Used BRANSON / IPC PM 1813 #49785 for sale

URL successfully copied!

Tap to zoom

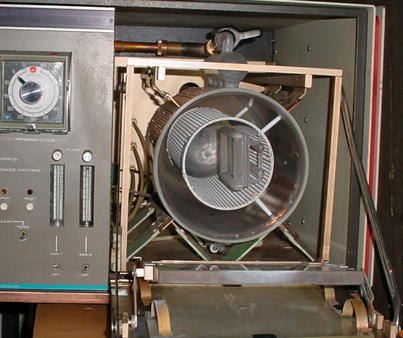

BRANSON / IPC PM 1813 is an etcher/asher, also known as a plasma etching equipment. It is designed to provide precise, reliable etching and ashing of a wide range of materials, including metals, plastics, composites and semiconductors. The system consists of two main components: the controller and the etching/ashing chamber. The controller is the user interface to the unit. It contains a full-color touchscreen, status indicators, and controls that allow the user to operate the machine in manual or automated modes. The controller also allows users to program and save process parameters, enabling them to replicate a given process multiple times. The etching/ashing chamber is the primary component of the tool. It features a vacuum-sealed enclosure, with a removable lid and port for access. Inside the chamber, a series of rollers, injectors, and platforms guide the sample material through the process sequence. The unique design of the asset, and its exclusive high-powered etching tools, allow it to handle both small and large parts quickly and consistently. The model is capable of etching and ashing metals and plastics with a variety of gases, including oxygen, nitrogen, and fluorine. The gases can be optimized for each material, depending on the desired end result. The flexibility of the equipment allows for both isotropic (uniform) and anisotropic (directional) etching, Ashing involves the use of chemical etchants to remove the surface of a material. IPC PM 1813 offers both wet and dry ashing. Safety is a priority when using the system. It has built-in detectors and alarms to protect personnel and equipment from hazard potential due to pressure, temperature, and/or electrical problems. Furthermore, the unit has ample provisions to control and monitor the material disposition, preventing accidental processing of incorrect samples. BRANSON PM 1813 is a highly capable etching/ashing machine that offers precision and reliability for a wide range of materials. It represents a reliable, cost-effective solution for many industrial and semiconductor manufacturing operations.

There are no reviews yet