Used HITACHI M 308 #9271719 for sale

URL successfully copied!

Tap to zoom

ID: 9271719

Metal etcher

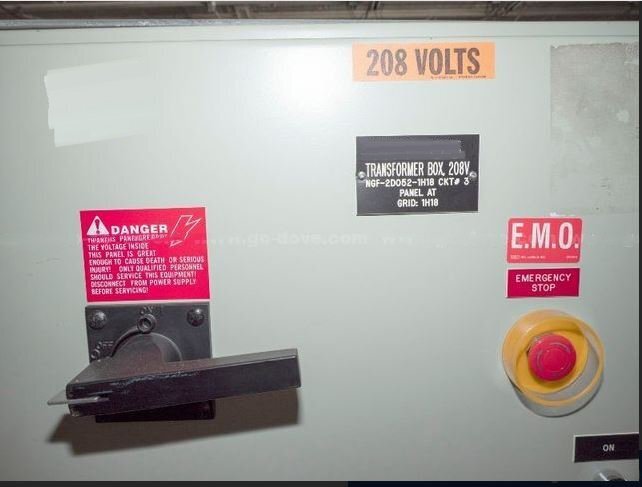

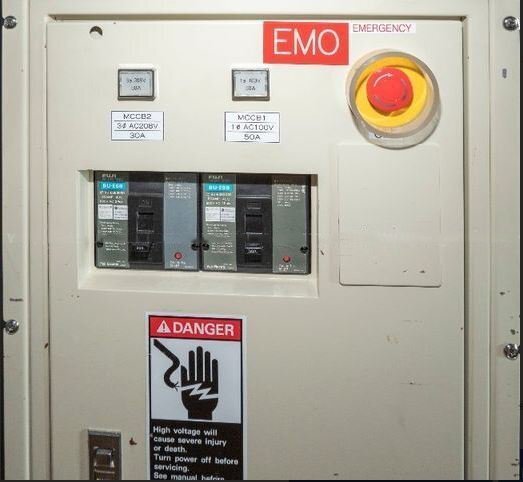

Transformer box

RF Generator

Remote console

SHIMADZU Power source

Microwave generator

Cooling pump

Stainless steel doors

Spare parts.

HITACHI M 308 etcher / asher is a high performance etching and ashing equipment that is designed specifically for use in semiconductor device development and production. It is equipped with the latest in automated process control and monitoring systems, and is highly reliable and efficient. The system is a fully integrated etching and ashing unit that is able to handle a wide range of substrates, such as silicon wafers, gallium arsenide substrates, and other substrates. It is capable of both etching and ashing operations from a single platform, with high throughput and excellent surface uniformity. The machine is equipped with advanced precision equipment, including a high-precision etching and ashing chamber, gas circulator/shower chamber, and substrate wafer carousel tool. The etching chamber and circulator/shower chamber feature an Automatic Gas Supply (AGS) asset, which allows the user to control the gas supply in a very precise manner. The etcher/aser model also features a sophisticated substrate tracking equipment, which automatically checks the status of the substrate during etching and ashing processes, and reports any abnormalities or errors. The system's temperature control unit ensures that the desired etch and ashing temperatures are maintained throughout the process, while the gas delivery machine enables the user to select the desired vacuum level, which can be used to control the etching rate. The tool is also equipped with an advanced image processing asset, which can be used to analyze and evaluate substrates before and after the etching and ashing processes. This feature allows users to optimize the rate of etching and ashing for each specific substrate material. HITACHI M-308 is a reliable, efficient, and highly automated model that is capable of handling a wide range of substrate materials. Its automated process control and monitoring systems make it easy to use and highly reliable, while its advanced features and flexible substrate handling equipment make it the perfect choice for semiconductor device fabrication.

There are no reviews yet