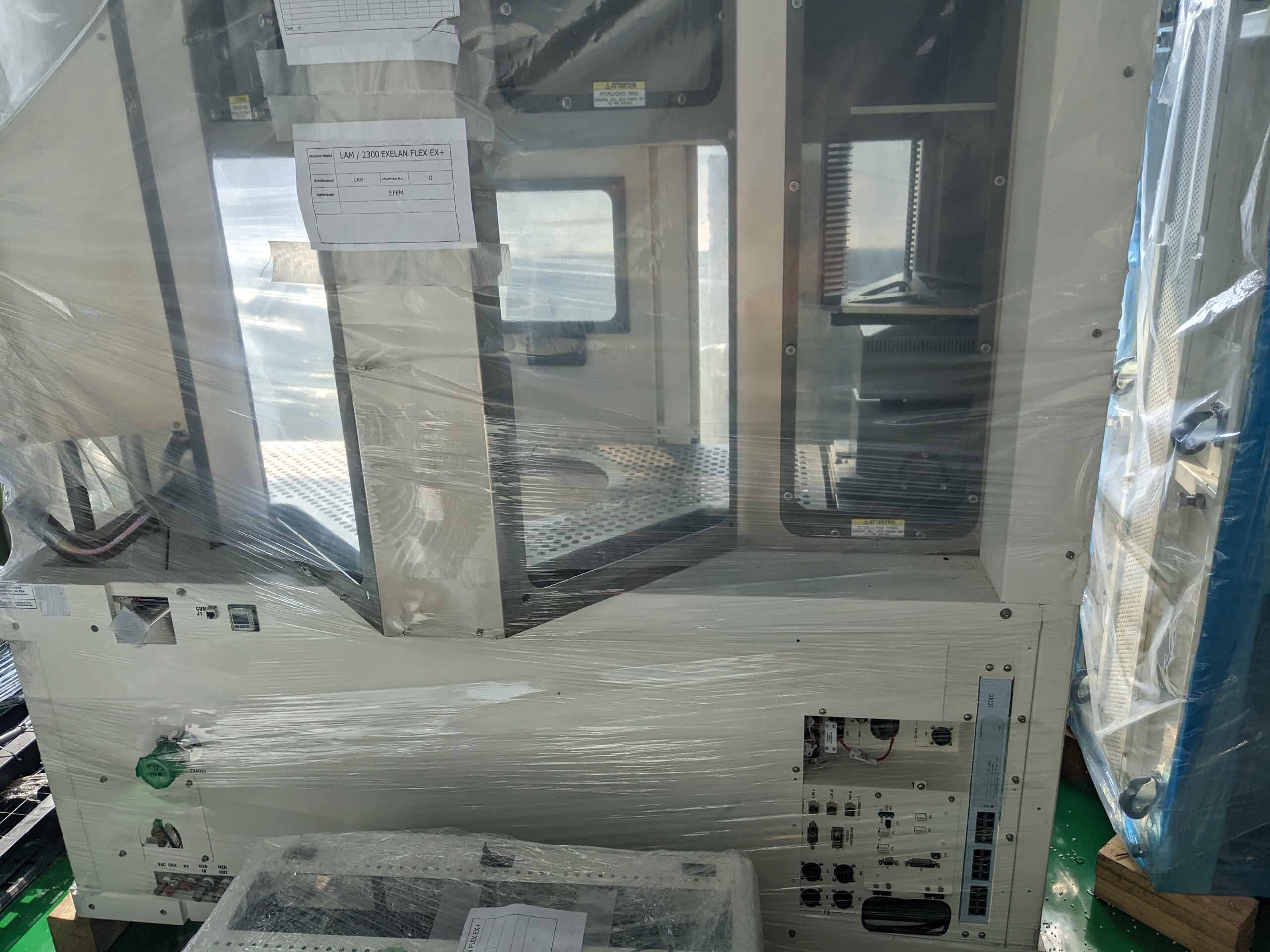

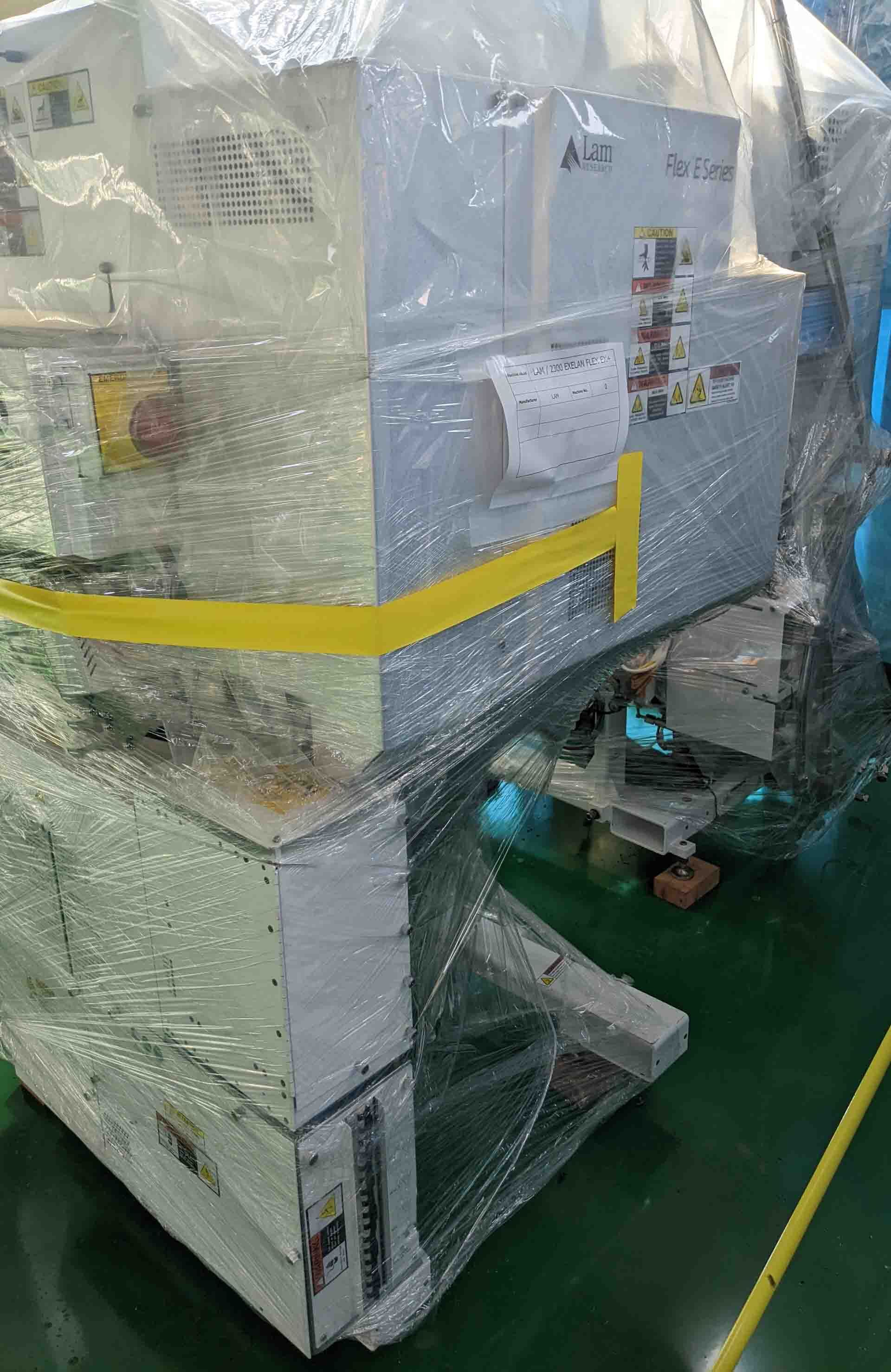

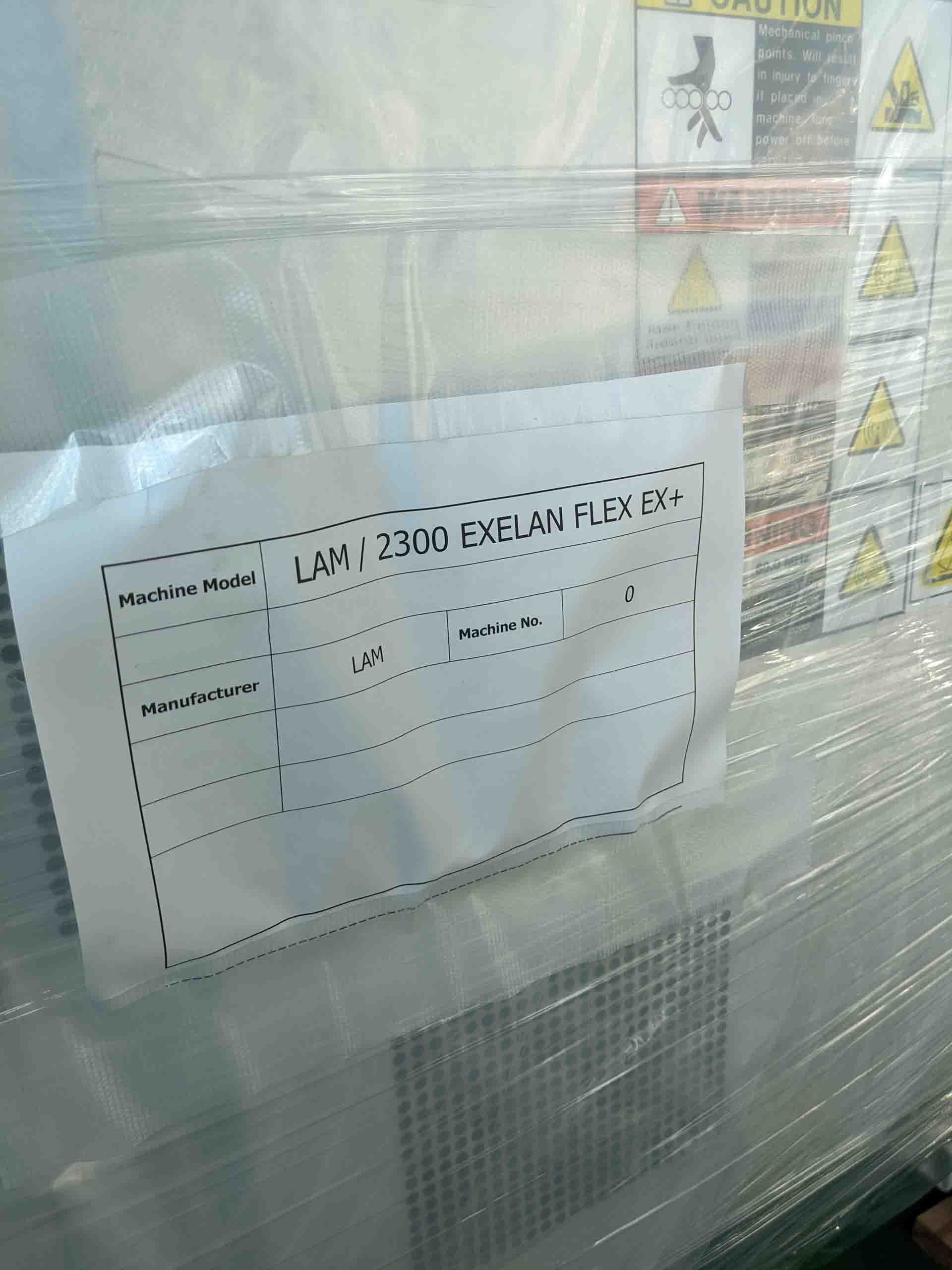

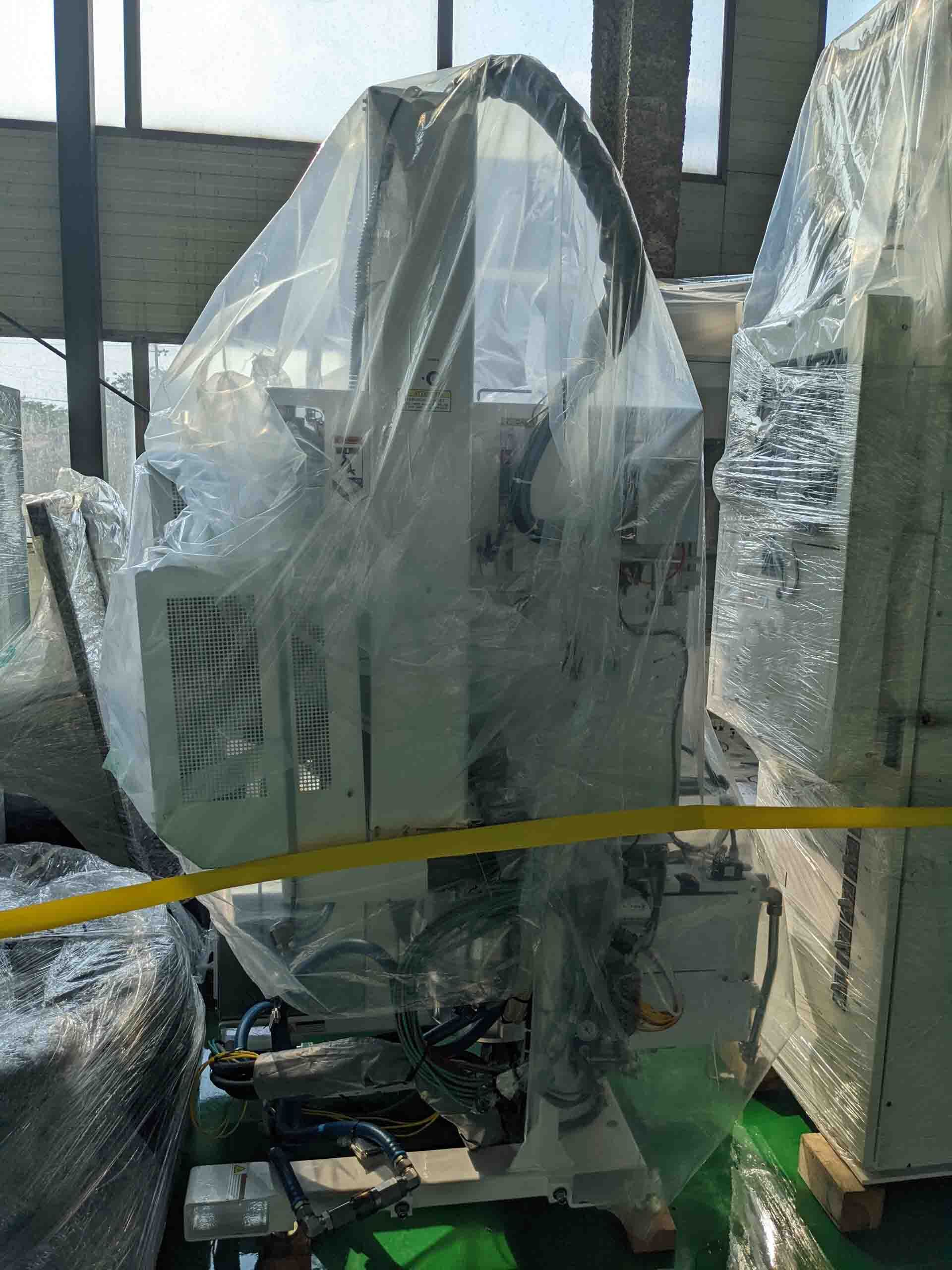

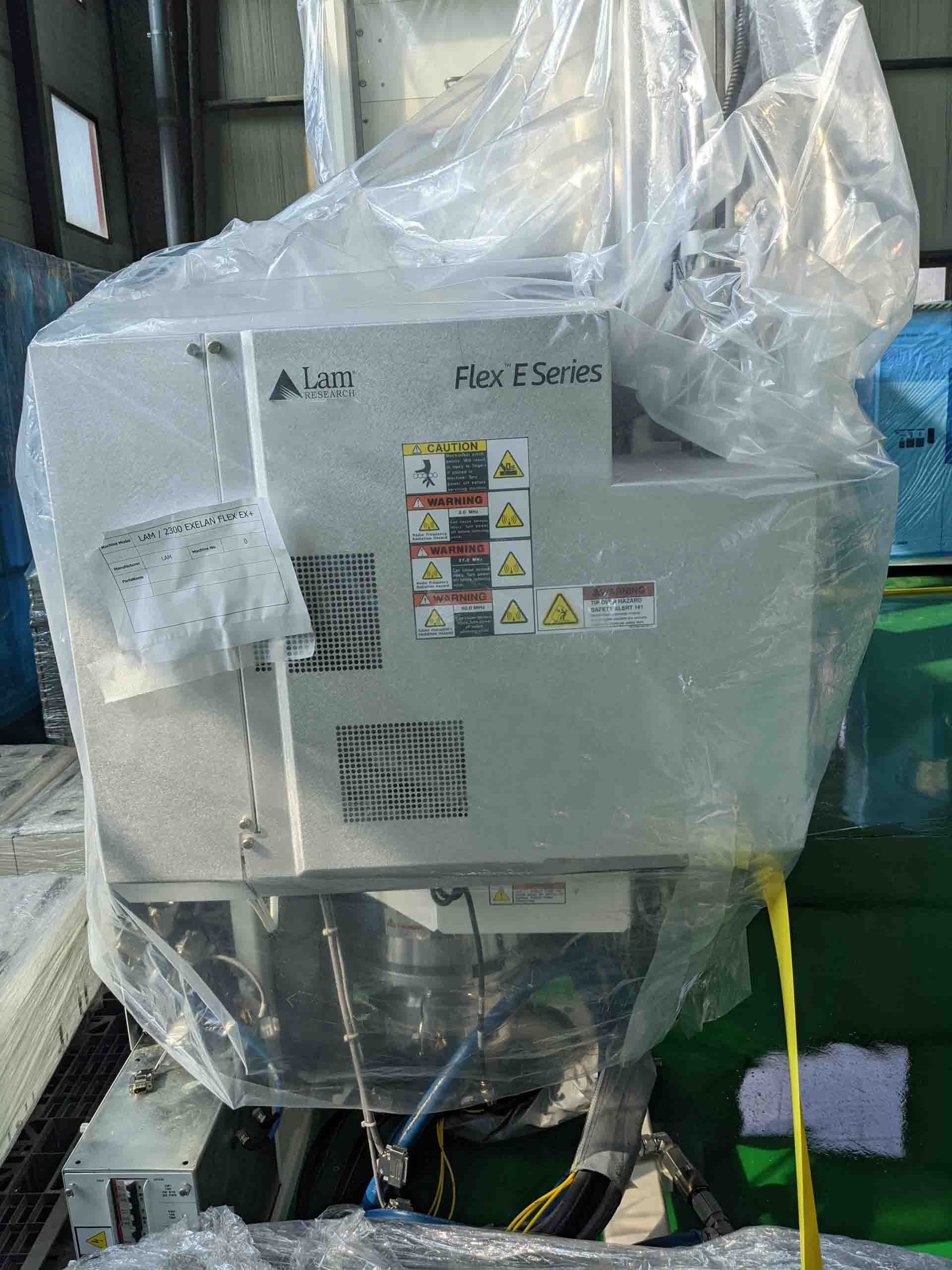

