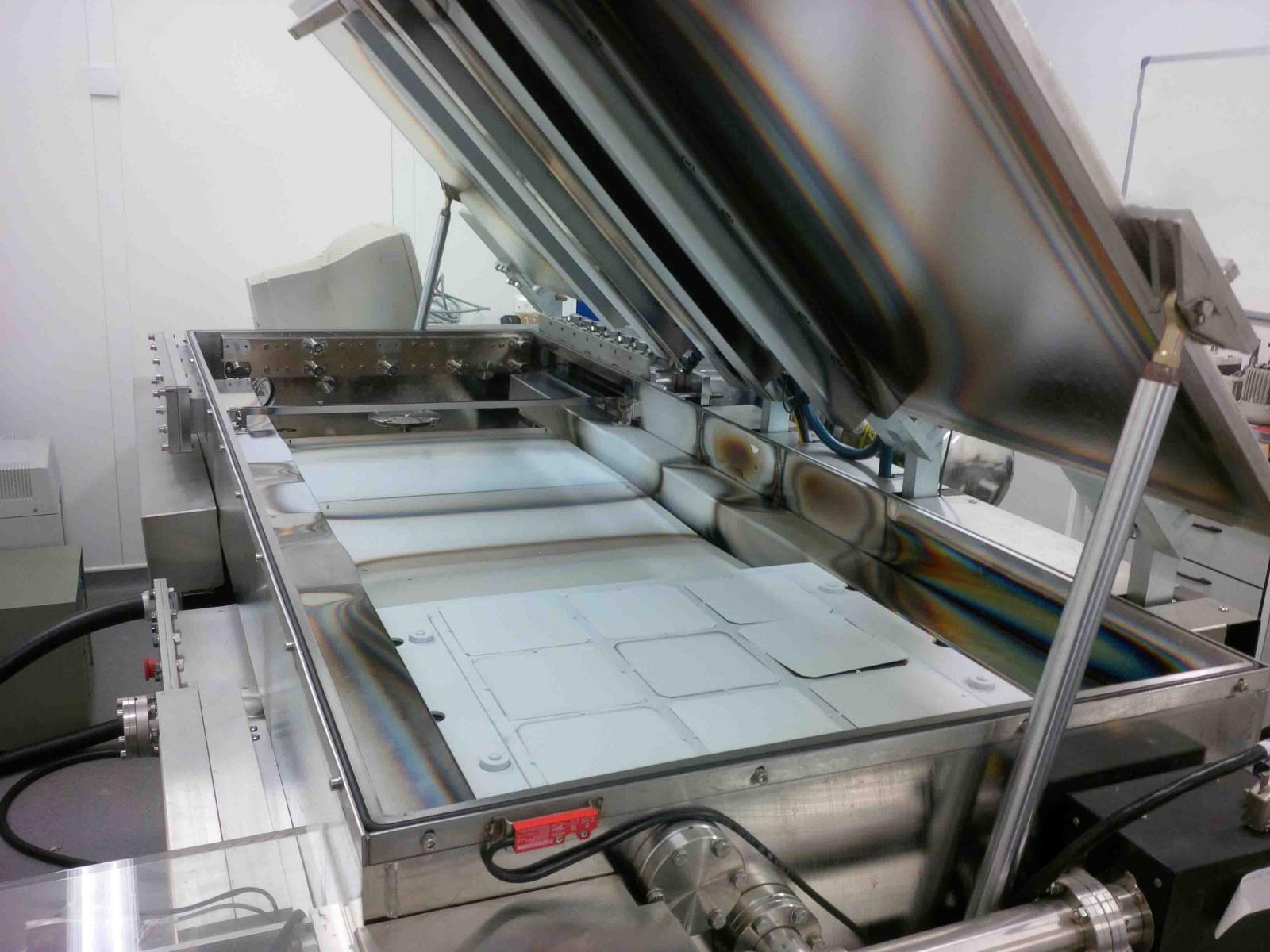

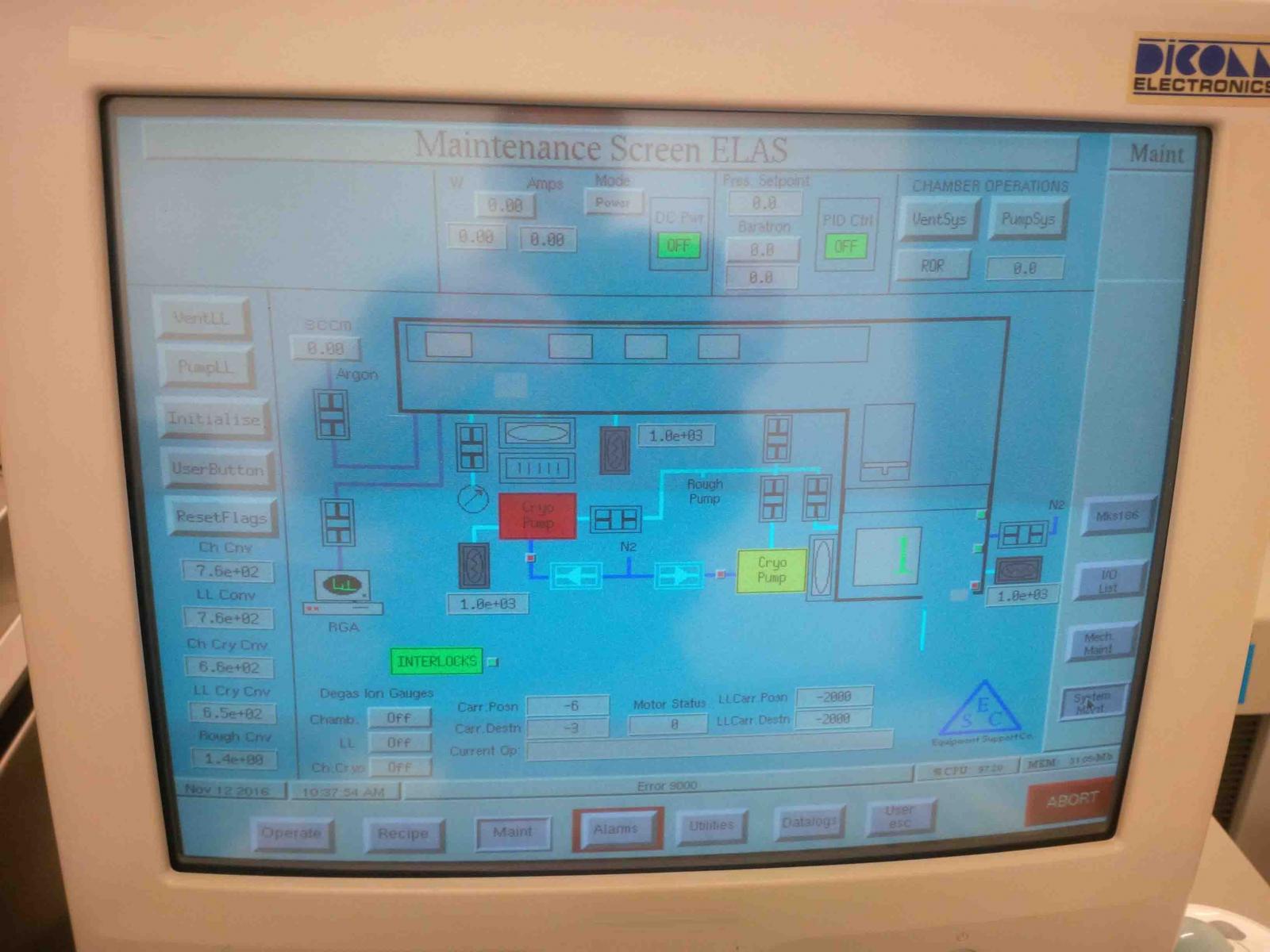

Used ESC ELAS #9131115 for sale

URL successfully copied!

