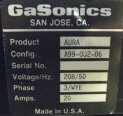

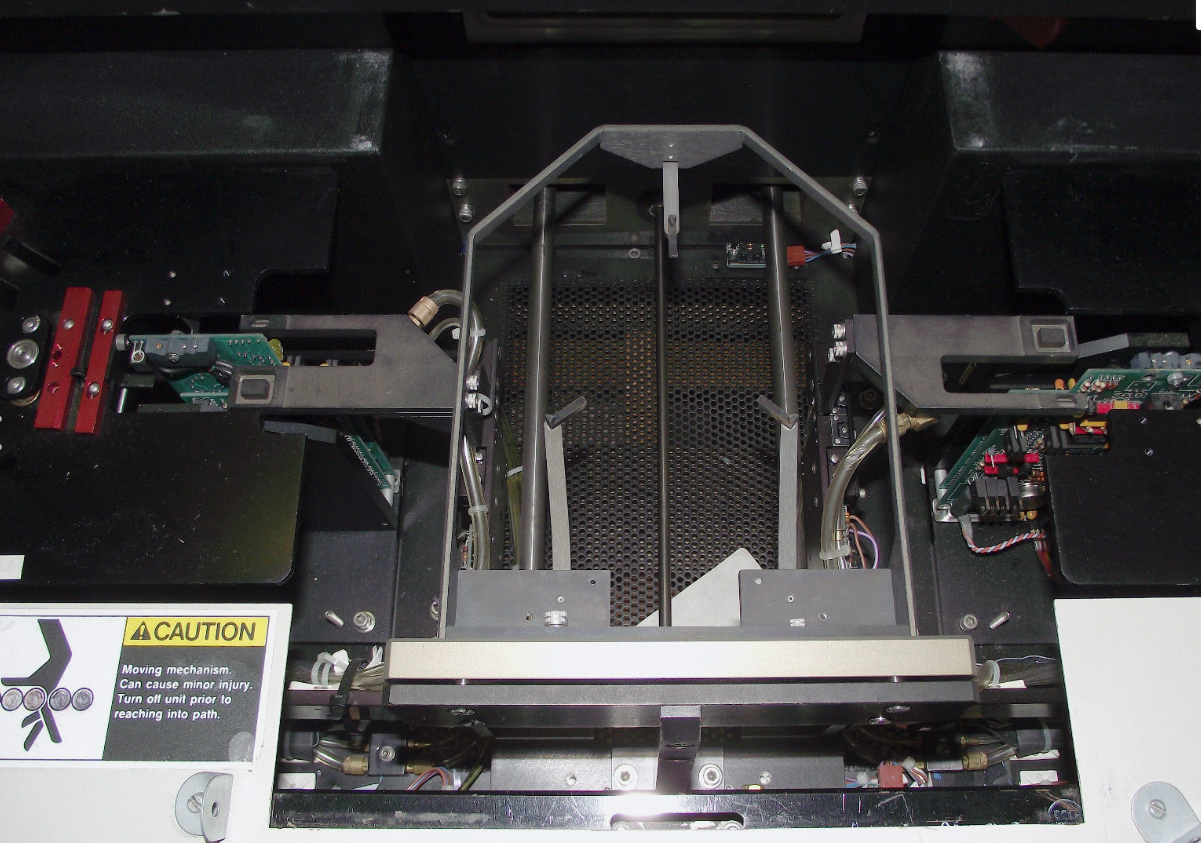

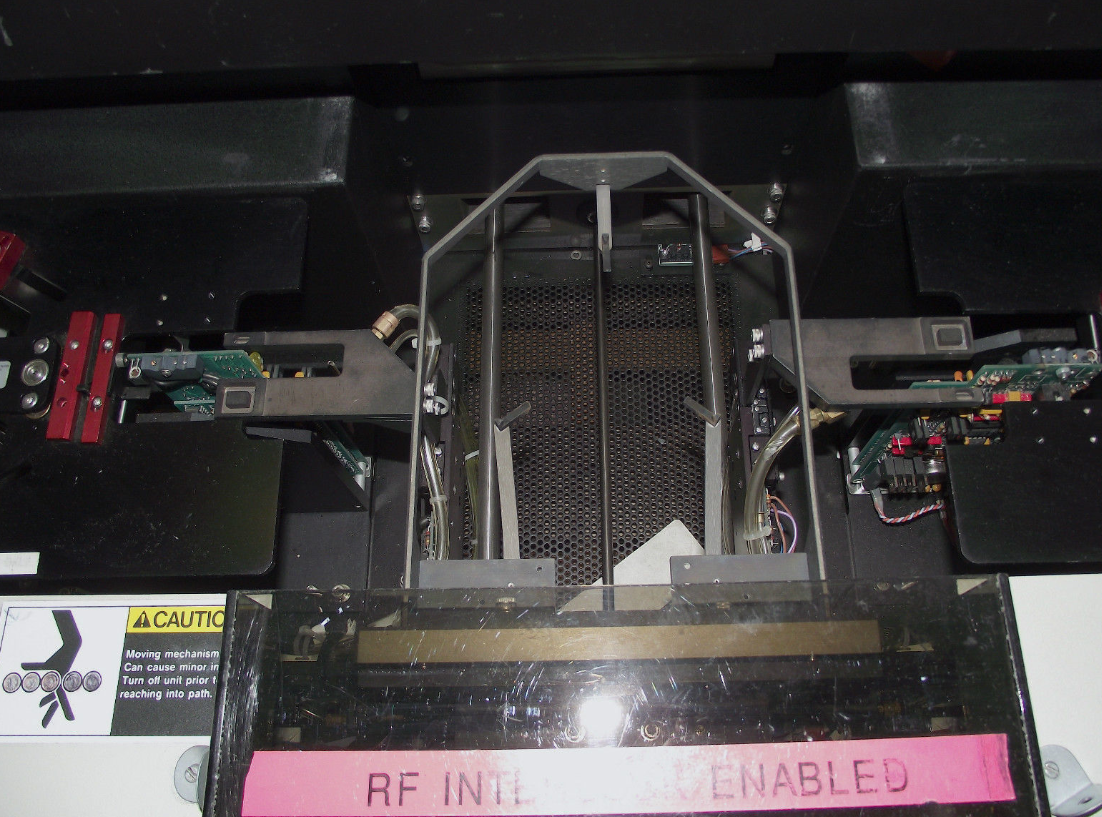

