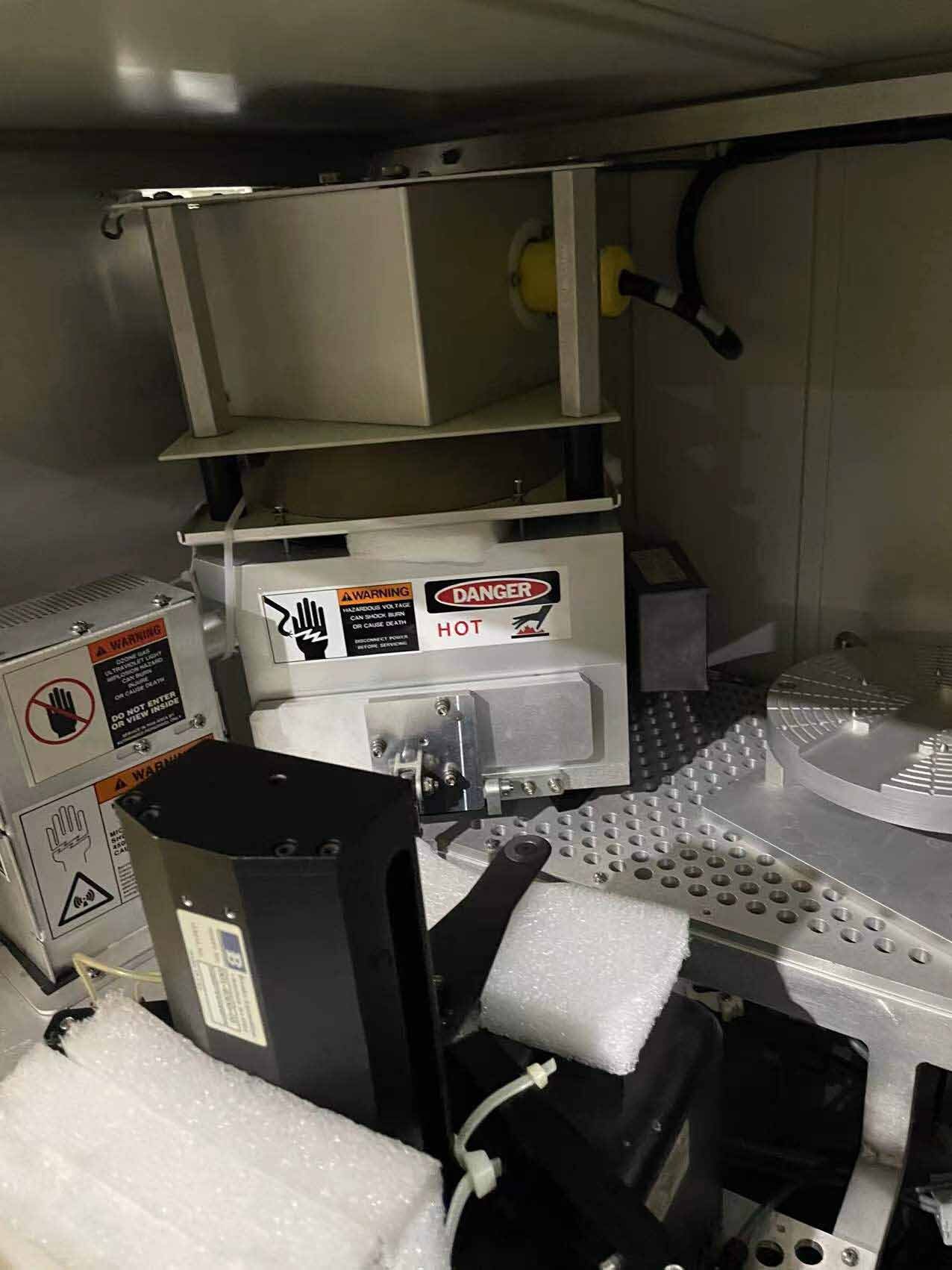

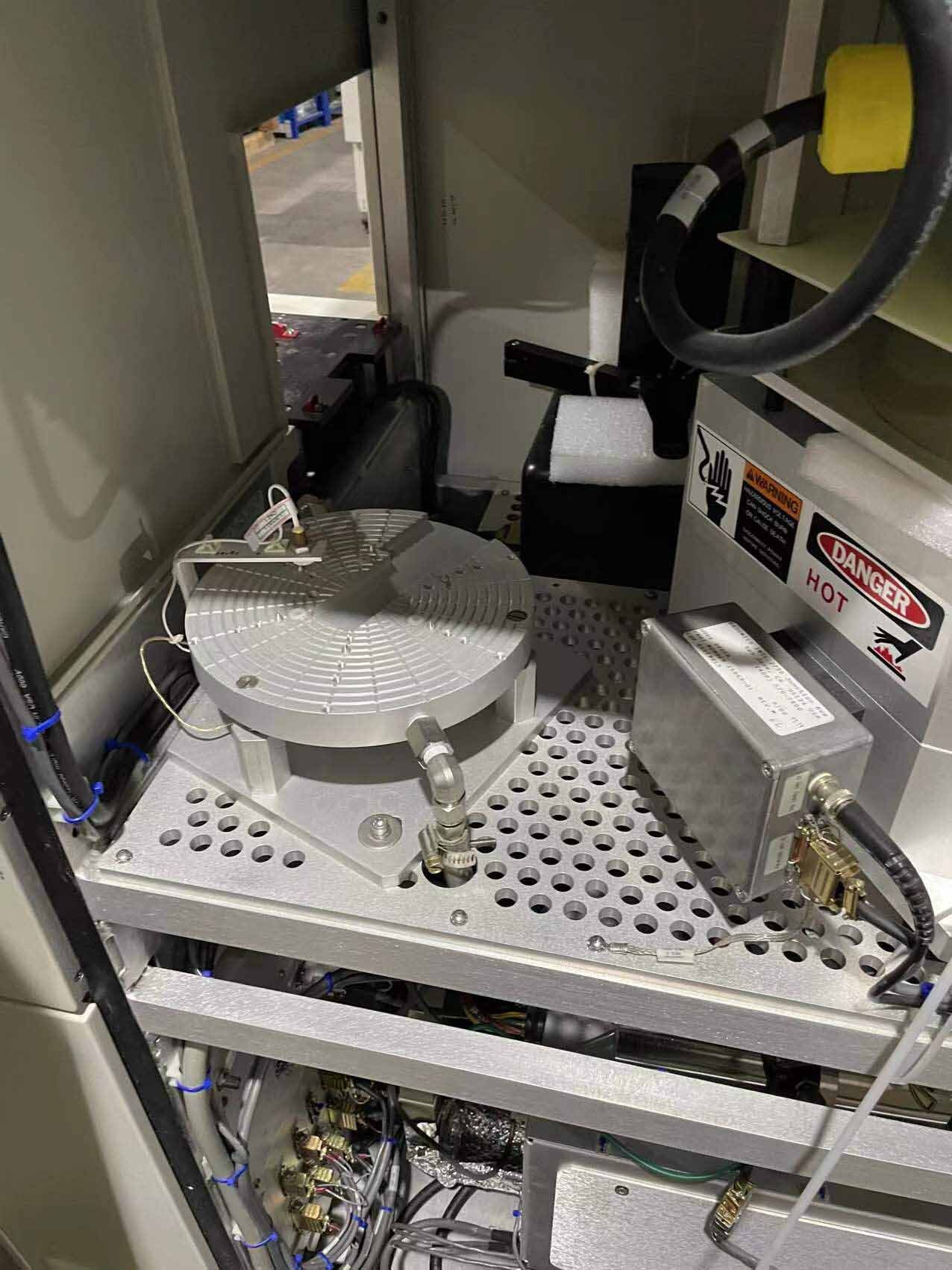