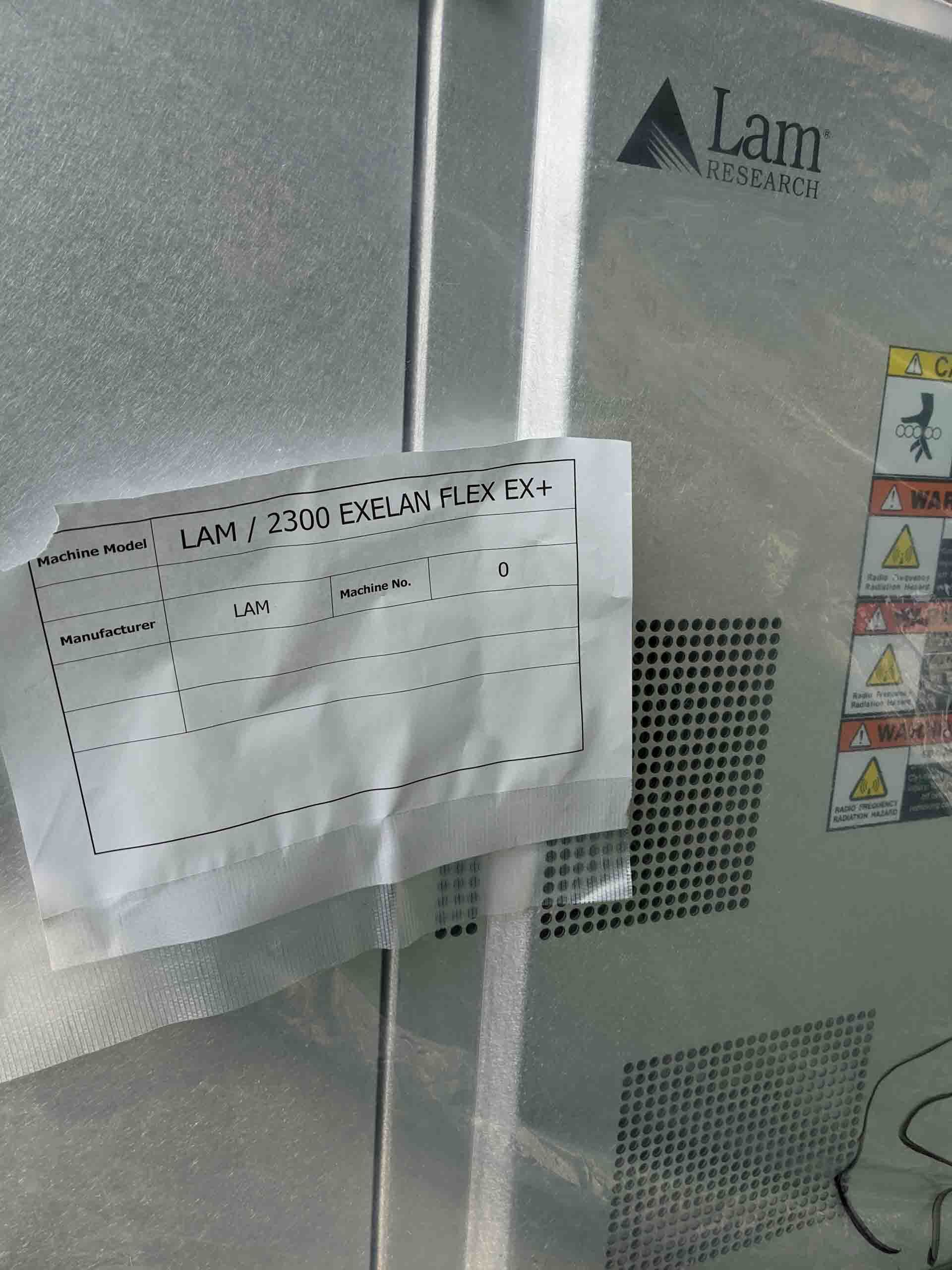

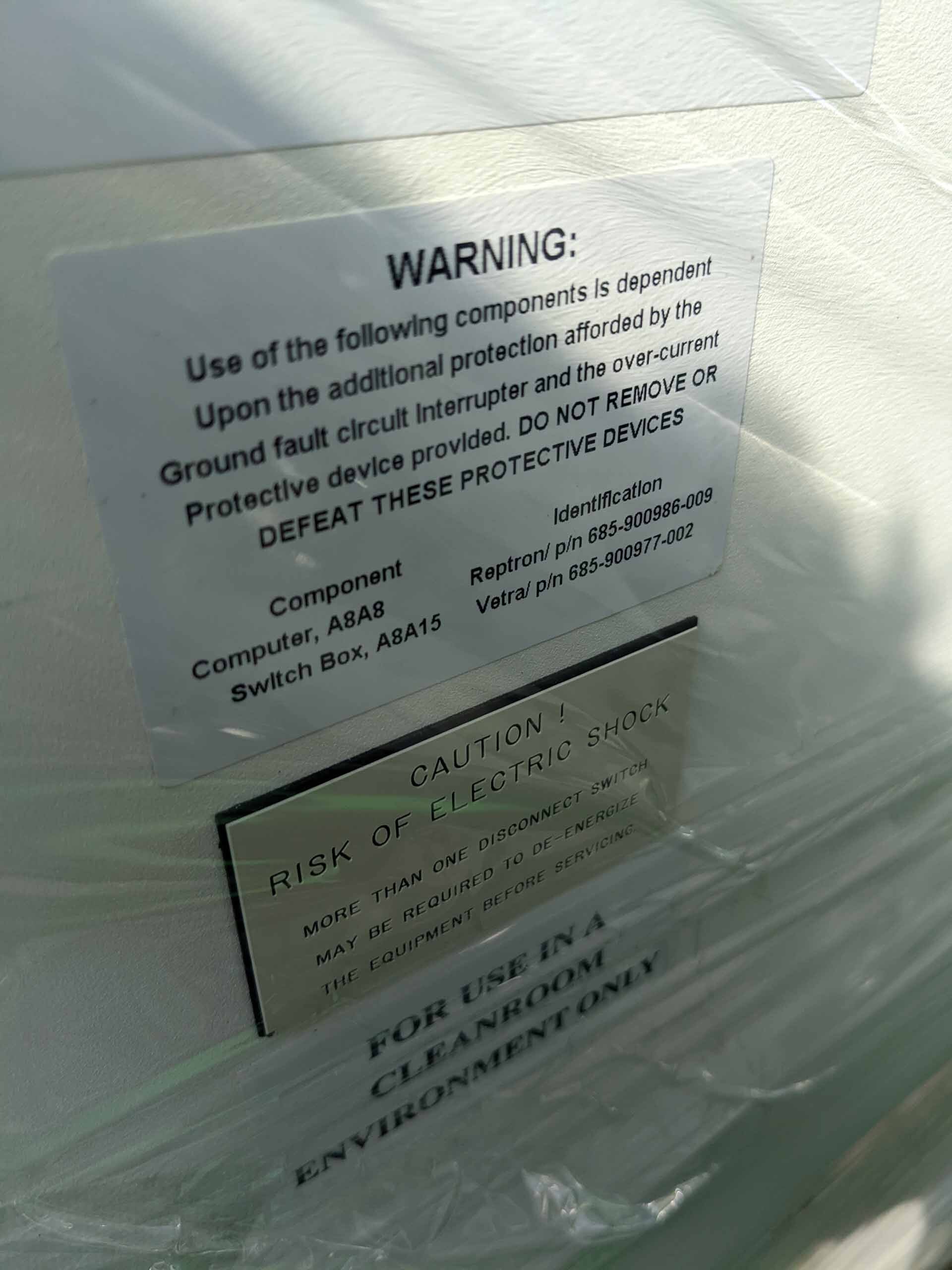

Used LAM RESEARCH 2300 Exelan Flex EX+ #293619655 for sale

URL successfully copied!

