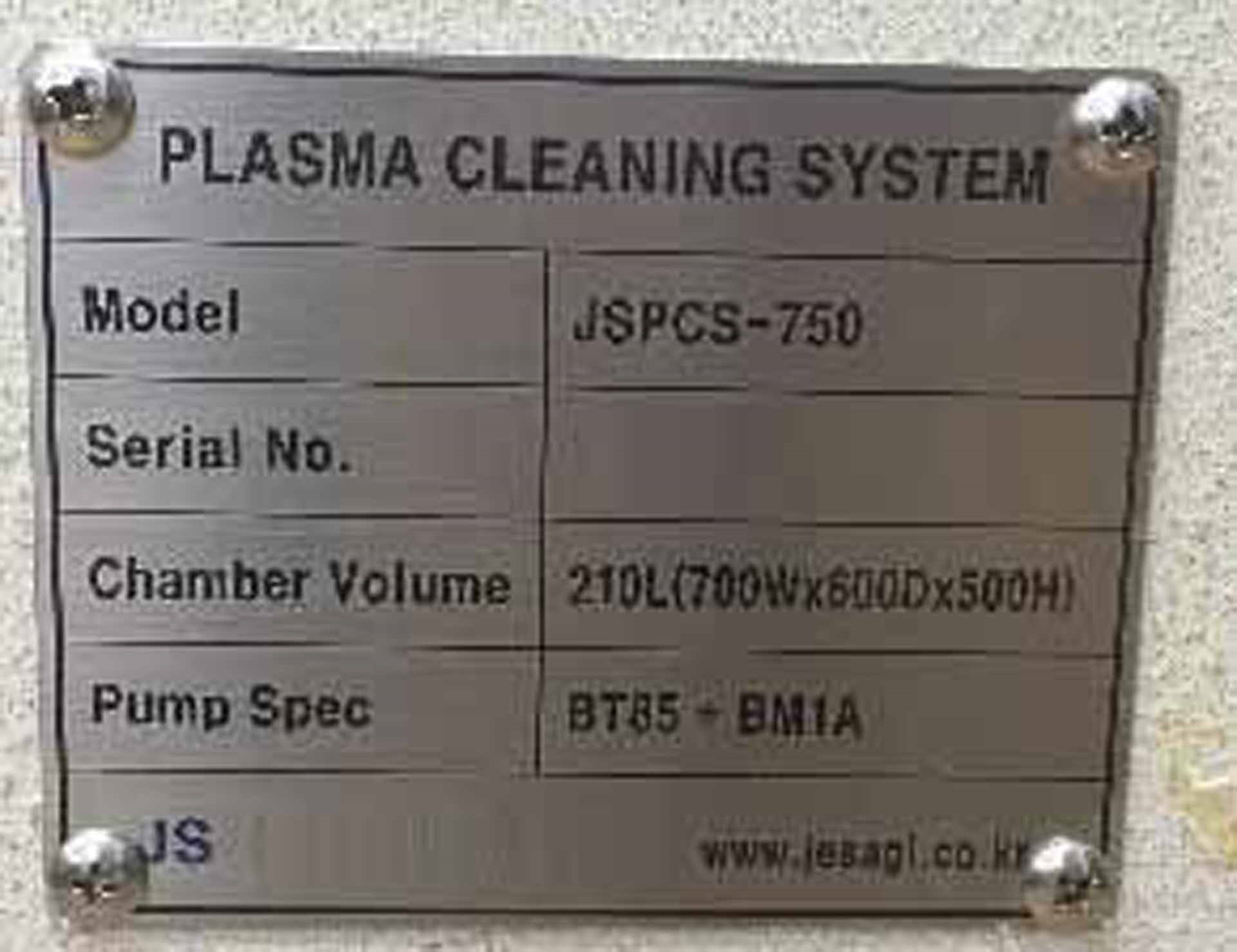

Used JESAGI JSPCS-750 #9253518 for sale

URL successfully copied!

Tap to zoom

ID: 9253518

Vintage: 2009

Plasma cleaner

BT85 Main pump

No BM1A Booster pump

2009 vintage.