Tap to zoom

ID: 9131115

Wafer Size: 6"-8"

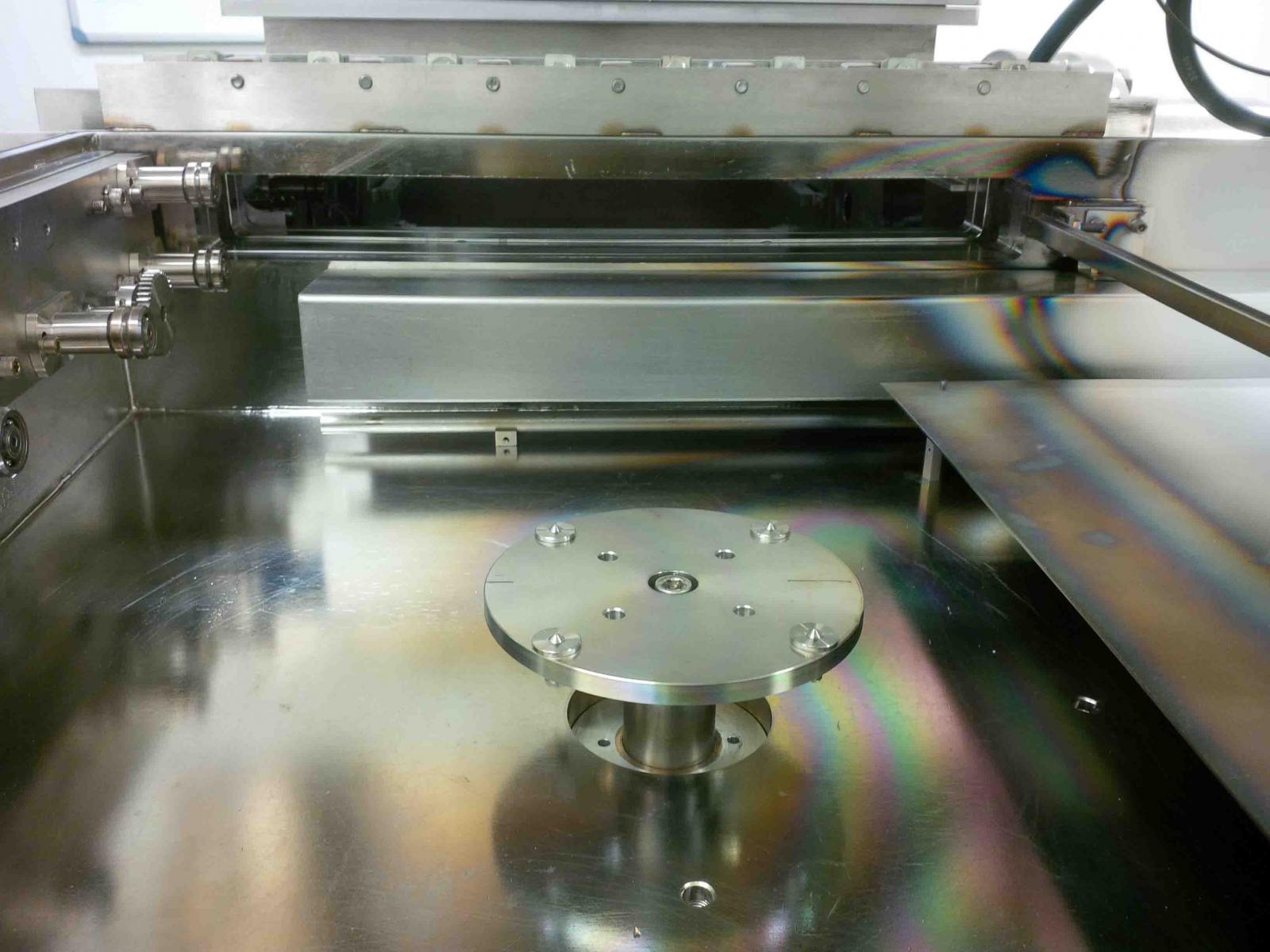

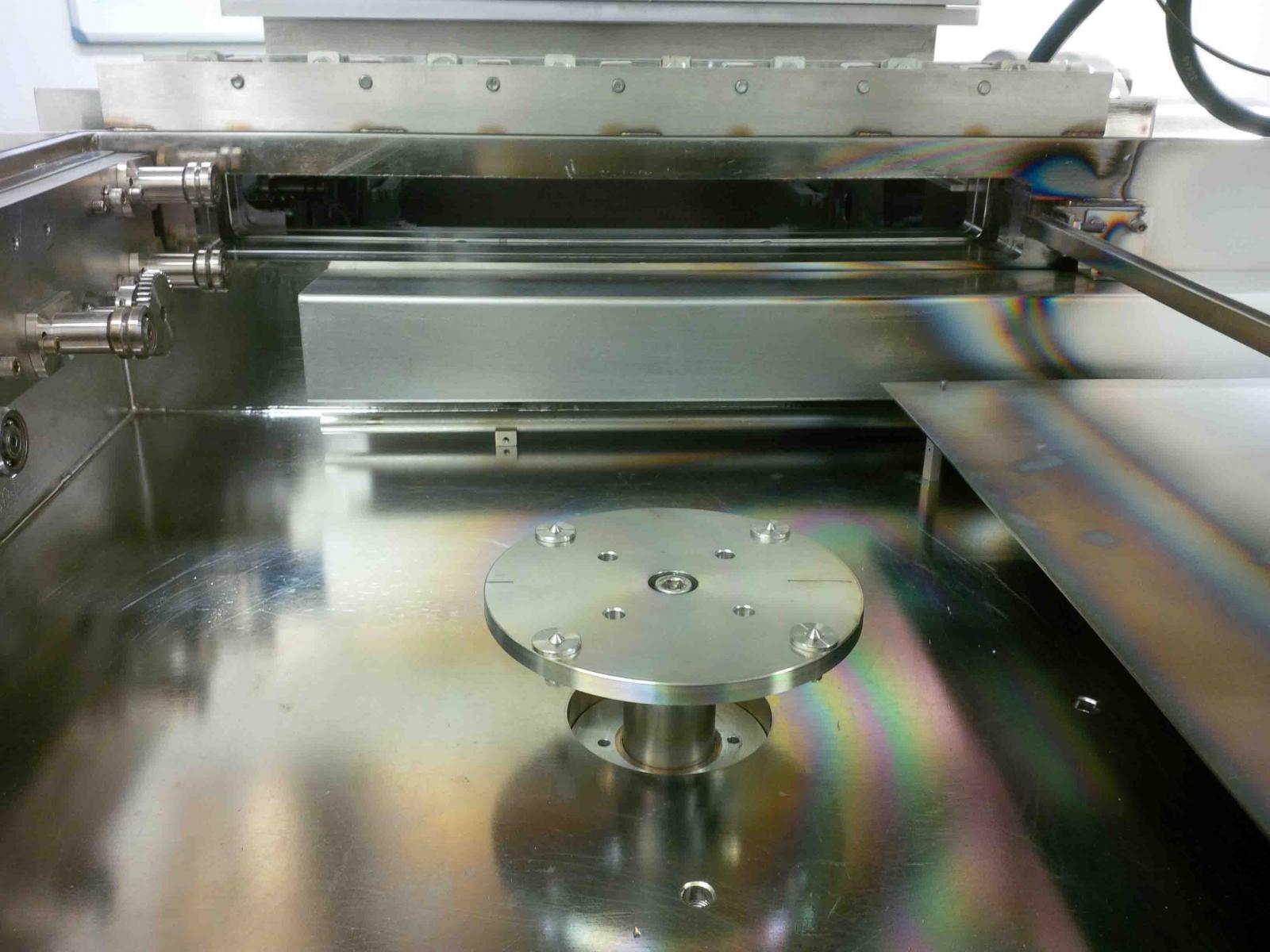

RF / DC Sputtering system, 6"-8"