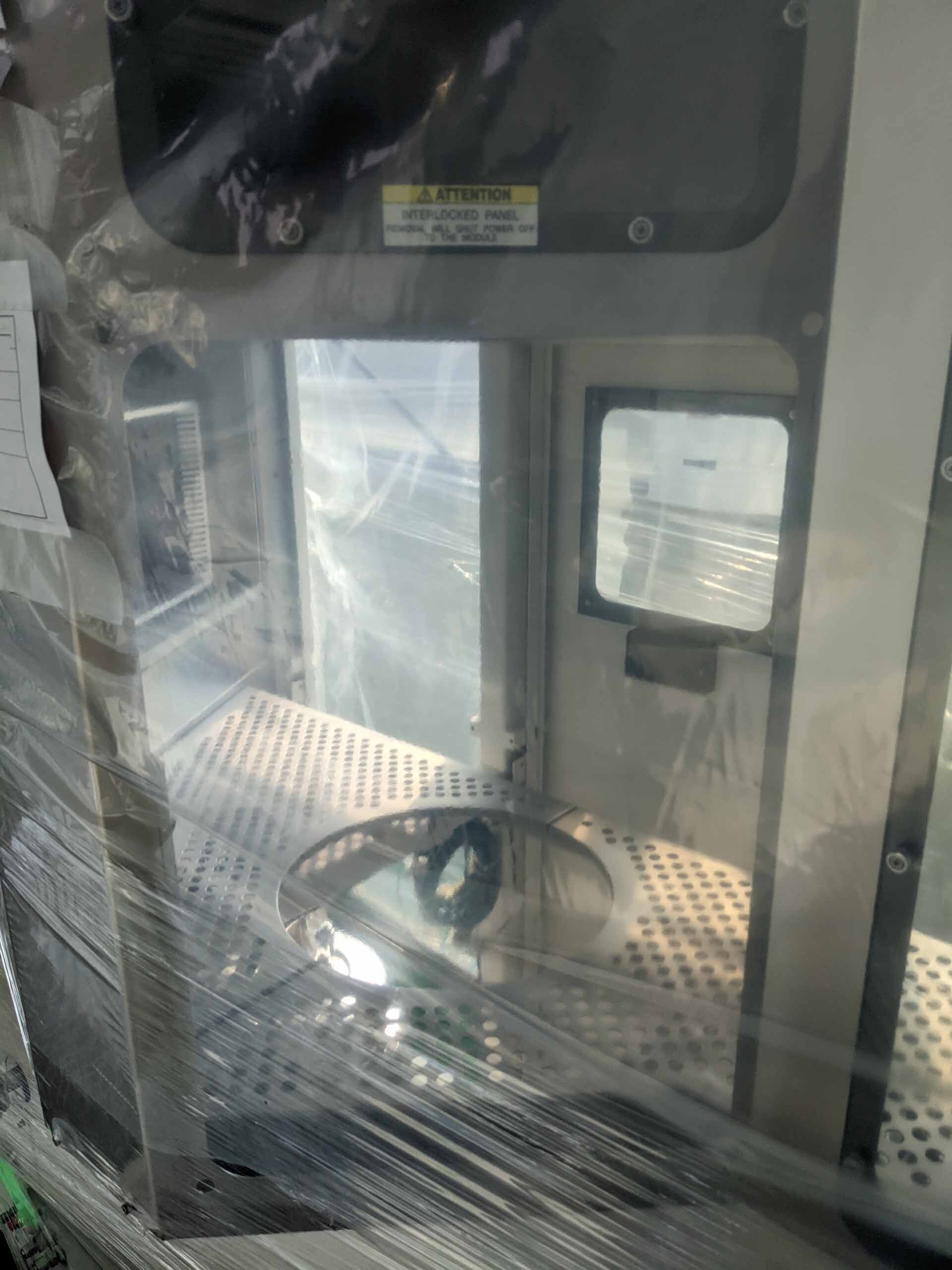

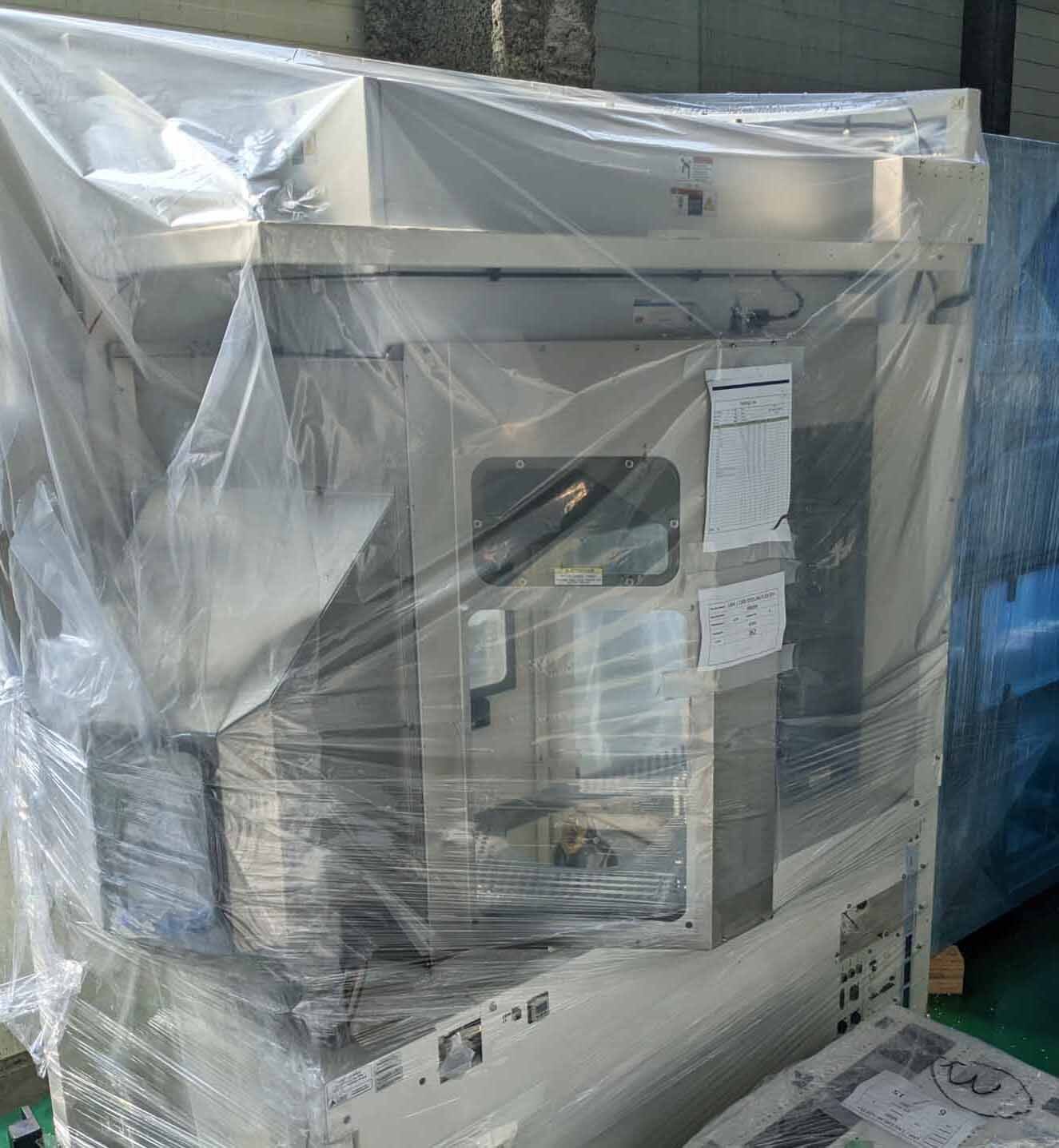

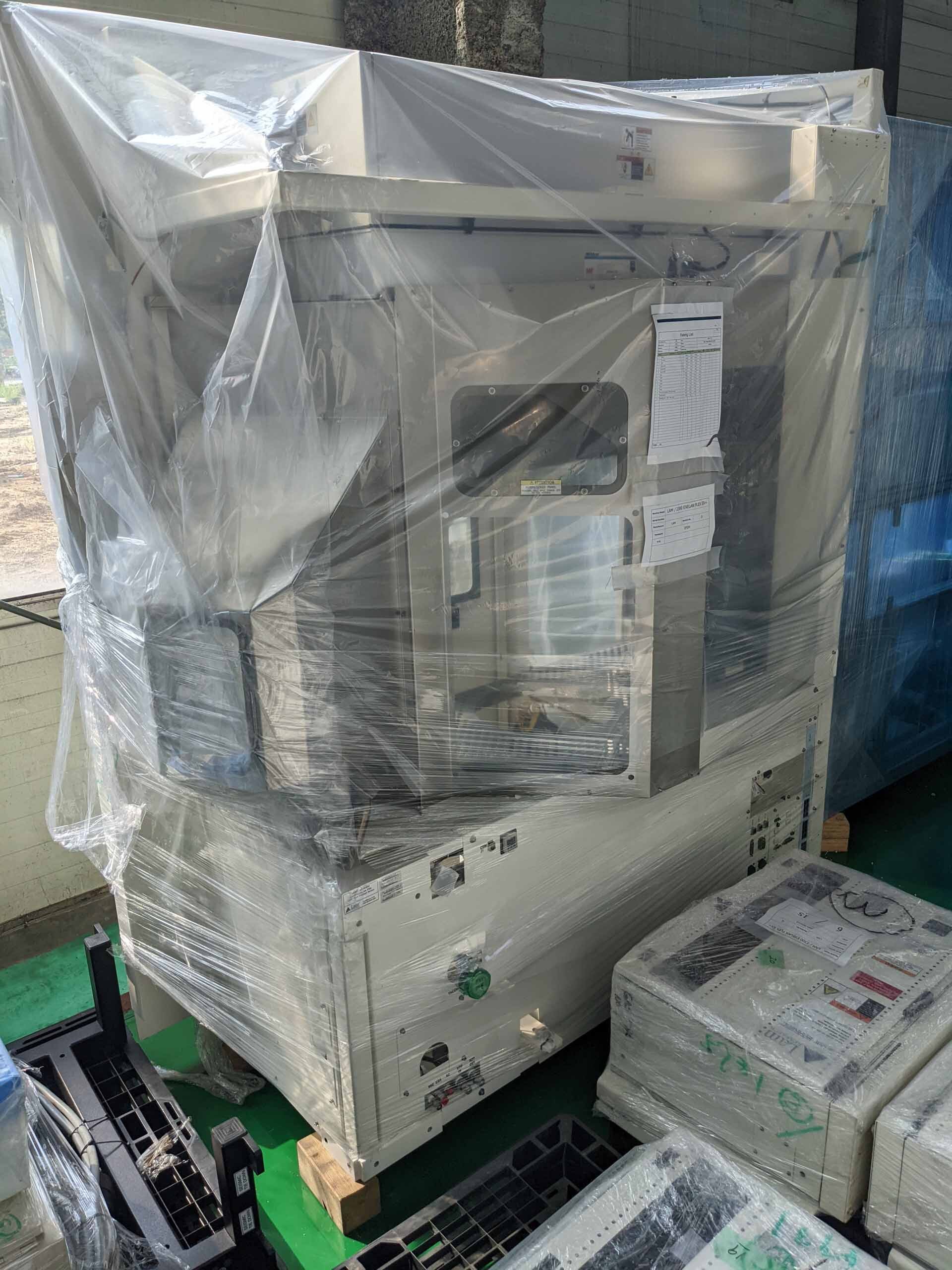

Tap to zoom

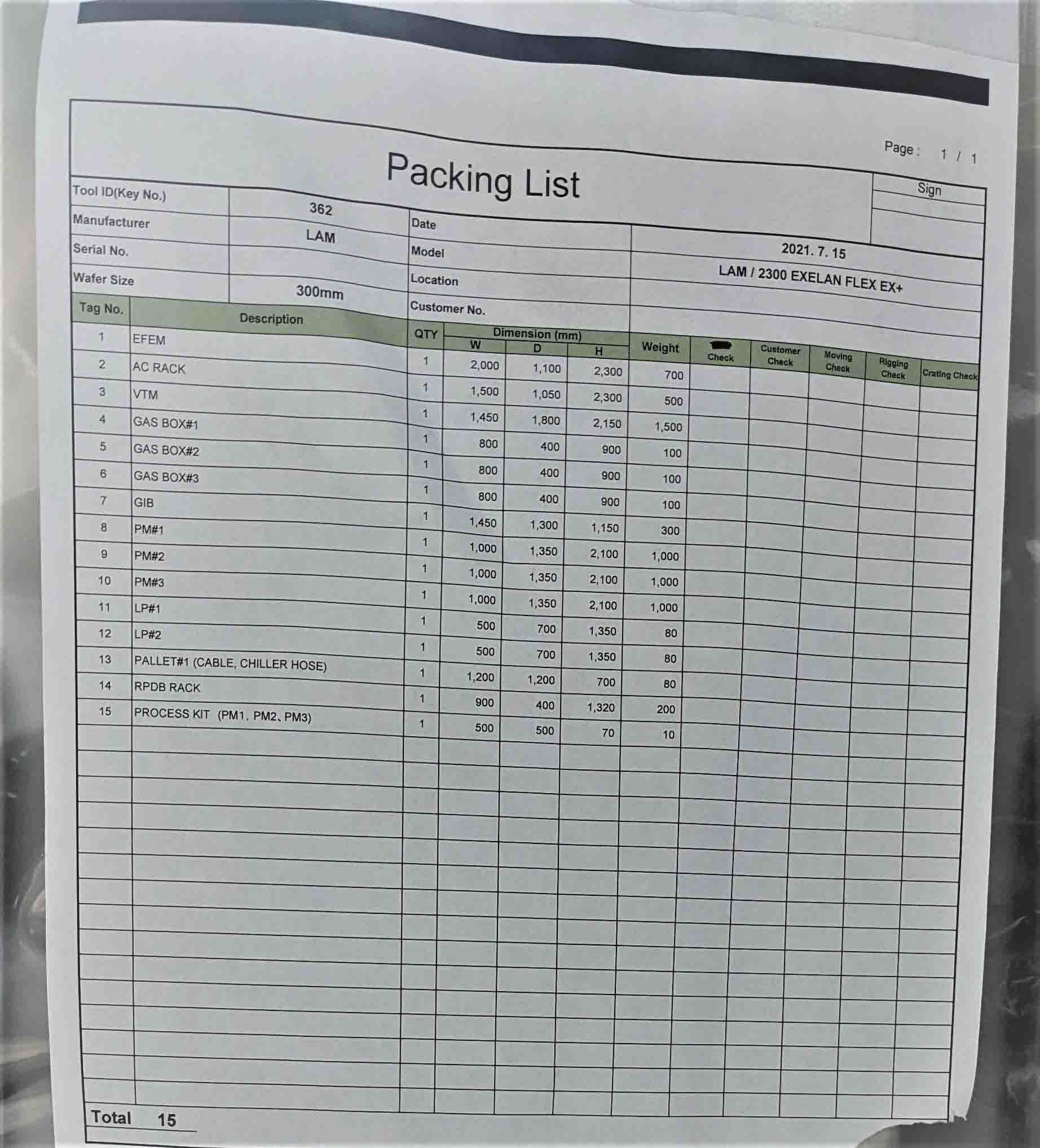

ID: 293619655

Wafer Size: 12"

Dielectric etcher, 12"

