistry recipes and maximize asset throughput for single-sided and dual-sided substrates. The model also comes with a comprehensive suite of optional features, including two full microprocessors, a crisp TFT touchscreen, password protection, digital sensors for temperature monitoring, programmable feedback controls, interlock switches, and more. Its modular, open architecture design also enables it to be integrated easily with other components or production lines. Overall, BRANSON 7102 etcher / asher is a robust, reliable solution for those in search of a versatile, high-quality etching solution. Its extensive feature set and advanced technology constructions enable users to effectively and consistently etch a wide variety of substrates with precision, even in demanding production environments.

There are no reviews yet