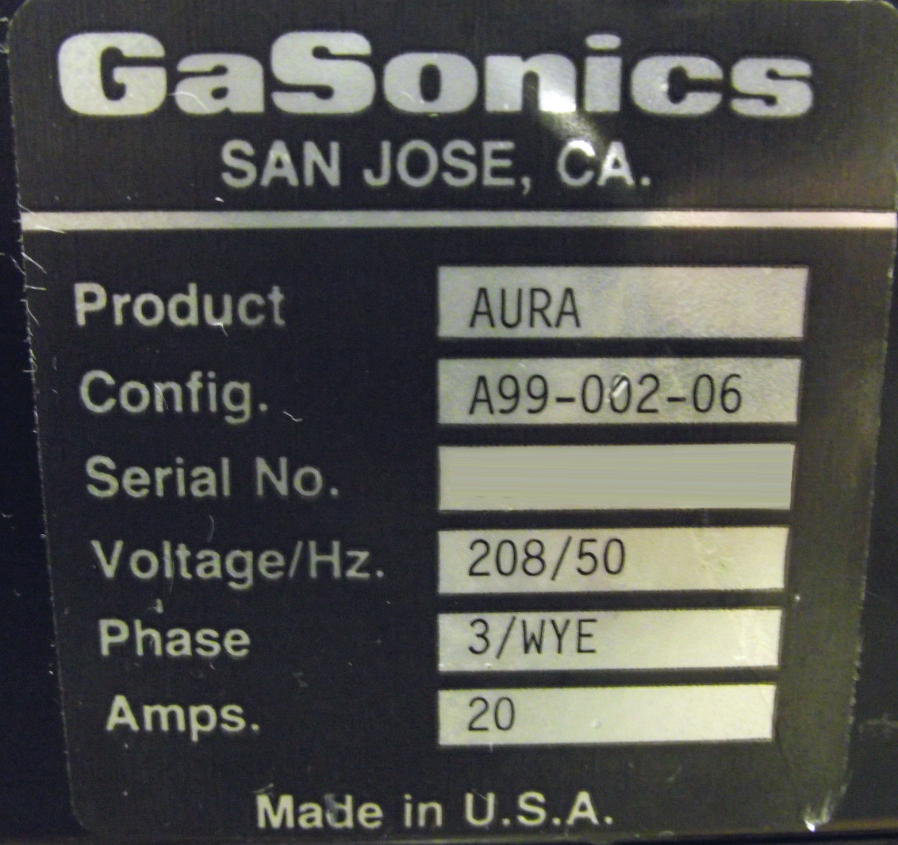

Used GASONICS / NOVELLUS Aura 1000 #9105746 for sale

URL successfully copied!