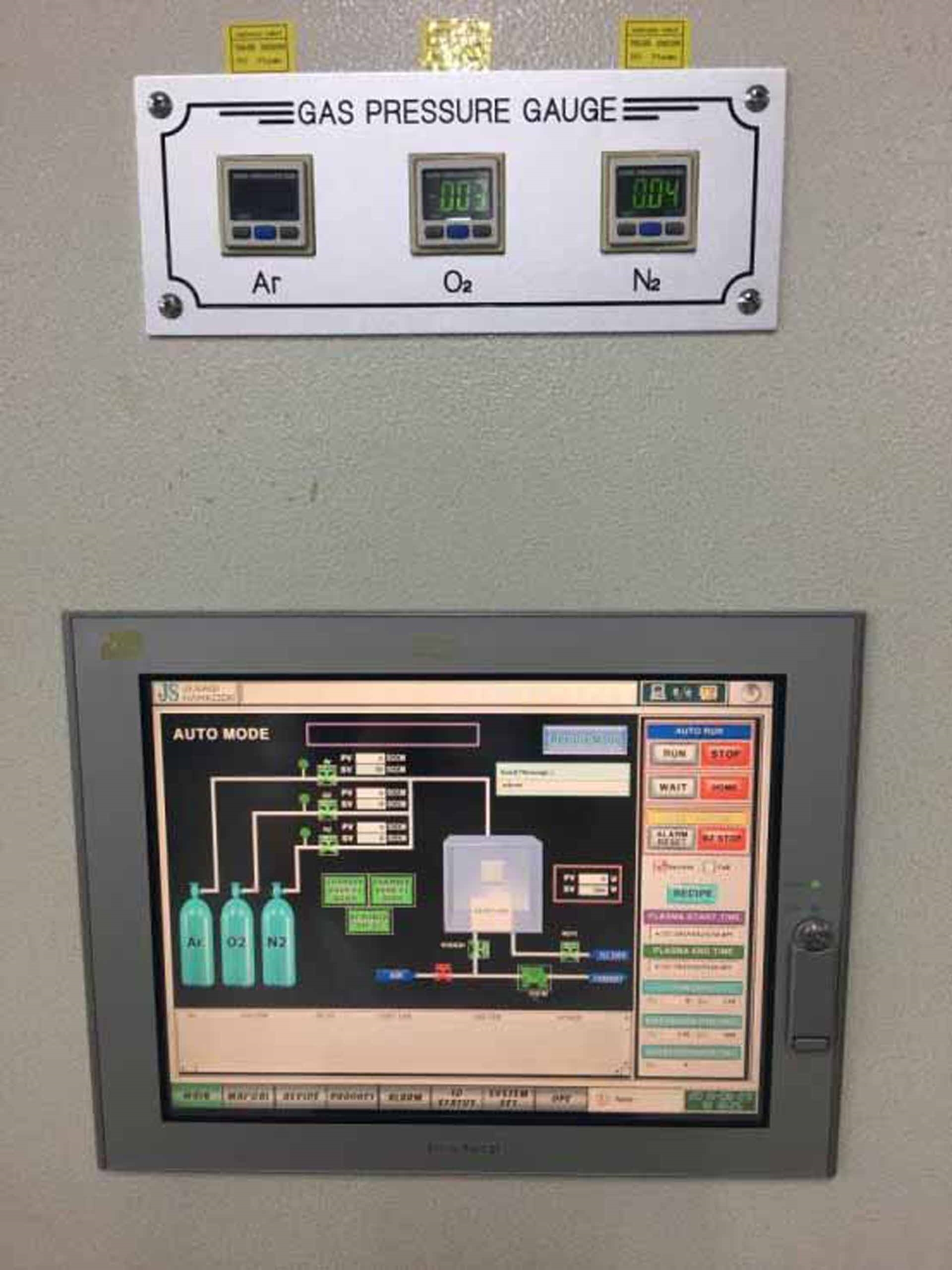

JESAGI JSPCS-750 is a state-of-the-art etcher / asher, featuring advanced multi-beam technology and precision process control. The system is enclosed in a vacuum chamber with a FOUP loader isolation, providing excellent repeatability and precise thin-film results. JSPCS-750 is ideal for advanced nanofabrication processes, enabling low volume production with cycle times of twenty seconds per wafer. JESAGI JSPCS-750 is capable of producing highest-quality etching and ashing results with particle-free, low-roughness, and uniformity across the entire wafer. It is designed for high throughput and accuracy as it features simultaneous multi-beam operation which is ideal for multiple application in one process. The multi-beam technology also offers low-cost operations and minimal maintenance. To support reliability and long-term performance, JSPCS-750 is equipped with a large selection of sensors and automated feedback algorithms to control the uniformity and etch quality. JESAGI JSPCS-750 is equipped with a range of features for advanced etching and ashing. Its advanced inert etching technology supports a wide variety of gases, enabling it to reach high etching rates with low-density damage. The reaction chamber is also able to reach temperatures between 290°C and 800°C to create a wide range of film thicknesses. The chamber also features an integrated substrate cooler for fast cooling after processes. Furthermore, JSPCS-750 features a cleaning cycle for increased process repeatability. This cleaning cycle is ideal for semi-conductor applications. Its low O2 gas consumption reduces the cost of integrated operations. The integrated automation with FOUP loading provides fast and efficient throughput. The system also includes an intuitive touch-screen interface with a large graphical display. JESAGI JPSCS-750 is a high-end etcher/asher that provides superior results across a wide range of processes. Its advanced multi-beam technology, precision process control, integrated automation and intuitive user interface make it an ideal choice for advanced nanofabrication applications.

There are no reviews yet