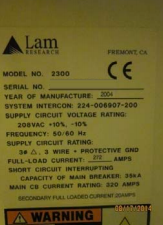

Used LAM RESEARCH 2300 Kiyo #9074799 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9074799

Multi-process etcher, 12"

(4) chambers Kiyo system

(1) 2300 VERSYS SILICON PM, 12"

(1) 2300 System platform

(1) 2300 Process module

(1) 2300 Versys silicon options

2300 Versys Star with tunable ESC

Chemraz O-ring

Heated Foreline

2300 LSR endpoint option: 1 PM

NSR-Kiyo configuration

NSR-Nova 3030 module

(1) Versys silicon quick clean kit

(1) Versys silicon pend. valve kit

(1) 2300 Versys silicon gas box

(1) 9 Gas configuration (IGS)

(7) Additional gas line (IGS)

(1) IGS tool kit

(1) MFC ERGO tool kit

(1) service ladder

(1) Gas box hoist

2300 Platform

(1) 3 FOUP

(3) ASYST RF ADVANTAG

WIDS BTM Read

OHT PIO sensor

Conditioning station

SW: customer supply 3030 CD

User interface: side and front monitor

System up circuitry

Cable: TM-subpanel, 50 ft

System calibration and alignment'

2300 Peripherals

Pump exhaust dilution box

2300 Software features:

Blanket Thickness: Included

Removed the Versys chamber and Modified in 2005,

(3) 2300 VERSYS KIYO PM, 12"

(3) 2300 Process modules

(3) 2300 Versys KIYO options

(3) 2300 Versys KIYO with Tunable ESC

(3) Chemraz O-rings

(3) Heated Forelines

(3) 2300 Versys KIYO gas boxes

(3) 9 Gas configurations (IGS)

(21) Additional gas lines (IGS)

(6) Non Standard MFC

(3) NSR5648_A: gas configuration line 11

2300 Software Features

Blanket thickness: (3) included

2004 vintage.

LAM RESEARCH 2300 Kiyo is a multi-wafer, single-chamber, dry etching and ashing platform used primarily for the etching and ashing of silicon wafers and dielectric layers. The Kiyo's hardware consists of a process chamber, its enclosed power electronics, and its enclosed gas distribution lines. It uses advanced process control, including pressure and temperature control, along with proprietary gas flow control, to help ensure consistent and uniform results across hundreds of wafers. The primary benefit of the Kiyo is its uniform etching performance over large numbers of wafers. It is capable of handling wafers up to 300 millimeters in diameter with a maximum of 4,950 wafers per cycle. The Kiyo uses pulsed Vertical Collimated Ion Source (VCIS) technology to etch the silicon wafers, with precision of less than 1 nanometer, allowing for high-precision etching results. The Kiyo also offers a variety of materials etching process modules, from etching to compound removal, along with vacuum process options such as low-pressure explosive etching. The built-in gas supply system of the Kiyo is designed to ensure uniform gas flow throughout the entire process chamber. It is capable of running both collimated and non-collimated etching processes, as well as a variety of other processes. It also features a smart wafer-handling system, with automated cassette loading, unloading, and tracking capabilities. To ensure process repeatability, the Kiyo uses multiple software systems to monitor and control the process steps. The Kiyo has a dual chamber design, allowing it to process both etching and ashing simultaneously at different temperatures, as well as allowing for a faster run time. It is also equipped with a powerful automated end-point calculation system, providing users with real-time feedback regarding the etching and ashing progress. Lastly, the Kiyo is compatible with a variety of operating systems and has a wide range of process and safety monitoring tools, ensuring reliability and safety throughout the process.

There are no reviews yet