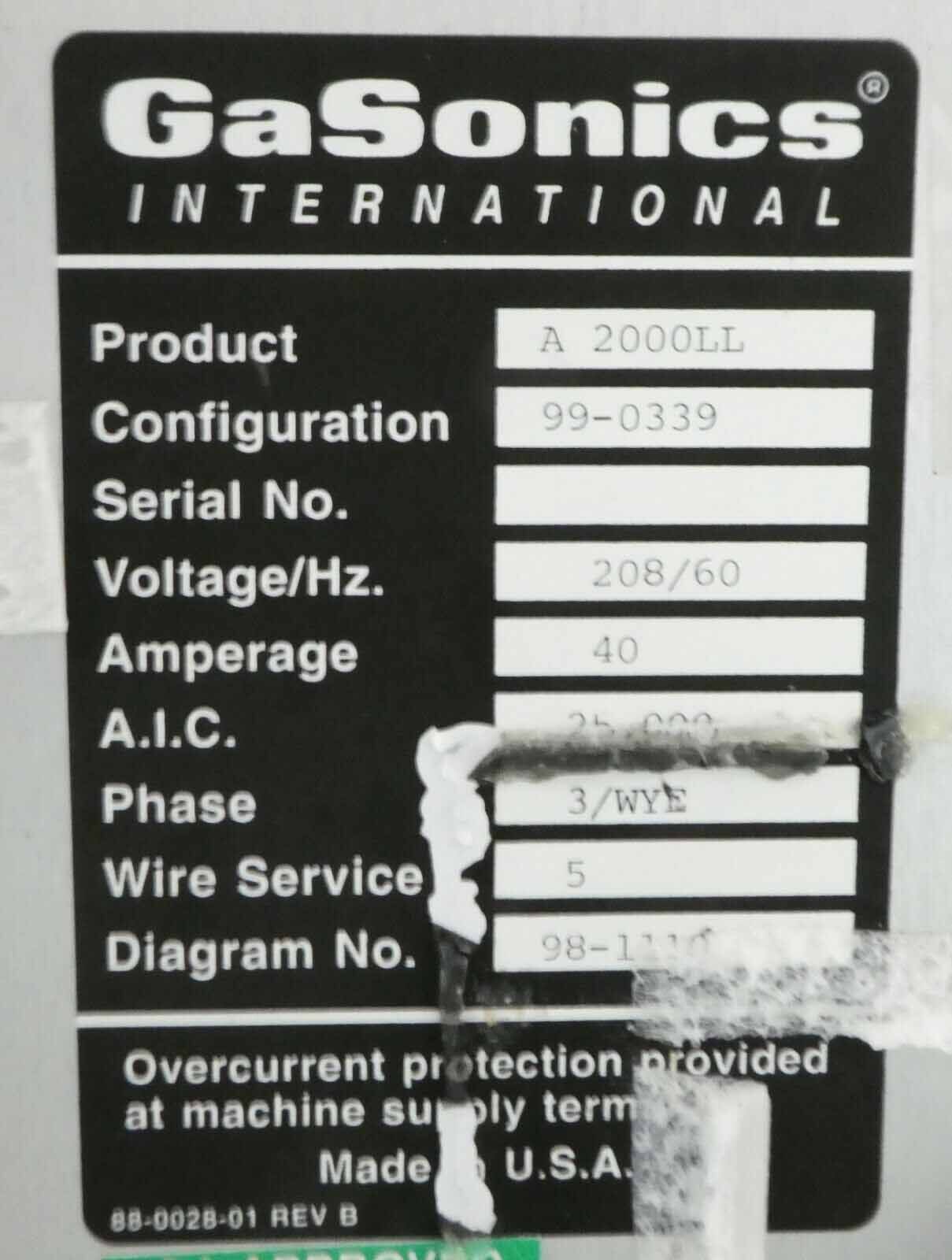

Used GASONICS / NOVELLUS A 2000LL #293595026 for sale

URL successfully copied!