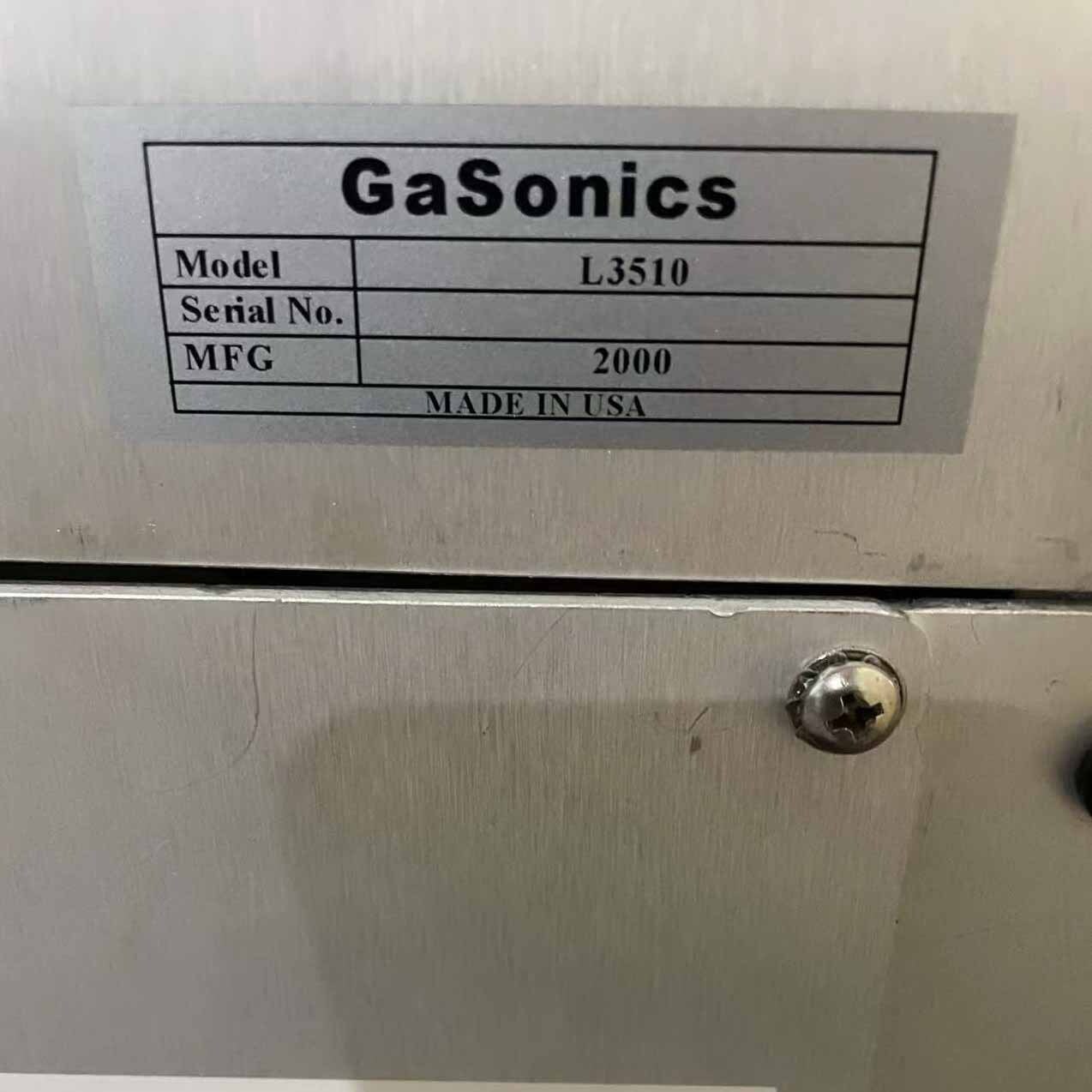

Used GASONICS / NOVELLUS L 3510 #9411534 for sale

URL successfully copied!

