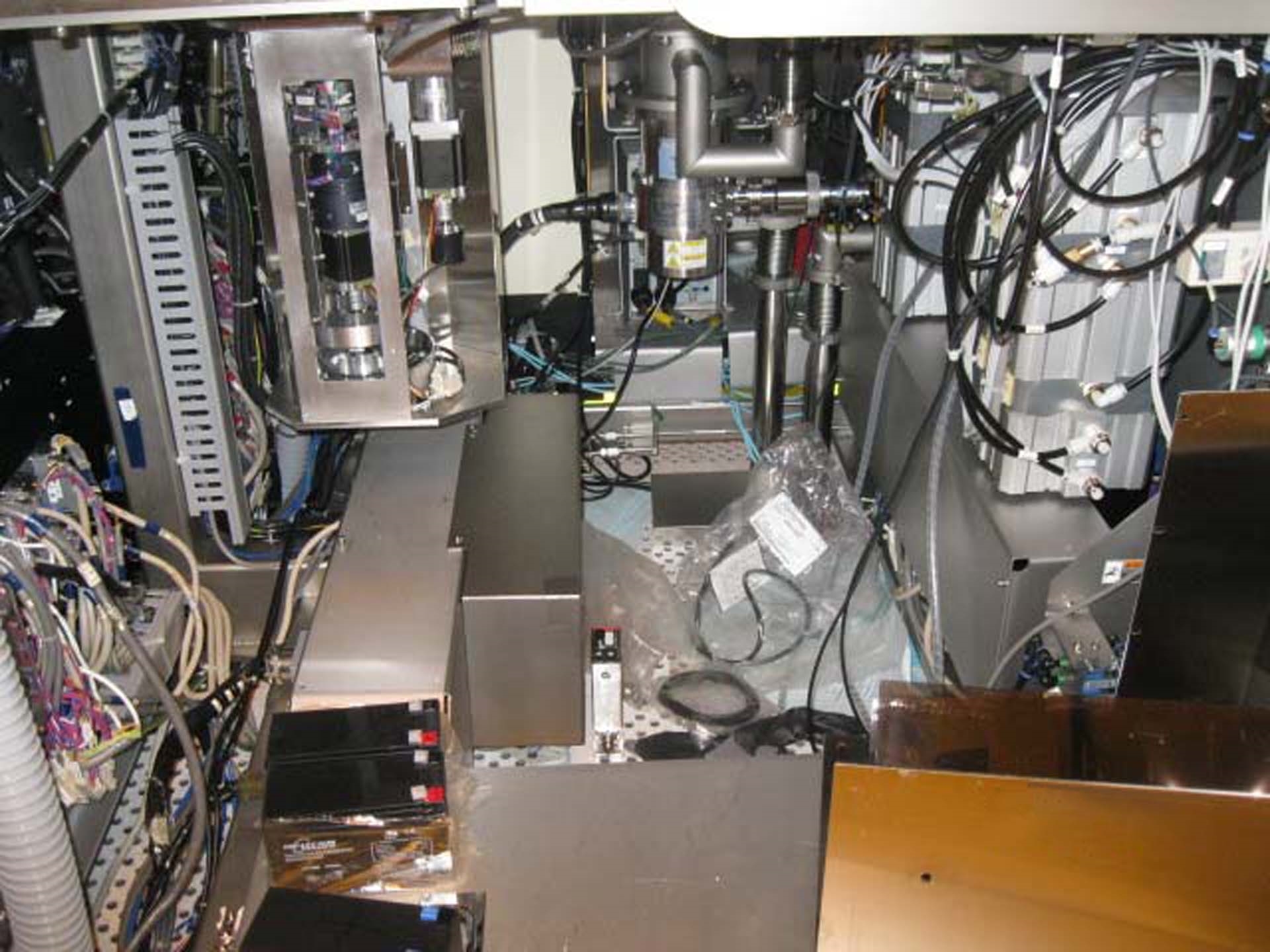

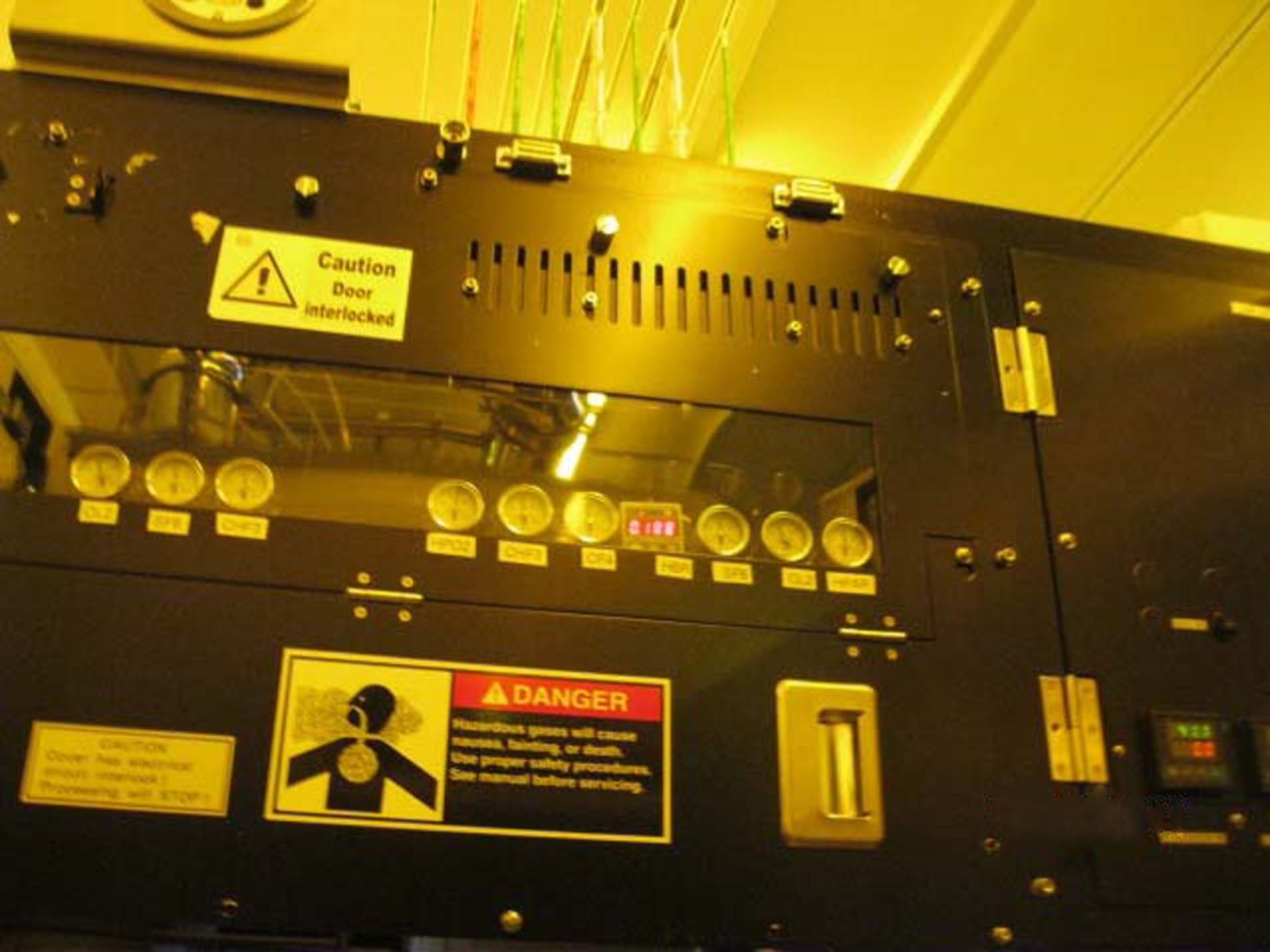

Used HITACHI M 712 #9242176 for sale

URL successfully copied!

Tap to zoom

ID: 9242176

Wafer Size: 8"

Etcher, 8"

(3) Cassettes / FOUP Positions

SECS II Interface: HSMS

(2) EDWARDS iQDP80 Loadlock pumps

(2) EDWARDS iQDP80 Chamber pumps

(2) SMC INR-497-001 Chillers

2-Channels cooling

Power supply: 208 VAC, 3-Phase, 50/60 Hz

Mainframe:

Robot

P/N: CR-712V

HITACHI FOUP Loader

Chamber:

ESC Type: Bipolar

Endpoint type: PMT/ OES

SHIMAZU EC TMP

3203LMC-K1 EC TMP Controller

DAIHEN ES7-IIA EC Source generator

PEARL CF-500-400K EC Bias generator

Gas configuration:

Line / EC1 / EC2

1 / Ar 500 / Ar 500

2 / C12 300 / C12 300

3 / SF6 200 / SF6 200

4 / HBr 200 / HBr 200

5 / CF4 150 / CF4 150

6 / CHF 3200 / CHF3 200

7 / O2 30 / O2 30

8 / CHF3 50 / CHF3 50

9 / SF6 50 / SF6 50

10 / C12 30 / C12 30

2006 vintage.

HITACHI M 712 is an etcher/ashor designed for microelectronic device fabrication. It is an advanced etching and ashing ( dry-etch) technology that can be used for etching of any material, including metals, non-metals, oxides and polymers. The equipment is a combined plasma-based etching and ashing process, and is equipped with a low-temperature chemical dry etching (LTCDE) and ashing chamber in which vaporized elements react with the substrate. The system is capable of processing a variety of substrates including glass, quartz, and polyimide. It also contains a high-power generator, a turbo-molecular pumping unit and a low-temperature chemical dry etching chamber. M 712 etching and ashing process is a two-step process in which the etching and ashing conditions are