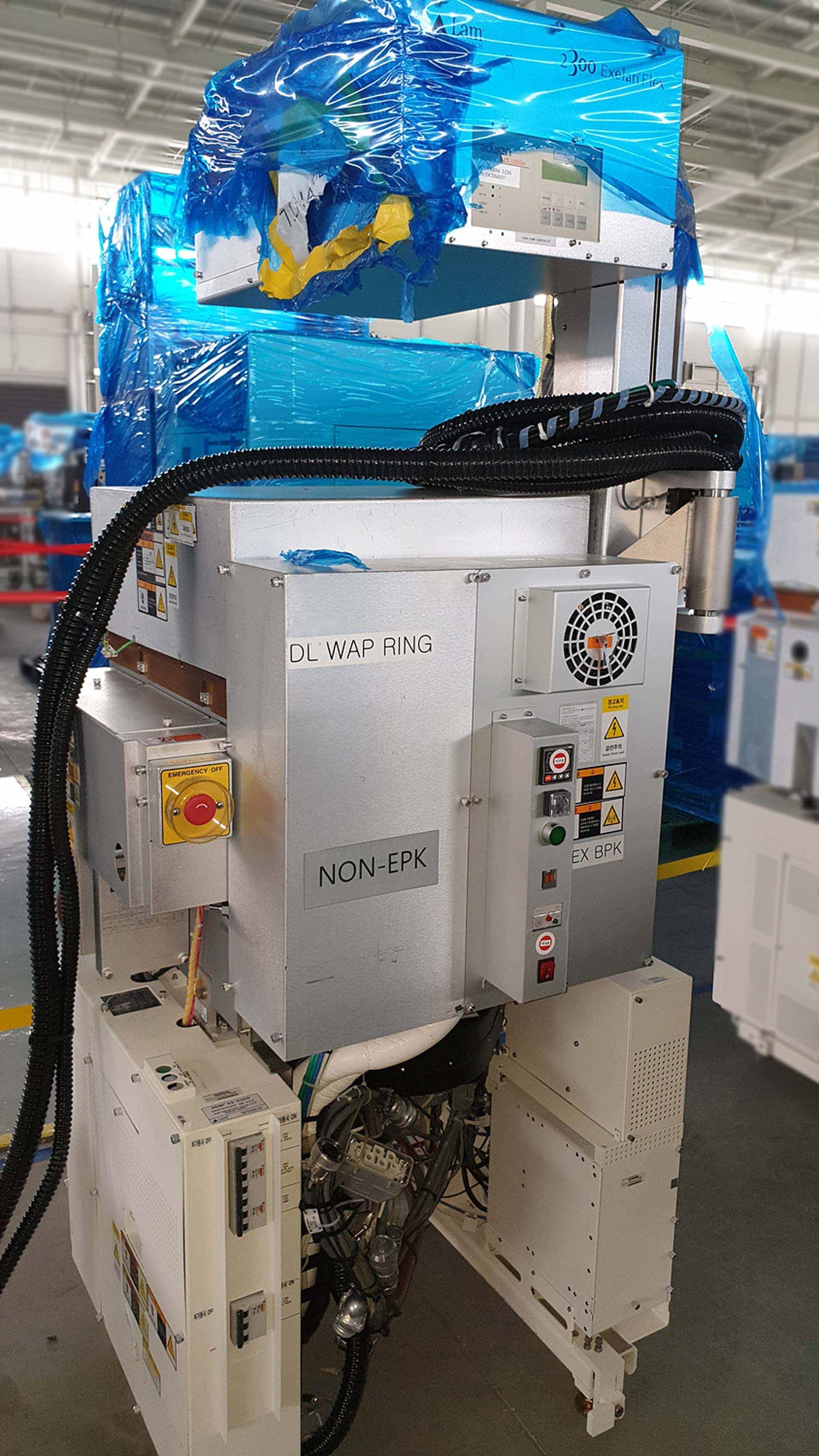

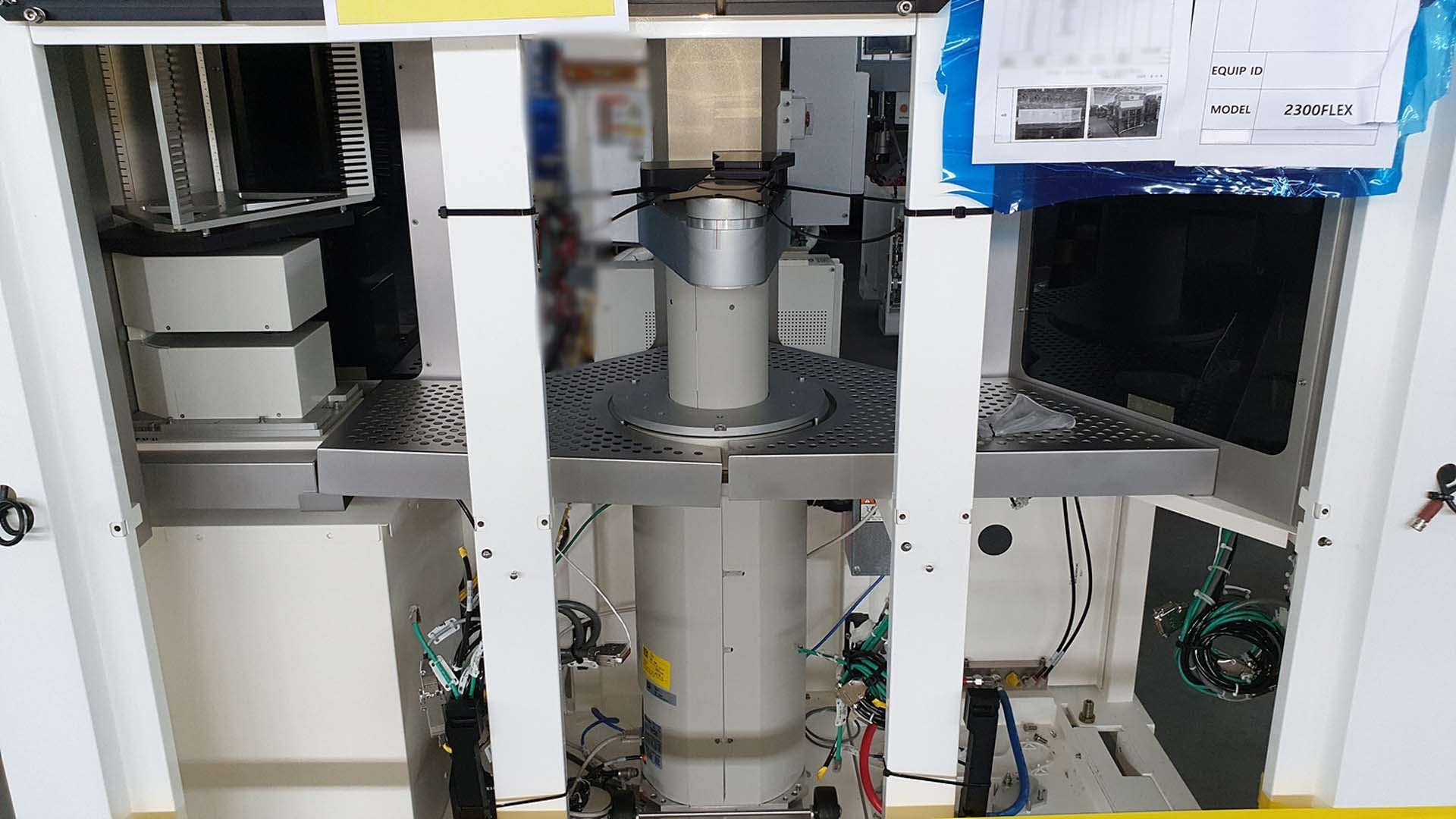

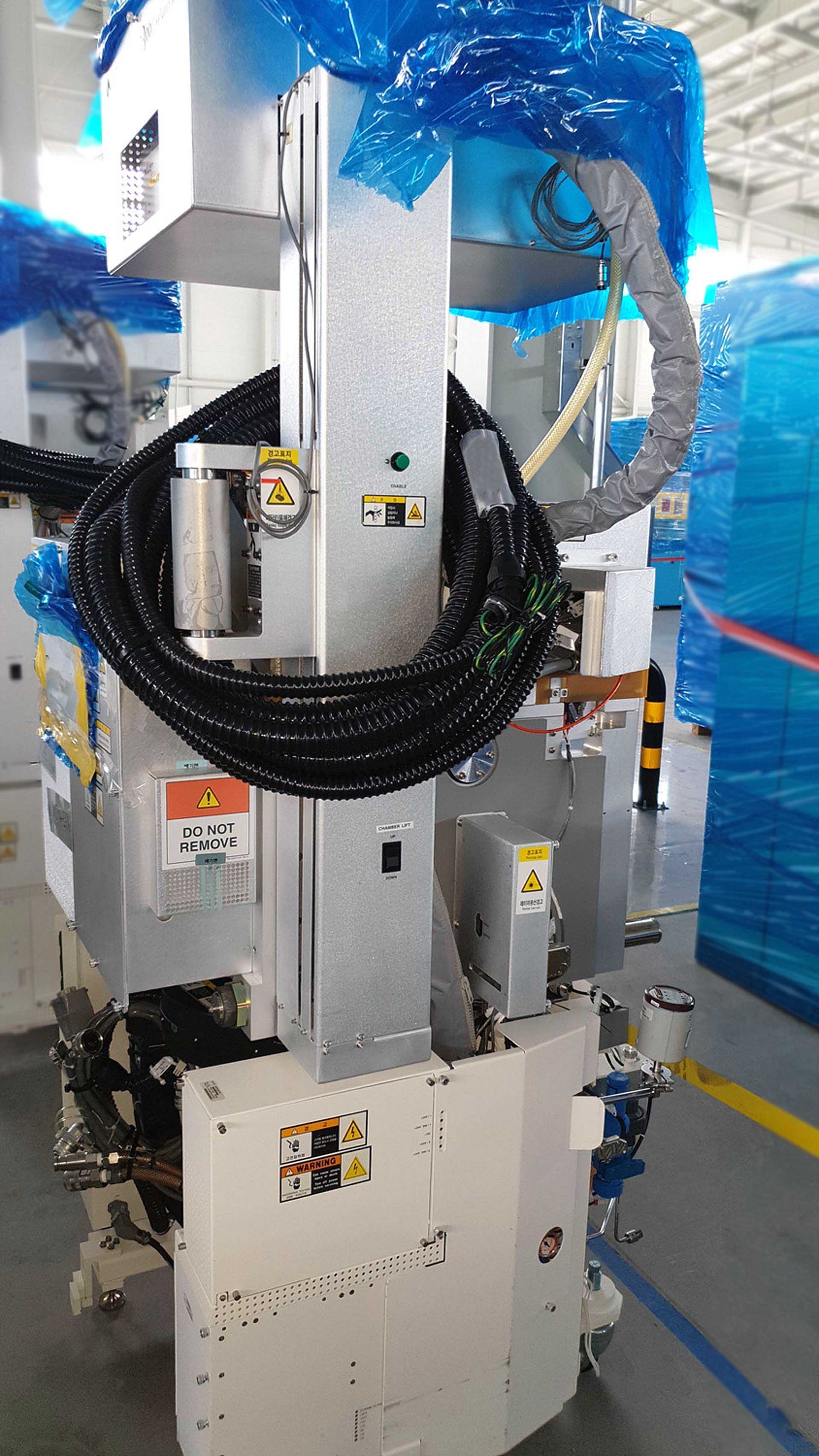

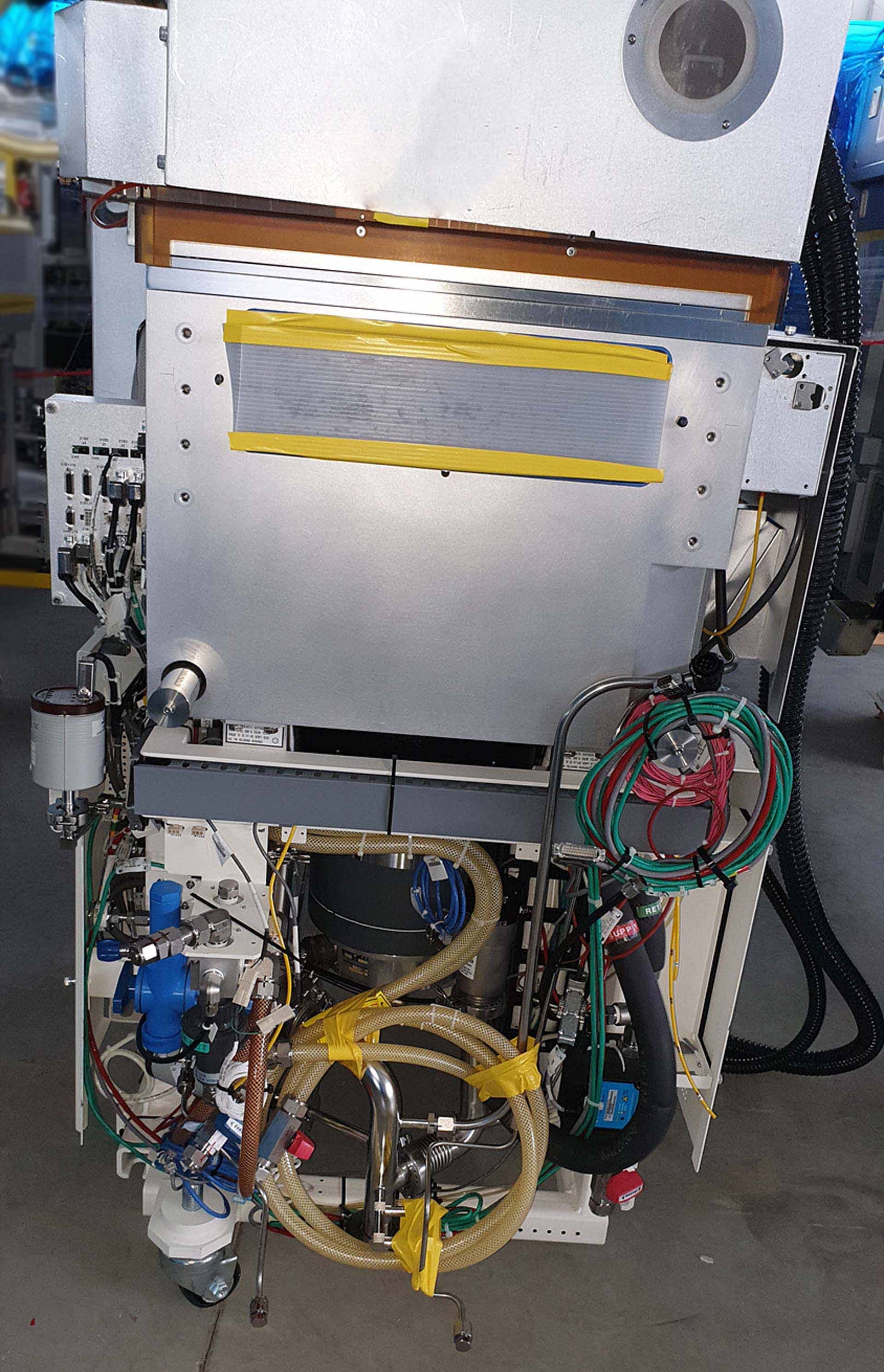