Tap to zoom

ID: 9411534

Vintage: 2000

Asher

Photoresist strip

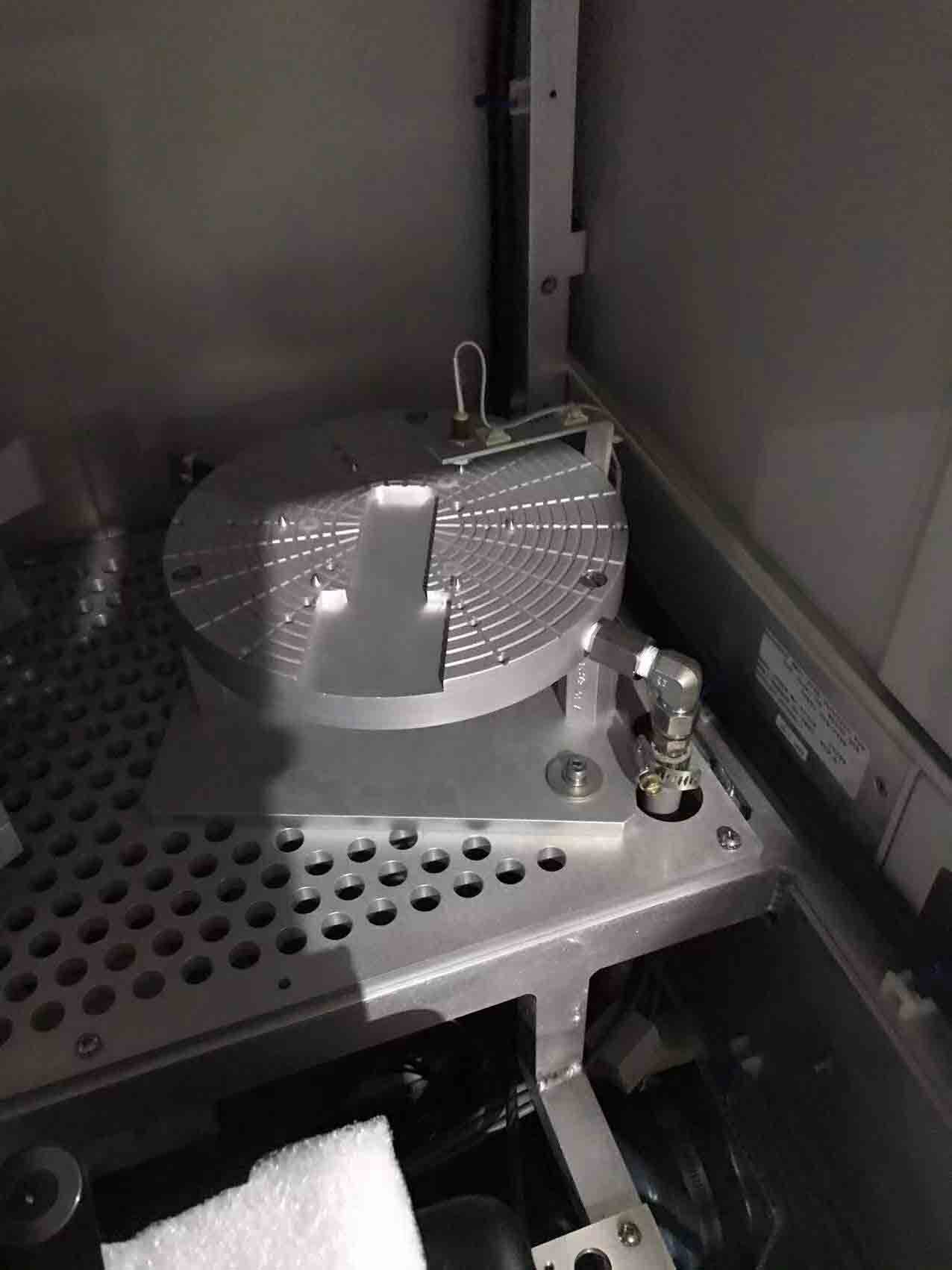

Substrate size: 3"-8"

Footprint: 30"

Main frame:

Aluminum chamber

Quartz chamber

Wafer cooling station with PCW

Platen and lamp heating (Flexibility)

Reliable endpoint detection

Z-Bot station (Robot)