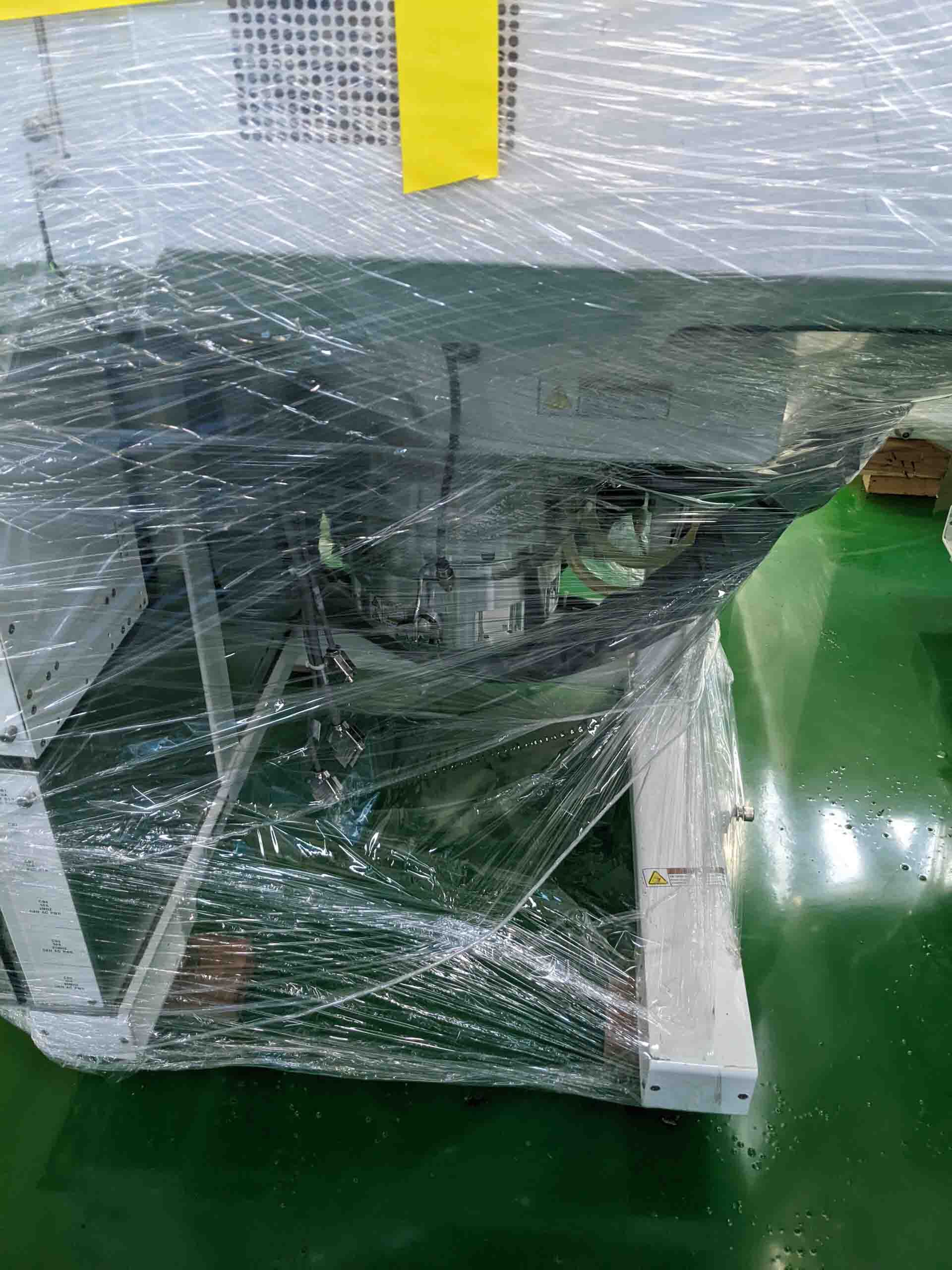

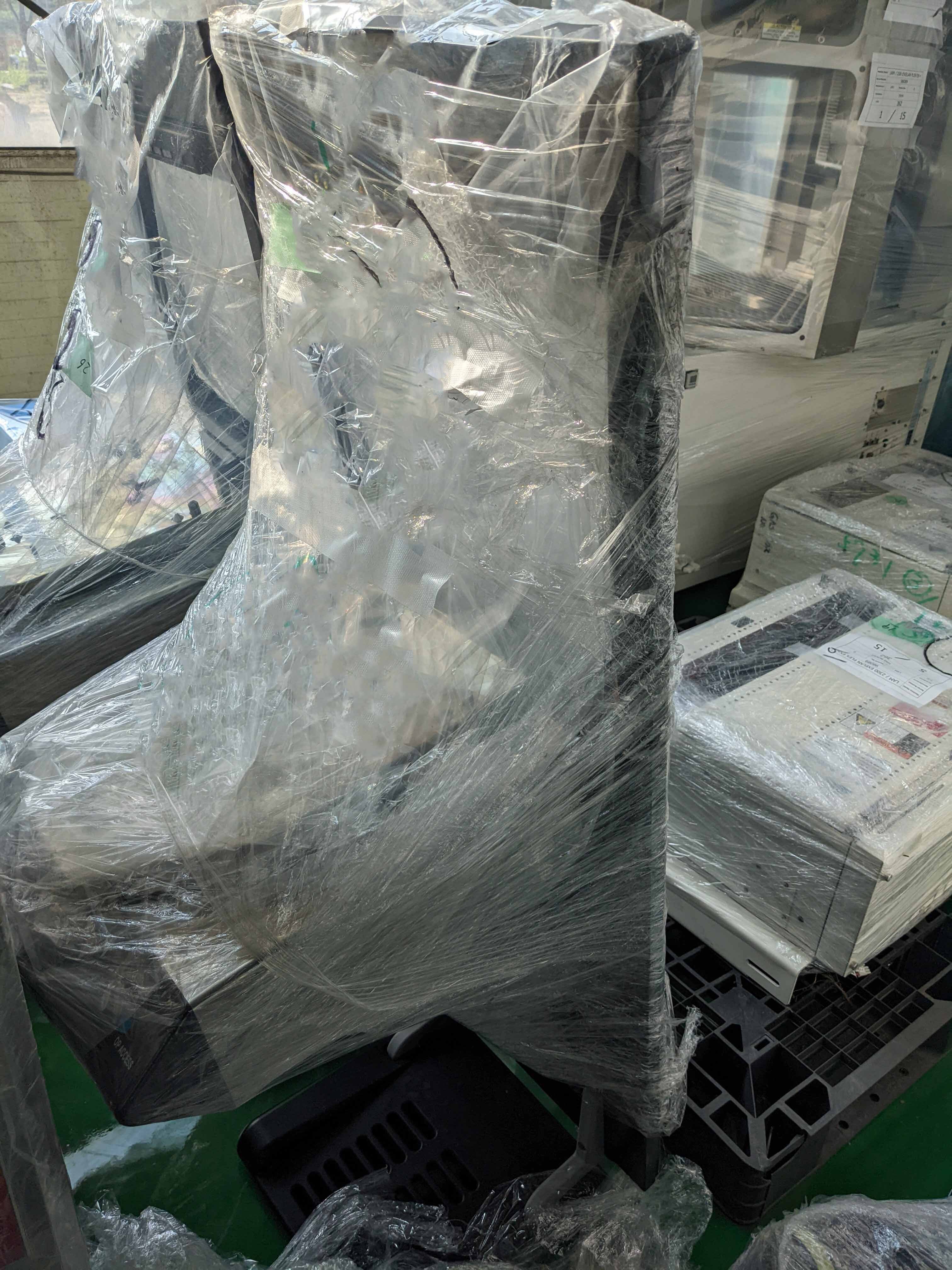

EFEM

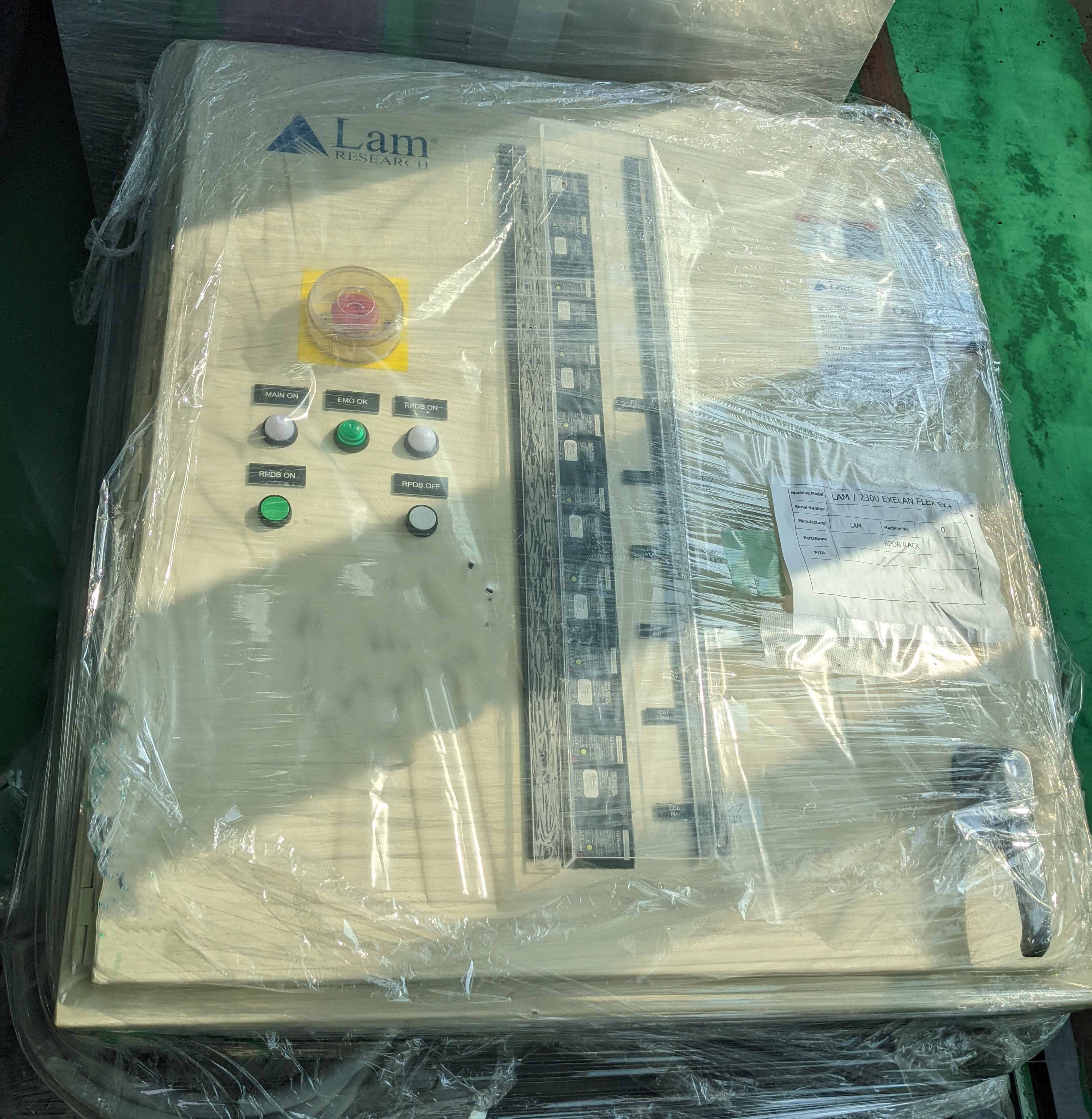

AC Rack

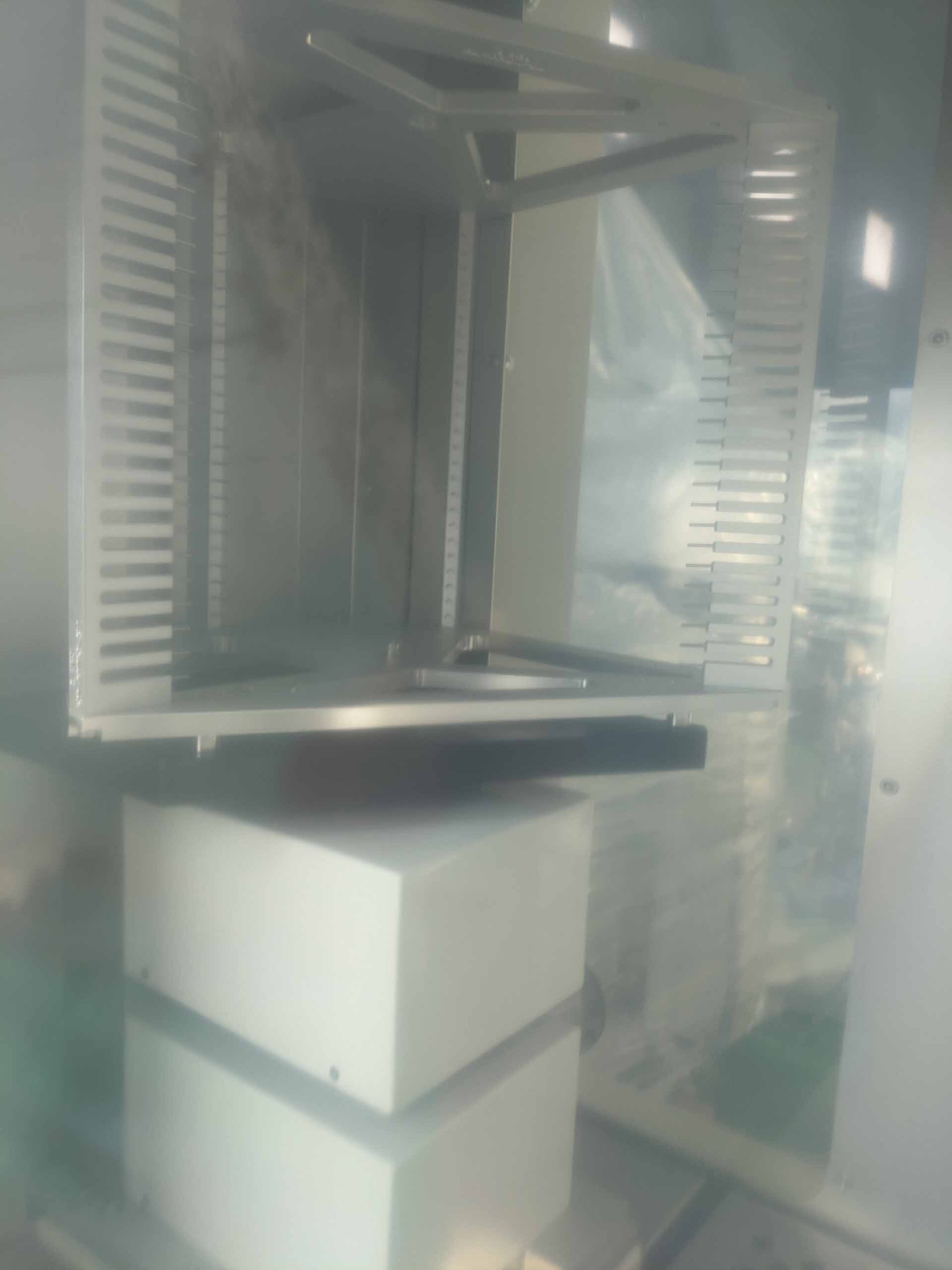

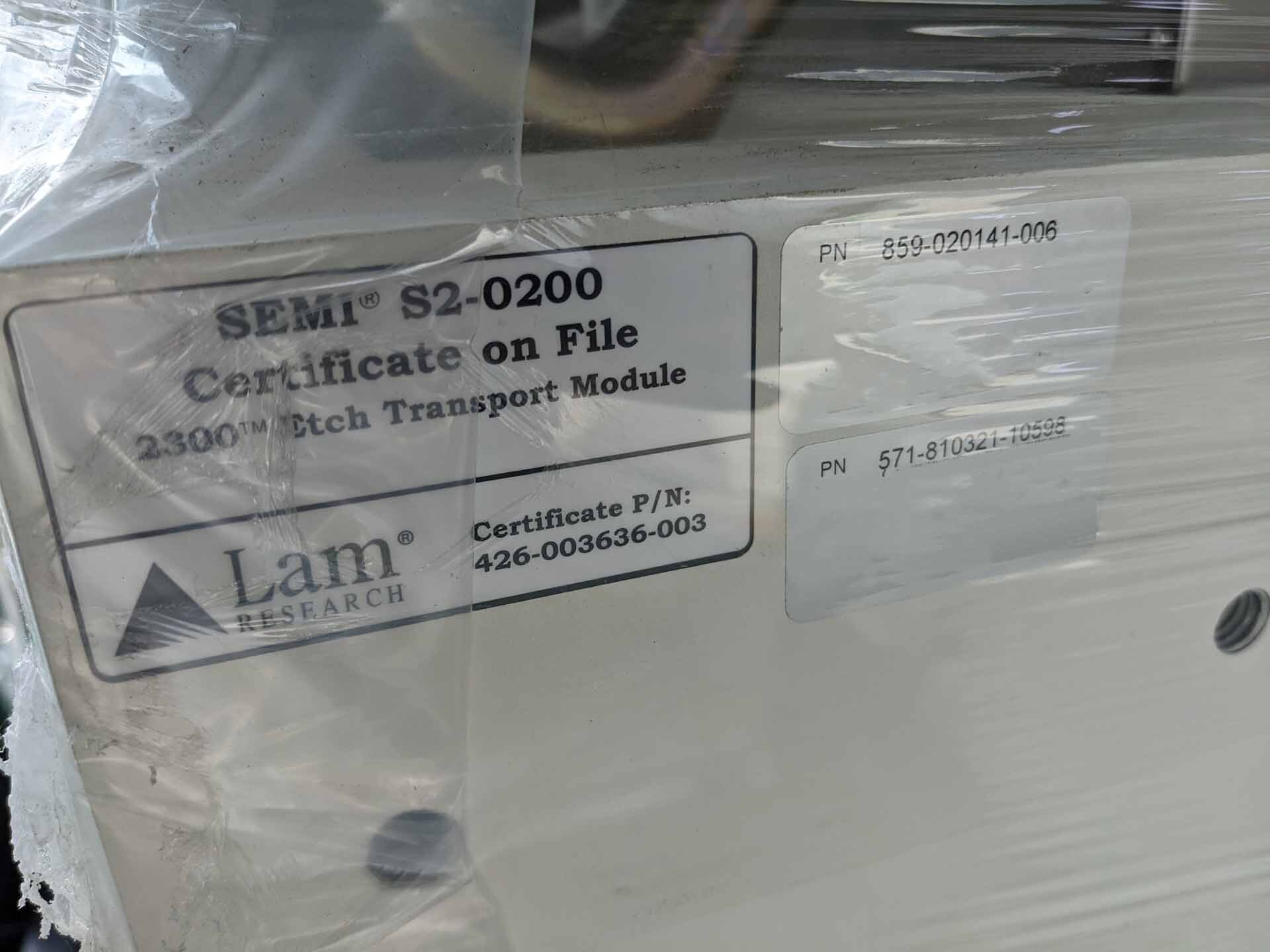

VTM

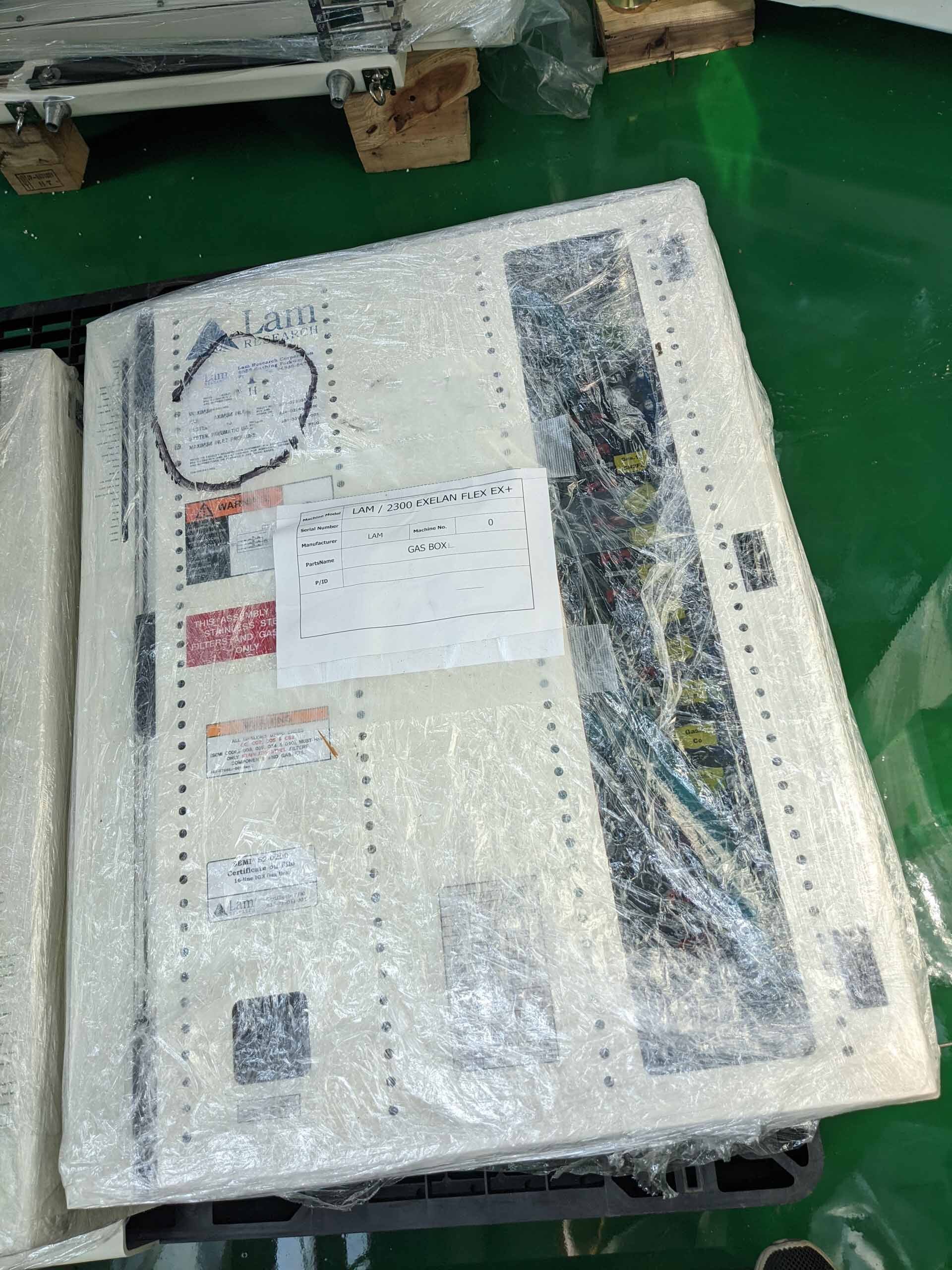

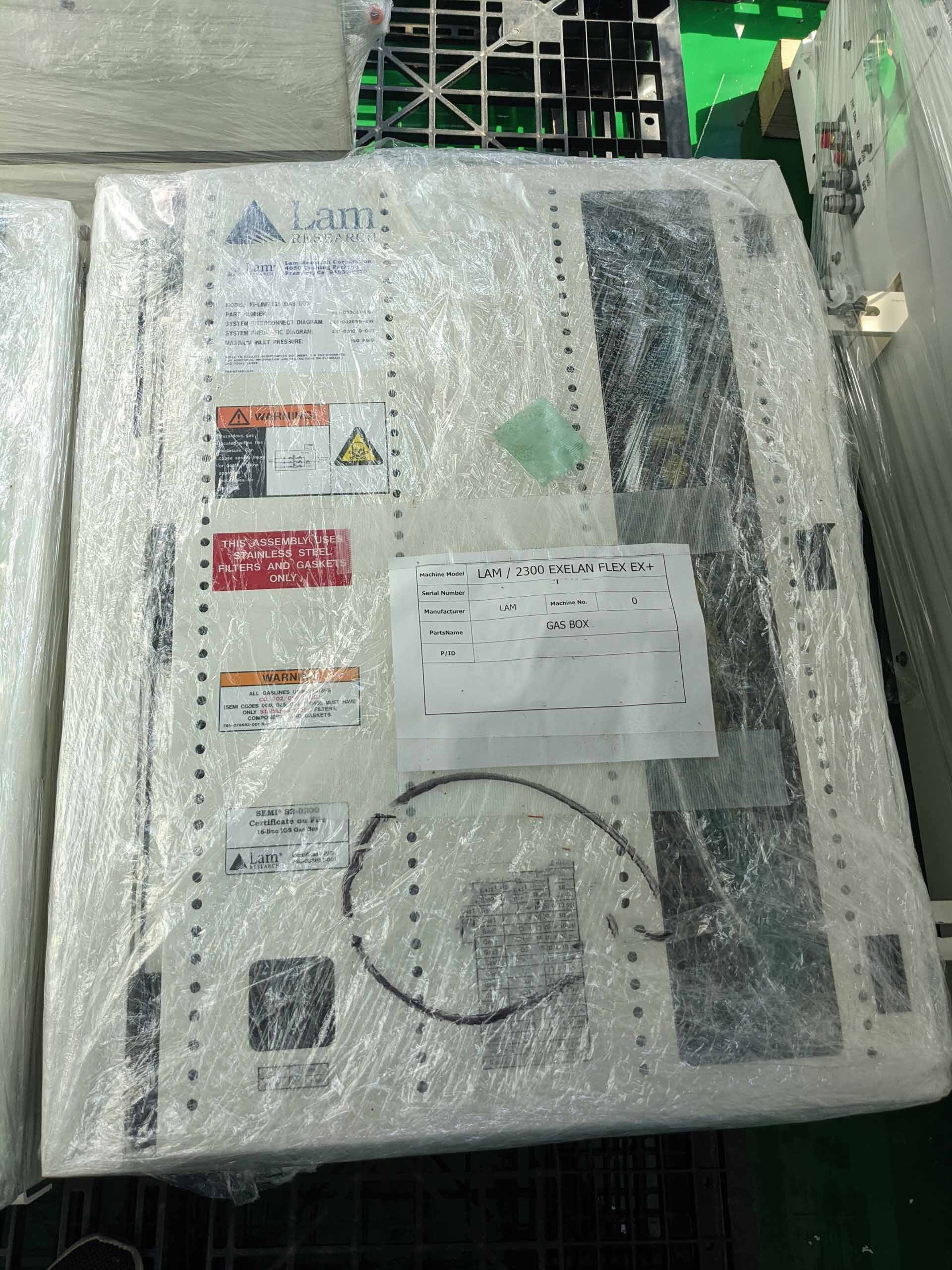

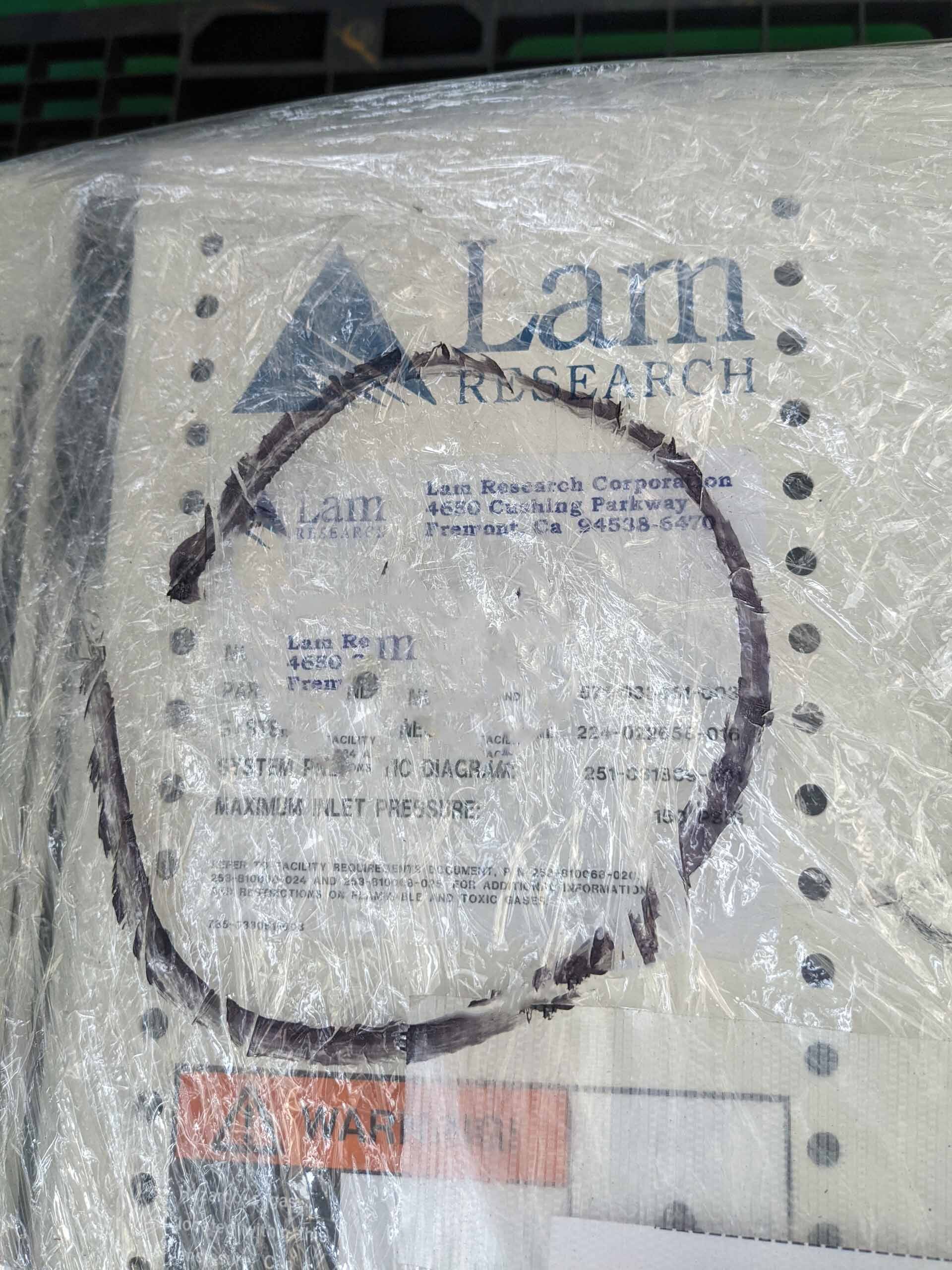

(3) Gas boxes

GIB

(3) PM

(2) LP

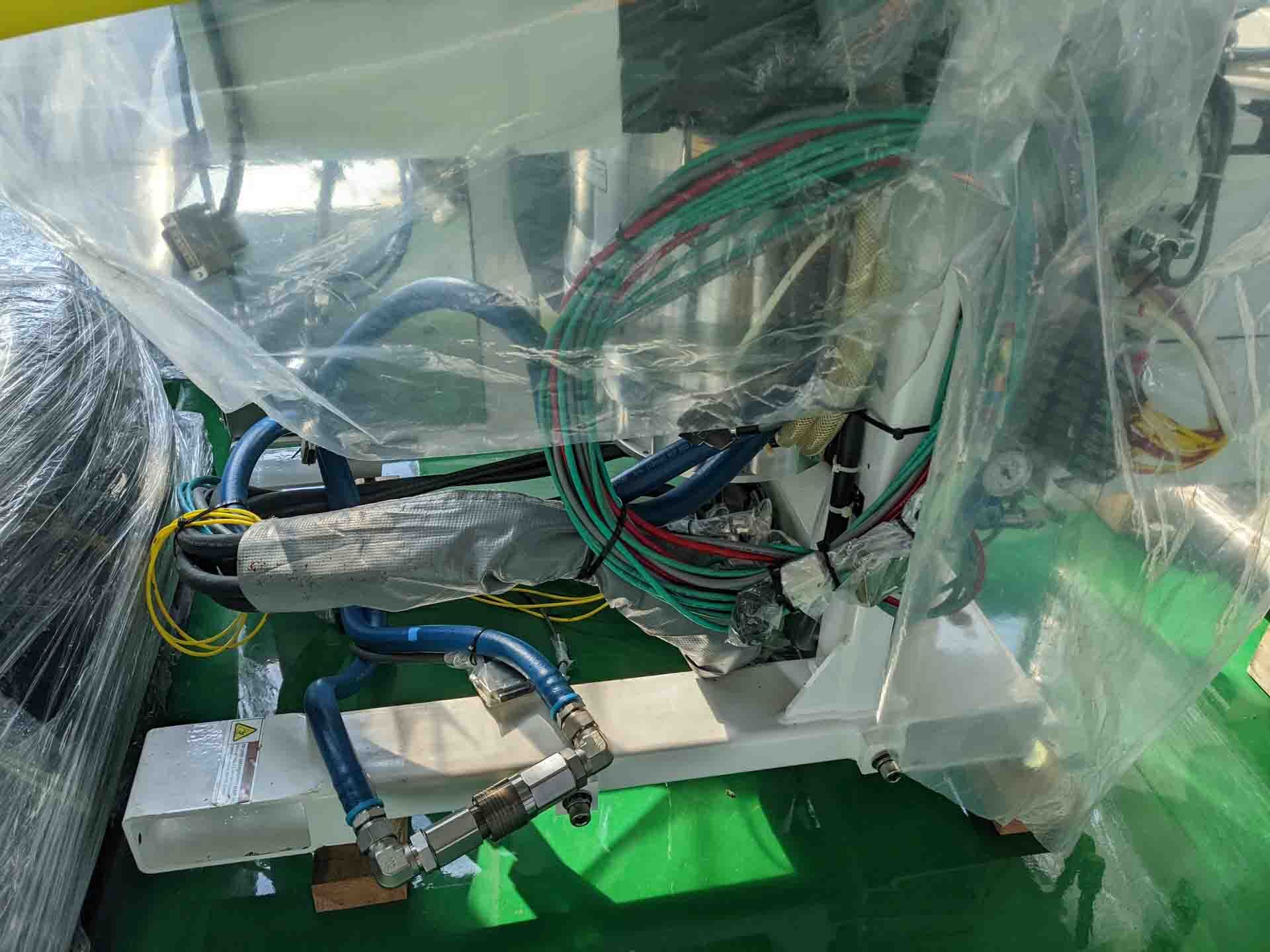

Pallet: Cable and chiller hose

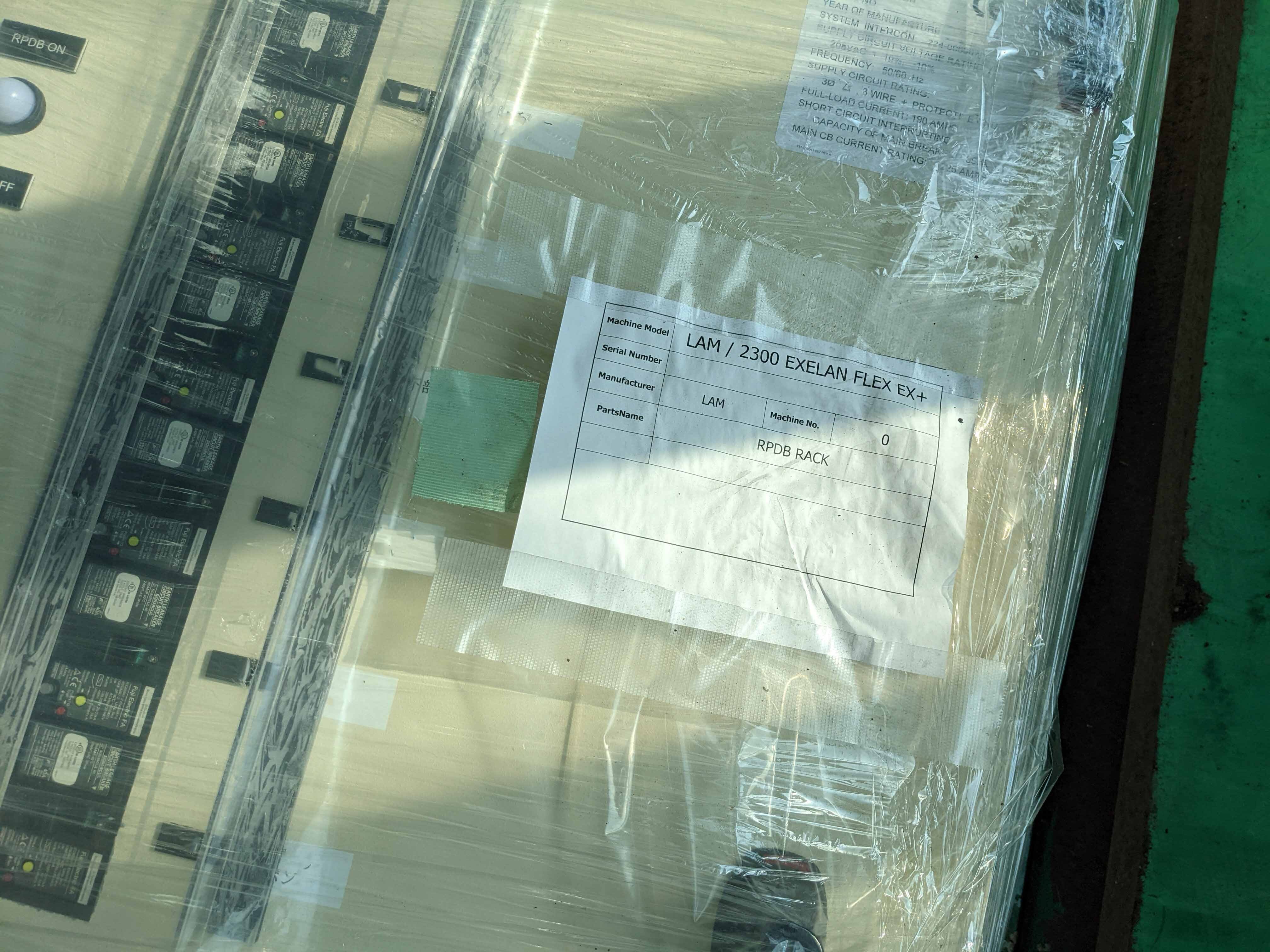

RPDB Rack

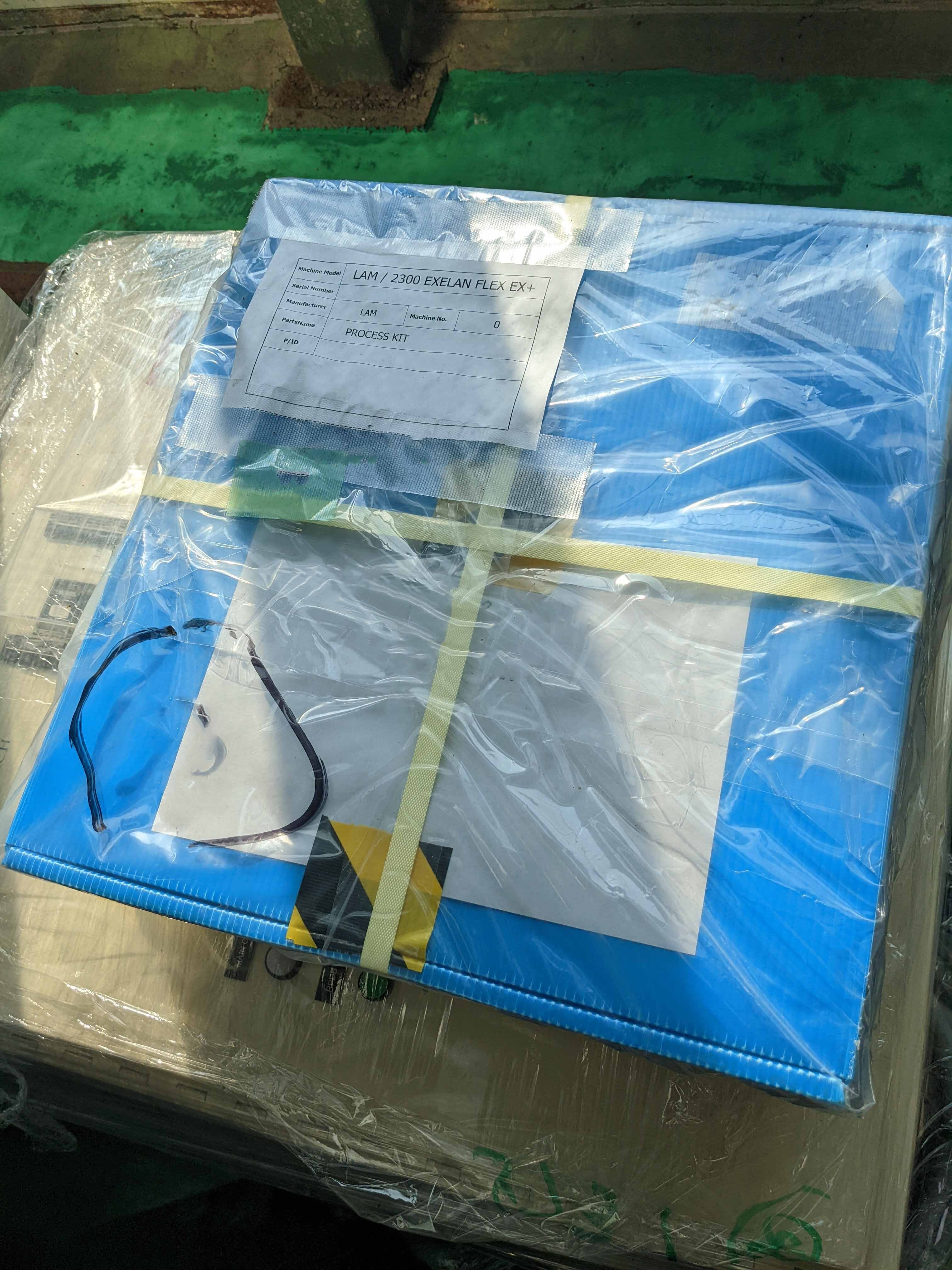

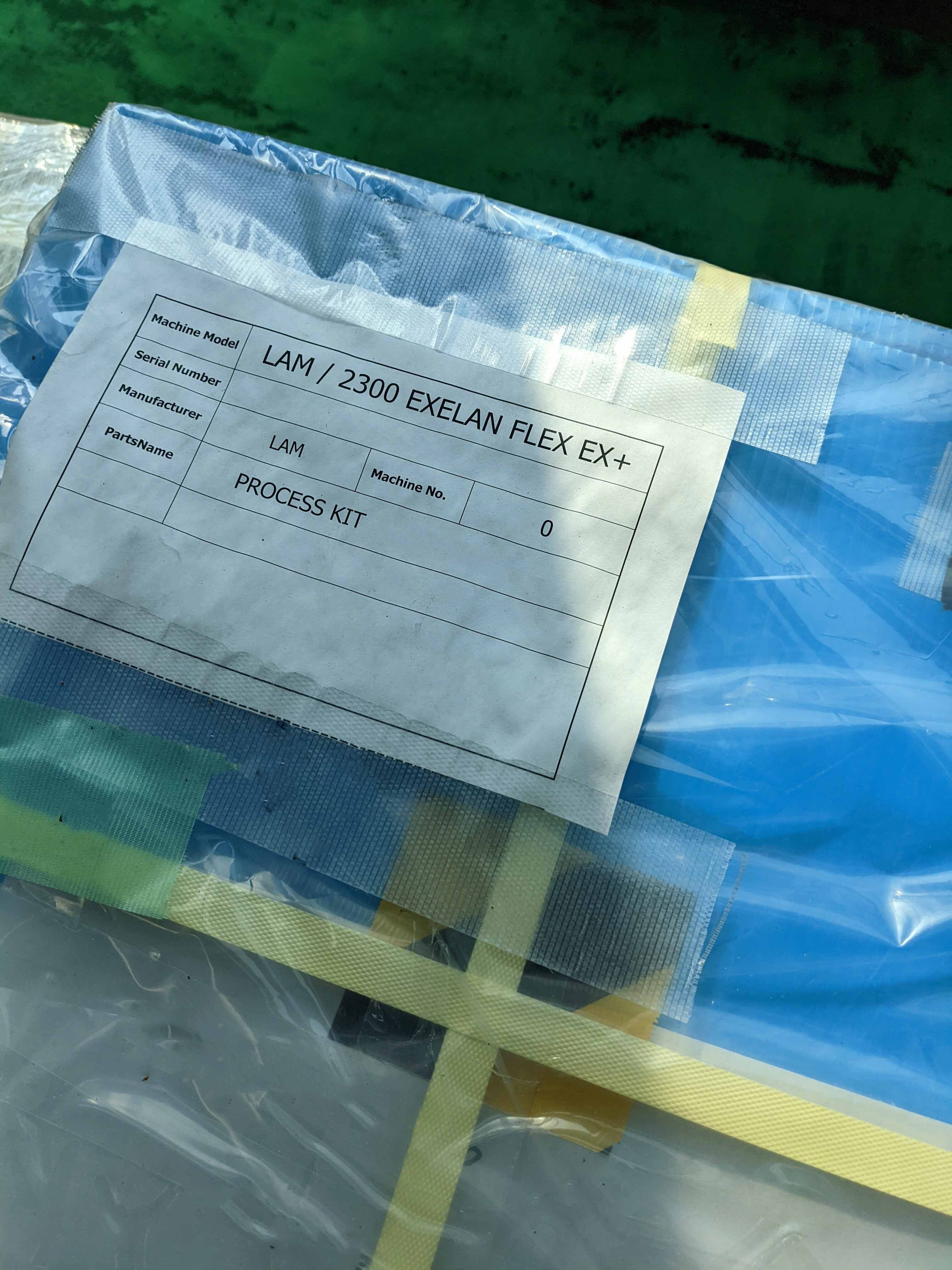

Process kit

Missing parts:

Qty / Part number / Description