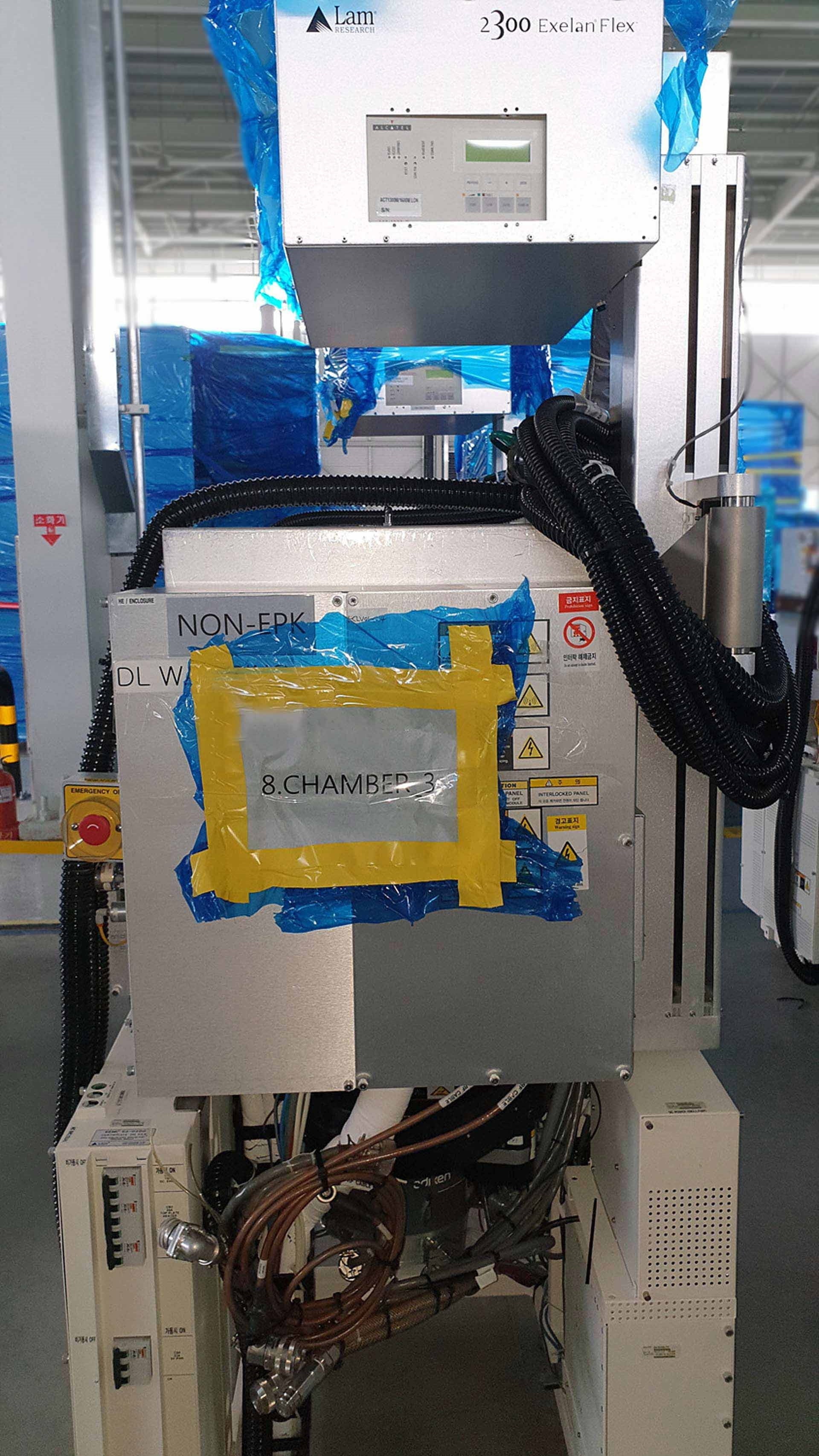

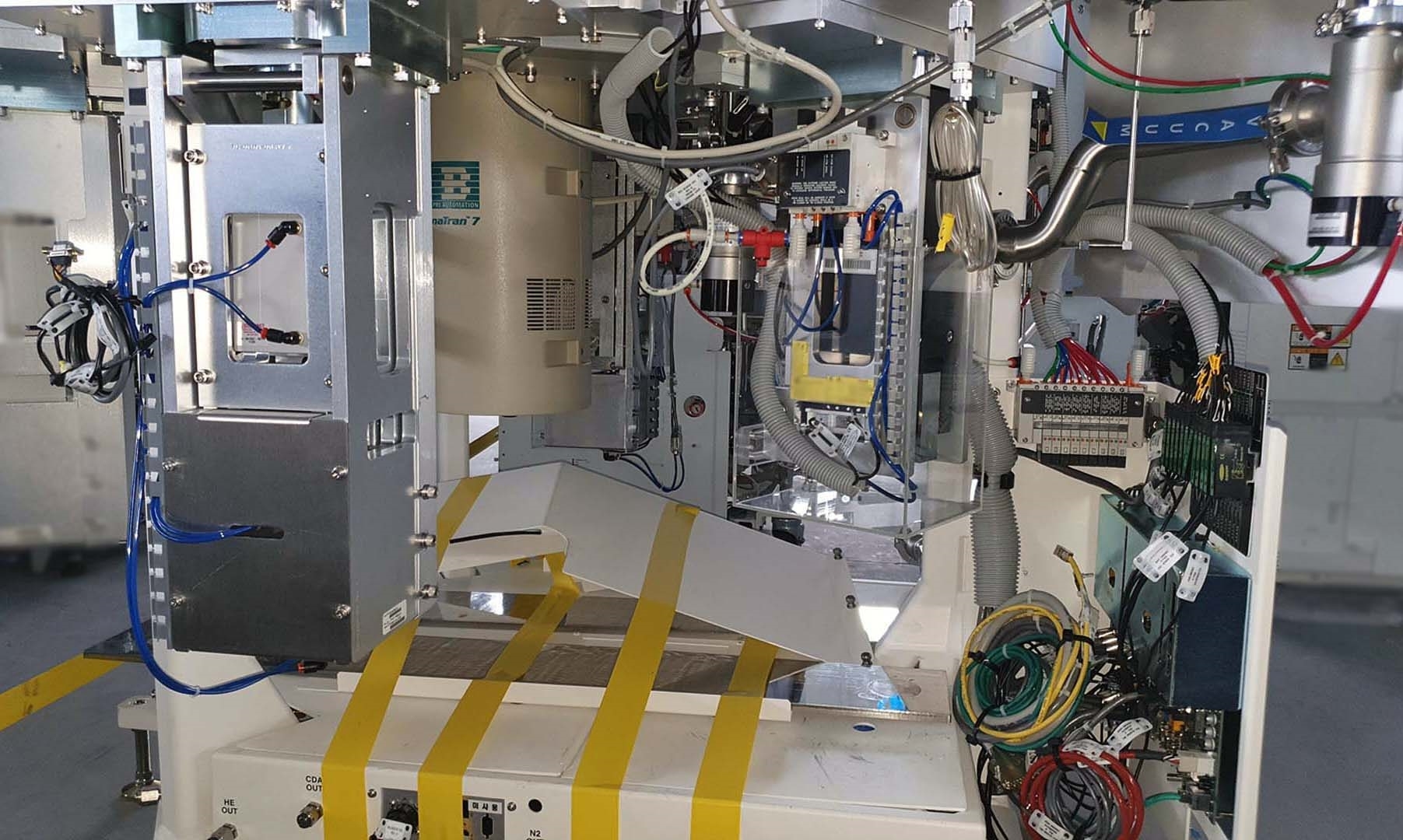

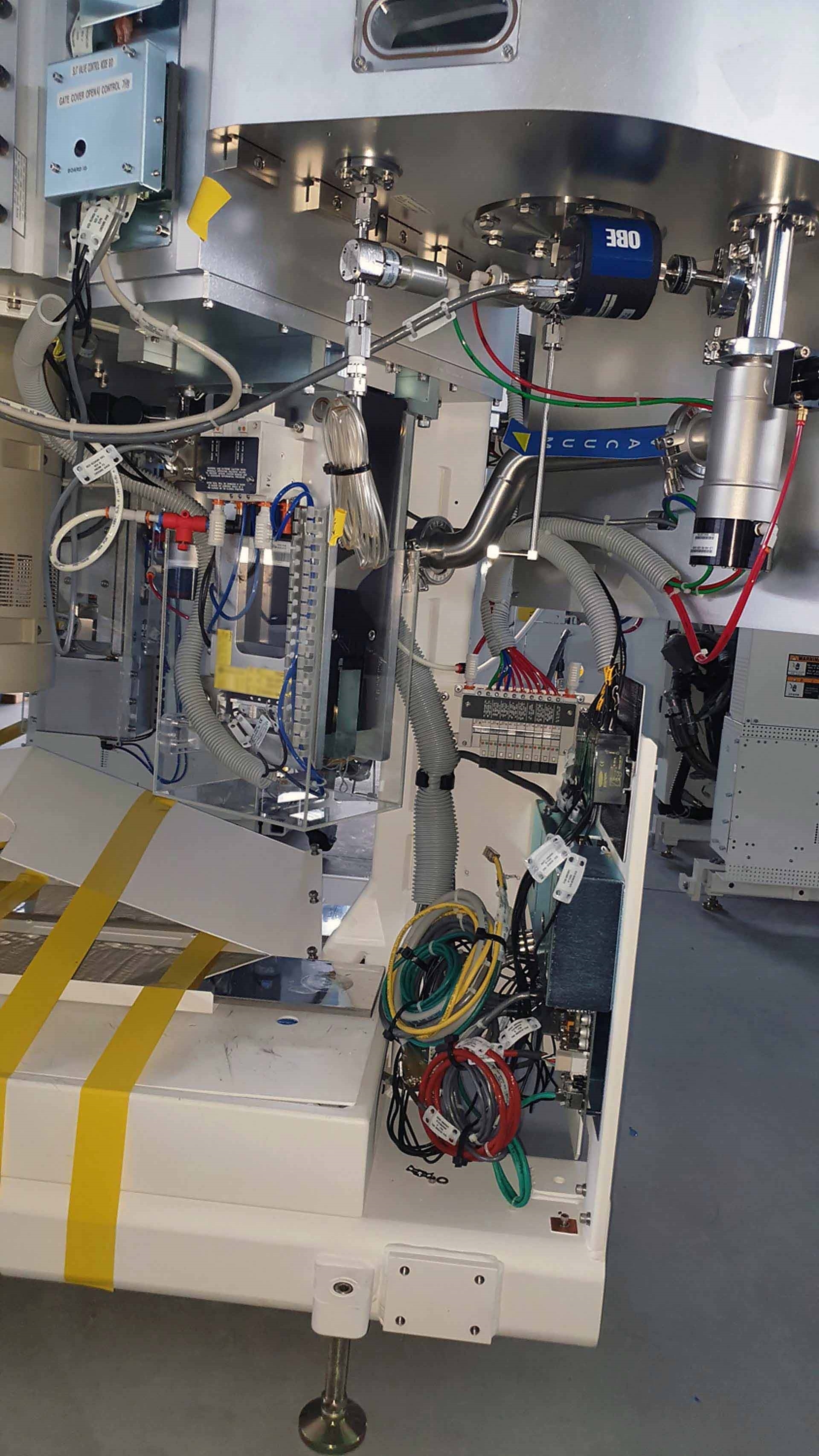

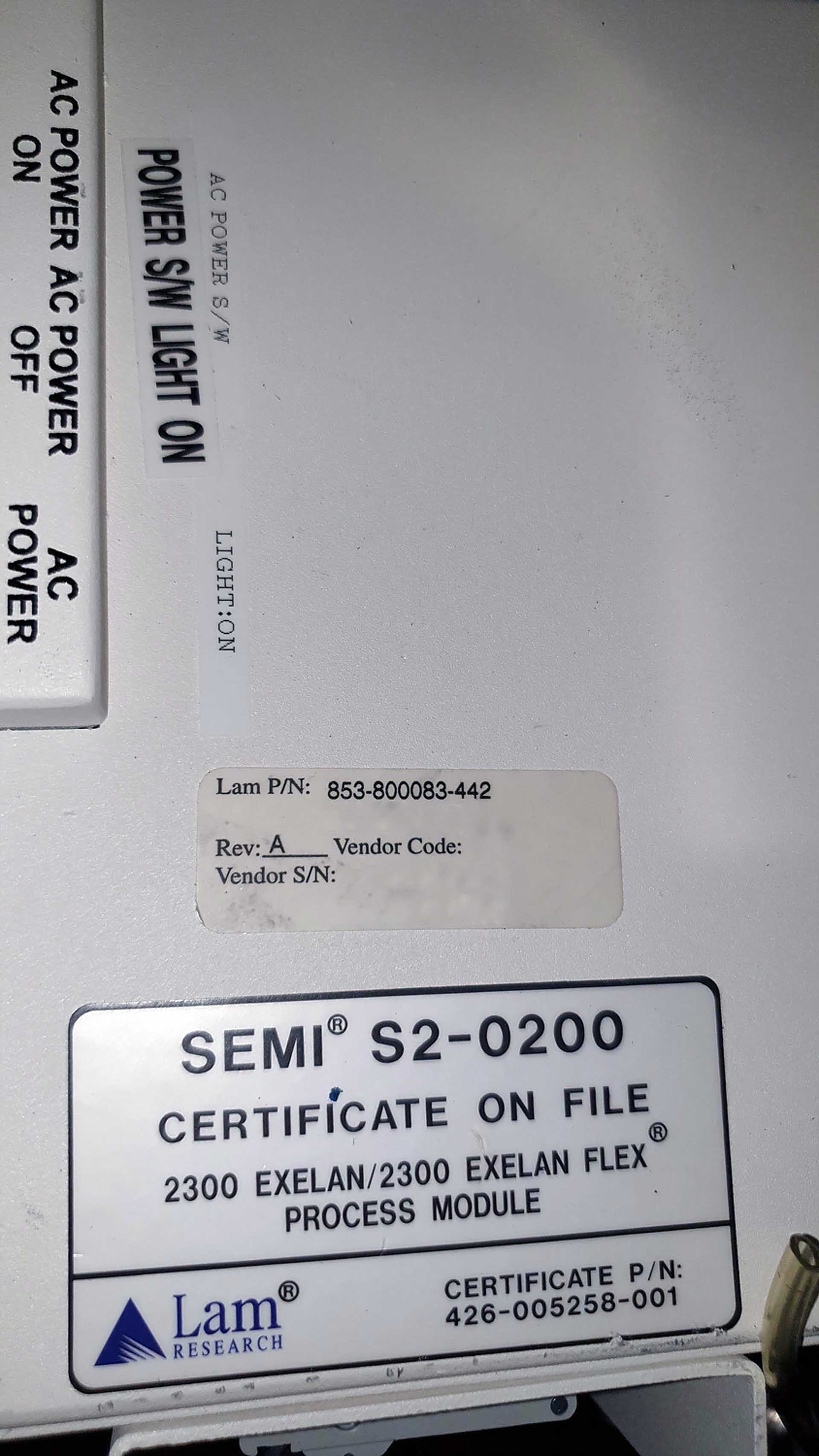

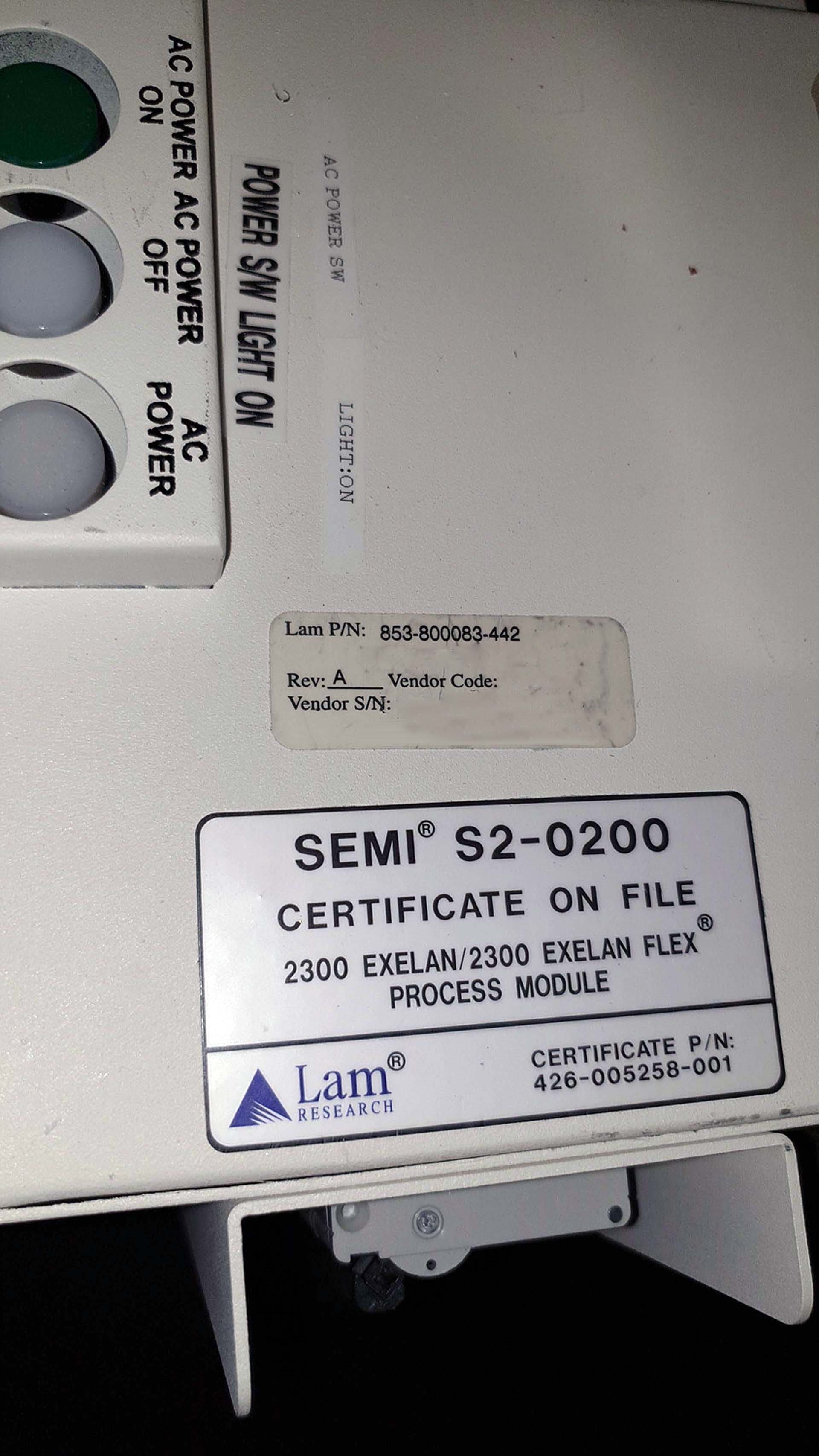

