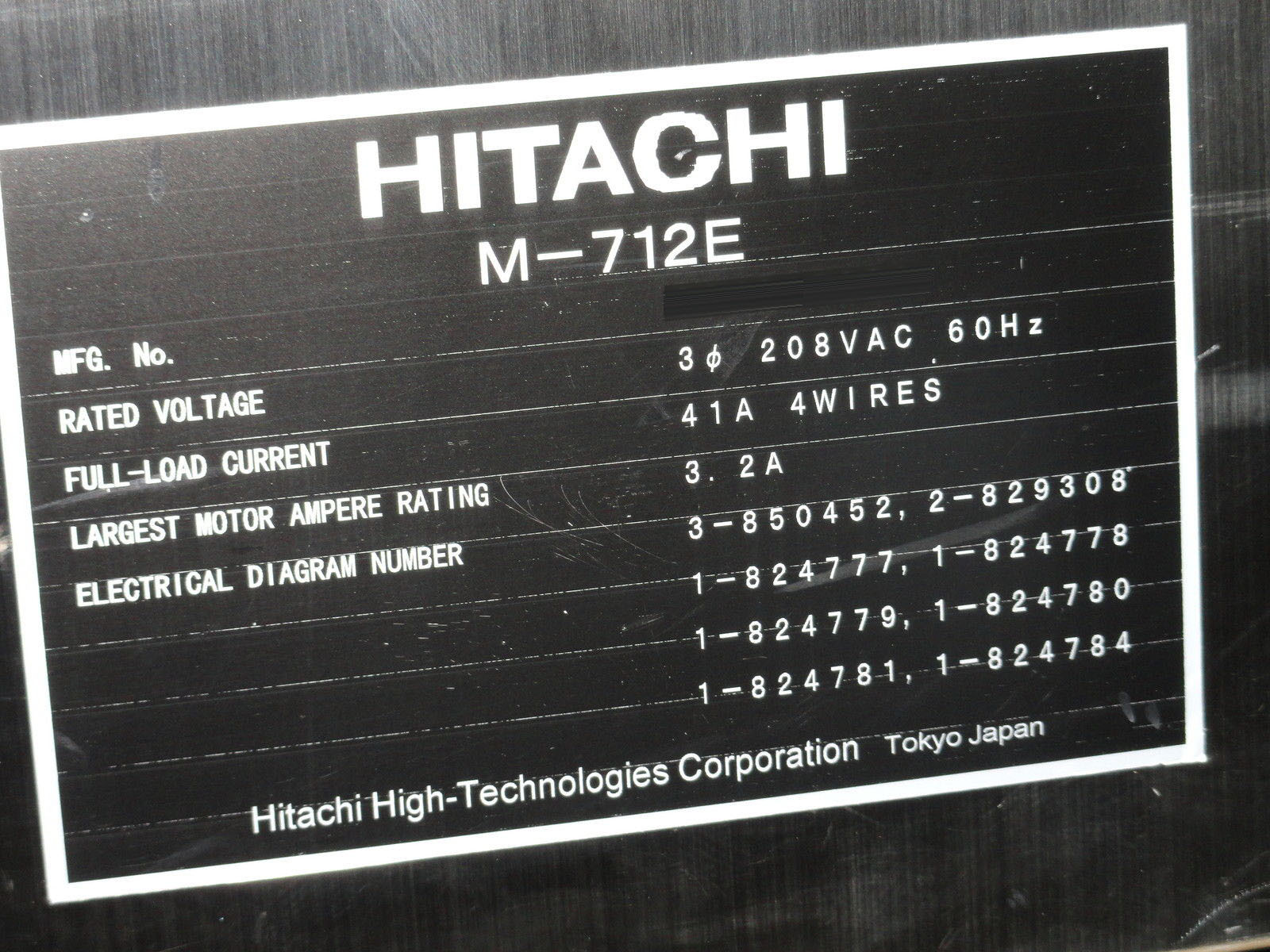

Used HITACHI M 712E #9105848 for sale

URL successfully copied!