(2) / - / Signal tower lamp assembly

(1) / 685-068190-004 / Gaille board

(1) / 685-068191-004 / Gap drive

(1) / 685-319860-001 / Iron server

(1) / 605-109114-001 / CPU Board

(1) / 857-019053-004 / ATM Robot

(1) / 799-000492-003 / VTM Robot body

(1) / - / VTM Robot arm

(1) / 810-066590-004 / Stepper board

(3) / 853-040482-600 / 3-Frequency matcher

(3) / 660-080455-300 / 2 Mhz Gen

(3) / 660-072825-200 / 27 Mhz Gen

(3) / 660-072826-200 / 60 Mhz Gen

(1) / 810-800256-207 / Node Board

(1) / - / LP Motherboard

(1) / - / LP Motherboard

(1) / - / LP Solenoid box

(1) / - / LP Solenoid box

(1) / 2/8 Add / OES Unit

(1) / 2/8 Add / APC Actuator board

(1) / 2/8 Add / V10P Board

(1) / 2/8 Add / LTC Board

(1) / 2/8 Add / VME Box (I/B+M/B).

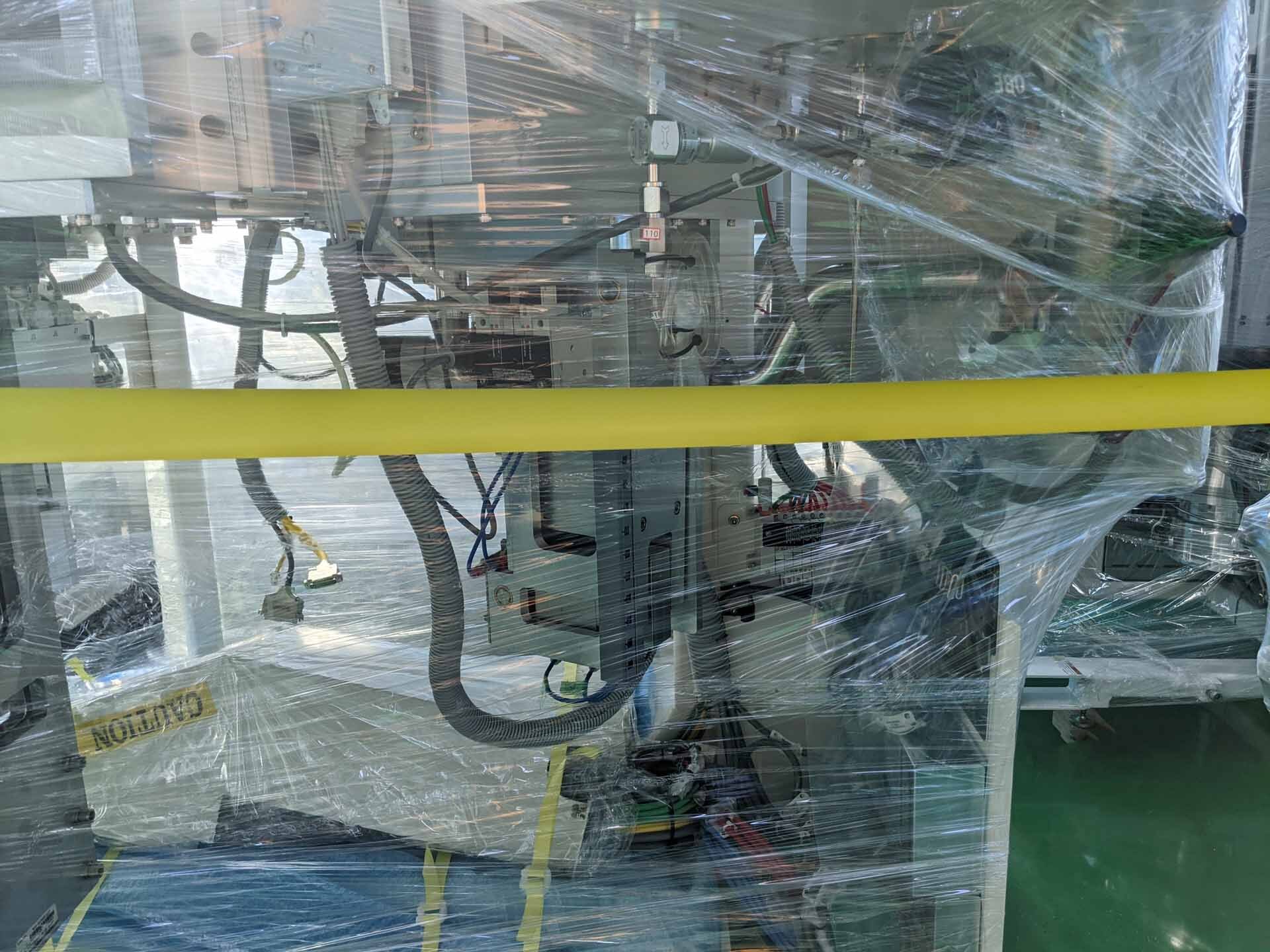

LAM RESEARCH 2300 Exelan Flex EX+ is an advanced etcher/asher equipment that provides semiconductor manufacturers with a reliable and accurate etching and ashing solution. This system is an advanced, fully automated, single-wafer device that uses multiple technologies, including hot CVD, plasma etching, and vacuum technologies. The unit features a large chamber and plenty of room for extended wafers of up to 300mm in diameter. The chambers are filled with inert gases and provide a very clean environment for etching and ashing. The machine features a precision motion tool, which provides for extremely accurate etching and ashing. This asset also provides for pre-programmable etching and ashing recipes, which enable precision process control and enable the user to adjust etching and ashing parameters for exact results. The model also has high inherent etch quality and uniformities, which allows for reliable and repeatable processes. 2300 Exelan Flex EX+ is also equipped with advanced safety features that ensure process reliability. These safety features include automatic termination of etching and ashing processes if any set limits are exceeded, temperature monitoring to prevent over-temperature damage and result data logging, which allows the user to quickly identify any process related issues. Overall, LAM RESEARCH 2300 Exelan Flex EX+ is an ideal etching and ashing solution for semiconductor manufacturing. This equipment is reliable and provides excellent consistent results, due to its precision motion system and pre-programmable recipes. Its safety features also ensure process reliability, by thwarting any potential problems before they happen. This unit is a dependable, high-performance solution for any semi-conductor etching and ashing needs.

There are no reviews yet