Used GASONICS / BRANSON / IPC 9104 #9251583 for sale

URL successfully copied!

Tap to zoom

ID: 9251583

Wafer Size: 4"-8"

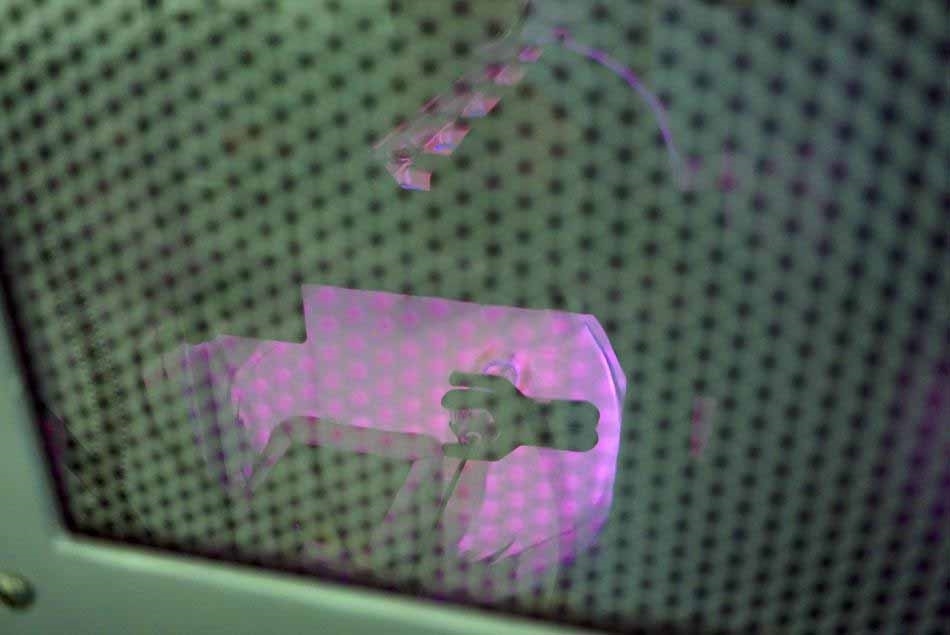

Plasma asher, 4"-8"

(2) Channels

Quartz barrel: 12" x 22" Diameter

Soft pumping and purge valving

(2) Mass flow gas inputs with VCR fittings

Stainless steel plumbing

Temperature monitor: Quartz-coated thermocouple in process chamber

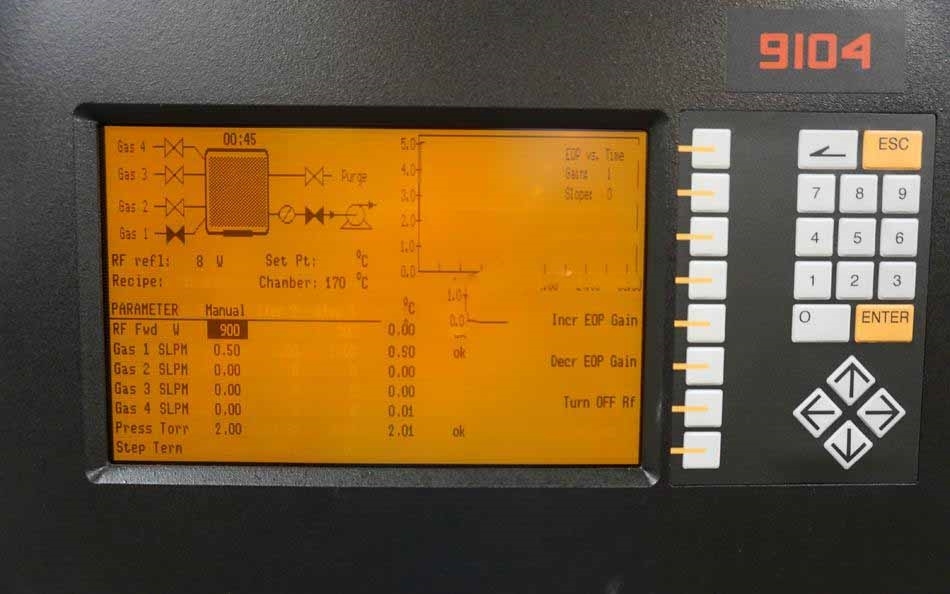

Multi channel / Single board computer controlled with floppy storage

ENI OEM 12B RF Generator: 1250 Watt

13.56 MHz Air cooled with automatic impedance matching network

Display: Touch screen, 21"

For control and monitoring of process parameters

Automatic recipes or manual plasma treatments

Temperature controller

(4) User specified gases with 500 sccm stainless steel MFCs

NEMA-12 Wall mounting enclosure with locking handle

Process pressure: ~120- 2000 mtorr

CE Certified

Power supply: 208-240 Volts, 3Φ, 50/60 Hz, 5 wire.

This etcher / asher is a high speed automated wet process machine manufactured by IPC. It is capable of etching and ashing various substrates such as wafer, thick films, and silicon. The system is comprised of three areas: an acid/solvent and ambient tank, a work zone, and an oven zone. The acid/solvent tank contains a basket trolley that can hold up to fifteen 4''/100mm wafers, and provide precise acid control for up to three separate tanks. The amount of solvents and acids can be automatically regulated by the machine. The basket trolley is removed from the tank for cleaning, and the tanks can be replenished. The work zone is the heart of the process and carries out the etching or ashing action. A Micro controller actuates an injector head to deliver acid/solvents to the wafer station. The micro controller also controls the SCR power controller, which provides a high-frequency energy source to electronically activate the etch/ash process. This is where the machine really shines, as it can perform etching/ashing simultaneously while all other process conditions are kept constant. The oven zone helps to dry the wafers after the etching/ashing process. The oven chamber is constructed of stainless steel and can reach temperatures up to 700 C for the ultimate drying process. The temperature can be set and controlled with the adjustable time and temperature parameter set. Overall, GASONICS / BRANSON / IPC 9104 is an accurate and precise etcher / asher. It features a high speed process, as well as an adjustable time and temperature parameter set. The machine also includes a stainless steel oven zone to ensure the perfect drying of the etched/ashed products. With this machine, users can expect excellent results each time.

There are no reviews yet