Used LAM RESEARCH 2300 Kiyo #293593184 for sale

URL successfully copied!

Tap to zoom

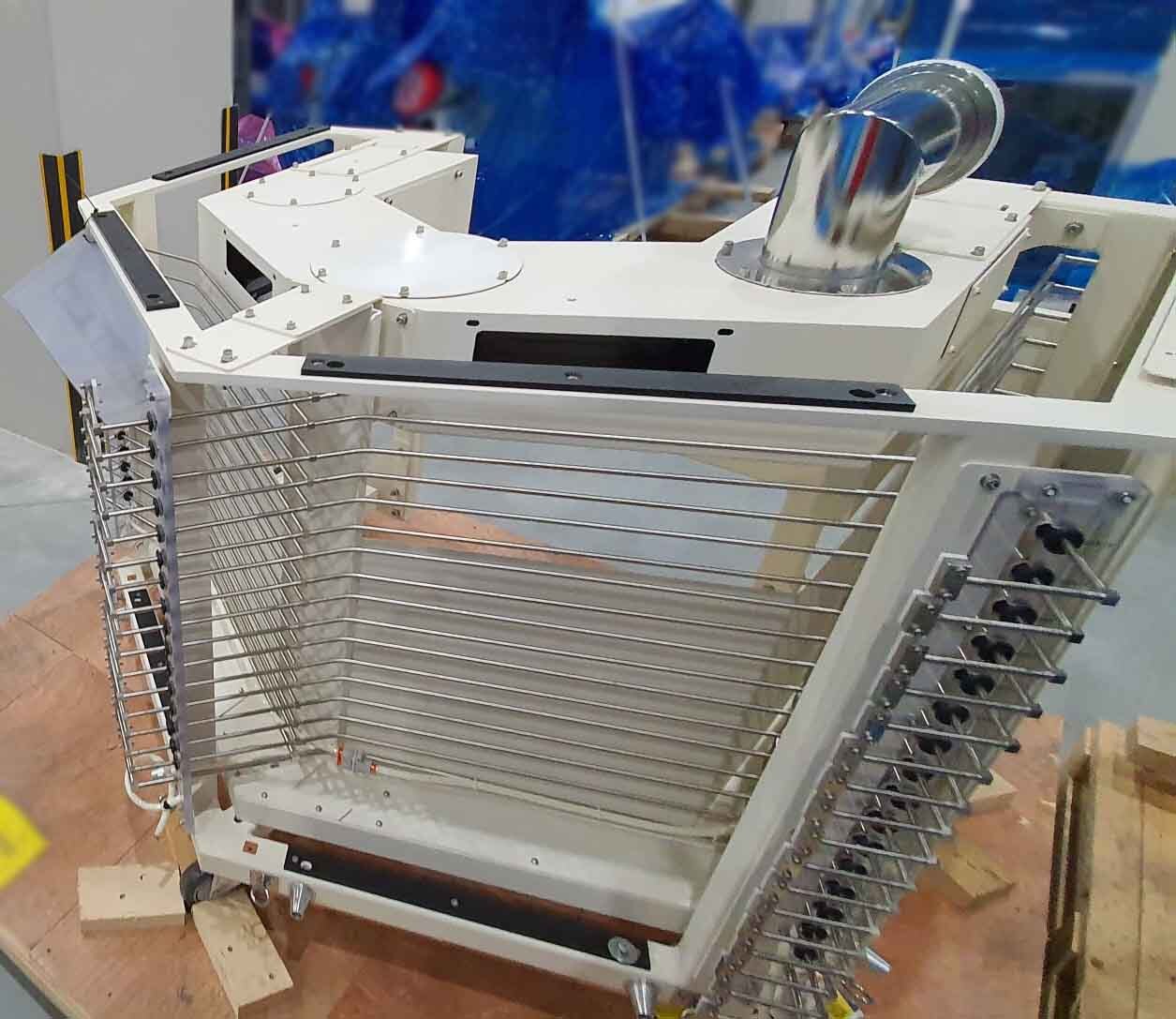

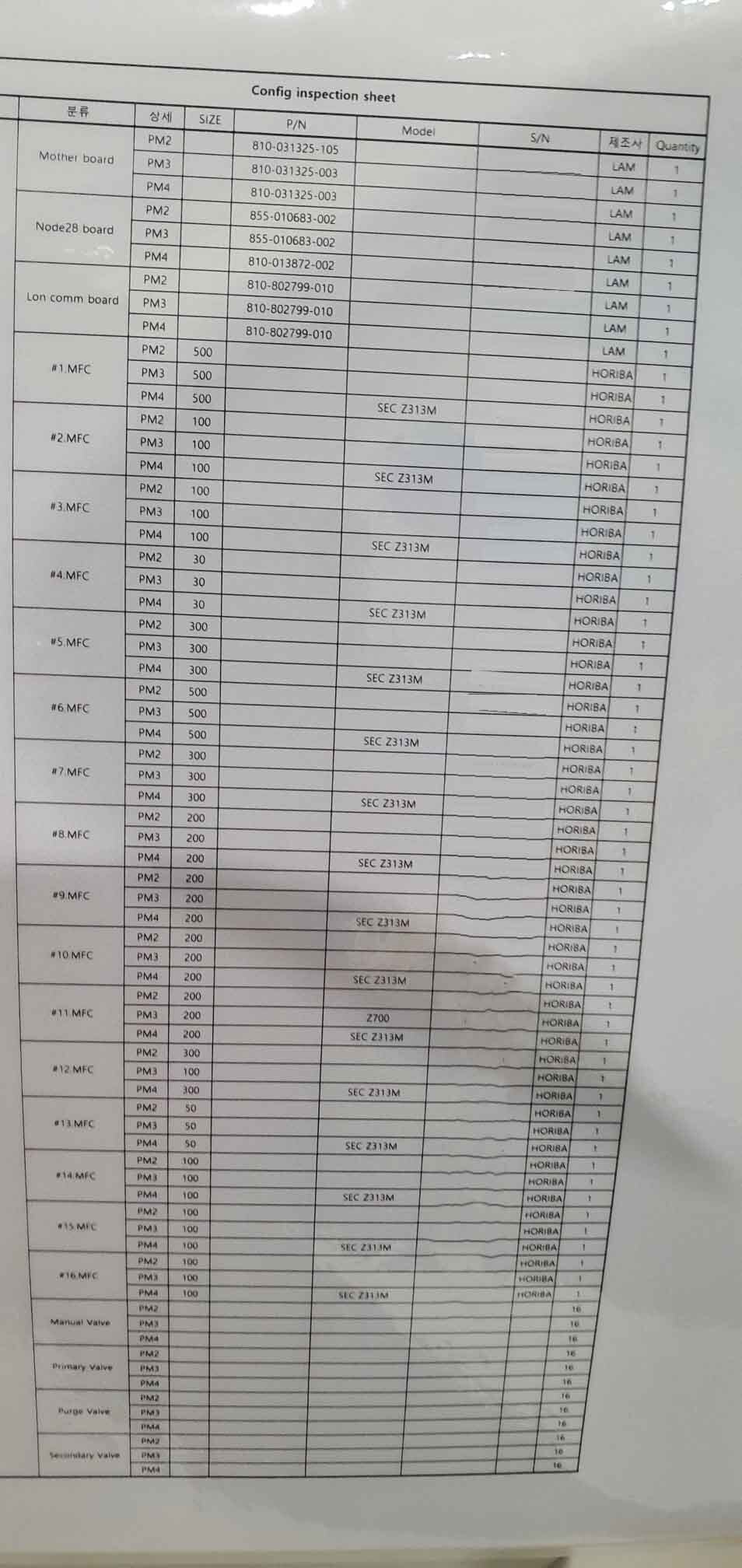

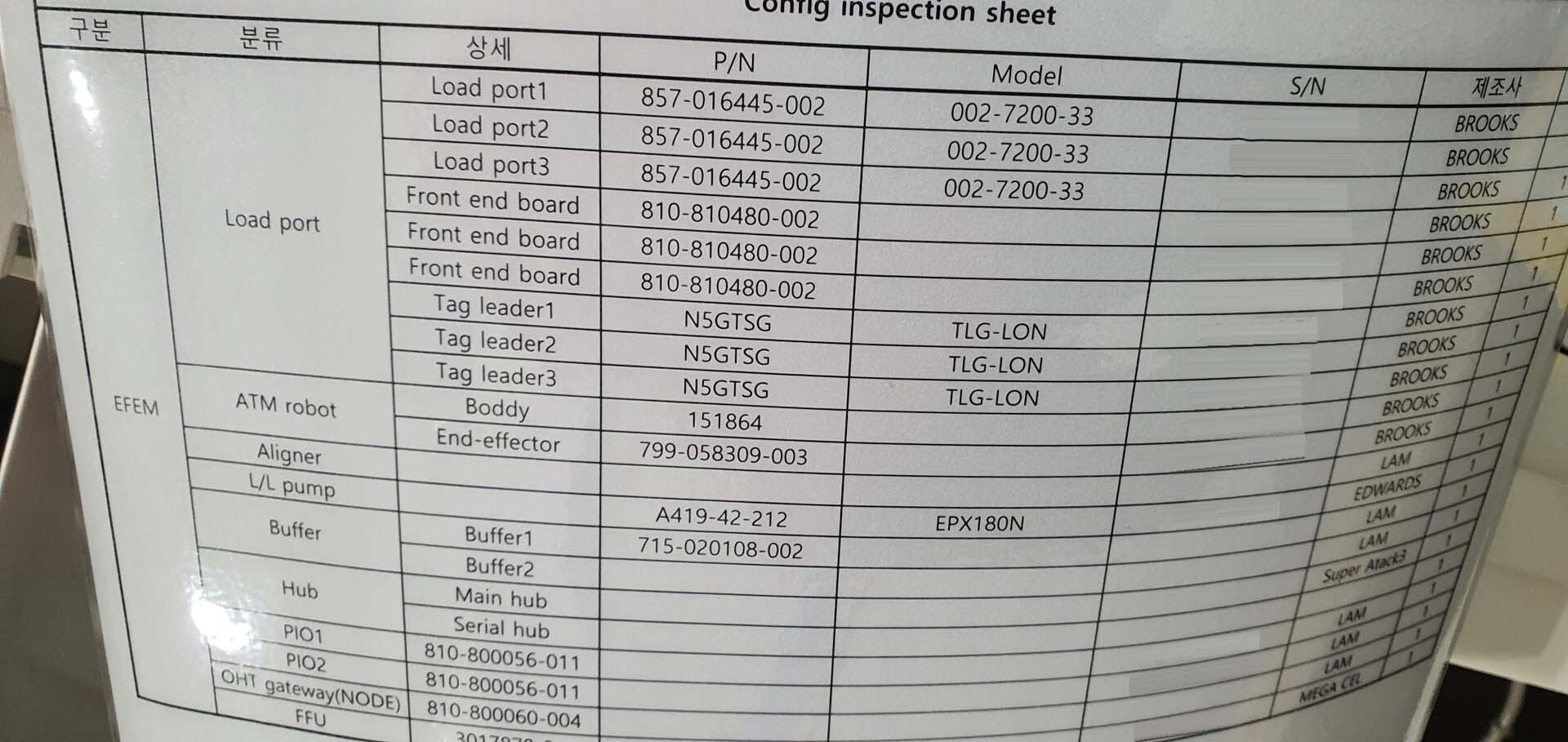

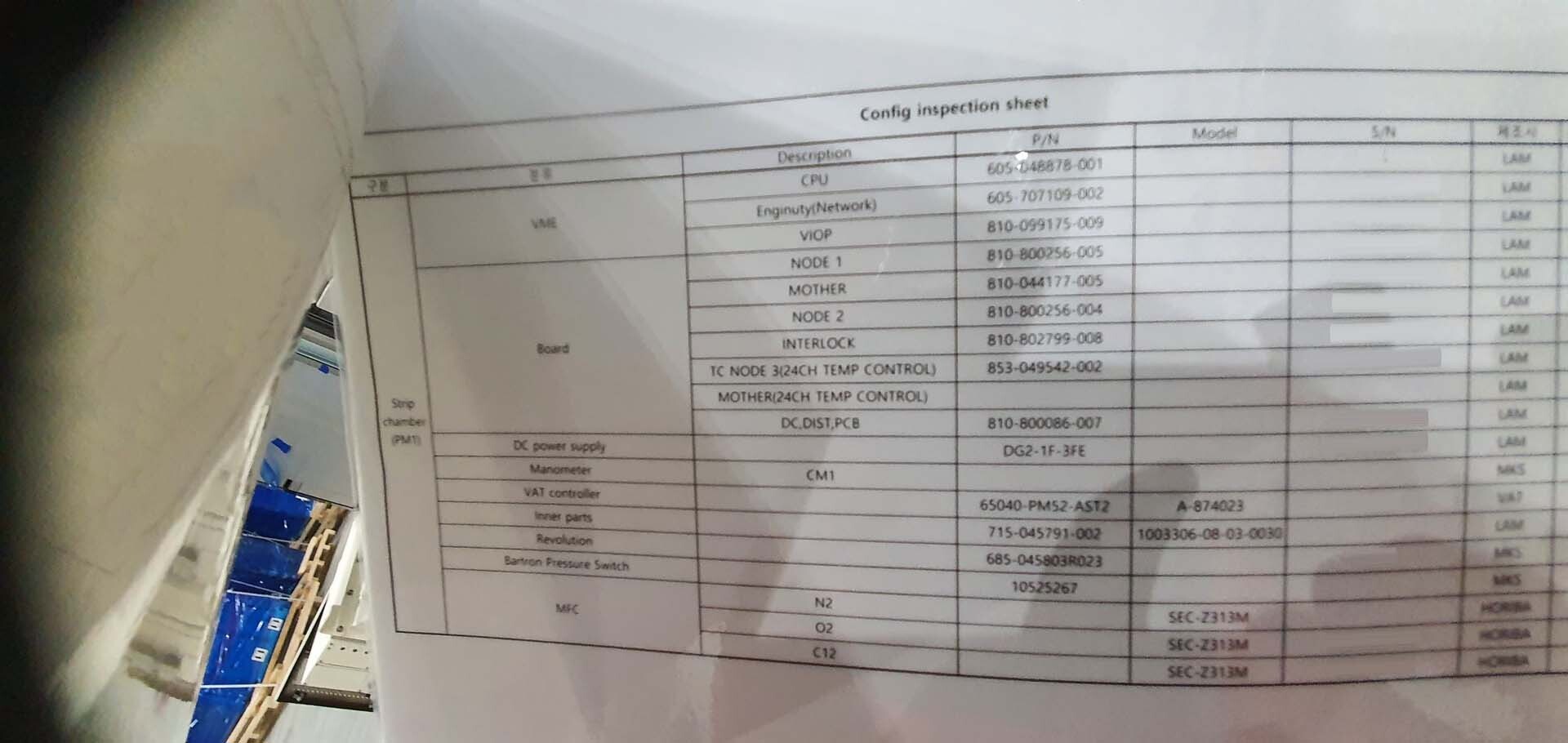

LAM RESEARCH 2300 Kiyo is a multi-function vacuum etcher/asher designed to provide high-precision etching and ashing of a variety of materials. This equipment is used extensively in semiconductor fabrication processes and is capable of etching and ashing wafers and substrates at high repeatability and accuracy. The system can etch and as hard materials as well as mixed plastics and