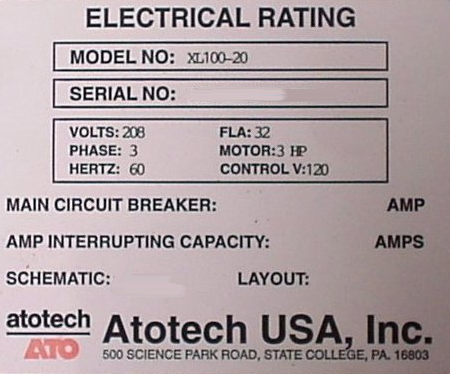

Used CHEMCUT / ATOTECH XL100-20 #142277 for sale

URL successfully copied!

Tap to zoom

CHEMCUT / ATOTECH XL100-20 is an etcher and asher used for various applications in the semiconductor industry. It is well-suited for removing oxide, etching of metals and other material, and glass ashing. It also provides control over both temperature and power. This etch/ash machine features a 20" multi-chamber, stainless steel wave soldering tank equipped with an adjustable horizontal wave able to accommodate up to 14" of PCBs. It is designed for large area operations with 100 KW energy capacity. The dual wave technology used in the machine reduces cycle time by performing two processes at once. CHEMCUT XL100-20 is a fully programmable system to provide precise temperature, etch time, pressure, dwell time, and other parameters. The computerized touch control panel comes with a graphical interface, allowing for easy programming and efficient operation. The multiple process stations feature built-in safety features such as thermal overload protection and low-water cut off, protecting the system from damage due to overload or insufficient water supply. The enclosed work area featured with the machine increases safety, reduce hazardous VOCs, and allow for higher production rates. This machine has a 3-stage pre-treatment system, two high-energy ion guns, four magnetrons, and two infrared thermocouples to monitor the process. It is able to process all types of materials, including metal, polymers, glass, and quartz. ATOTECH XL100-20 is a reliable and efficient machine, making it a perfect choice for semiconductor and capability manufacturers. It is also cost effective and easy to maintain, providing cost savings over time. With its user-friendly control panel, customized programming capabilities, and robust design, XL100-20 provides the perfect solution for a variety of etch, ash, and PCB cleaning requirements.

There are no reviews yet