Load cassettes elevator

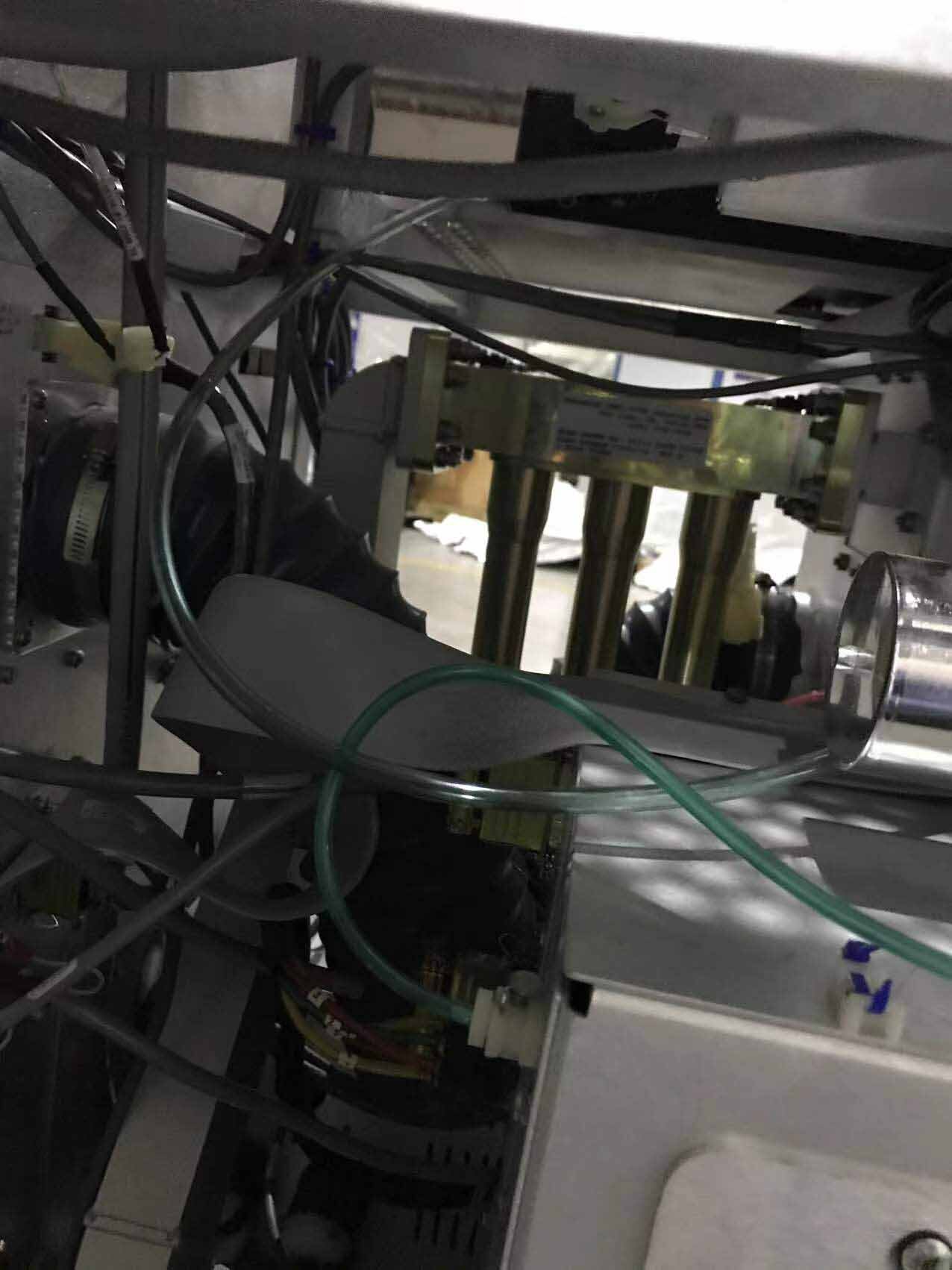

DC Power supply: -5, +5, -12, +12 VDC

(2) DC Power supplies: +5, -15, +15, +24 VDC

I/O Board

Distribution board

Display board

Graphics control board

Hard Disk Drive (HDD)

Floppy Disk Drive (FDD), 3.5"

Microwave generator: 2.45 GHz, 1250 W

Interlock wafer transport

Microwave power supply

Gas flow controller

Visual alarm indicator lamp

Quartz gas distribution shower heads

Radiant heating plate

UV Lamp

End point detection

Plasma system controller

Tolerance limit alarm (pressure, flow, lamps)

Gas handling module and control features

(3) Gas lines with purge:

O2 MFC

(2) N2 MFC

Stainless steel valves gas line

Solenoid control: 24 VDC

Soft pump to limit chamber turbulence

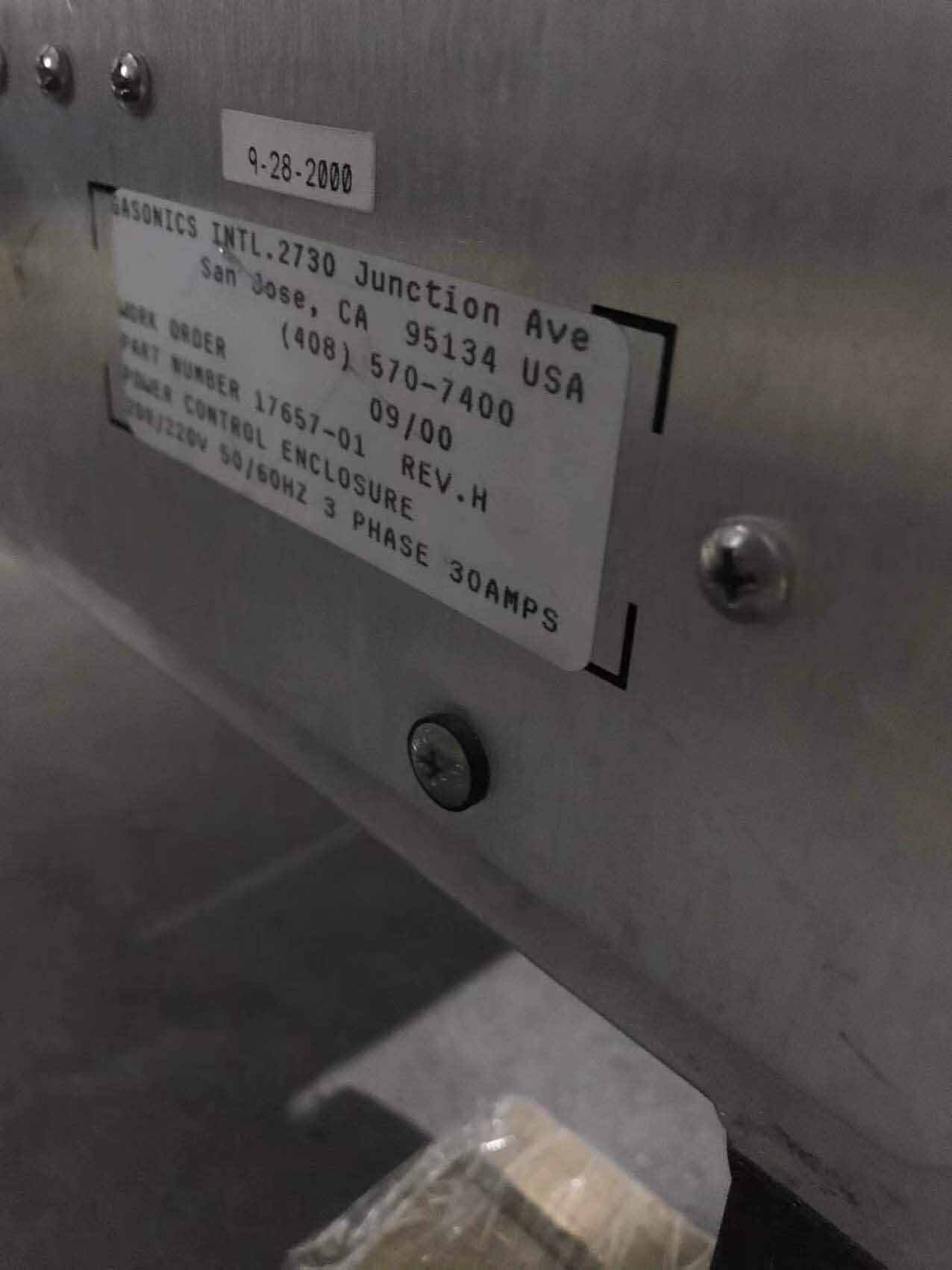

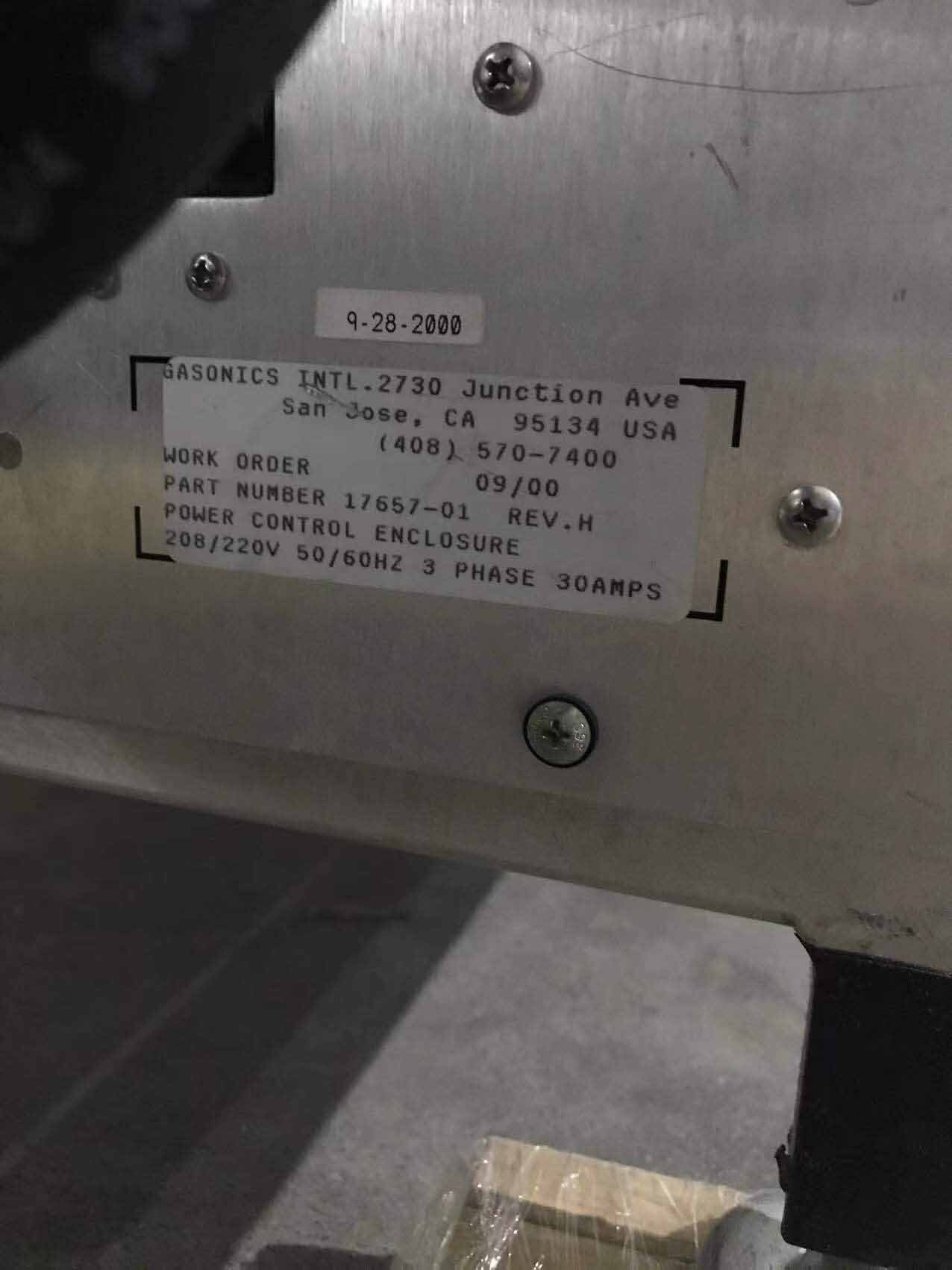

AC Power box

Circuit breaker: 30 Amp

Remote option connector

EMO Control to master system

Circuit breaker

Magnetron

Schematic display driver

Process kits

Panel included

Manuals included

Power supply: 200-240 VAC, 50/60 Hz, Single phase, 30 A

2000 vintage.

GASONICS / NOVELLUS L 3510 is a state-of-the-art etcher/asher equipment designed to provide maximized throughput and total process control in production environments. The system is a self-integrated platform, featuring high-end laser control and software solutions to identify, measure, and modify etch and asher parameters according to specific needs. The innovative features and performance of GASONICS L 3510 Etcher/Asher are unmatched. Laser-based technology ensures maximum accuracy and precision in the fabrication of even the most intricate of devices. Furthermore, the unit is compatible with various substrate materials and various technologies, ranging from thin-film formulations and advanced dielectric layers to etching and ashing of optical materials such as sapphire and silicon oxide. NOVELLUS L 3510 is built on a robust, industrial-grade platform, making it suitable for demanding production cycles. Its large, 15-inch deck allows for quick disconnections and modular add-ons, so the machine can quickly evolve to match changing production requirements. The tool also comes equipped with monolithic linear resonant actuators that minimize drift over large batches of substrates, ensuring evenly distributed results and maintaining consistent etch parameters. The asset's software platform itself is designed to make every aspect of etching easier. The user interface allows for total control over the entire process, including the step-by-step response of the laser and simultaneous control of multiple resonators. Additionally, the software allows for individualized process monitoring, configuration control, and external feedback for quick and precise process adjustments. Overall, L 3510 Etcher/Asher is a best-in-class model that guarantees reliable, repeatable results in a wide range of production processes. The high-precision laser control, integrated hardware platform, and comprehensive software suite ensure the utmost accuracy and control for demanding etch and ashing operations.

There are no reviews yet