Tap to zoom

ID: 293595026

Asher

Part No: 99-0339

Non-copper

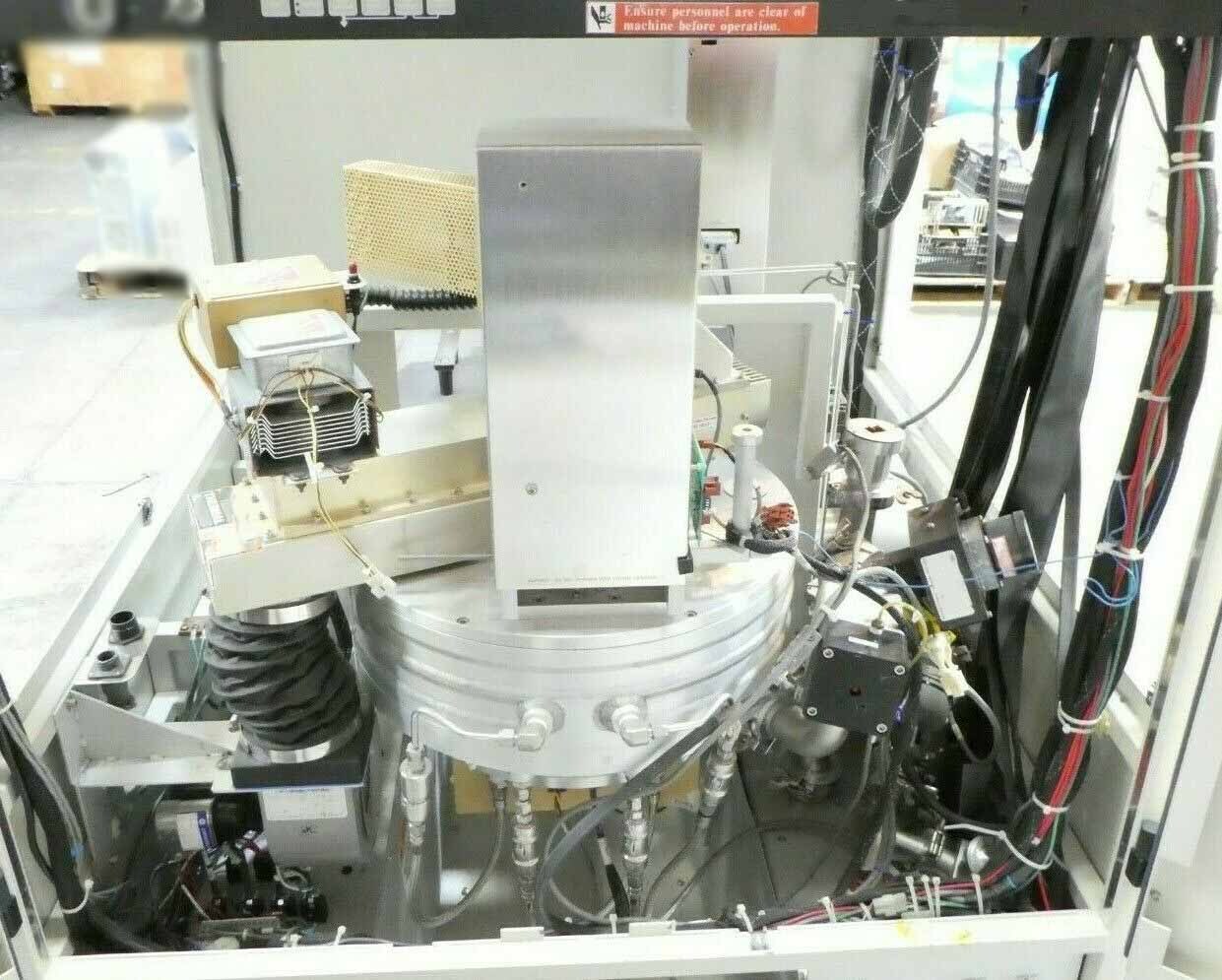

Components:

Qty / Make / Model / Description / Part number

(1) / - / - / Load lock chamber / A95-205-01 / 56-7923

(1) / GASONICS / 94-1175 / Indexer elevator / 04630-003

(1) / GASONICS / 94-1174 / Indexer elevator / 04630-004

(2) / GASONICS / 94-1118 / Load lock elevators / 04290-201

(1) / GASONICS / - / Loadlock rear panel display / -

(1) / MKS INSTRUMENTS / Baratron / - / 122A

(1) / MKS INSTRUMENTS / 152 / Pressure controller / 152H-P0

(1) / MKS INSTRUMENTS / - / Valve / 253B-11020

(1) / - / - / HNL Asher module / -

(1) / VARIAN / - / Valve / L6281-701

(1) / VARIAN / - / Valve / L6281703

(1) / OMRON / Sysmac C40H / PLC / C40H-060R-DE-V1

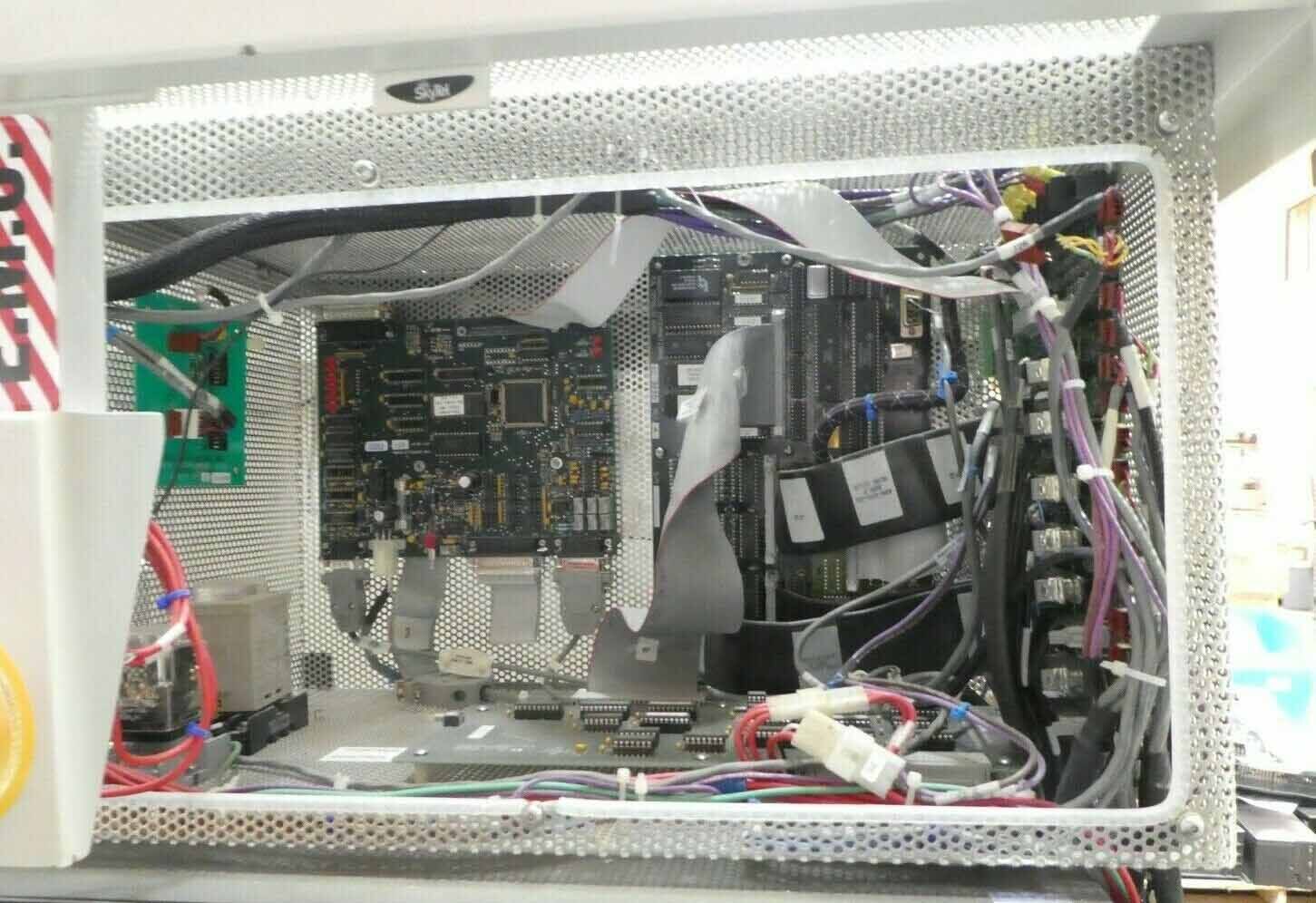

PCB:

Make / Model / Description / Part number

GASONICS / - / Controller board / 90-2658

GASONICS / - / Display decoder / 90-2609

GASONICS / - / Loadlock interface BD / 90-2608

HINE DESIGN / - / ARM Controller board / 02423-001 / 06764-001

NOVELLUS / A2000 / Interlock BD / 90-2735

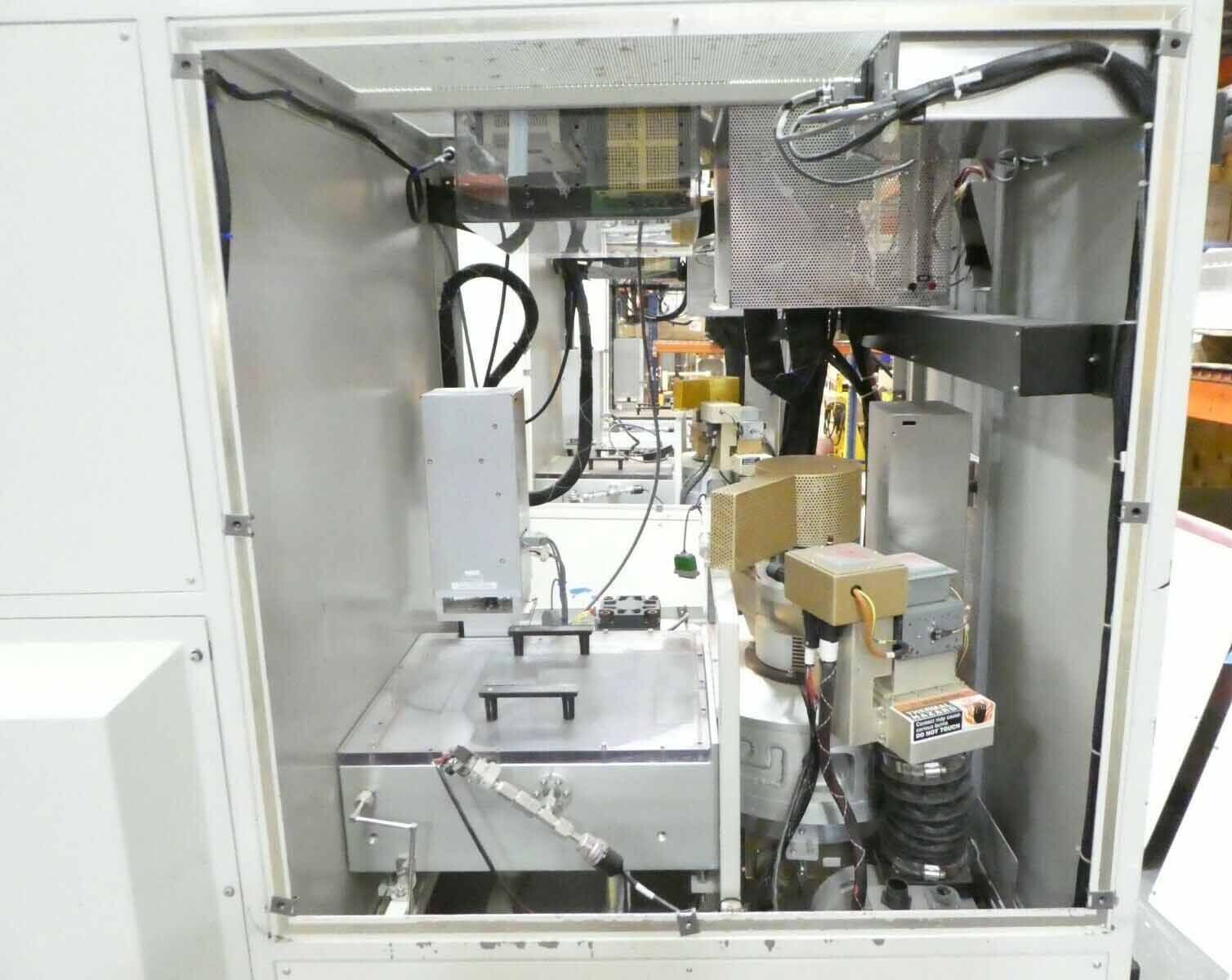

Wafer handling robot / arm unit missing

CE Marked.

GASONICS / NOVELLUS A 2000LL is an high performance etcher/asher, designed for advanced semiconductor manufacturing. It uses advanced plasma etching and ashing technology to enable controlled etching and ashing of various kinds of materials at a high level of accuracy. The device utilizes a powerful magnetron to create a high energy plasma which is very efficient in etching and ashing various kinds of materials. Its advanced control algorithm to precisely control the parameters ensures minimal process variation, repeatability and improved yields. In order to achieve its desired etching and ashing results, GASONICS A 2000LL utilizes an advanced 2-chamber system which allows for a high degree of uniformity and accuracy in etching and ashing. The process is started by introducing a mixture of etching and ashing gases into the first chamber. An inductively coupled plasma is produced by irradiating the gas with radio-frequency radiation, which will be used to etch and ashing the materials. The plasma is deactivated at the end of the etching/ashing cycle and the chamber is emptied of the processing gases. The process is then continued in the second chamber by introducing fresh etching and ashing gases. This device also utilizes effective thermal management techniques for precise etching and ashing performance. The chamber's path is temperature-controlled to ensure process uniformity and consistency. A high-pressure cleaning cycle is enabled in this chamber which helps to reduce lateral overexposure. This device can also adjust the frequency and magnitude of the RF generator depending on the application. With its advanced plasma etching/ashing technology, powerful magnetron and effective thermal management techniques, NOVELLUS A 2000LL is an outstanding device to etch and ashing various kinds of materials with a high level of accuracy. It provides excellent yield, process repeatability and significant improvements in reliability.

There are no reviews yet