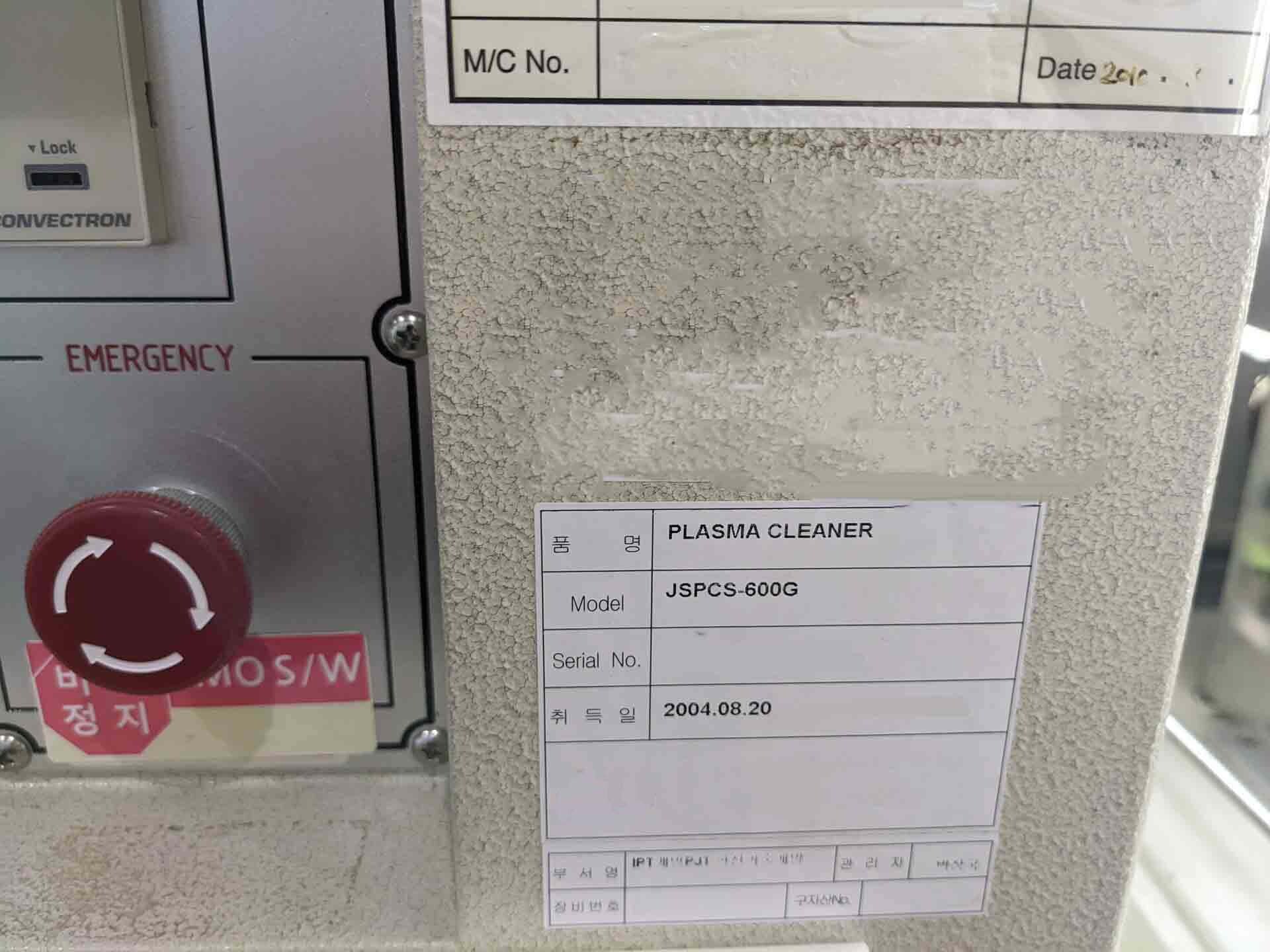

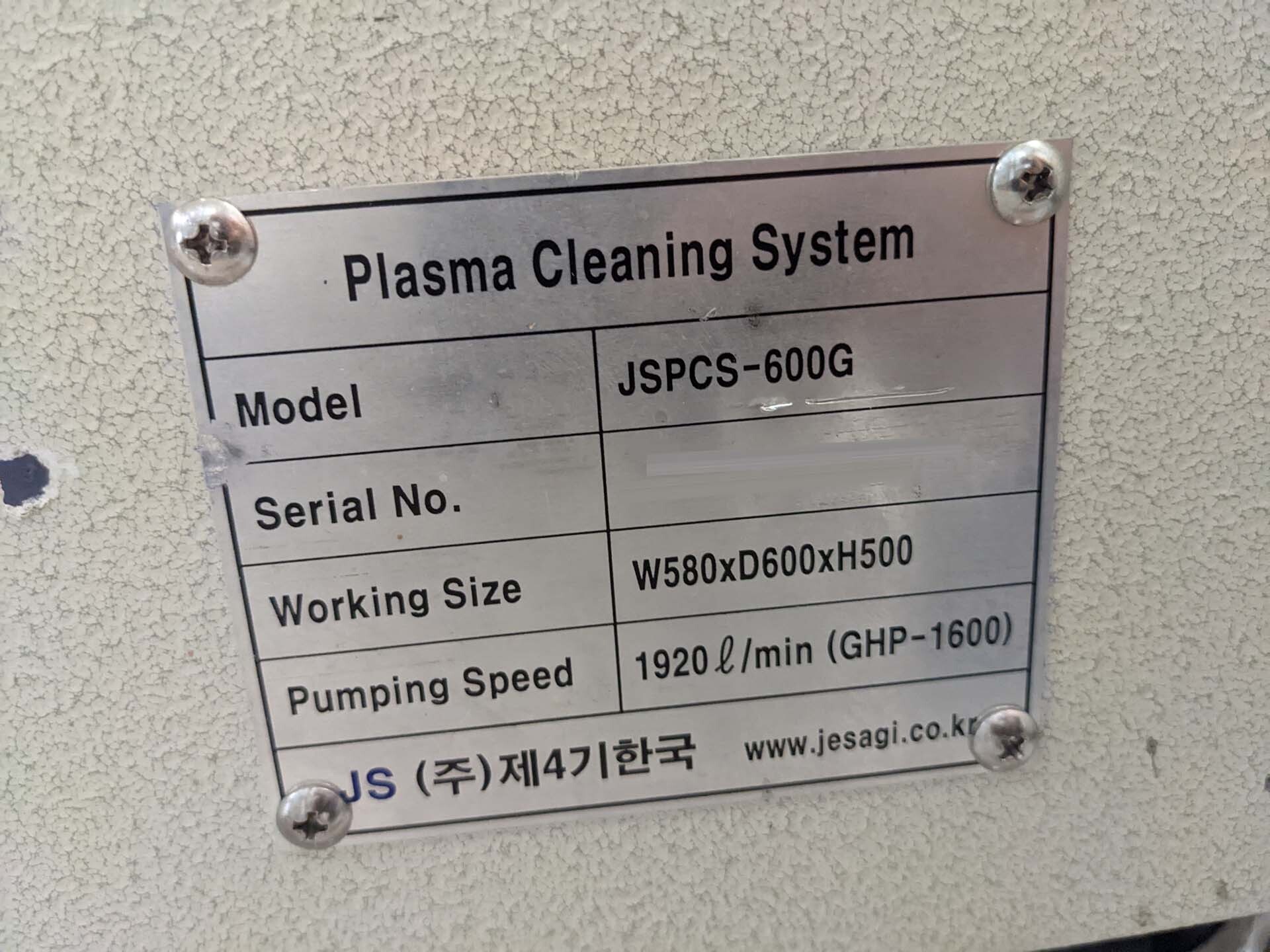

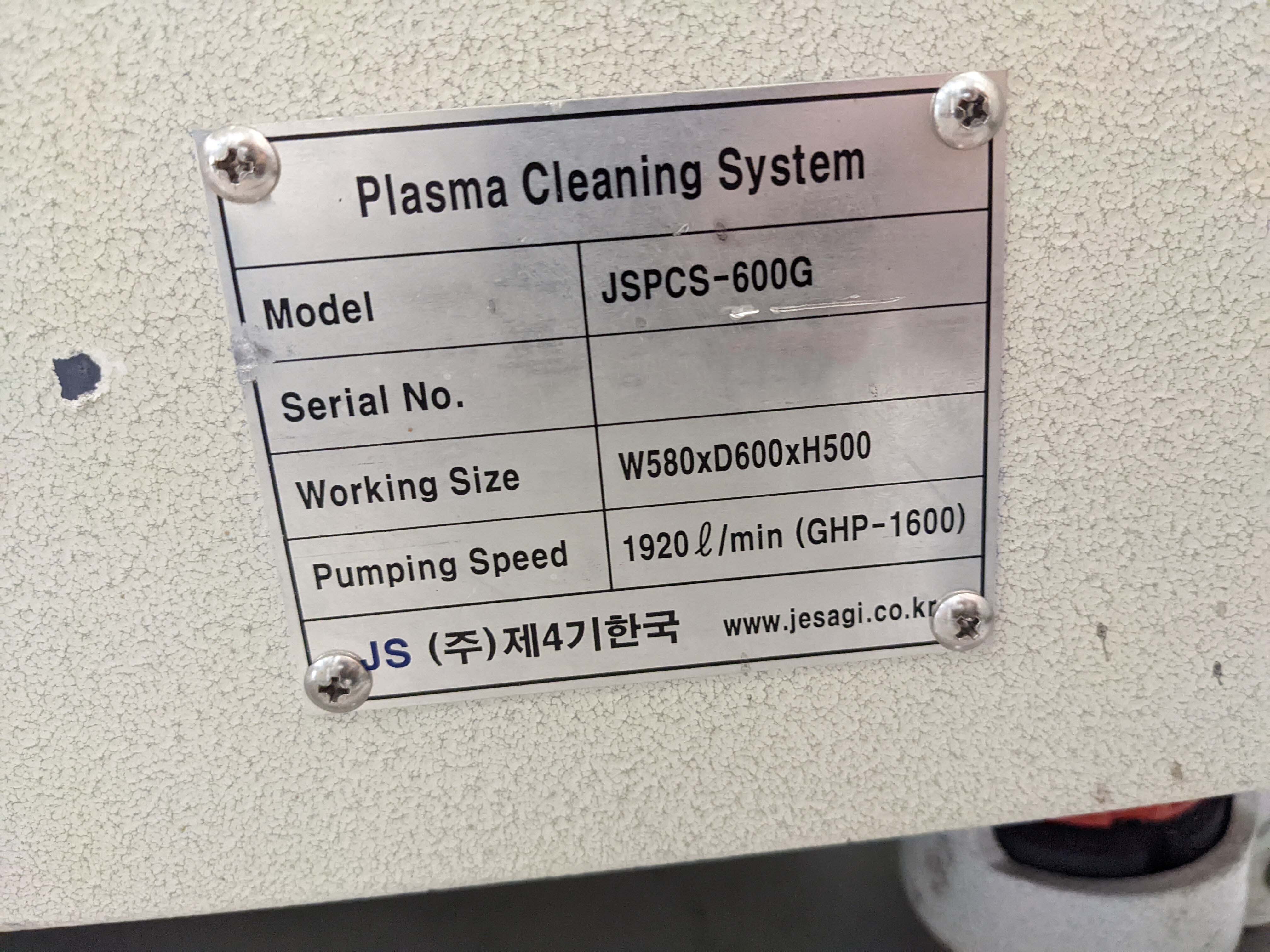

Used JESAGI JSPCS-600G #293635086 for sale

URL successfully copied!

Tap to zoom

JESAGI JSPCS-600G etching equipment is an ideal solution for applications requiring high-precision etching and high-resolution photoresist stripping. The system is equipped with a high-performance, direct current (DC) sputtering source. It is suitable for etching a variety of materials, including aluminum, copper, glass, and stainless steel. The unit also provides excellent photoresist stripping capabilities. JSPCS-600G features a 4-chamber design, each with an independent process chamber and platen. The process chamber accommodates a variety of wafers and substrates up to 8" in diameter. It is designed with an ion source for etching, a filament for etching, and