Tap to zoom

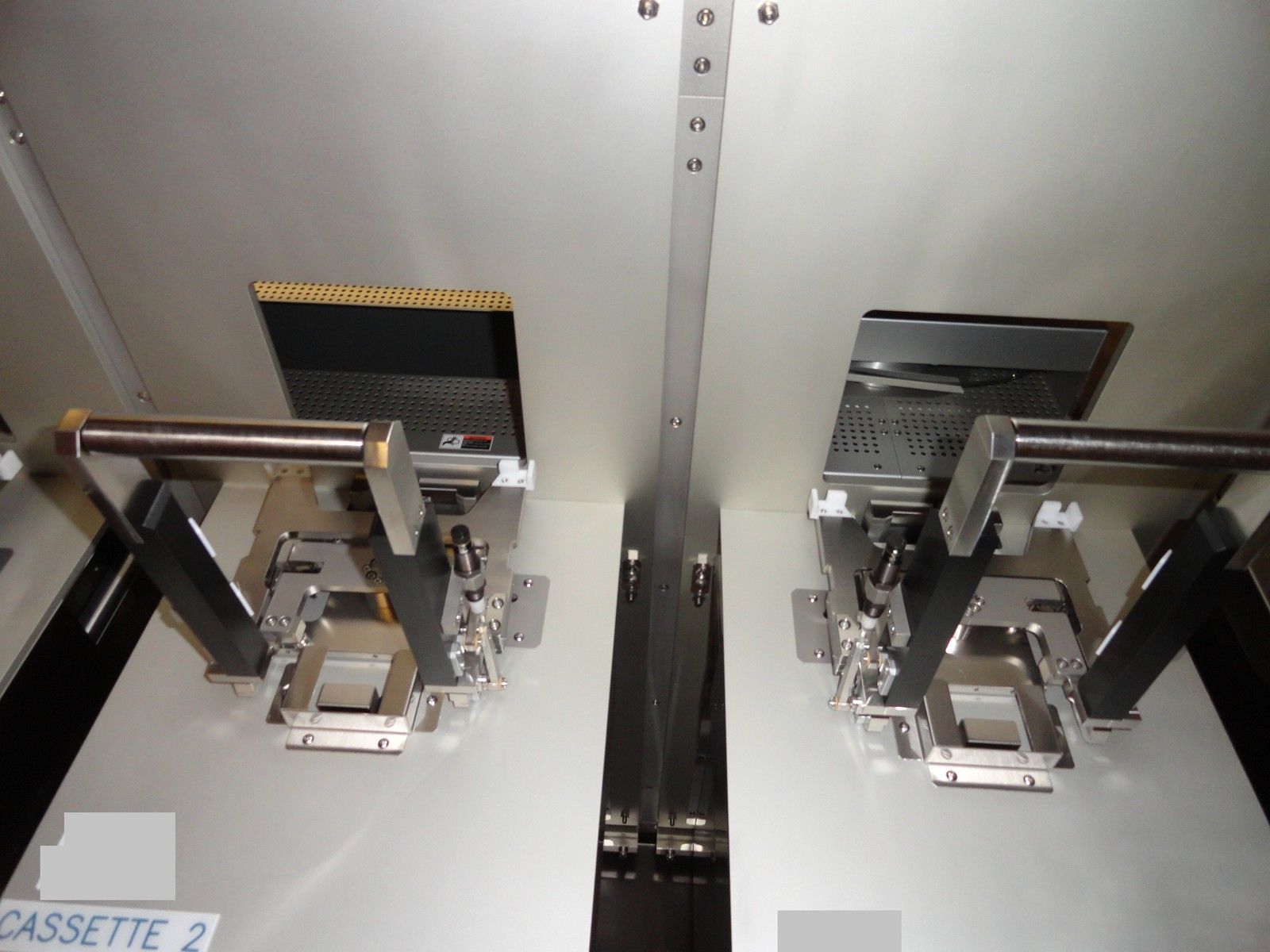

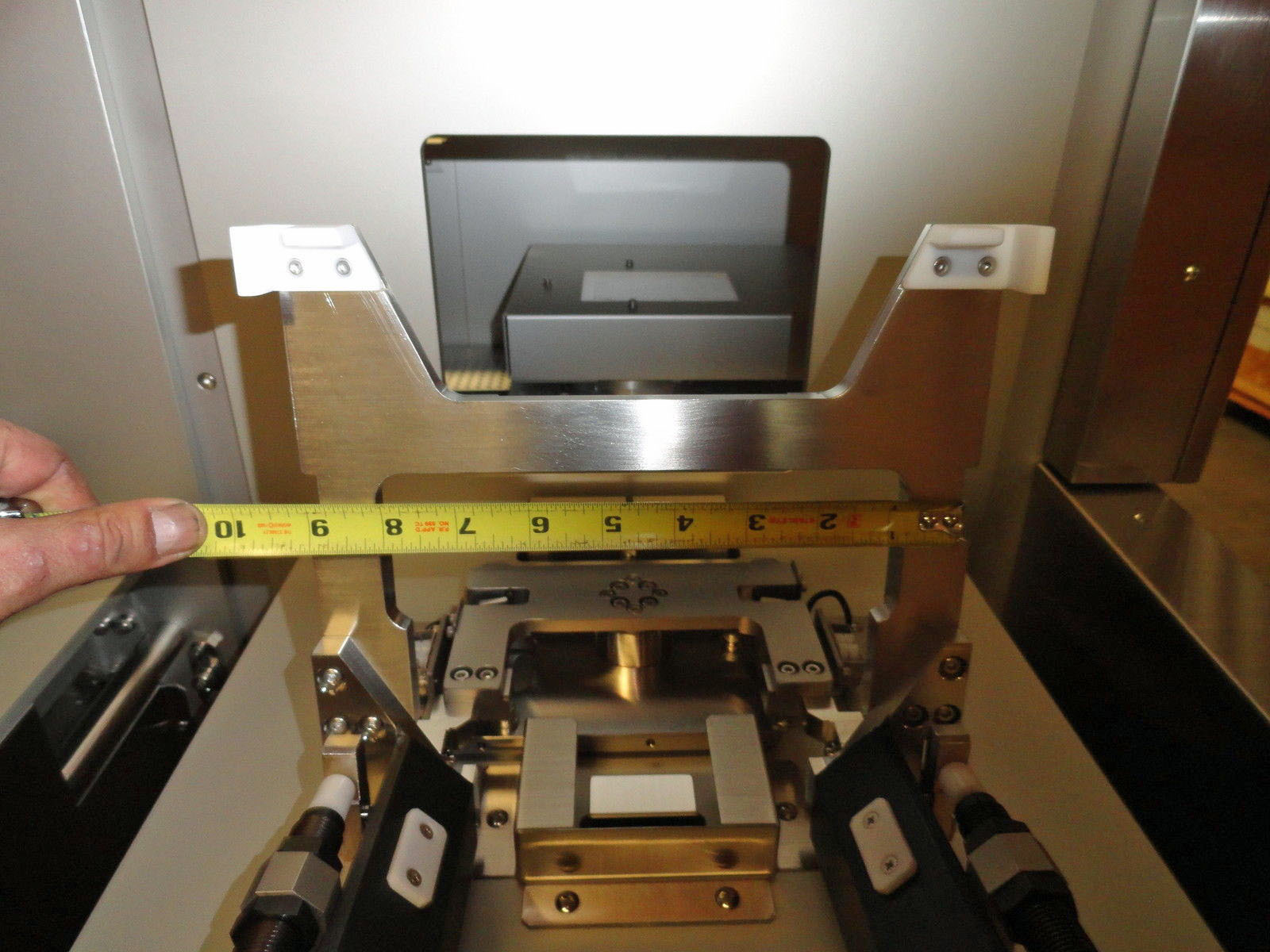

HITACHI M 712E etcher / asher is a high precision instrument used for sample treatment prior to analysis and deposition. This etcher / asher is designed for etching or ashing of small or large sample areas with high accuracy, efficiency, and safety. The etching / ashing process is utilized to remove contaminants from the material surface or to modify surface properties and prepare the sample for analysis. It features a maintenance-free, fully computer controlled operation that enables real-time monitoring of the etching / ashing process and feedback control system for optimal results. The unit is equipped with an all-in-one design that integrates all related components into a single compact device. It is composed of a precision sample chamber, sample heater, vacuum pump, and etch / Ash nozzle. The chamber is constructed from high grade stainless steel and includes a stainless steel lining for gas-tight sealing and superior thermal insulation. An adjustable sample holder is included for holding the sample in place while the process is being carried out. The sample is heated at precise temperatures to initiate the etching / ashing process. The vacuum pump is used to evacuate the chamber, removing gas-phase reaction products and creating a low-pressure environment that helps to prevent reaction products from adsorbing onto the sample surface. The etching / ashing process is activated by switching on the etch / ash nozzle to create a focused ion stream at atmospheric pressure. The high velocity, focused ion streams help to etch or ash the material surface. The etch / ash nozzle can be adjusted to enhance the efficiency of the etching / ashing process and reduce reaction times. Depending on the sample, a gas flow can also be used in conjunction with the etch / ash nozzle or as an independent etching / ashing process. HITACHI M712E etcher / asher is suitable for a wide variety of applications including high throughput research, semiconductor and microelectronic device fabrication, and surface conditioning for medical device manufacturing. The device is designed to operate at elevated temperatures up to 200 ℃ with a maximum pressure of 1 Torr and a maximum etch / ash rate of 10 nm/min. With its intuitive and easy-to-use interface, M 712E offers high reliability and performance for etching and ashing applications. It is designed for optimal user safety and efficiency and provides reliable operations with low maintenance requirements.

There are no reviews yet