Used LAM RESEARCH 2300 Flex #9244871 for sale

URL successfully copied!

Tap to zoom

ID: 9244871

Wafer Size: 12"

Vintage: 2005

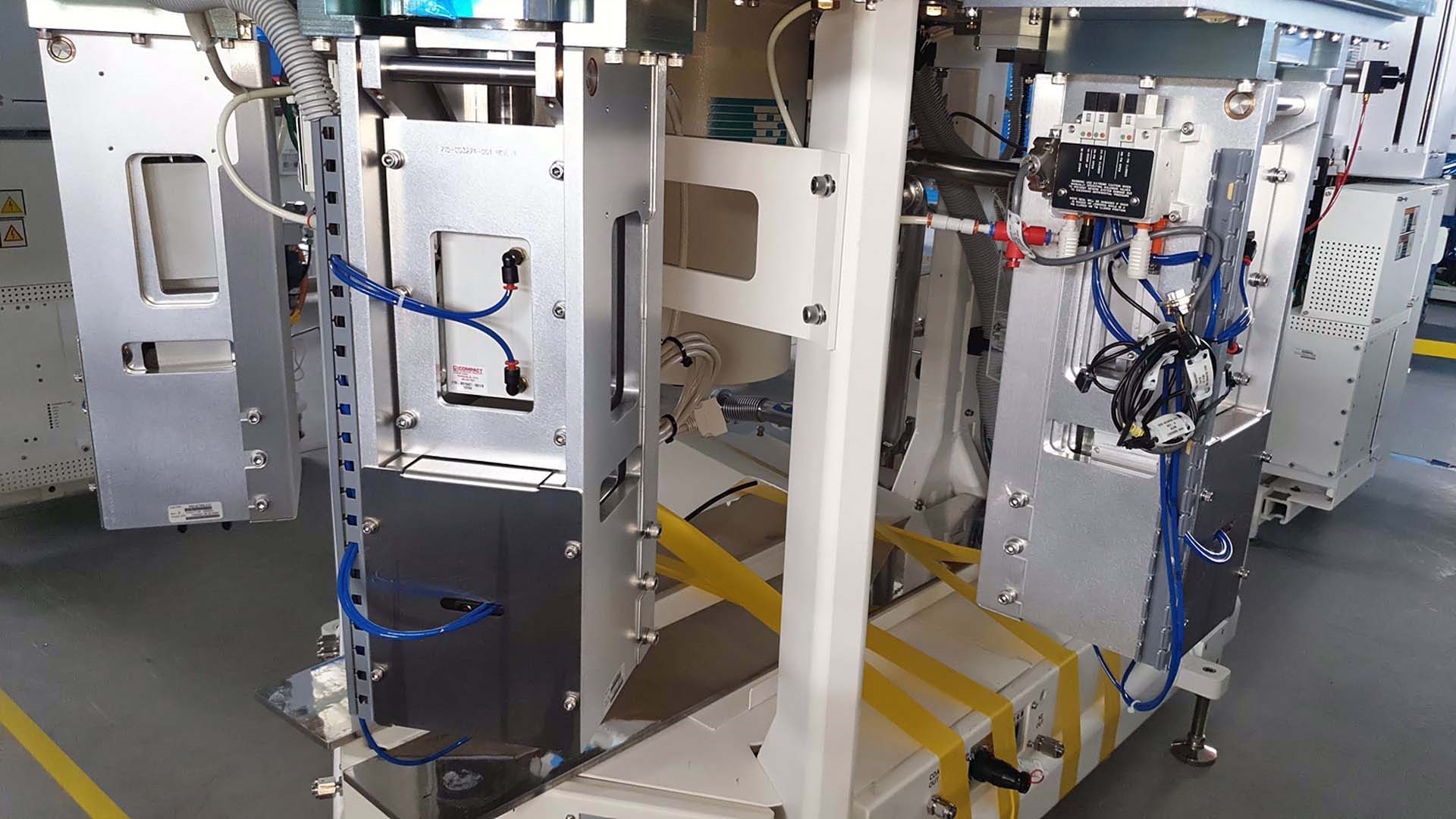

Etcher, 12"

