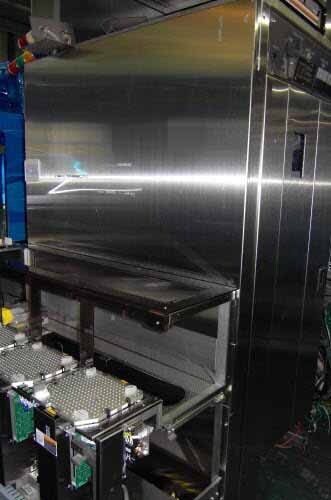

Used HITACHI M 501AWE #9133882 for sale

URL successfully copied!

Tap to zoom

ID: 9133882

Wafer Size: 8"

Vintage: 1997

Plasma etching system, 8"

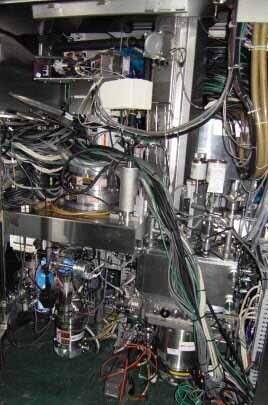

System configuration:

2-Metal etching

1-Ashing CH

Etching CH gases: O2, CH4/Ar, CL2, BCl3, Ar, CH2F2, H2

Ashing CH gases: O2, CH3OH

Gas Jungle Information :

Cl2: STEC7440, 200SCCM

BCl3: STEC7440, 200SCCM

N2: STEC7440, 50SCCM

SF6: STEC7440, 50SCCM

O2: STEC7440, 200SCCM

Ar: STEC7440, 300SCCM

CHF3: STEC7440, 100SCCM

CH4: STEC7440, 200SCCM

HW unit :

PC Rack

Transfer box

Main body

Power supply unit

Temp control unit

Chiller

1997 vintage.

HITACHI M 501AWE is an industrial etcher and asher designed for use in high-temperature and/or high-pressure applications. This etcher/asher uses a four-stage etching process to create a precise and durable finish on most metals, including aluminum and stainless steel. The result is a highly detailed and long-lasting product. M 501AWE is constructed using the highest-grade components and welded stainless steel frame. Its robust construction helps to withstand high temperatures and high pressures, and its well-designed safety features ensure that it can be operated safely in a variety of settings. The etcher/asher also features a wide range of variable controls for precise and cost-effective operation. HITACHI M 501AWE utilizes a four-stage etching process which begins with abrasive blasting to roughen the surface of the work piece. It then uses acid etching to etch away the unwanted material. The third step is a chemical bonder to promote adhesion before the material is finished with an etchant or asher. The etcher/asher is equipped with an onboard air compressor for convenience and the ability to etch most metals, including aluminum and stainless steel. The air compressor allows fast, consistent etching and pressure. The unit also includes a digital timer, allowing the user to set the length of time of the etching or ashing process. Of course, M 501AWE also comes with a wide range of accessories. These include protective shields and sputtering shields to protect the machine, etching gun nozzles to shoot etch solution onto the workpiece, and many others. With these accessories, the etcher/asher can be plastic, ceramic, and glass components. HITACHI M 501AWE includes additional safety features, such as a safety interlock switch, thermal overload protection, and anti-static covers for the air compressor. It also includes an adjustable temperature control to ensure precision and consistency of the etching process. M 501AWE is a versatile and reliable etcher/asher capable of performing both etching and ashing processes with precision and reliability. Its robust construction, wide range of variable controls, and comprehensive safety features make it an excellent choice for use in high-temperature and/or high-pressure applications.

There are no reviews yet