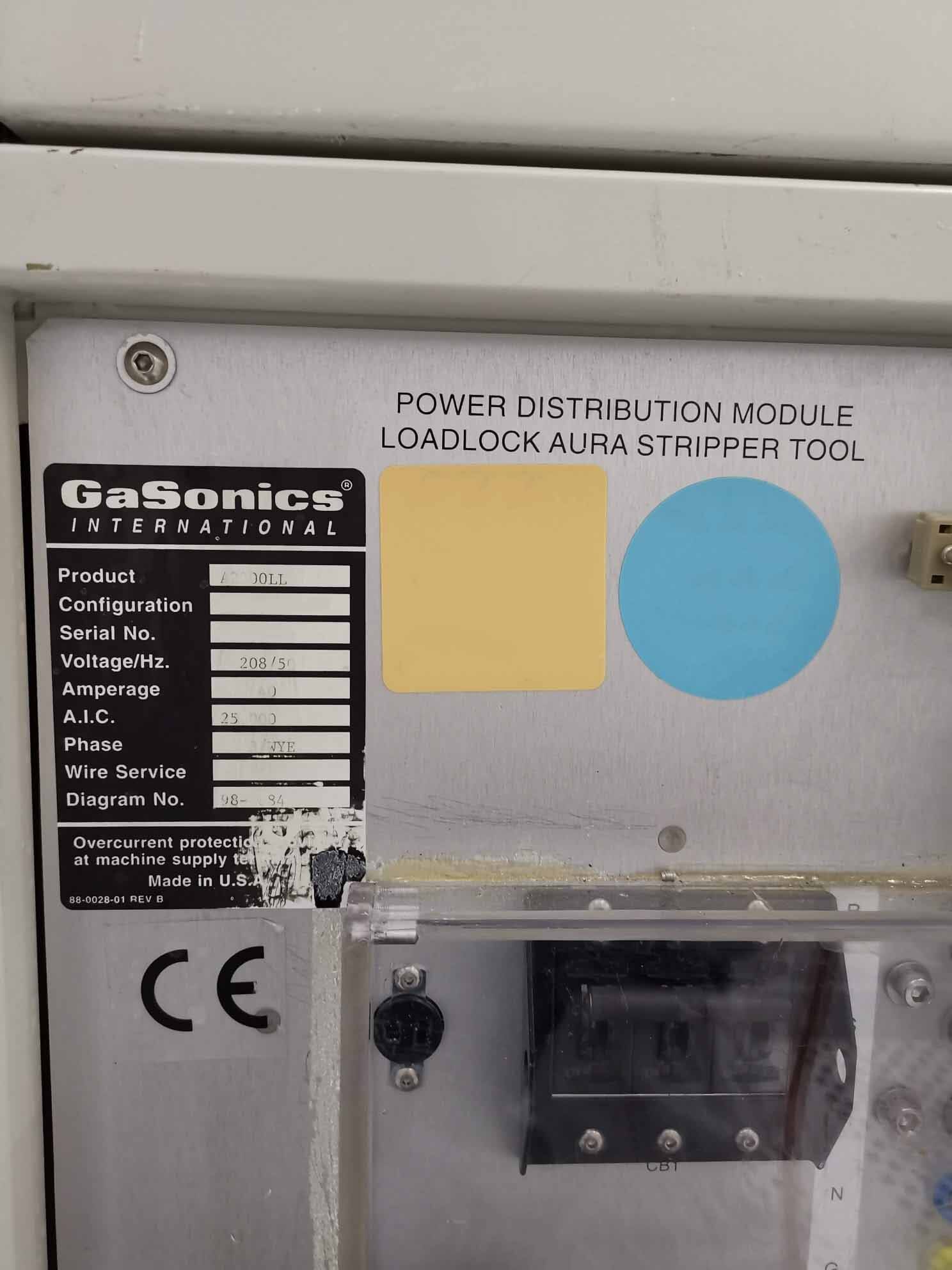

Used GASONICS / NOVELLUS Aura 2000 #293654416 for sale

URL successfully copied!

Tap to zoom

ID: 293654416

Wafer Size: 8"

Asher, 8"

806 Process photo stripper

Single chamber type

Operate aluminium material

PLC Controller.

GASONICS / NOVELLUS Aura 2000 is an etcher and asher used in the semiconductor manufacturing industry. Its unique physical design is ideal for use in tight and crowded process lines, since it has a smaller footprint than many of its competitors. The machine features advanced optics, image sensing and enhanced robotic controls that allow the equipment to significantly increase processing yields. Additionally, it features a wide range of automated functions, including the loading and unloading of wafers, gas delivery and depostion, as well as wafer alignment and patterning. This unique combination of efficient design and reliable processing makes GASONICS Aura 2000 an ideal choice for semiconductor fabrication. The machine is designed with a special, fast-track laser image scanning (FLIS) system that is capable of quickly and accurately detecting the desired patternings on the wafer. This unit enables an extremely high etching precision rate and allows for a much higher degree of process flexibility. Additionally, the optical multiplexer allows the machine to perform up to eight concurrent etching tasks, increasing its throughput and maximizing the machine's capabilities. Depending on the desired etching parameters, the machine can be used for a wide variety of process types, including line width scaling, metal patterning, metal layer deposition and custom design patterning. In terms of gas and deposition delivery, NOVELLUS Aura 2000 is equipped with a five-valve gas delivery tool that enables the asset to effectively handle up to 15 gases simultaneously. This model includes a gas delivery station, which includes an auto purge unit and a gas control station, which allows technicians to control the gas flows and balances remotely. The machine also features a completely automated handler equipment that helps increase throughput and reduce manual labor costs. Moreover, the system is capable of placing pre-defined etch layers on the wafer in no time, thanks to its advanced robotic controls. Furthermore, Aura 2000 is designed with several safety features. It includes a dual-pressure filtration unit that helps to purify the gases before they enter the chamber, as well as laser safety interlocks and multiple safeguards to prevent accidents from happening due to the use of hazardous materials. Additionally, the machine has both electrical and cathode ray protection for added safety. In sum, no matter the application, GASONICS / NOVELLUS Aura 2000 is the ideal choice for efficient, reliable, and safe etching and ashing.

There are no reviews yet