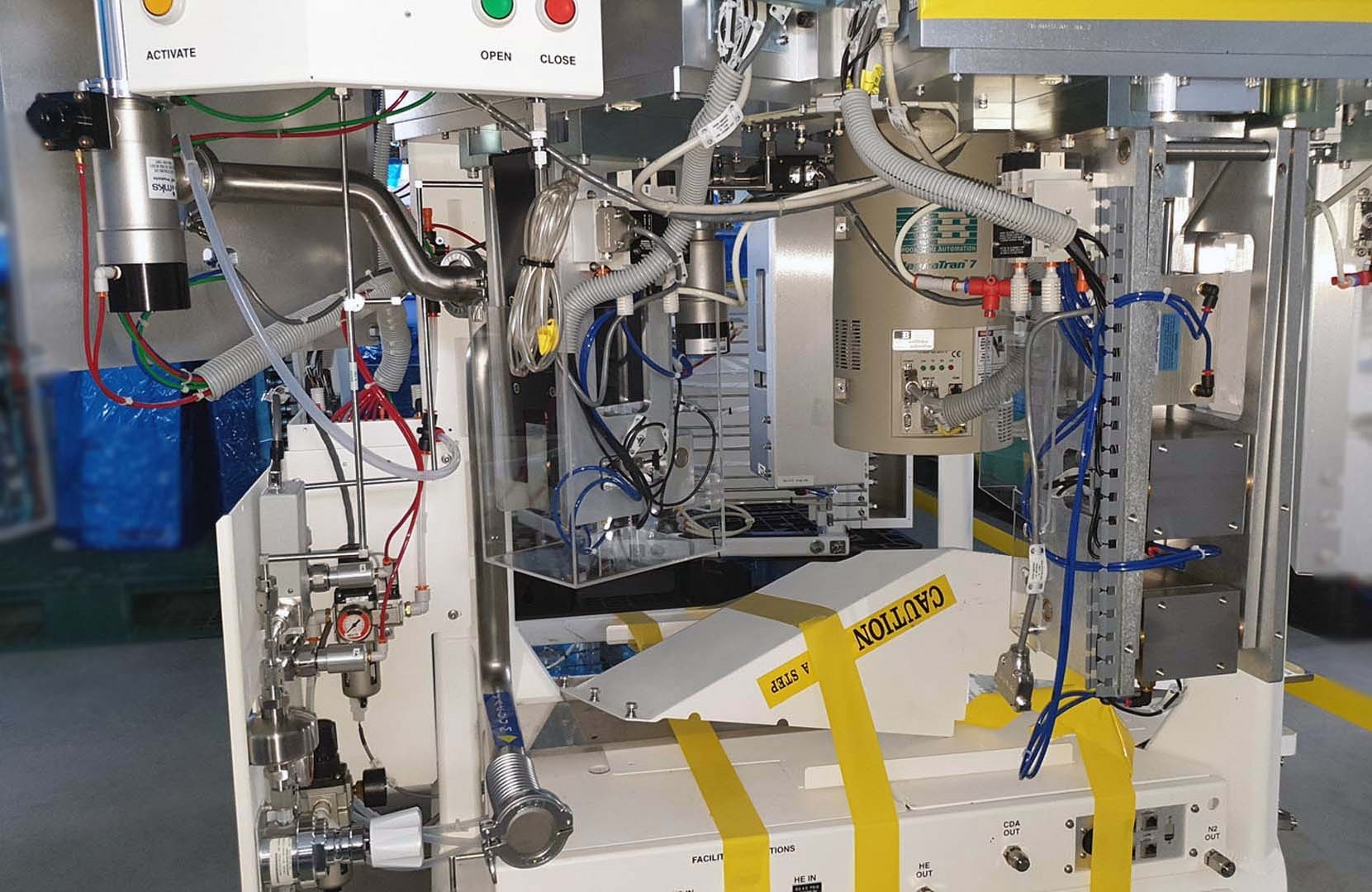

FOUP

EFEM

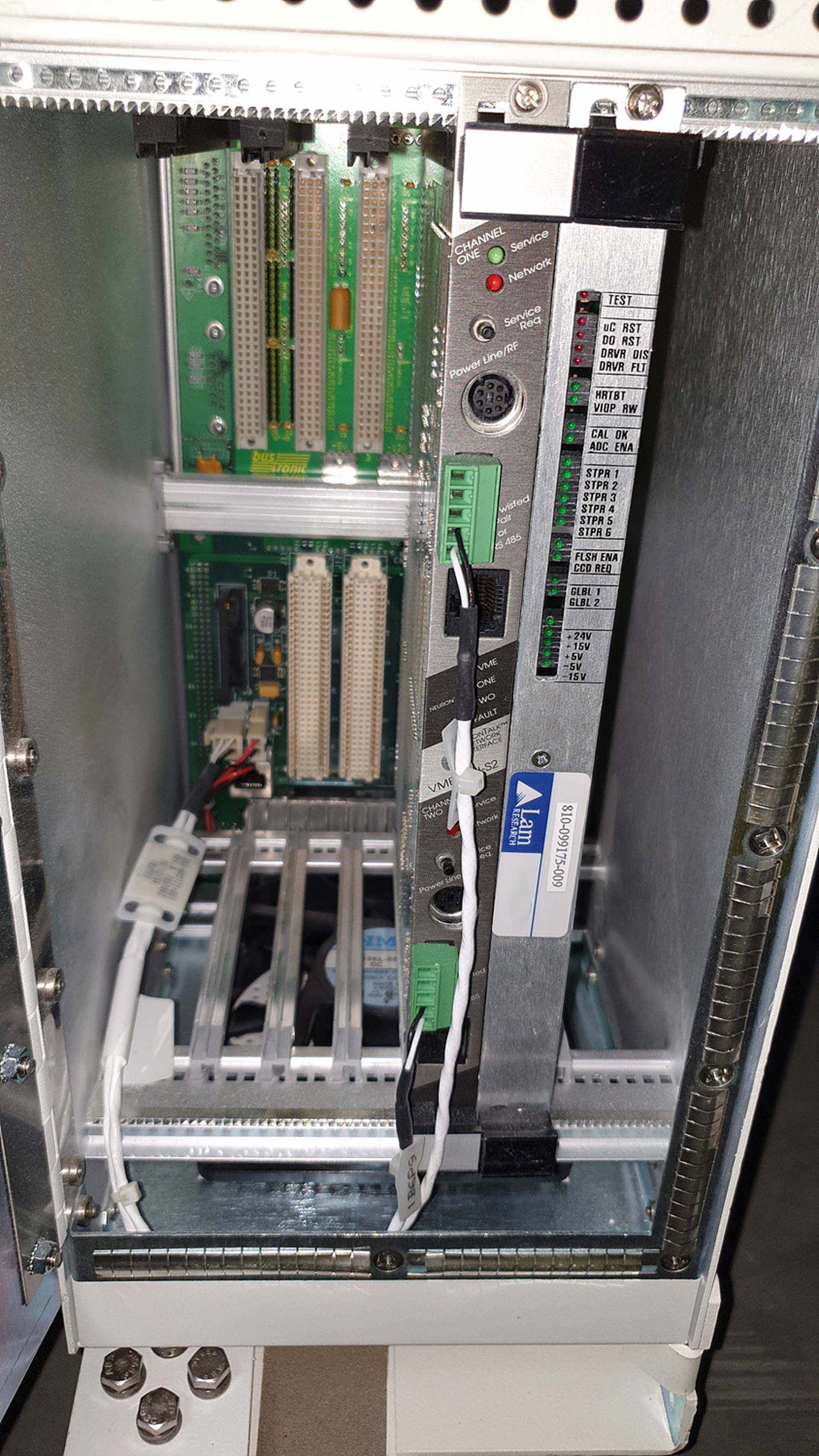

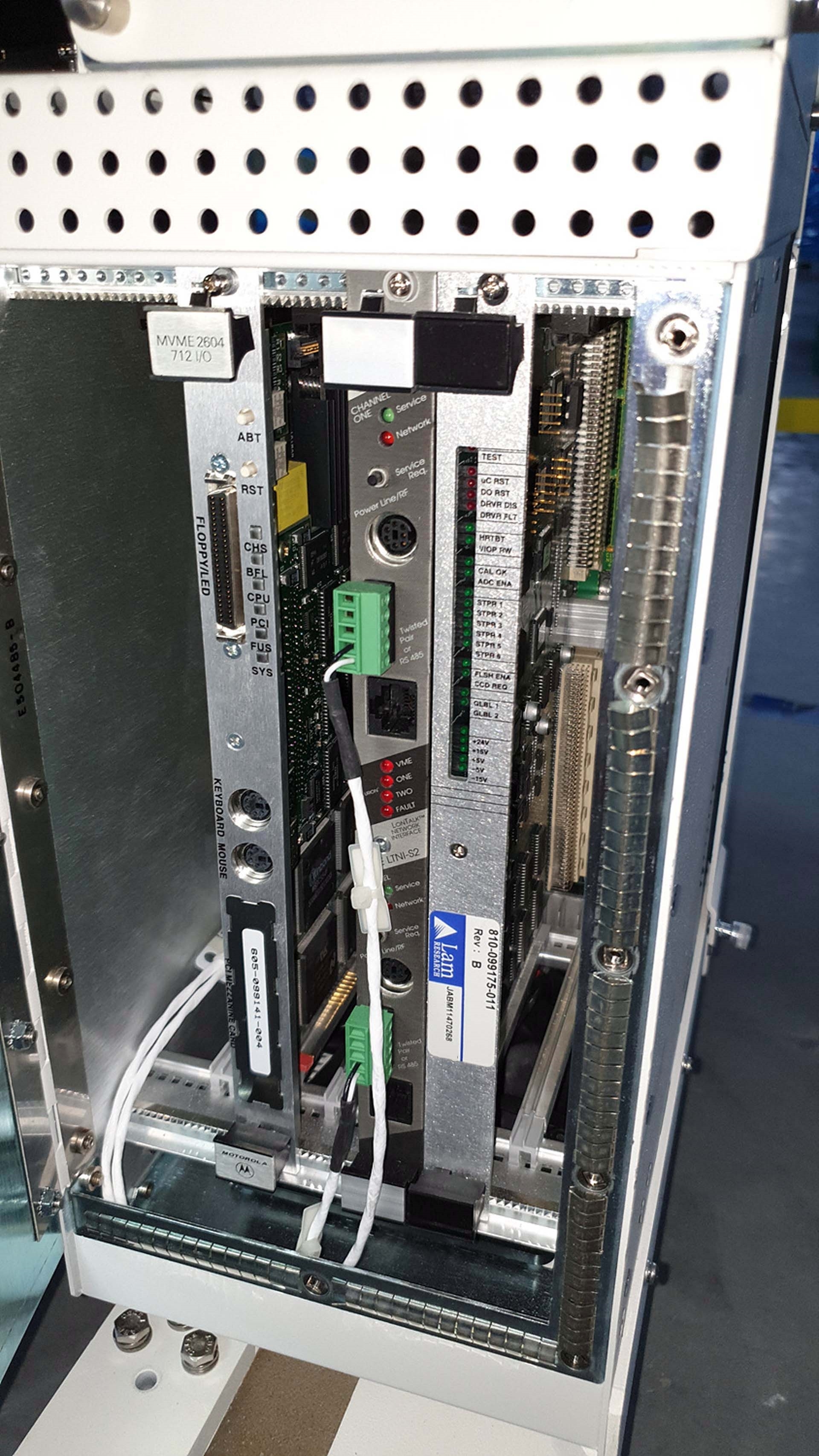

AC Rack