RF Magnetron

RF Diode operation

Loadlock cryo pump, 8"

Chamber, 10"

Rectangular

Heliarc welded

304 Stainless steel plate: 16 mm

View-port: Pyrex window

Pump-out port: 225 mm Diameter

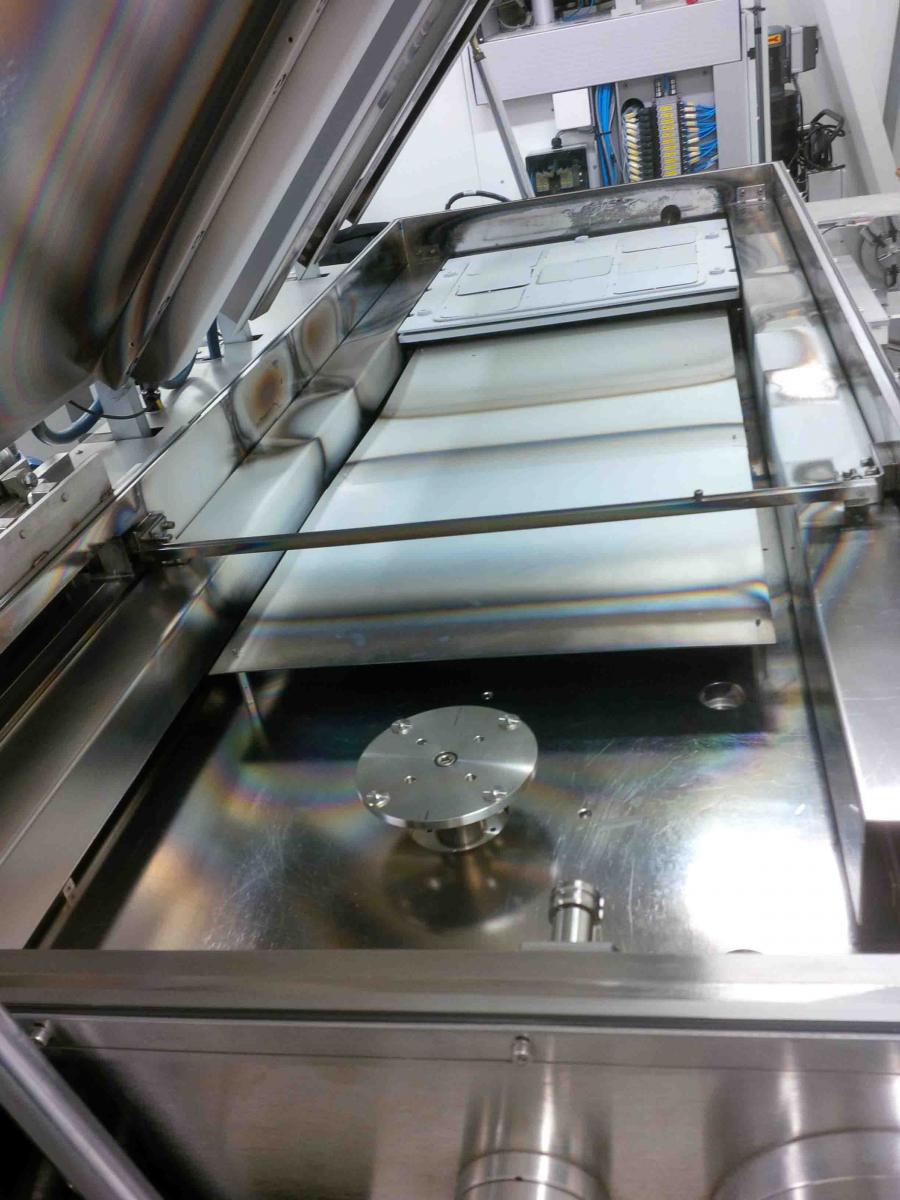

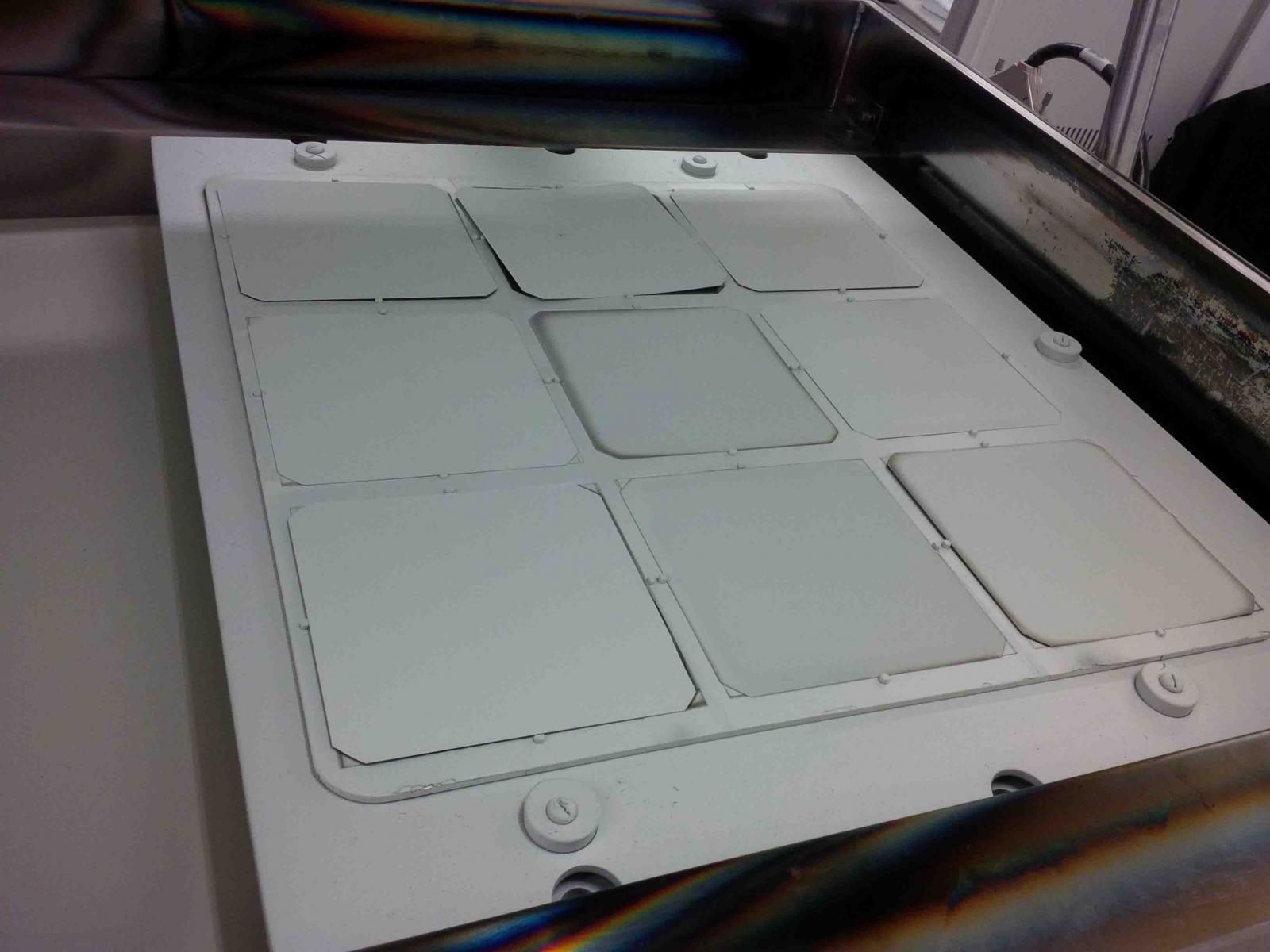

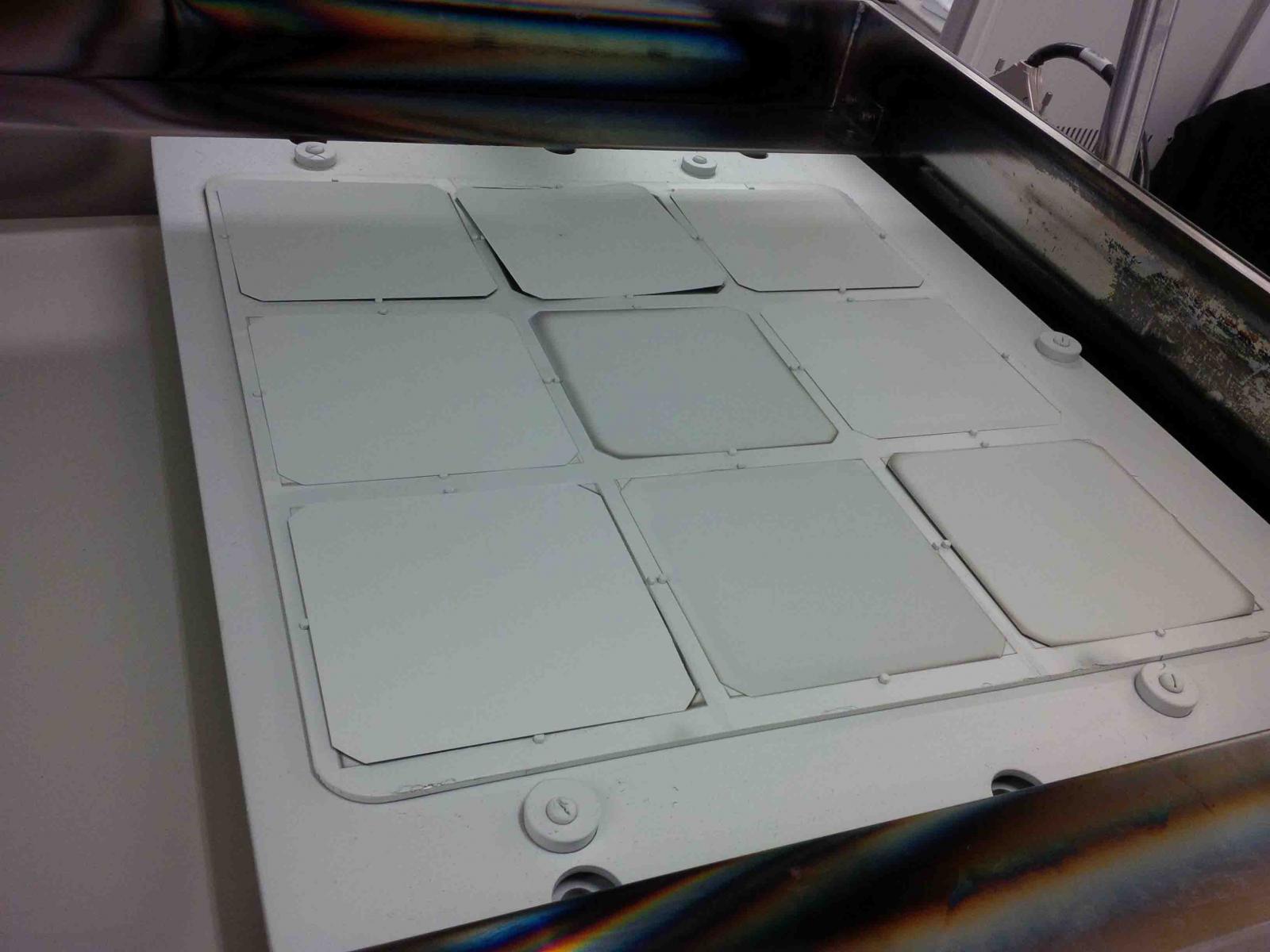

Load lock:

