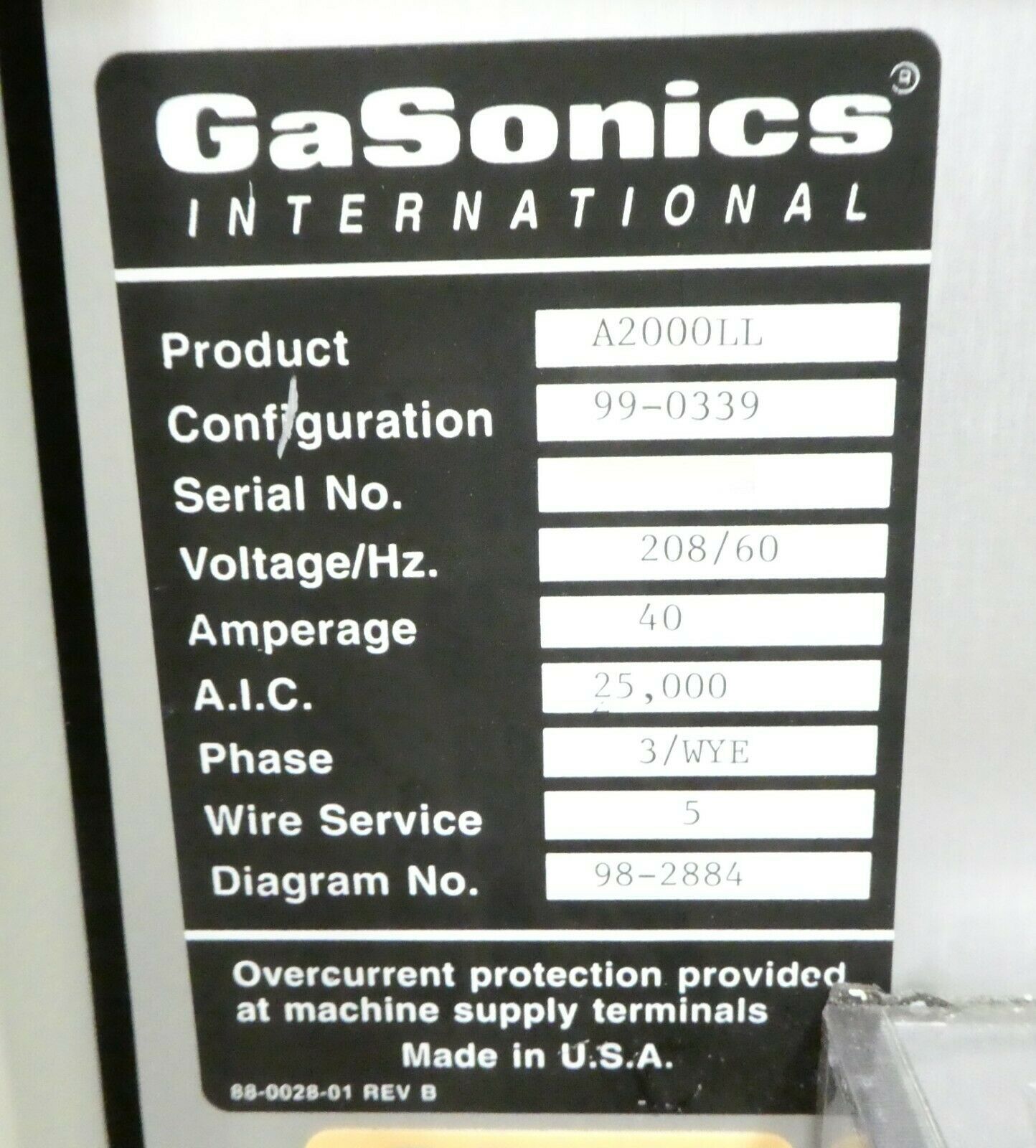

Used GASONICS / NOVELLUS A 2000LL #293595030 for sale

URL successfully copied!