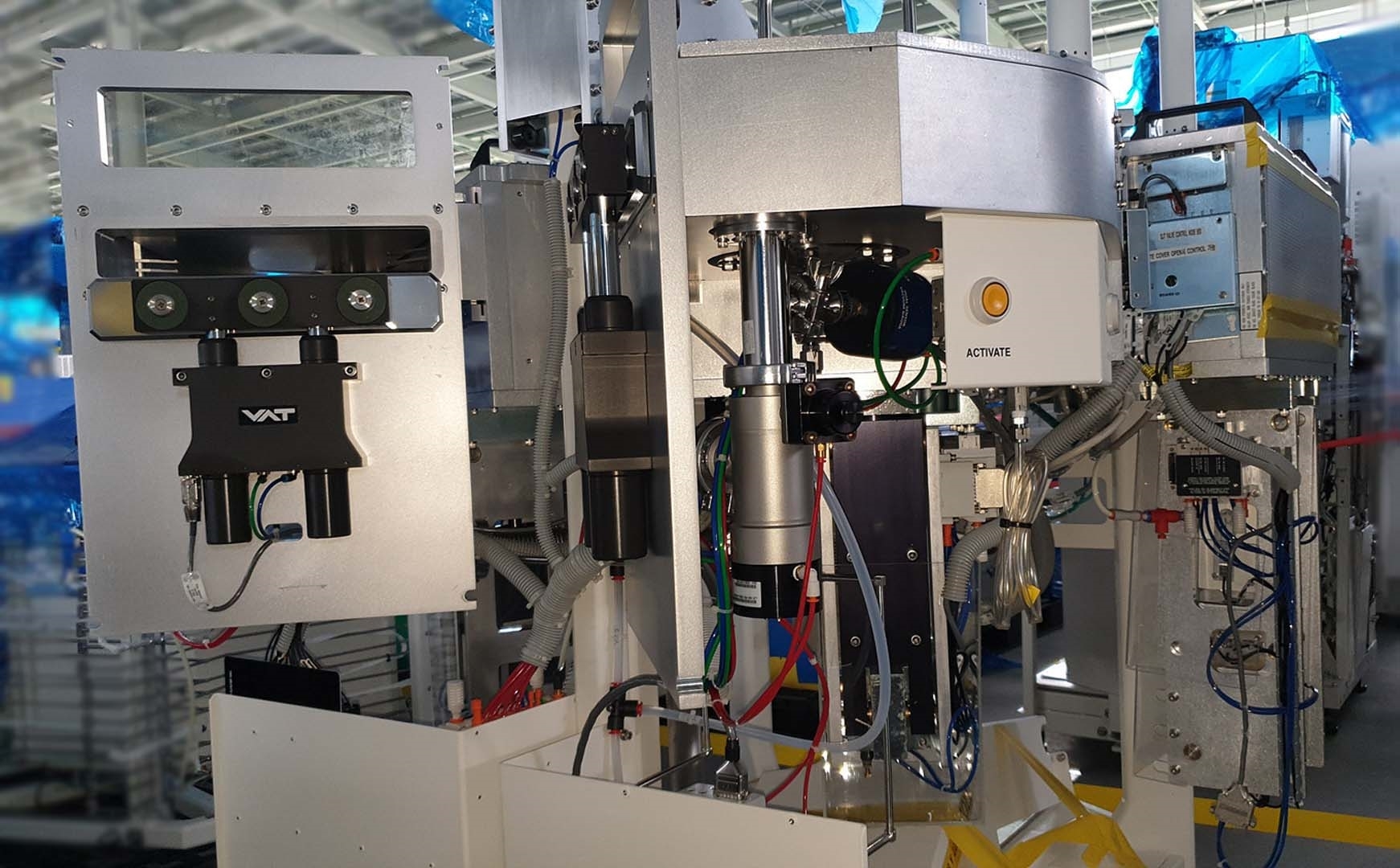

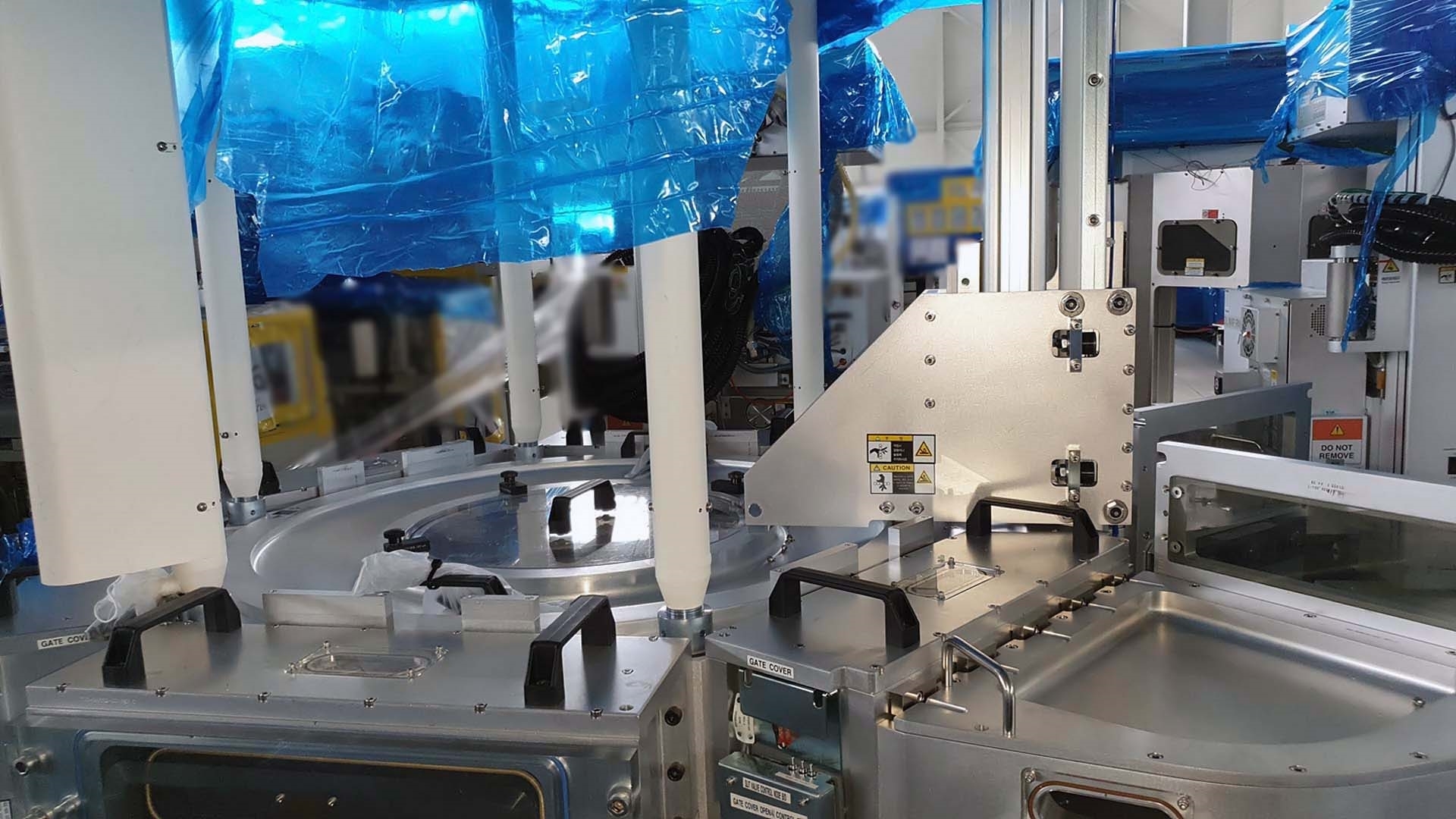

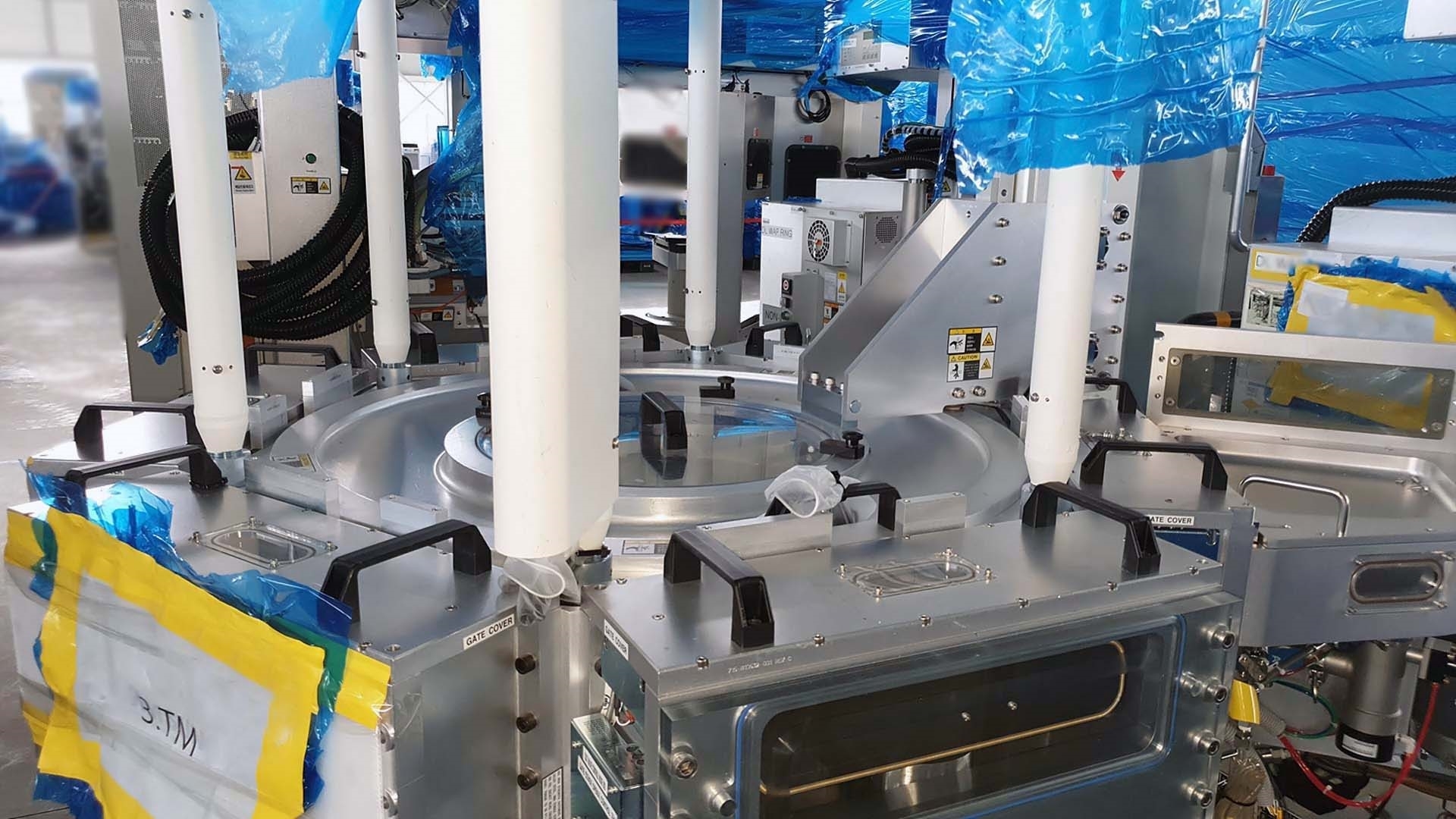

TM