2-Level elevator

Non-coated pallets loaded on upper level

Processed pallets unloaded from lower level

VITON O-ring

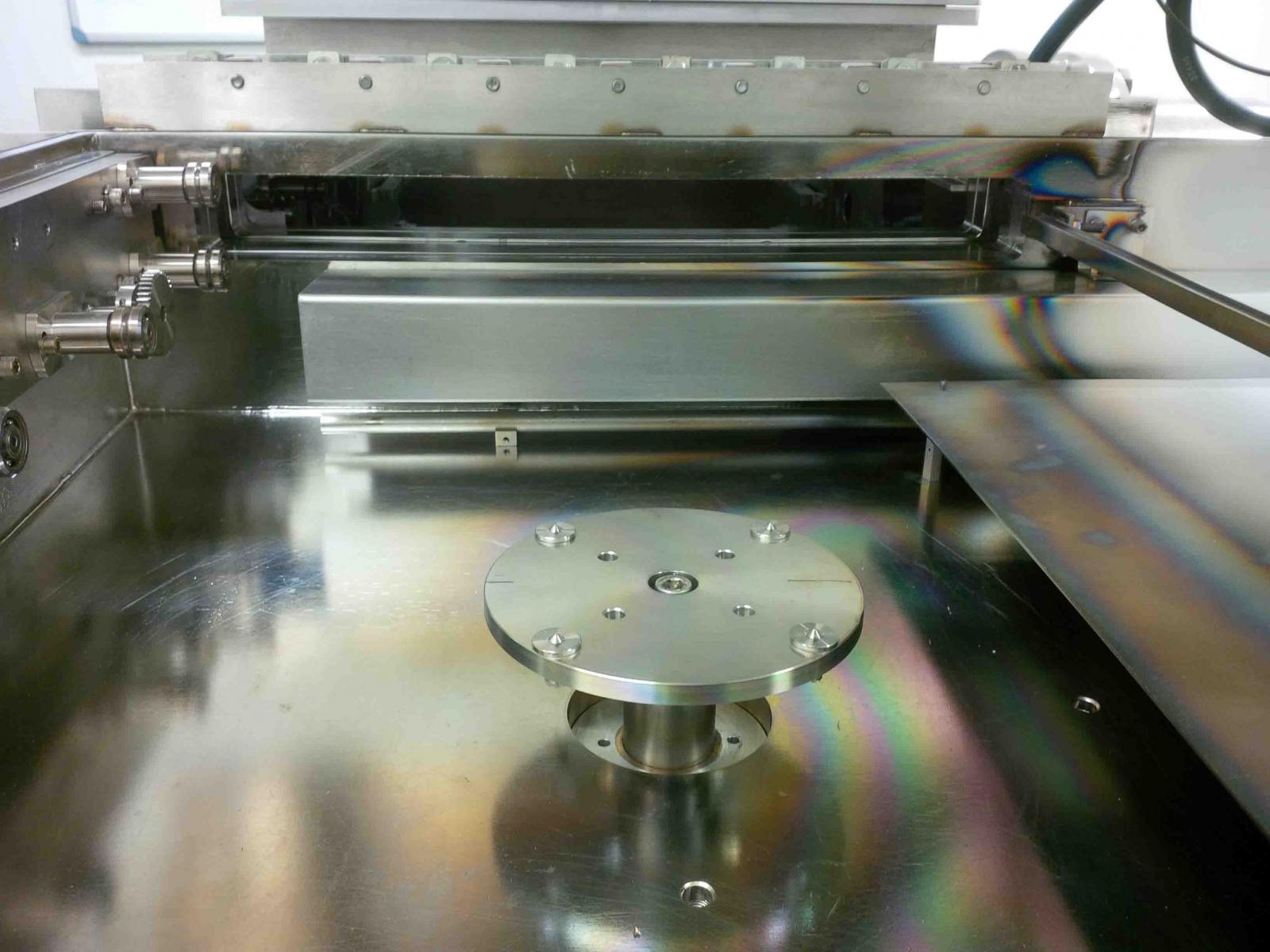

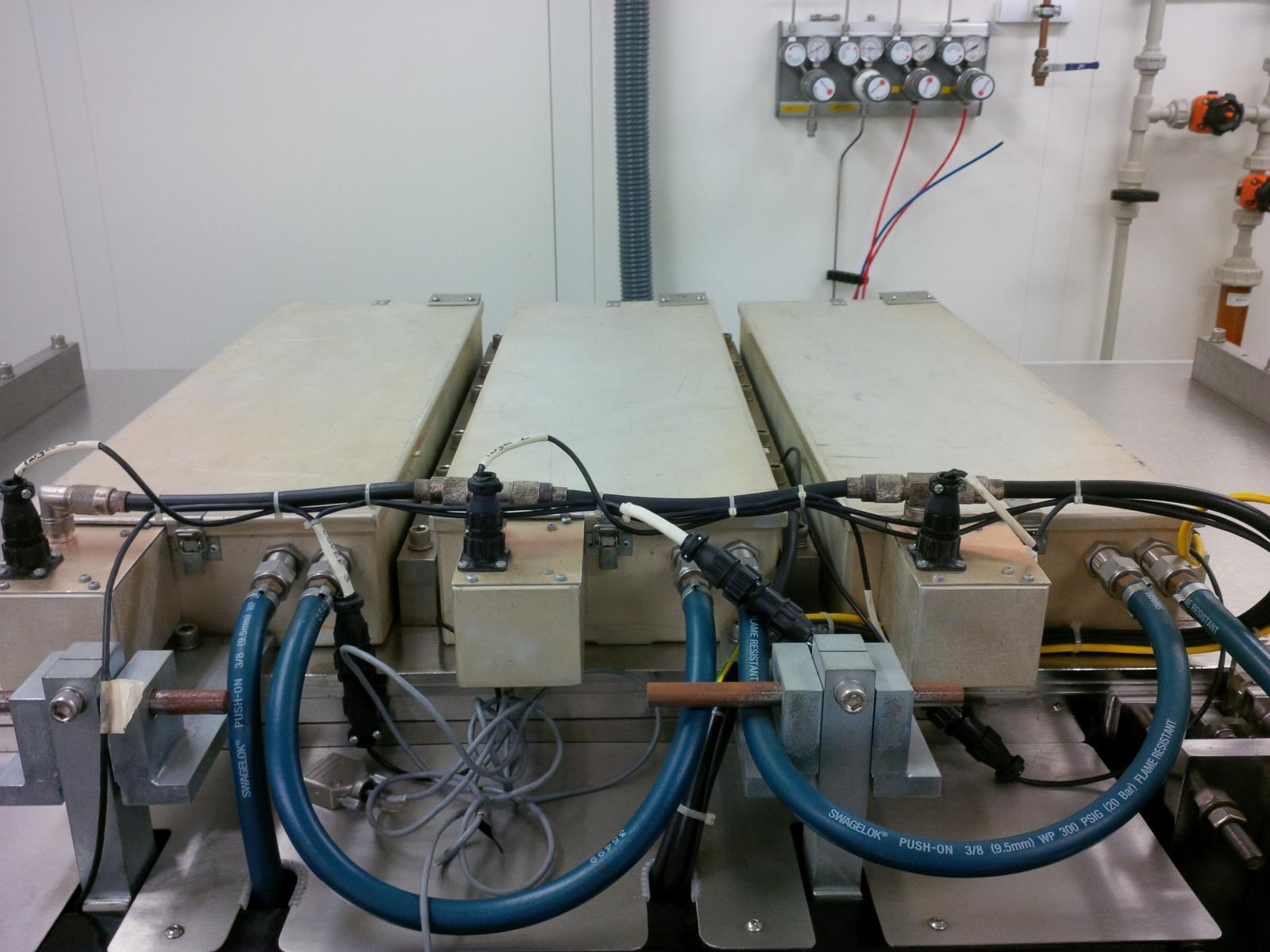

Feedthrough:

Linear bellows

Magnetically coupled drive

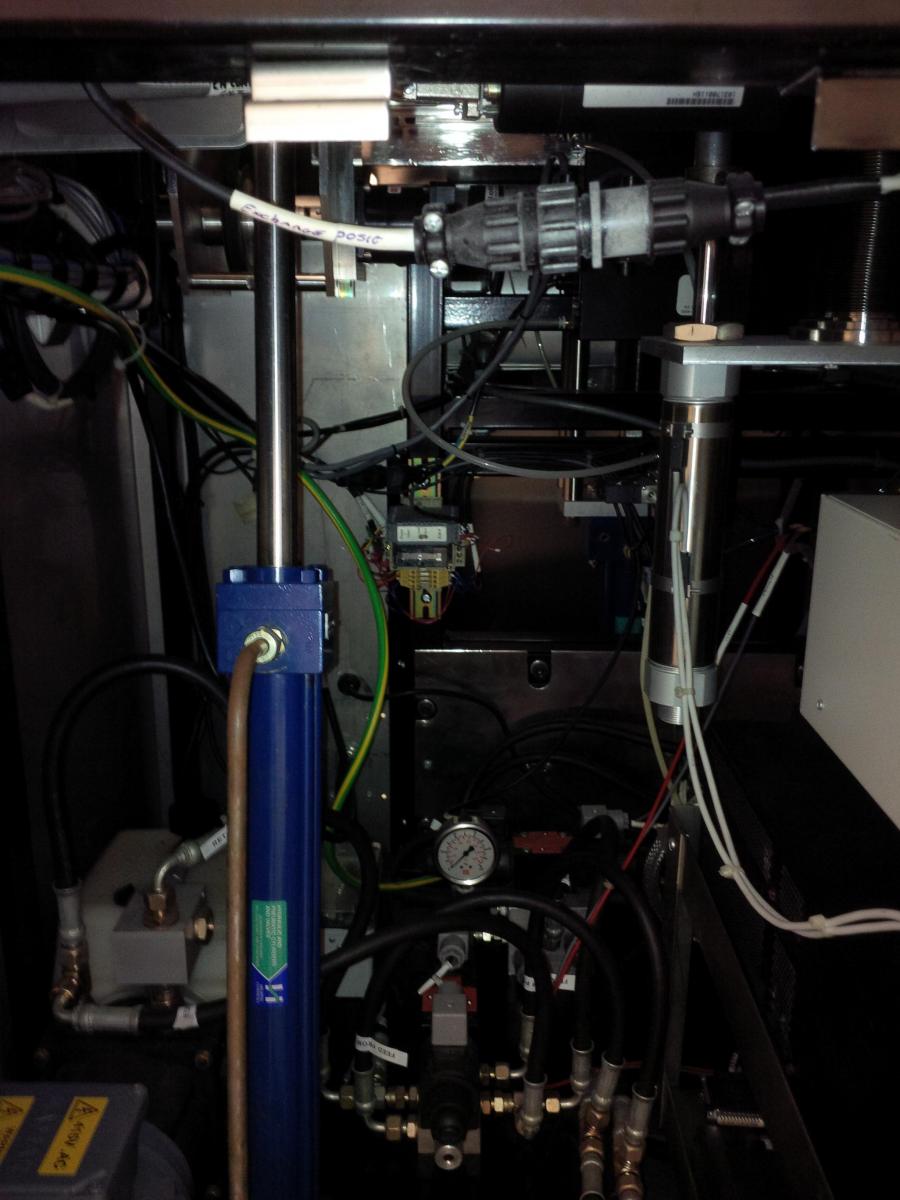

Drive:

Hydraulics

Low pressure drive

Motion:

Loading and unloading

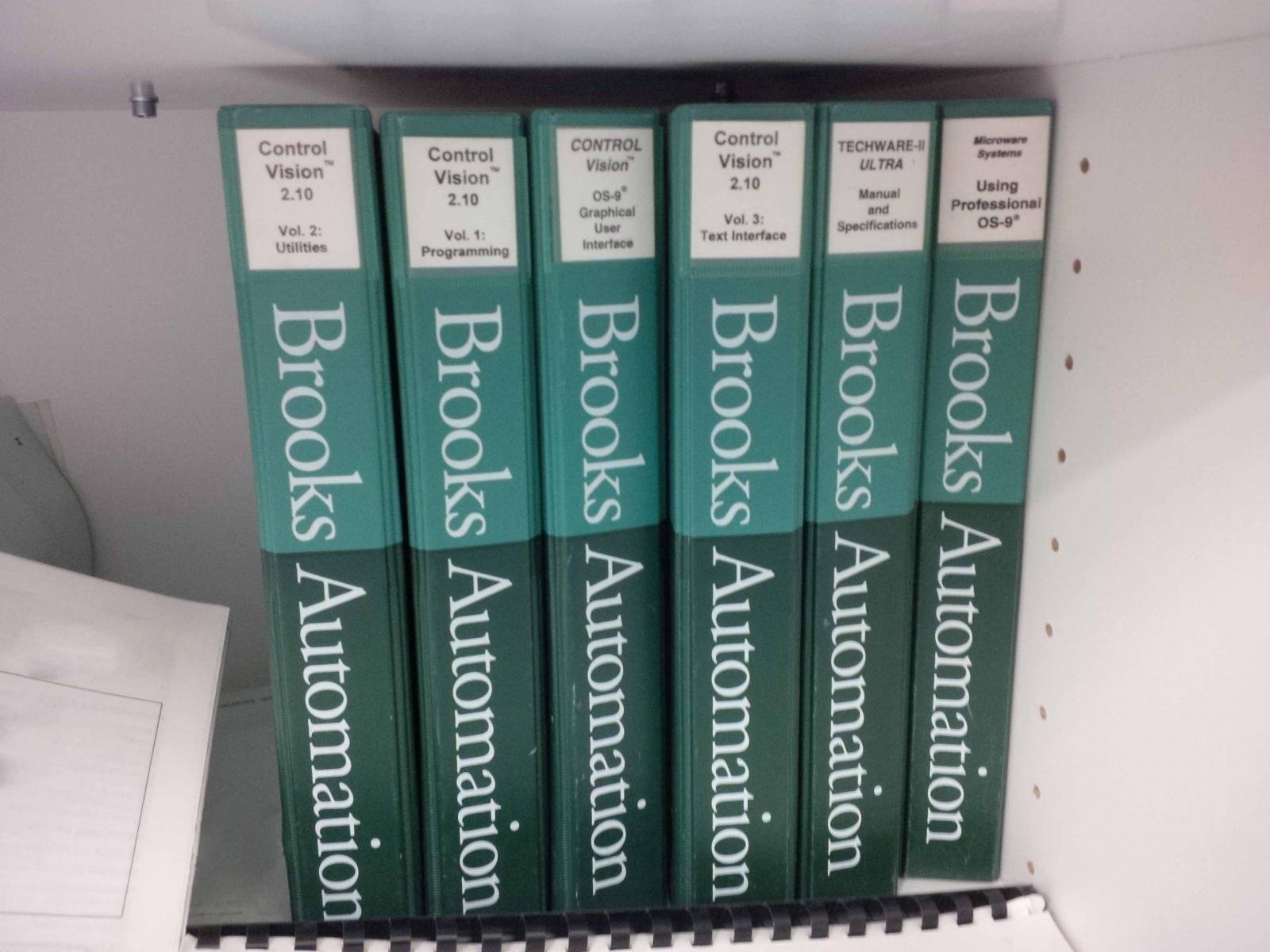

Fully-automatic computer controlled

Capacity:

Diameter wafers: 6-150 mm

Diameter wafers: 4-200 mm

Drive:

Precision DC motor

With optical encoder feedback control

Chain drive

Labyrinth shielded

Option: DC Bias / RF Bias

Coating speed: 3-350 cm/min, Bi-directional

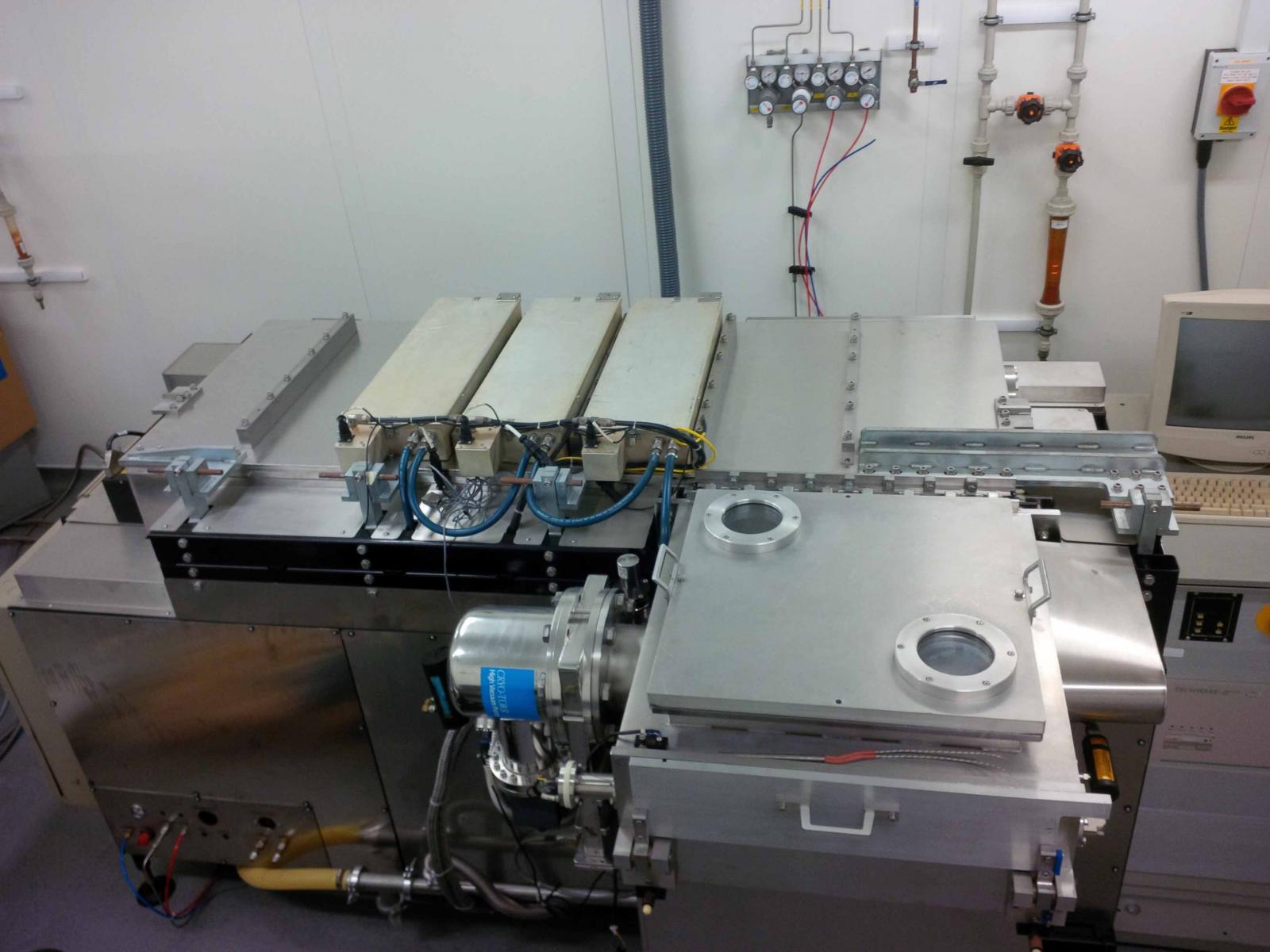

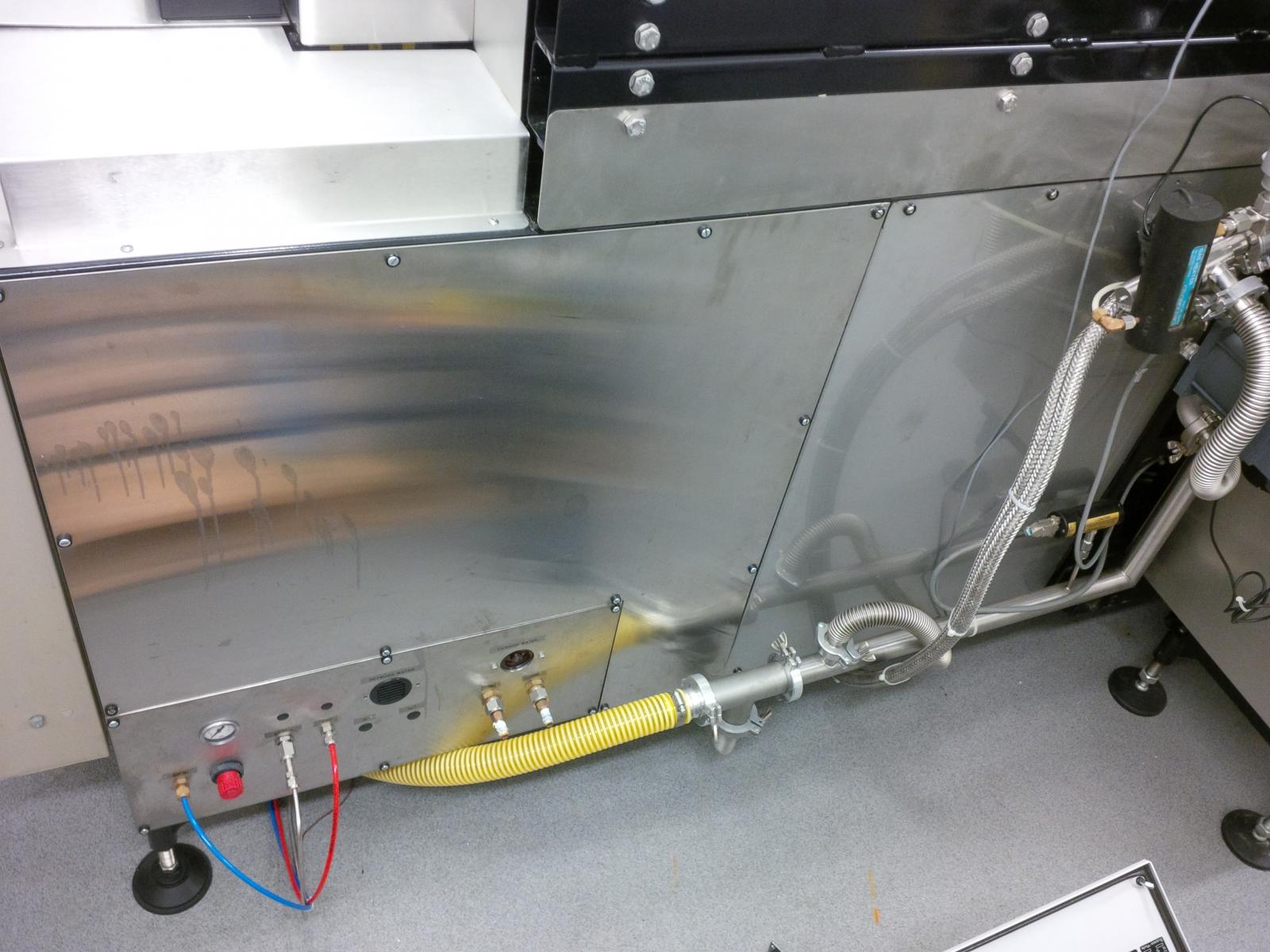

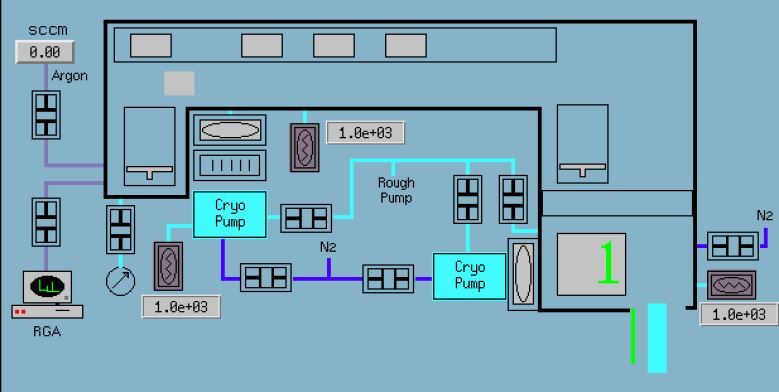