separately controlled. During the etching process, a flow of high temperature argon plasma is applied over the substrate to etch the substrate surface. The ashing process follows the etching process and the plasma is replaced by a neutral hydrogen ashing agent. The temperature of the ashing agent is adjustable to ensure optimum etching and ashing results. The machine also includes a controller with a remote terminal to fine-tune the parameters for desired etching and ashing results. HITACHI M 712 has a maximum etching depth of 5000 nanometers (5 microns), a minimum etching depth of 500 nanometers (0.5 microns) and a maximum etching rate of 1 micron/minute, allowing for precise etching and ashing. The tool is also capable of a maximum throughput of 200 wafers in 45 minutes. Additionally, the asset includes advanced process control software to ensure accuracy and repeatability. In addition to etching and ashing, M 712 also offers the ability to utilize add-on modules such as a thermal oxide film deposition model, a resist strip, an etch stop and a backside cleaning process. The equipment also has the capacity to etch both sides of substrates simultaneously. These add-on modules offer high process repeatability and flexibility. Overall, HITACHI M7 12 is an advanced etching and ashing system designed for microelectronic device fabrication. Its advanced process control software and add-on modules allow for precise and repeatable processing of a variety of substrates. Additionally, its low-temperature etching and ashing process allows for greater control over etch depth, rate, and through-put, providing a versatile and efficient etching and ashing solution.

There are no reviews yet