Used GASONICS / BRANSON / IPC 9104 #9221031 for sale

URL successfully copied!

Tap to zoom

ID: 9221031

Vintage: 1996

Plasma asher

Deep quartz barrel: 12" x 22" Diameter

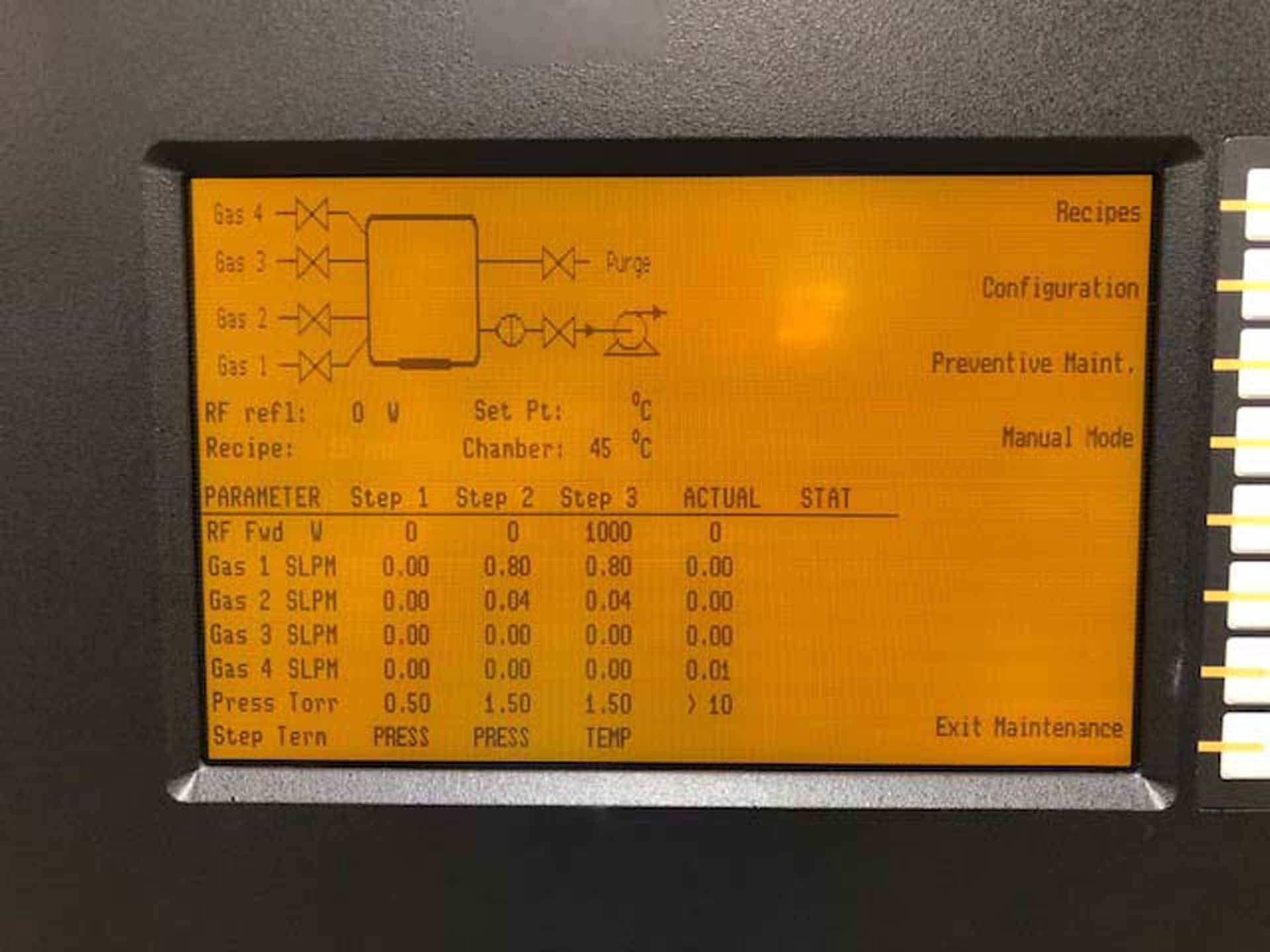

Microprocessor control

RF Cage

(4) Gas inputs, 208V/lph

Power control box (P/N 15677-02)

ENI OEM-12B-02 13.56 Mhz 1250W RF Generator

LEYBOLD D65BCS Pump

ARS40/65 Exhaust filter

Stainless steel table

Missing power supply

1996 vintage.

GASONICS / BRANSON / IPC 9104 Etching/Asher is a fully-automated, computerized wet process etch and asher equipment. Used primarily for circuit board fabrication, the system is designed to handle intricate and delicate job requirements with a minimum of manual intervention. Utilizing an imaging chamber, IPC 9104 features an advanced multi-level vapor etch unit that is capable of creating precise etching and ashing definitions, even in the thinnest materials. This cutting-edge technology is further enhanced by the precision process control, allowing users to set parameters for perfect etching or ashing. The machine also provides superior etch/ash process control, along with an adaptable spotting tool that allows for the inspection and process of components of varying sizes and shapes. BRANSON 9104 is equipped with both a light source and CCD camera to help verify proper conformal coating and etching/ashening of components. An optional Heated Substrate Coater is also available to ensure a consistent coating performance on almost any type of bare board substrate. 9104 features a robust, easy to use control panel and intuitive on-board software, allowing users to quickly calibrate the machine's settings and adjust its operations to suit many different requirements. Quick set-up and fast process changes allow for complete job customization with minimal effort. In addition, GASONICS 9104 is designed to be compatible with practically any etch or ashing asset, including lead-free etching. Utilizing advanced etching technologies, users can produce high-resolution patterns at very modest costs. GASONICS / BRANSON / IPC 9104 is also equipped with a number of features to ensure safe operation, such as light curtains for protection from chemical and high-voltage concerns. End-of-cycle alerts are provided, primary control cables are double sheathed for safety, and a built-in computer interface allows for easy data exchange and programming with other IPC compatible systems. Overall, IPC 9104 is an ideal solution for any application requiring precise, cost-efficient etch or ashing. With its advanced control technologies, easy set-up and operation, and safety features, this advanced model offers a superior performance, making it a must-have in any circuit board fabrication lab.

There are no reviews yet