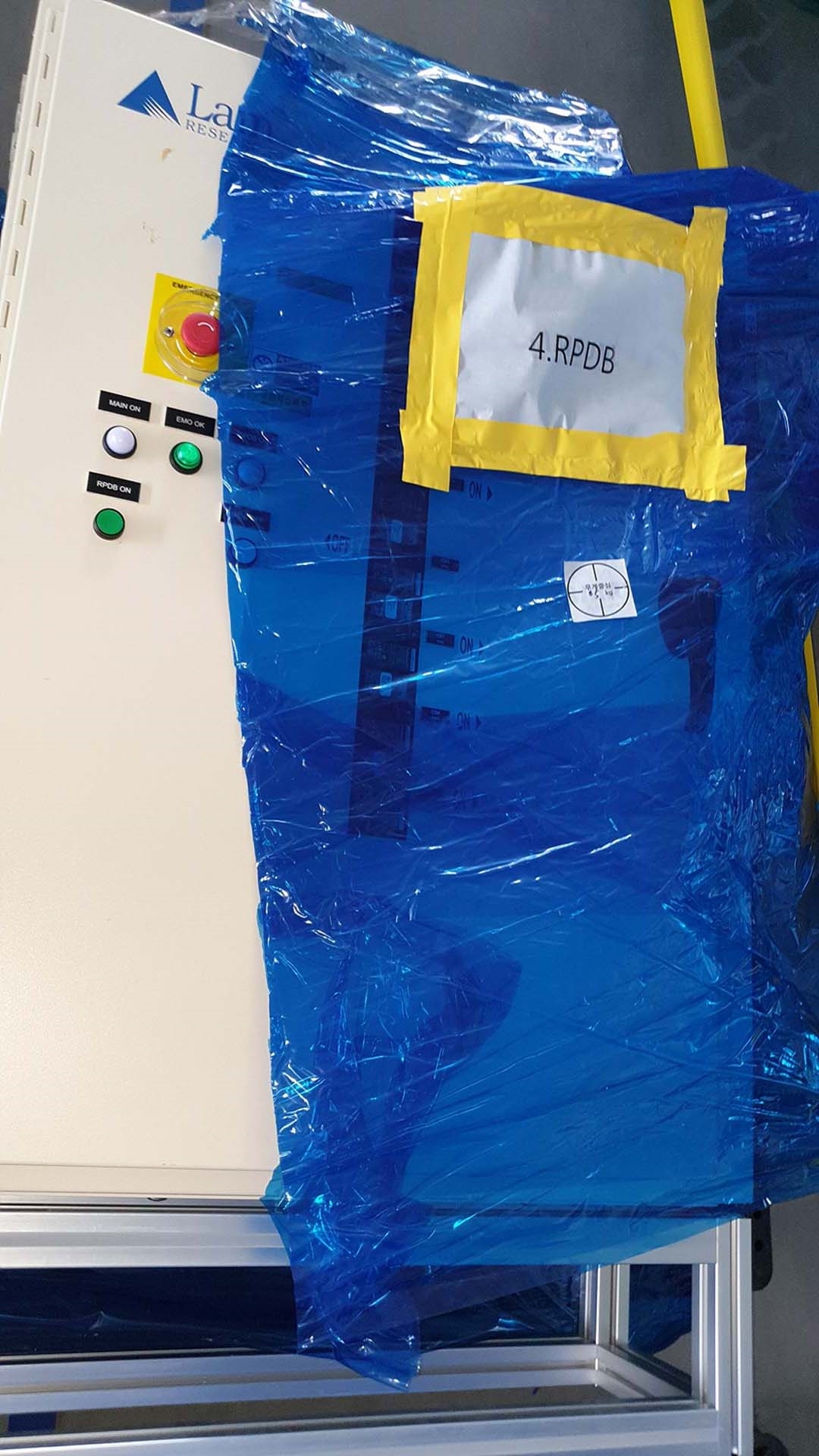

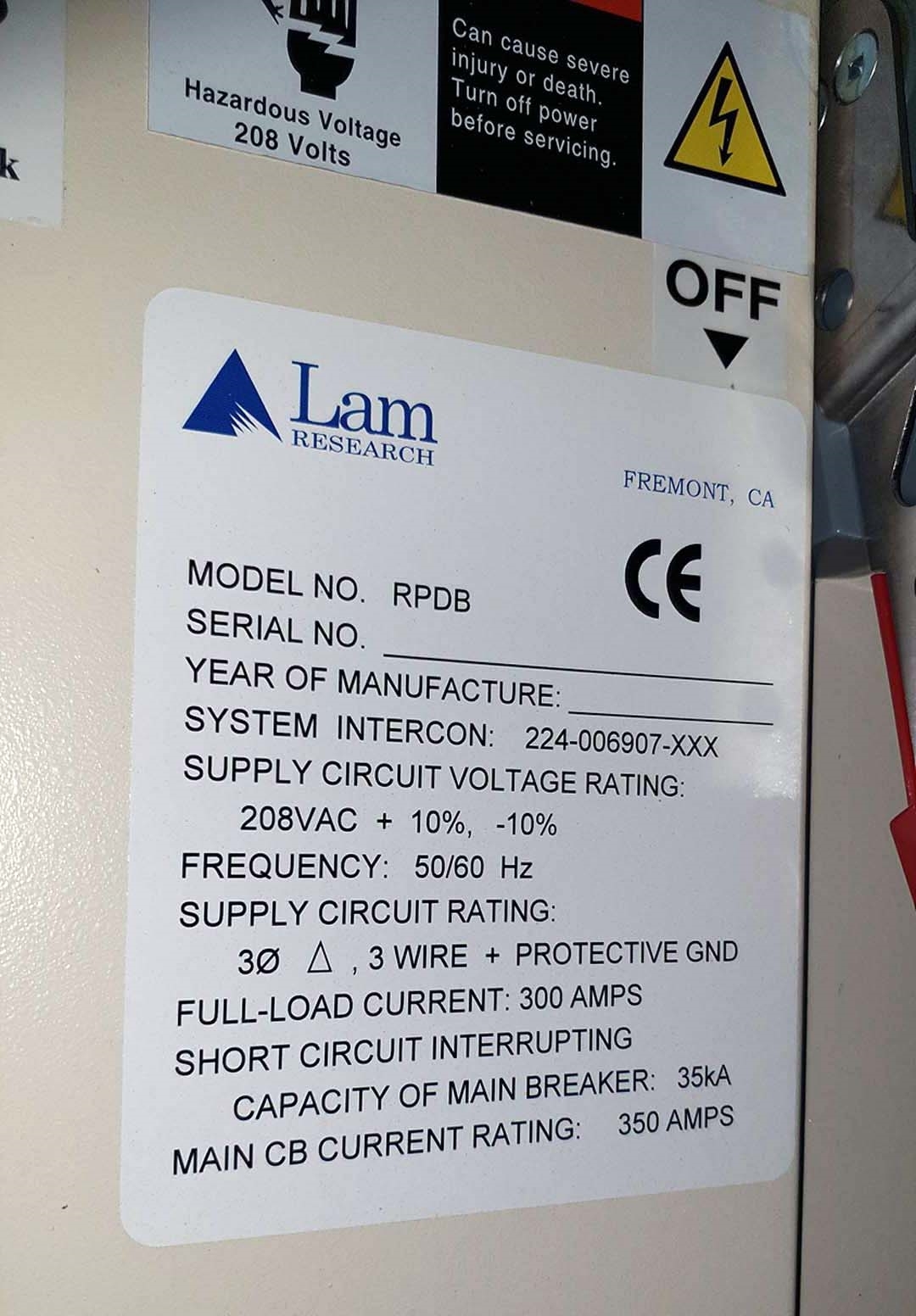

RPDB

GIB

Operating system: Windows XP

Chemical: FC-3283

Process module:

(3) Chambers

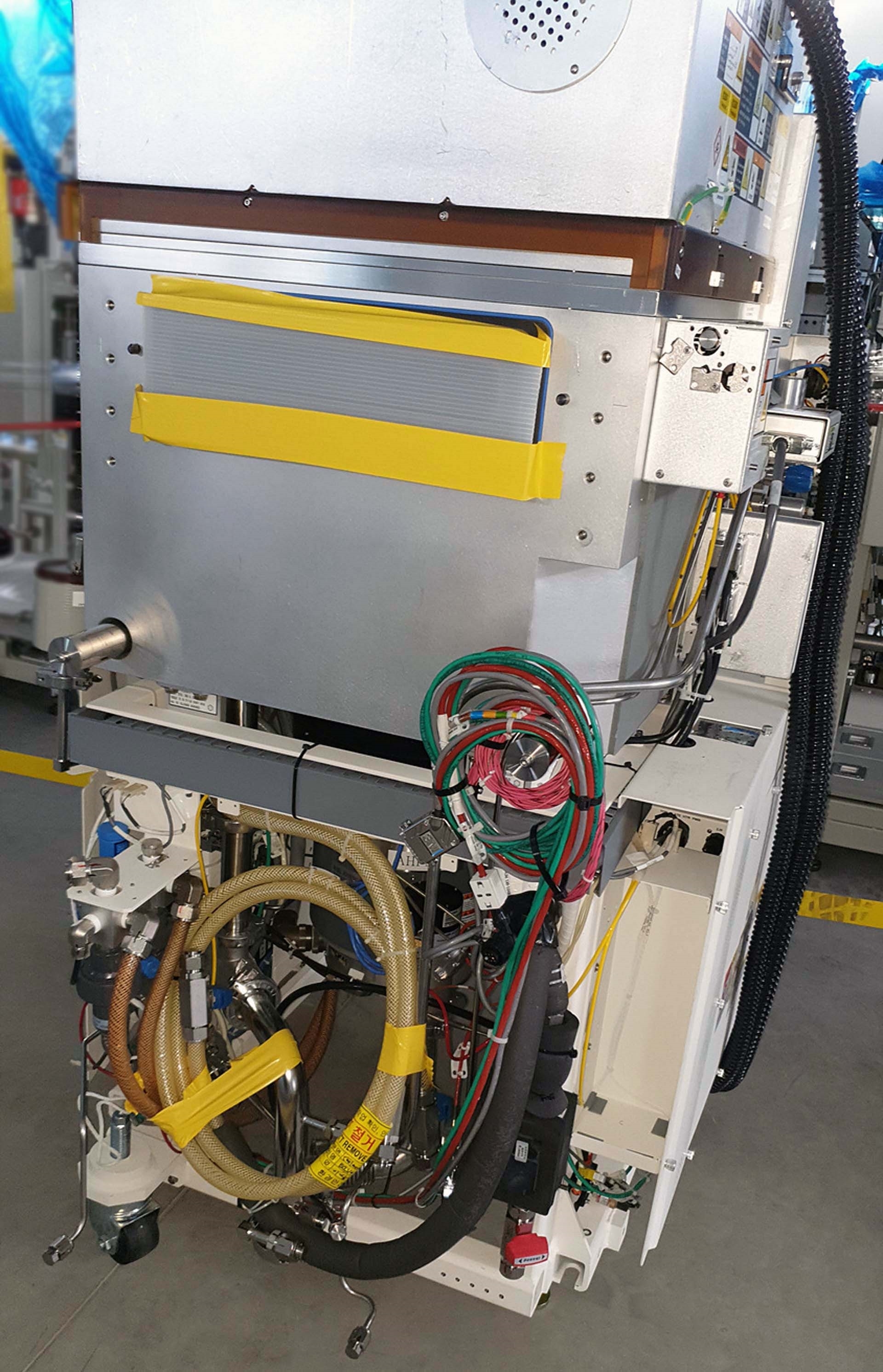

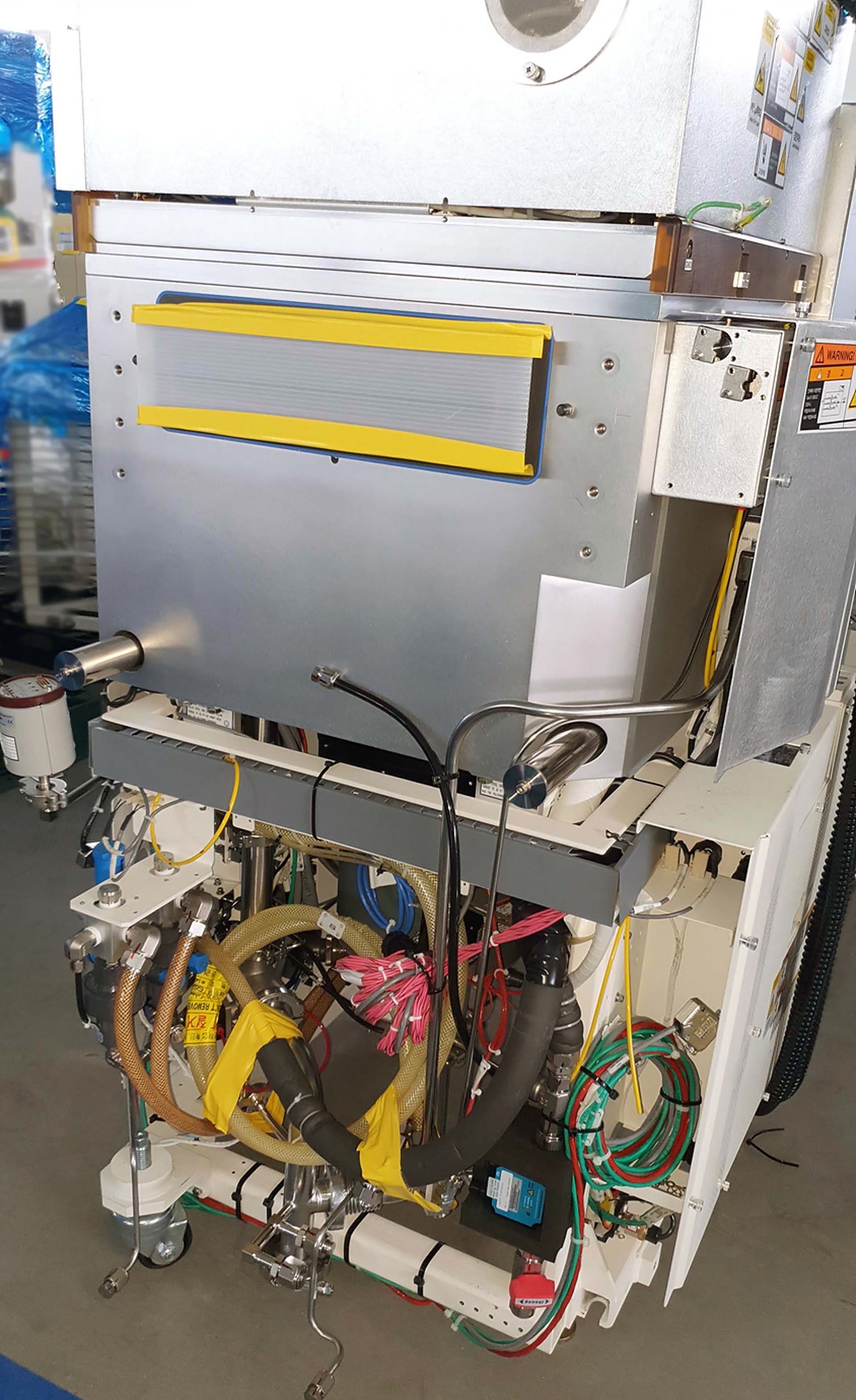

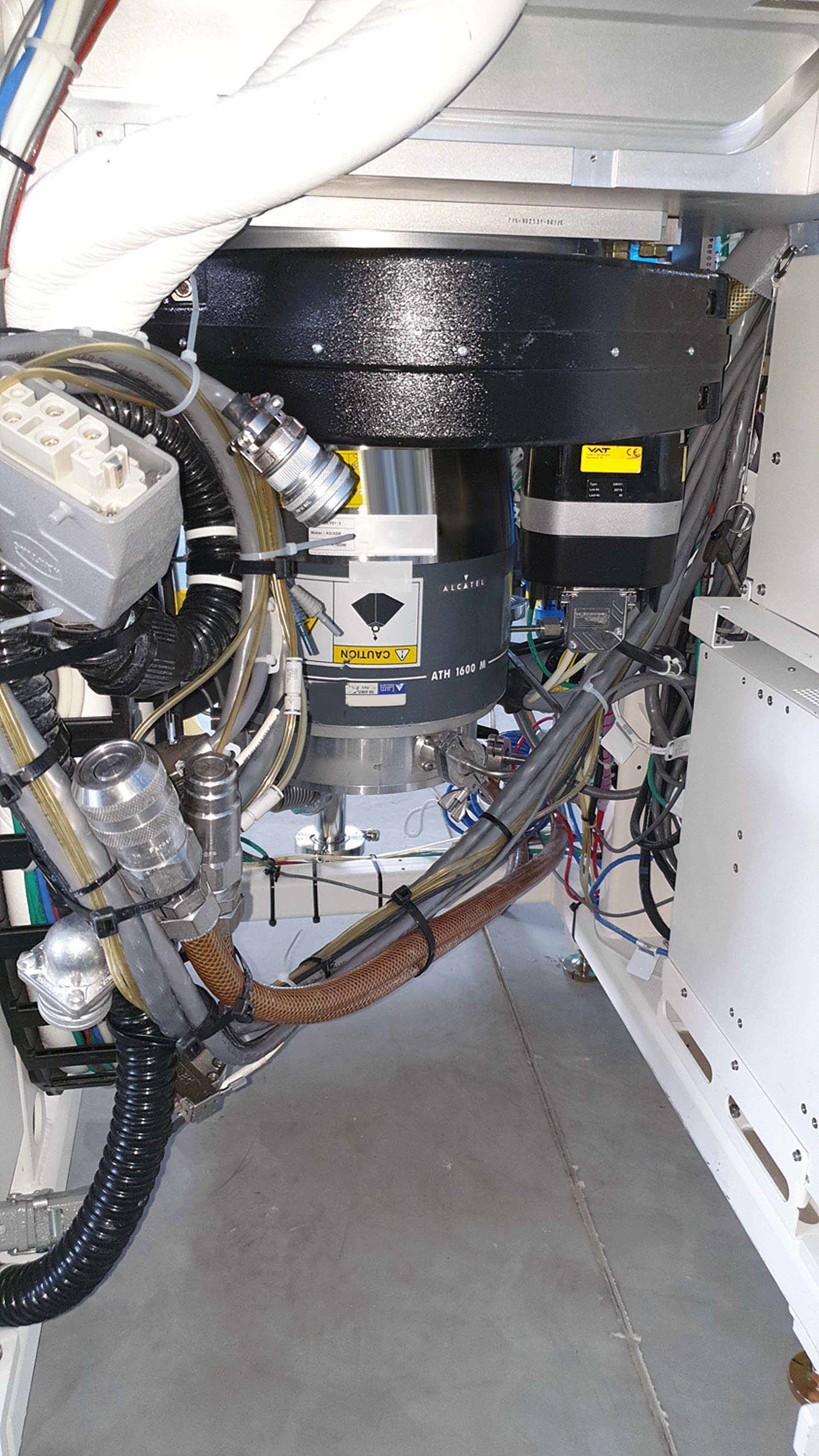

(3) ALCATEL / ADIXEN / PFEIFFER ADS 1202H Pumps

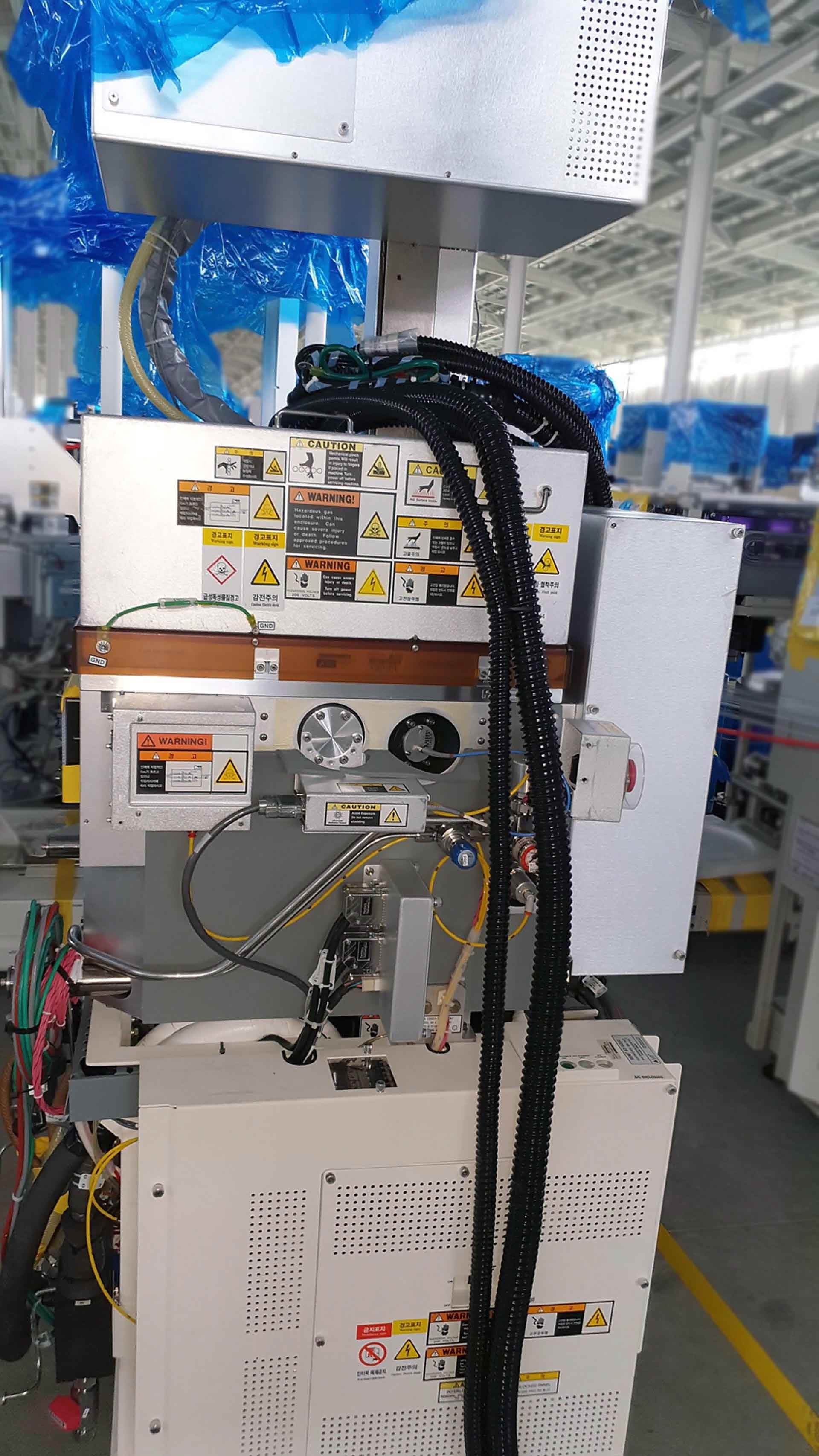

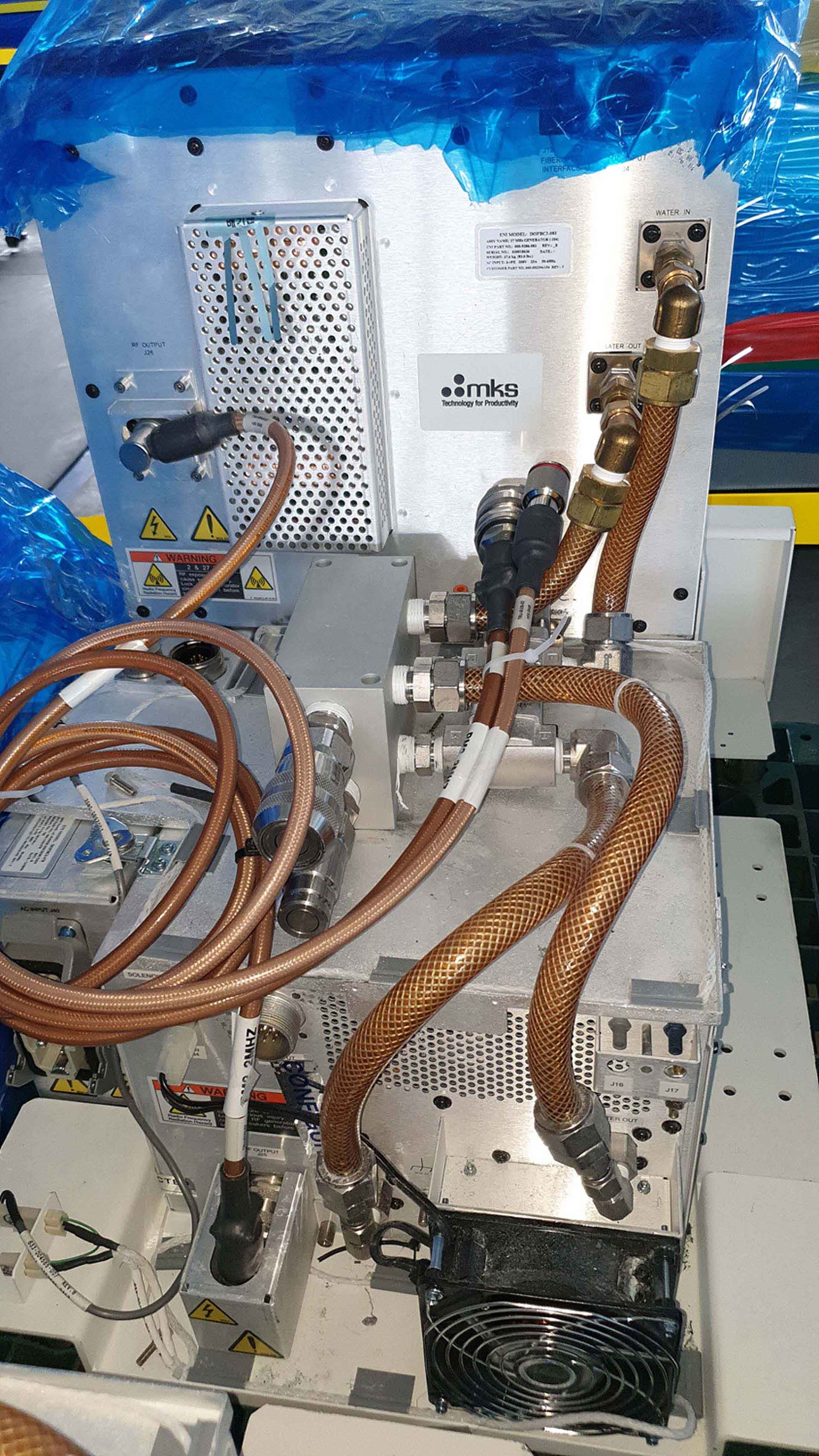

(3) AE DOFBC2-84 Generators

(3) AE DOFBC2-83 Generators

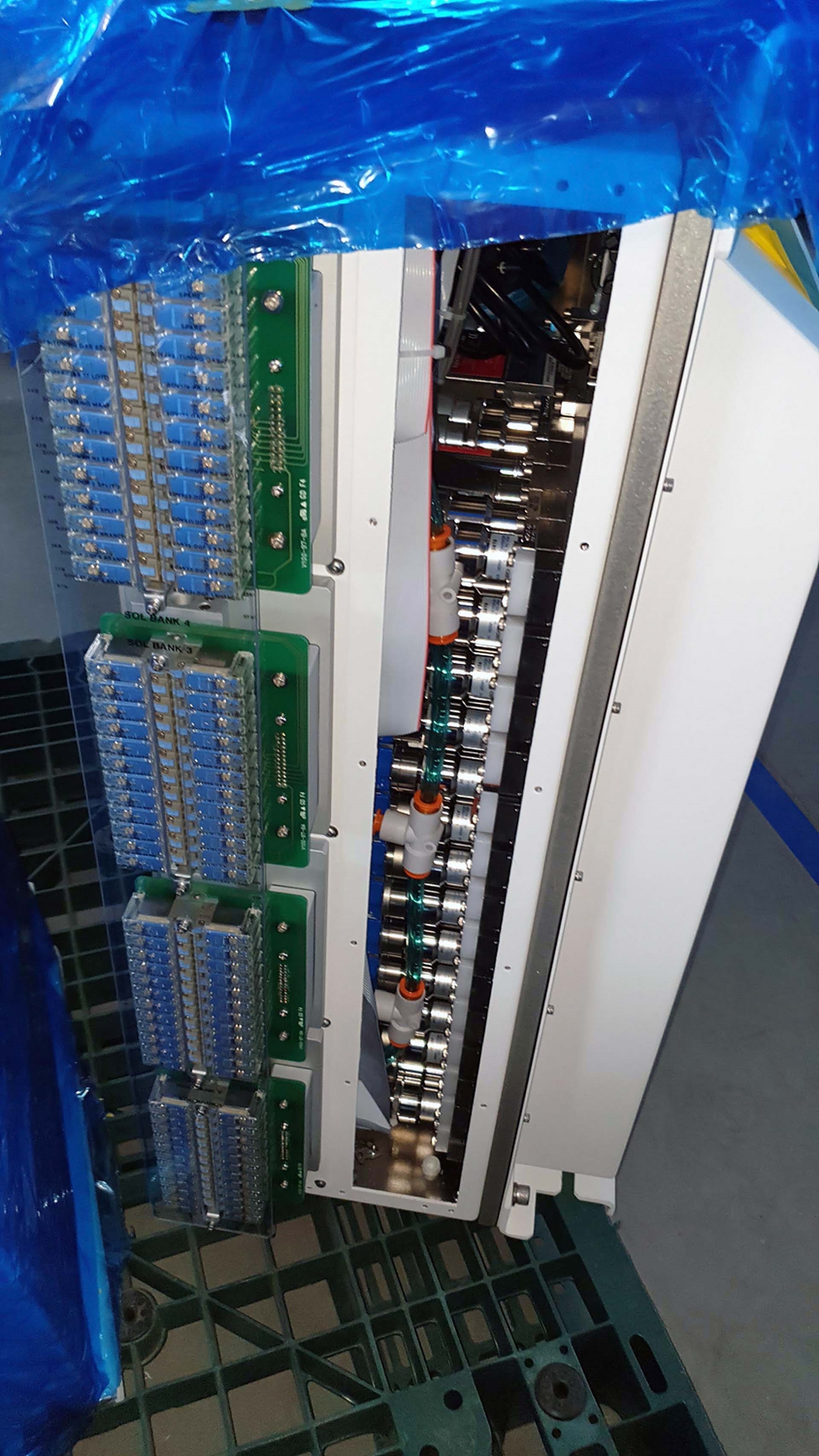

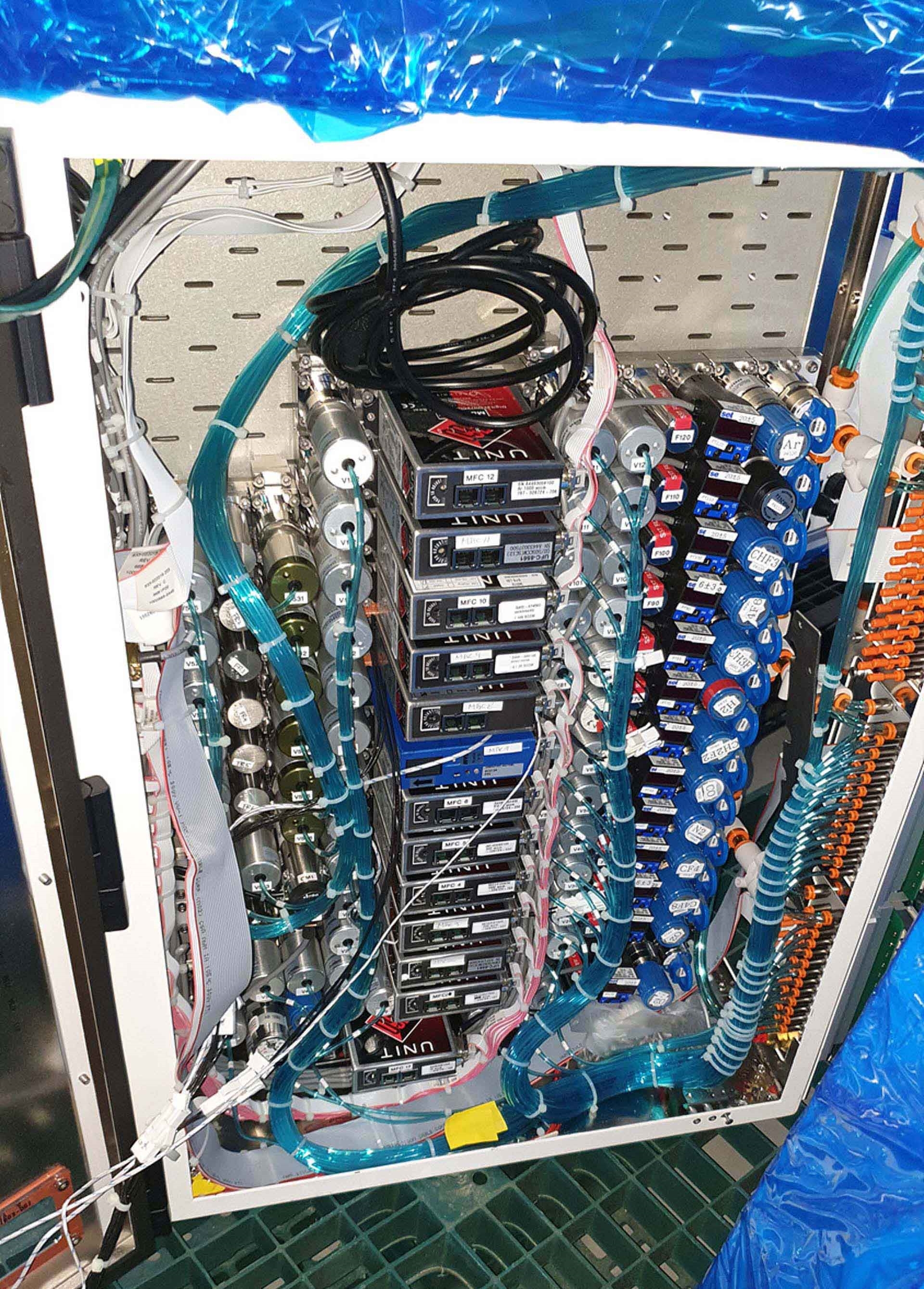

(3) IGS Gas boxes

(3) Load ports

(2) Boxes

(3) Panels

(3) FST FSTC-CD352 Chillers

UI Monitor

PC

Utility:

(4) PCW Cooling waters

(3) Vacuum pipes

(6) Coolant lines

Process gas:

C4F8

CF4

CO

CH2F2

H2

CH3F

C4F6

Missing parts:

(3) 308 ESC Power supplies

(3) ESC Current boards

Voltage: 30 kW

2005 vintage.

LAM RESEARCH 2300 Flex is an etcher/asher designed for the semiconductor industry. It provides an economical solution for the critical step of wafer fabrication. By employing an XeF2 (xenon fluoride) dry etching equipment and a wet ash system, 2300 Flex is able to remove both non-metallic and metallic films from the wafer. This precision unit has been designed for easy integration into existing fabs and is extremely robust. LAM RESEARCH 2300 Flex offers three different etch processes to best meet the needs of each application. These include chemical etch, plasma etch and thermal etch. By taking advantage of the XeF2 chemical etch process, the machine is able to uniformly etch extremely complex topographies and remove films at a much faster rate than traditional experimental etches. Utilizing a high-density inductively coupled plasma process allows the tool to etch through materials with a high level of selectivity, while still maintaining a high etch rate. Additionally, when used in combination with a downstream wet ash, 2300 Flex provides a two-step process with first plasma etching followed by a wet ash. LAM RESEARCH 2300 Flex is equipped with advanced features for precise control of the etching process parameters. These features include independent modulation of each of the process parameters, enabling precise control over etch rate, uniformity and selectivity. 2300 Flex can also be fully automated, allowing for repeatable processes and consistent results. A built-in data logging asset is also included, allowing for accurate results analysis and process reliability. The model also features premium safety features, including emergency bulk gas shutoff, gas line safety purge and a forced exhaust equipment for removing any hazardous byproducts resulting from an etch process. Additionally, LAM RESEARCH 2300 Flex includes an integrated electrostatic discharge system to protect the etching process from any static electricity present. Overall, 2300 Flex is an efficient and reliable etcher/ash offering improved process control and accuracy. With its simple integration capabilities and safety features, LAM RESEARCH 2300 Flex is a reliable and economical solution for any semiconductor fabrication process.

There are no reviews yet