Tap to zoom

ID: 293595030

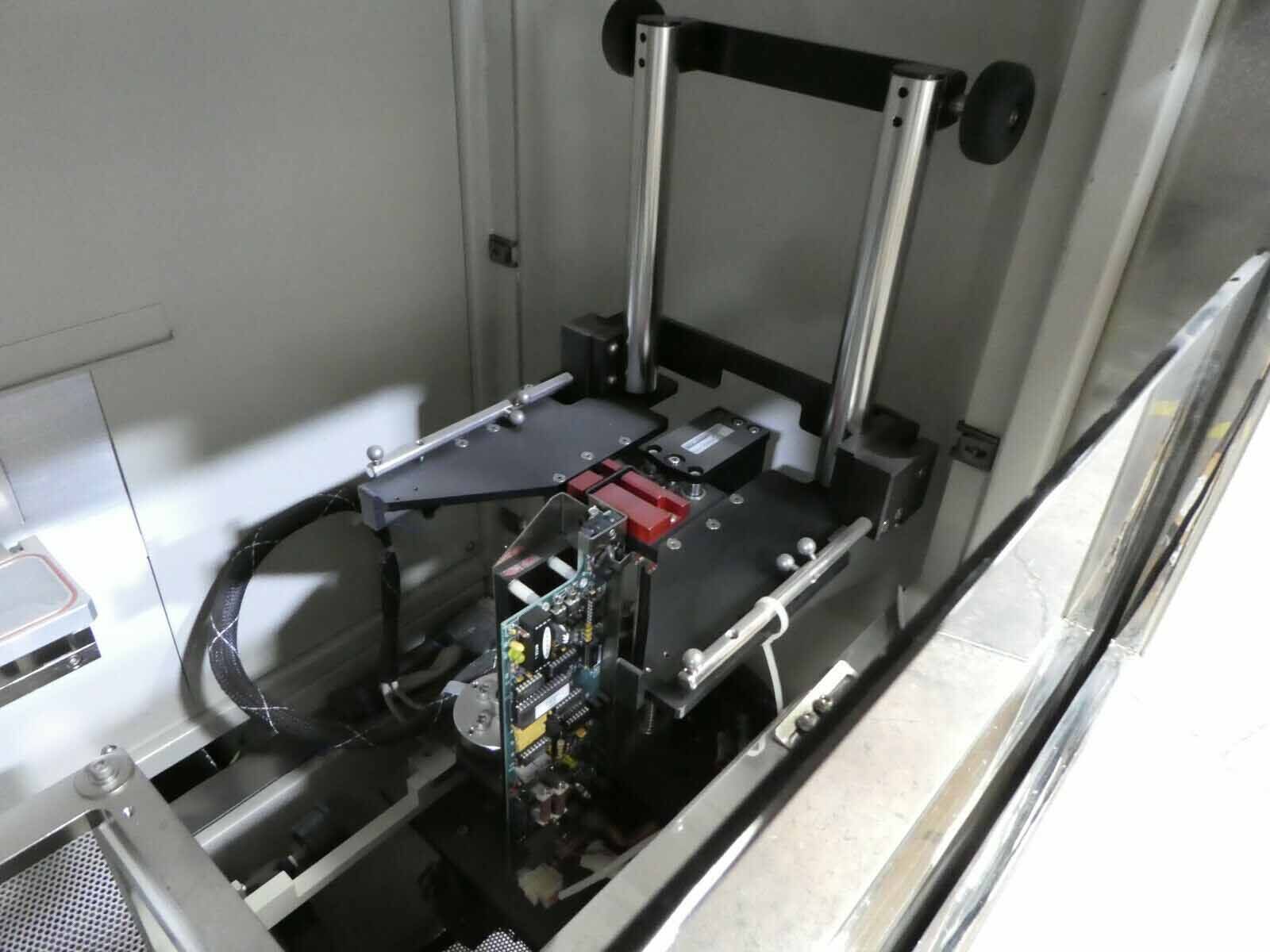

Asher

Part No: 99-0339

Non-copper

Components:

Qty / Make / Model / Description / Part number

(1) / - / - / Load lock chamber / A95-053-02

(1) / GASONICS / 94-1175 / Indexer elevator / 04630-003

(1) / GASONICS / 94-1174 / Indexer elevator / 04630-004

(1) / GASONICS / 94-1118 / Load lock elevators / 04290-201

(1) / GASONICS / 94-1119 / Load lock elevators / 04290-101

(1) / GASONICS / - / Loadlock rear panel display / -

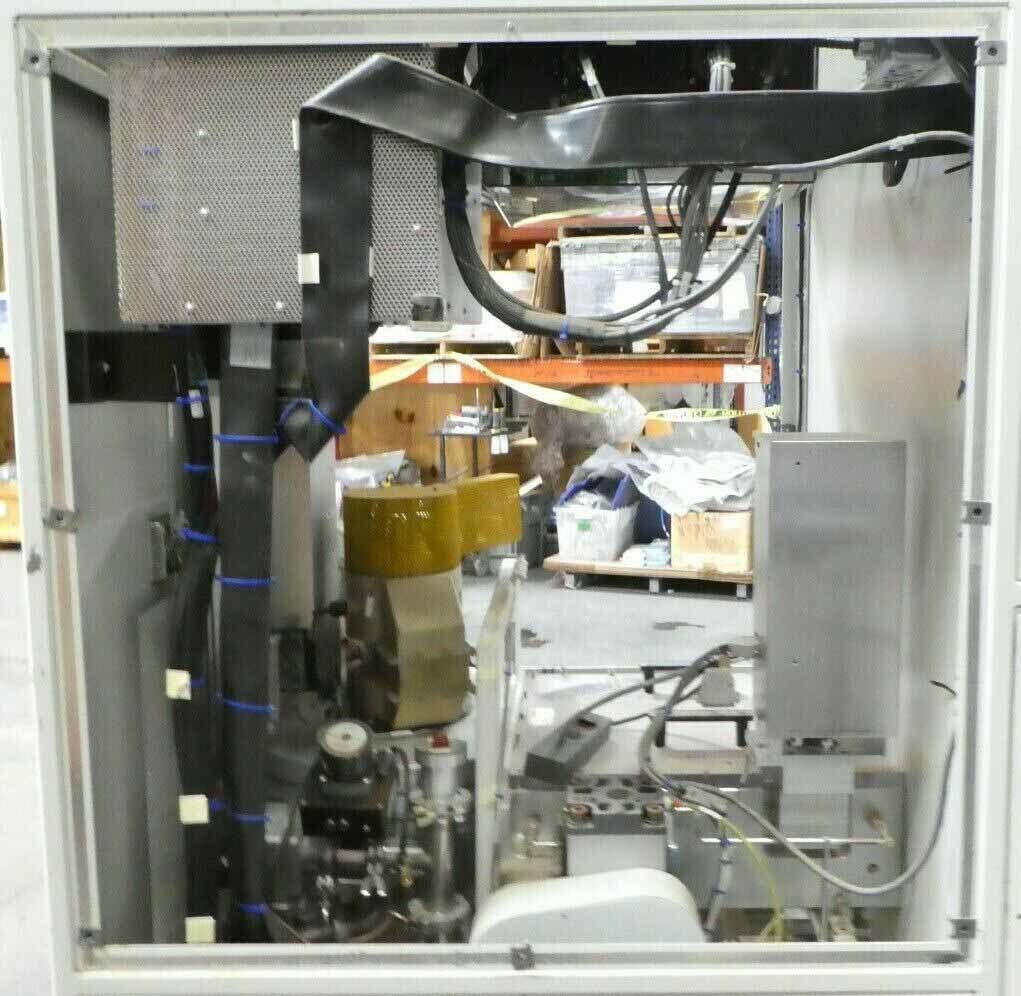

(1) / MKS INSTRUMENTS / Baratron / - / 122AA-00010DB

(1) / MKS INSTRUMENTS / 152 / Pressure controller / 152H-P0

(1) / MKS INSTRUMENTS / - / Valve / 253B-11020

(1) / - / - / HNL Asher module / A93-021-01

(1) / VARIAN / - / Valve / L6281-701

(1) / VARIAN / - / Valve / L6281703

(1) / VARIAN / - / Valve / L6280-302

(1) / OMRON / Sysmac C40H / PLC / C40H-060R-DE-V1

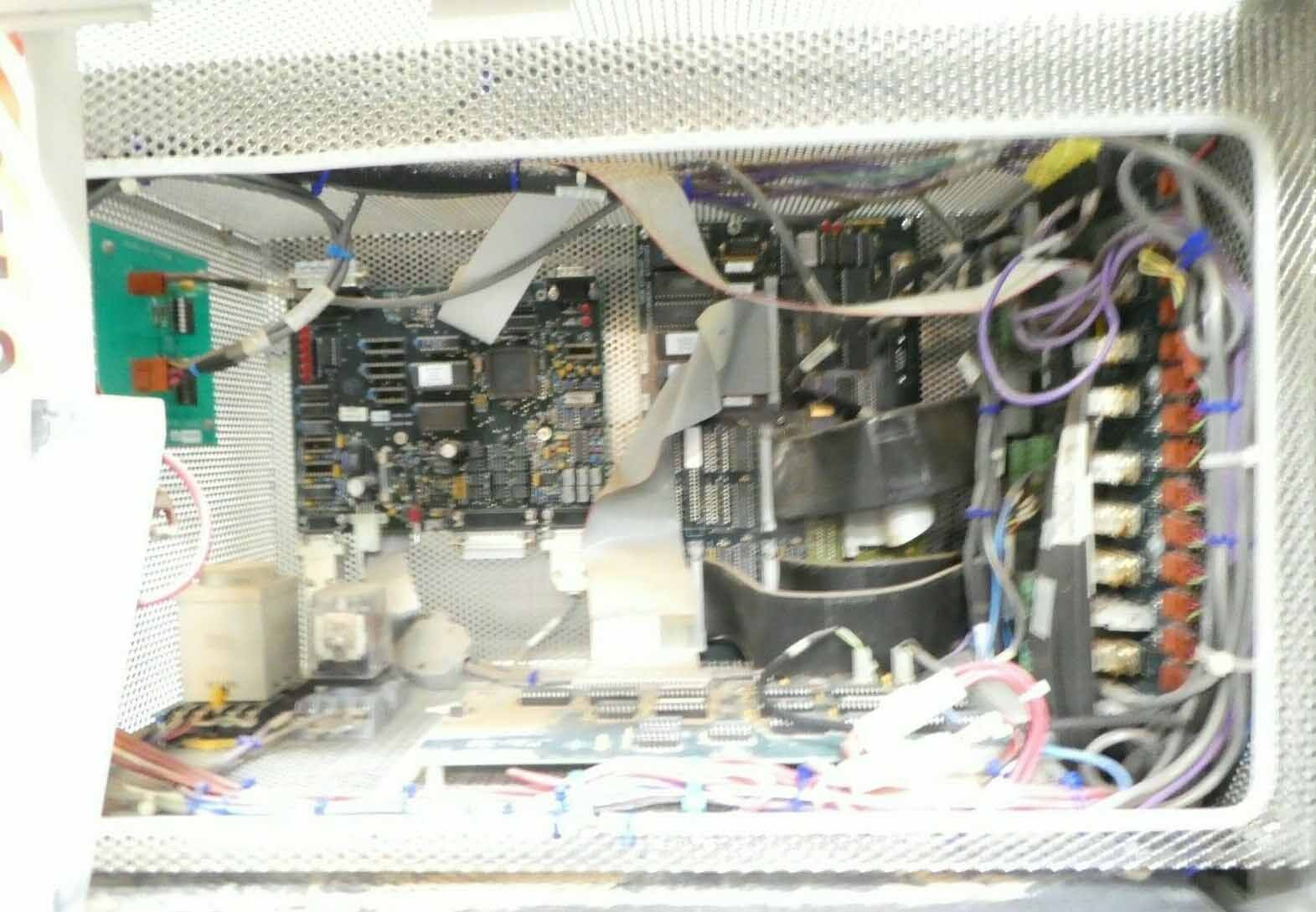

PCB:

Make / Model / Description / Part number

GASONICS / - / Controller board / 90-2658

GASONICS / - / Display decoder / 90-2609

GASONICS / - / Loadlock interface BD / 90-2608

HINE DESIGN / - / ARM Controller board / 02423-001 / 06764-001

NOVELLUS / A2000 / Interlock BD / 90-2735

Wafer handling robot / arm unit missing

CE Marked.

GASONICS / NOVELLUS A 2000LL is a highly advanced etcher/asher designed for research and development use in the semiconductor industry. This device is capable of producing extremely thin layers of material onto a silicon substrate with an accuracy of just one nanometer. It does this by using a chemical etching process combined with physical vapor deposition techniques. This can be used to deposit thin layers of material, such as aluminum oxide or aluminum nitride, onto a bulk material substrate in a controlled manner. GASONICS A 2000LL is equipped with two powerful laser systems, one of which is used to etch the substrate and the other to deposit thin layers onto it. It also has a built-in sensor to monitor the process parameters, so that the user can adjust the pressure, temperature, and other parameters for better results. It provides an extremely clean working environment, and its precision and accuracy are unmatched. NOVELLUS A 2000LL has a beam size of up to 200 microns, and the layers that it produces can be controlled down to thicknesses of 1 nanometers. It is a very fast device, capable of producing up to 2000 wafers per hour. Furthermore, its efficiency and reliability are top-notch, and it requires minimal operator intervention. In conclusion, A 2000LL is a highly advanced etcher/asher designed specifically for research and development use in the semiconductor industry. It is a fast, secure device with excellent accuracy and precision, capable of producing extremely thin layers of material onto a silicon substrate with just one nanometer of accuracy. Its efficiency, reliability, and clean working environment make it an ideal device for research and development applications.

There are no reviews yet