Tap to zoom

ID: 9105746

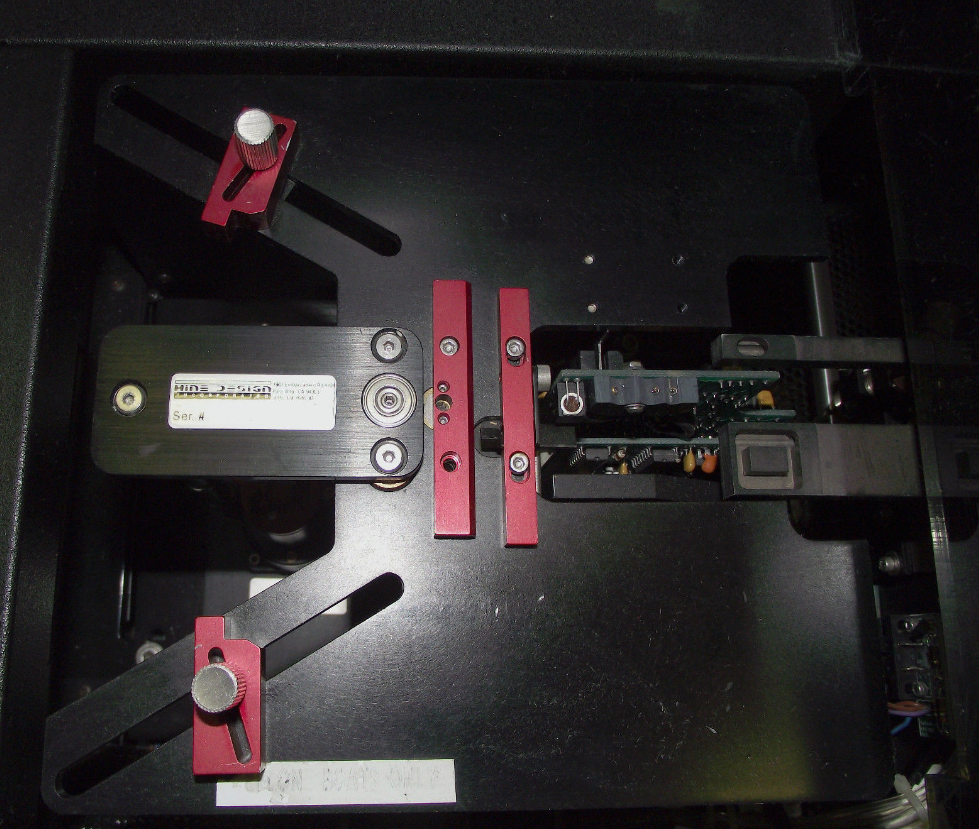

Wafer Size: 4"-6"

Plasma ashers, 4" - 6"