Vacuum system:

Load lock

CTI-CRYOGENICS Cryo-Torr 8 Vacuum pump

Vacuum valve: 6" ASA (7-1/8" Diameter) Gate valve

Electro-pneumatic operation

Valves: 1-1/2" Bellows sealed

Electro-pneumatic operation

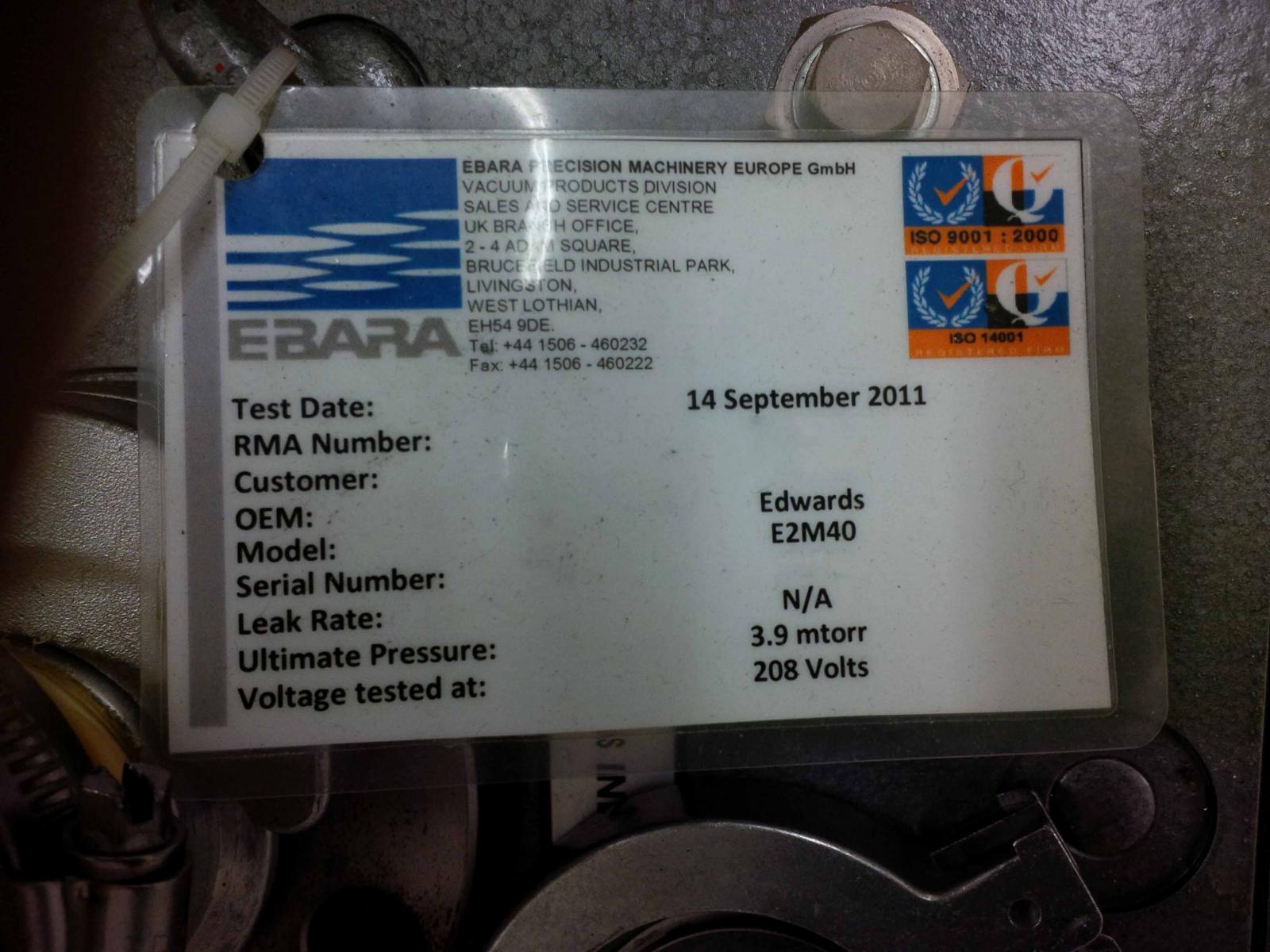

Roughing pump: 27 CFM (762 l/min)