an RF plasma generator for photoresist stripping. The 6-NC tower provides precise control over etching rate, selectivity, and depth of etching, allowing for fine-tuning of etch results. Additionally, the machine features an efficient, vacuum-shrouded, high-throughput wafer carrier with a vacuum wafer clamping mechanism capable of accommodating up to 20 wafers. The tool includes its own process control software, which is programmed to optimize etching and photoresist stripping times and results. The software has several predefined control parameters, as well as the ability to customize etching processes. The asset utilizes a user-friendly, graphical user interface (GUI) to easily access and modify the control parameters. JESAGI JSPCS-600G features an advanced sensors package which monitors the process parameters in real-time. This ensures maximal etching and photoresist stripping performance with consistent end results. The model also supports process automation, with fully programmable and customizable parameters. JSPCS-600G comes with comprehensive on-site user training and maintenance packages, as well as spare parts availability. In summary, JESAGI JSPCS-600G is an ideal solution for etching and photoresist stripping applications of varying complexity. Its advanced 4-chamber design, high-precision direct current sputtering source, and efficient wafer carrier make it a reliable and easy to use equipment. Its intuitive process control software, with customizable etching and stripping processes, provides the user with complete control over the etching and photoresist stripping process. The system's advanced sensors package ensures consistent end results with minimal maintenance requirements.

There are no reviews yet