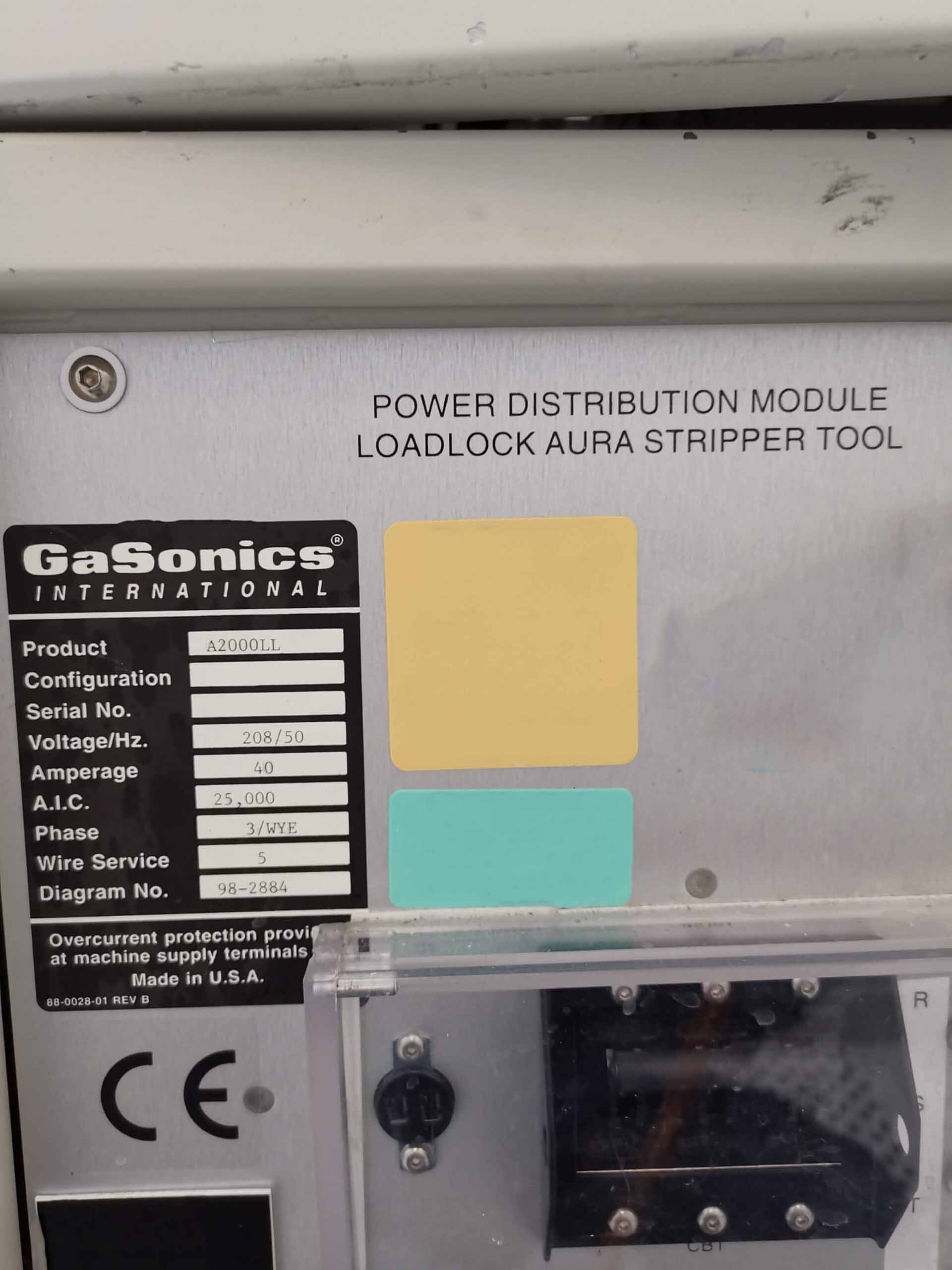

Used GASONICS / NOVELLUS Aura 2000 #293654417 for sale

URL successfully copied!

Tap to zoom

ID: 293654417

Wafer Size: 8"

Ashers, 8"

Operate aluminium material

806 Process photo stripper

Single chamber type

PLC Controller.

GASONICS / NOVELLUS Aura 2000 is a light and deep reactive-ion etching/asher equipment used in the fabrication of integrated circuits. It is used to create, modify and optimize the geometries of metalization layers, contacts and vias, other metal or semiconductor structures and metal lines. It is an advanced tool for ultra-fine processing of metal lines and patterns, with great accuracy and dimensional control over the metal structures. The system employs a high-speed vaporizer to convert a liquid metal solution into a vapor that is delivered to the substrate surface. The vaporized metal particles are deposited in a finely controlled fashion and a built-in pre-clean function helps to optimize the photoresist adhesion and minimize the probability of consequential contaminations. Once the metal layers are formed, the substrate is placed in the plasma reactor, where the reactive ion etching process can be optimized by adjustable parameters such as the pressure, the power and dwell time. GASONICS Aura 2000 boasts superior uniformity and selectivity, making it a perfect choice for "tapered" processing, which allows for both thick and thin metal lines to be etched in the same pattern. It also allows for the etching of transparent insulation materials that enable multi-layer metalization in three-dimensional objects. The unit is powered by GASONICS TM 10X operating platform which provides flexible process recipes and integrated data logging, offering operators great control of the process and detailed evaluation of the obtained structures. It also includes a 16" LCD monitor for convenient control and monitoring of the machine. NOVELLUS Aura 2000 is well known for its superior etching results and cleanliness. Its robust construction ensures reliable operation and stability even at the very high temperatures used in the reactive-ion etching process. Its extremely low maintenance and emission rates make it one of the most environmentally friendly etching systems available.

There are no reviews yet