With process chamber

Main chamber:

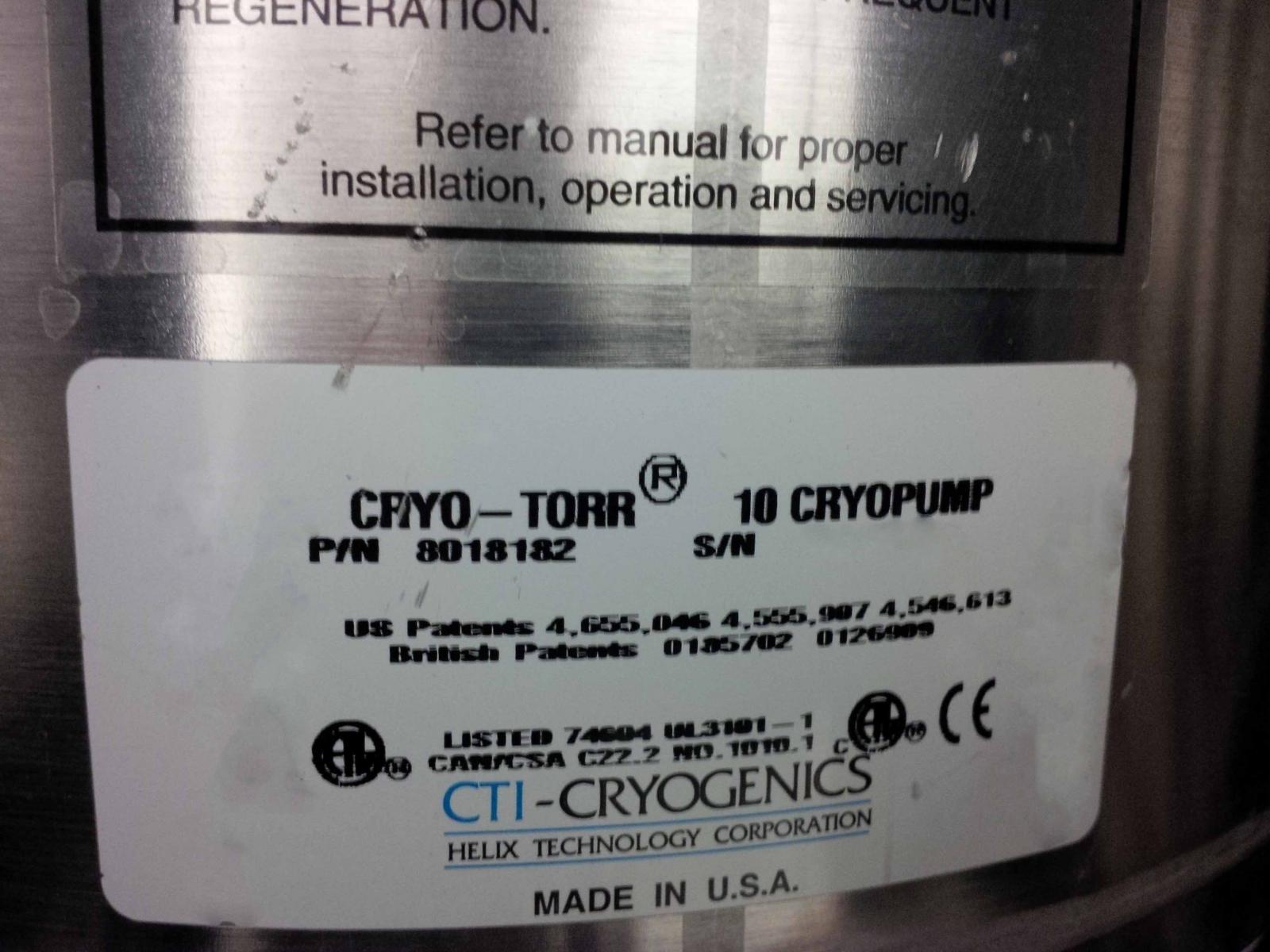

CTI-CRYOGENICS Cryo-Torr 10 Vacuum pump

Vacuum valve: ASA Gate valve, 10"

Electro-pneumatic operation for gas throttling

Load lock and cryo regeneration: 27 CFM Mechanical pump

Anti-back-streaming trap for mechanical pump

1-1/2" Bellows sealed electro-pneumatic operation

Etch platform:

Moves vertically to engage / Disengage the pallet

Cooling: Water-cooled

Material: Stainless steel

Insulator: Pyrex

Dark space shield: Stainless steel

Residual gas analyzer

RF Generator:

Continuously-rated and specifically designed for sputtering: 1 kW

ISM Frequency: 13.56 MHz

FCC and OSHA

DC Magnetron power supply:

ADVANCED ENERGY Pinnacle Power supply, 12 kW

System performance specifications:

Process parameter control ranges:

Description / Minimum / Maximum / Units

Sputtering pressure / 1 / 90 / Millitor

Scan speed (bi-directional) / 3 / 350 / cm/min

DC Sput / 100 / 12,000 / Watts

RF Sput / 0.02 / 2.10 / kVA

- / 0.1 / 2.00 / kW

Etch revel (Note 2) / 0.02 / 1.50 / kVA

- / 0.1 / 1.50 / kW

DC Bias capability:

Internal mechanism: DC Power

DC Bias activated during DC sputtering

Power supplies: 150 V.

ESC ELAS is an electrochemical etching / ashing equipment designed to meet the precision etching requirements of modern thin-film electronics. It is a robust and highly efficient etching system that uses high-density, pulsed DC power for fast, uniform processes. The unit is designed for a wide range of etching applications, including etchable thin-film materials like metals, oxides, and polymers. The process is capable of achieving an etch rate of up to several hundred nanometers per minute, with very precise control over selectivity, depth, line width, and surface roughness. ELAS machine is built on proven technology that includes a hermetically sealed, copper-jacketed torso for insulation and corrosion resistance. The unit is also equipped with an integrated heating element to maintain a stable temperature and a power-regulated etching chamber with self-adjusting pressure adjustments. This ensures uniform etching processes and facilitates repeatable results that are extremely precise. To achieve an optimal etching rate, the tool employs a wide variety of etching agencies, including chemical vapor deposition, or CVD, and high-temperature furnace processes. A separately controlled, inert atmosphere allows for longer etching times, producing deeper etches. Alternatively, short-duration etches with higher efficiency can be achieved using plasma etching in a vacuum environment. ESC ELAS asset can process a wide range of wafer sizes, from small, chip-sized pieces to large, rectangular panels. It is also equipped with an XYZ stage that allows for precise placement and fixturing of the worker during processing. The model also includes E-Beam and X-ray etching process, for more accurate etching results. All of these features combine to make ELAS an excellent choice for precision etching needs. The unit is very reliable and capable of consistently producing high-quality etching results. Furthermore, it allows users to continuously monitor the etch process through advanced diagnostics and offers high reproducibility of results. Therefore, it is ideal for high-precision electronics production applications in the industrial market.

There are no reviews yet