Option available: Dry pumps

208 V, 50 Hz, 20 A, 3Ph.

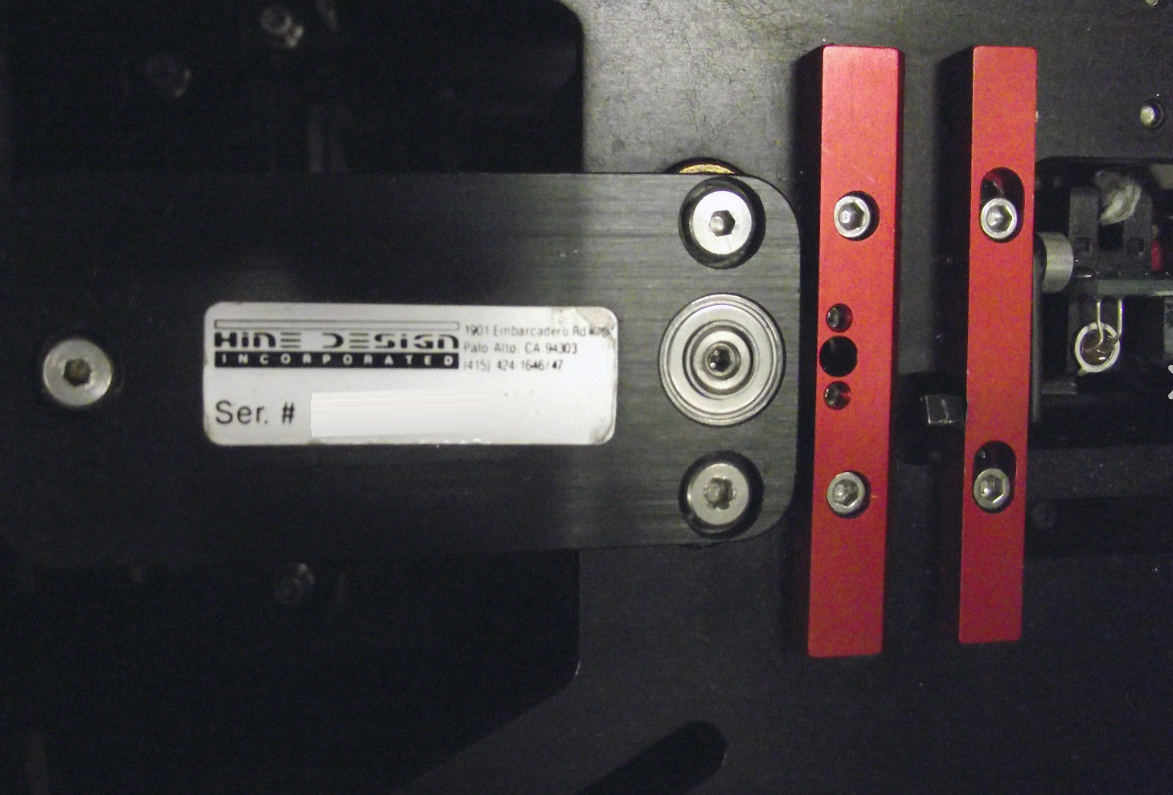

GASONICS / NOVELLUS Aura 1000 is an advanced etcher and asher that combines the established strengths of both GASONICS and NOVELLUS to create a robust, high-throughput tool. Utilizing GASONICS / NOVELLUS low temperature reactive ion etching (RIE) technology, along with GASONICS high temperature process technology, GASONICS Aura 1000 can process a wide range of materials, making it an ideal choice for any research and development, or commercial application. NOVELLUS Aura 1000 can perform etches at a wide range of temperatures (up to 700°C when required), ensuring a quality etch profile and high throughput. NOVELLUS RIE system consists of a low temperature, highly inductive coil and control electronics that allow for precise temperature, pressure and etchant flow control. This helps to ensure a consistent etch profile and process repeatability. Aura 1000 also offers an advanced etch-back capability via GASONICS / NOVELLUS directional microshower RIE. This process enables a precise, directional etch in both vertical and horizontal processes, with high precision and repeatability. For example, backside etching processes can be controlled in order to ensure the required depth, void and feature shape and size. The combination of GASONICS RIE and NOVELLUS directional microshower technology is available in both batch and single-wafer modes, making it an ideal tool for both research and production processes requiring directional etching. GASONICS / NOVELLUS Aura 1000 is a plug-and-play tool with an open platform that makes it highly configurable. A wide range of accessories and options are also available to make customizing the system to your workflow needs a breeze. It is designed to take advantage of both GASONICS / NOVELLUS and GASONICS leading technology and can grow with your applications. GASONICS Aura 1000 is a reliable and trusted etcher and asher that combines the best of both worlds. The advanced etch-back capability, highly precise temperature and pressure control, combined with robust high-throughput capabilities, make this a go-to tool for scientists and engineers seeking a versatile and efficient process solution.

There are no reviews yet