polymers films without any damage to the surface of the material. This is due to the accuracy and repeatability of the process, which allows for precise control over the thickness of the etch and the degree of ashing required. The unit enables multiple etching and ashing processes such as dielectric etching, reactive ion etching (RIE) and reactive ion ashing (RIA). It also has advanced process control capabilities to facilitate rapid and reliable results. Automated feedback control monitors the process to ensure uniform etching and ashing while maintaining repeatability and accuracy. The advanced process chamber design of 2300 Kiyo uses a dry vacuum to etch and ashe materials, reducing the risk of cross-contamination between different substrates and reducing the cost of operation. The chamber also features superior gas injection capabilities, enabling precise control over the deposition rate. The etching and ashing process is completed in a programmable and closed environment to ensure that exposure to chemicals, gases, and particles is minimized. This reduces the risk of particle contamination and improves the overall cleanliness of the process. The flexible chamber design and advanced process control also provide excellent process flexibility in terms of throughput, recipe management, and production scheduling. The machine is also designed for maximum process flexibility, with the ability to run both batch and continuous process modes. In conclusion, LAM RESEARCH 2300 Kiyo is an advanced etcher/asher specifically designed for the etching and ashing of wafers, substrates and a variety of other materials in the semiconductor manufacturing industry. It's advanced chamber design and process control capabilities provide superior process flexibility and precision, and its closed-tool operation ensures that exposure to chemicals, gases, and particles is minimized.

There are no reviews yet