Used LAM RESEARCH 2300 V2 #293595429 for sale

URL successfully copied!

Tap to zoom

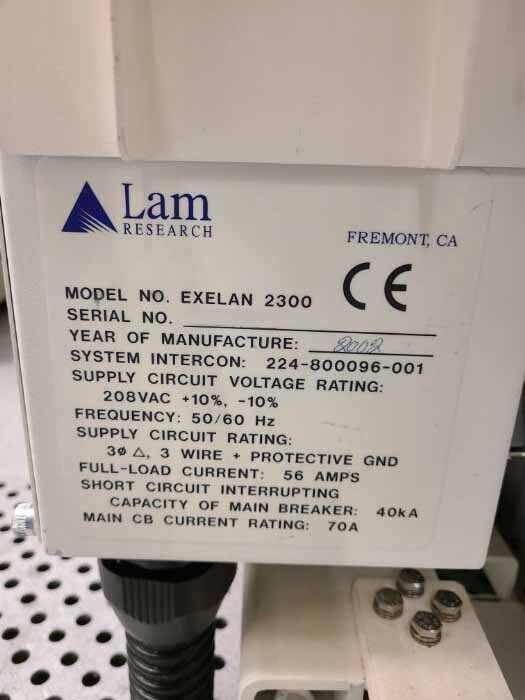

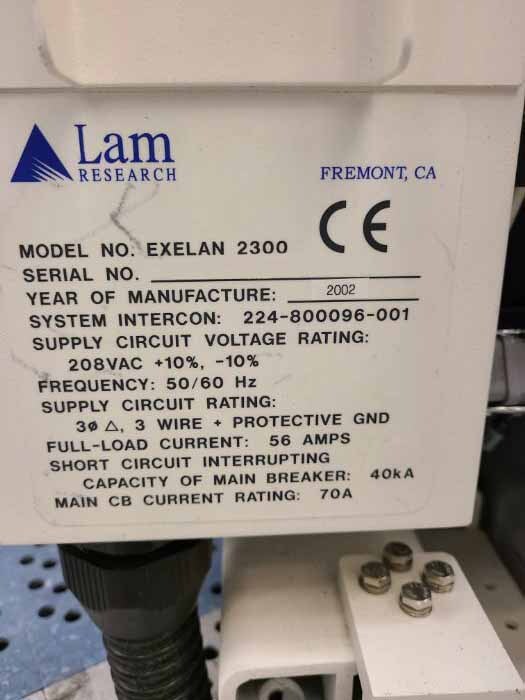

ID: 293595429

Wafer Size: 12"

Vintage: 2002

Plasma processing system, 12"

Etch platform

(4) Exelan Chambers

(4) Gas boxes

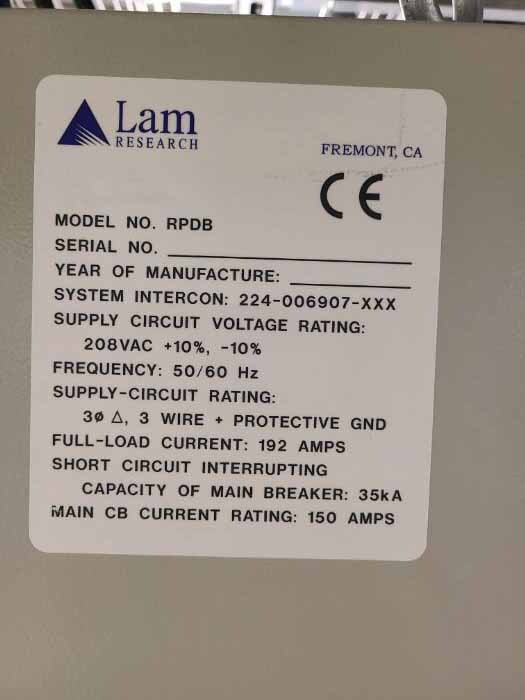

Remote power distribution box

3LP EFEM

Vacuum transfer module

Control rack

BROOKS AUTOMATION ATR8 ATM Robot

BROOKS AUTOMATION MAG7 VTM Robot

(2) FOUPs

Cassette type: 25

No conditioning station

IPX / EPX Pump for TM

Side monitor user interface

Stainless wafer pads

No UPS

No ELB

R-O-G-B Signal tower

ESC Wafer clamping mechanism

ESC Power supply

ESC Hose kit

ESC Barbed facility plate

Wafer life mechanism: Direct drive

O-rings: Fluorosilicon / Viton

ATH 1600 M Turbo pump

Optical emission spectroscopy

Chemraz gate valve

2002 vintage.

LAM RESEARCH 2300 V2 Asher is a fully automated, high-accuracy etcher/asher designed for dry etching of certain materials. It is ideal for use in applications such as device manufacture, semiconductor device processing, MEMS production, circuit board fabrication, and other mass production processes. It is capable of reaching etch depths of up to 300 µm, has an etching accuracy of ±0.05µm, and can operate at a variety of temperatures up to 3000°F (1650°C). 2300 V2 Asher is driven by a sophisticated controller that includes a blowback recirculated wafer cassette drive equipment and a closed-loop process chamber with a vacuum system for optimal process control. The process chamber contains two independent etching systems, the first for etching the substrate and the second for backside etching. It also includes an overhead robot locator and autofocus software. The wafer cassette drive unit allows for efficient loading/unloading of wafers for improved throughput. LAM RESEARCH 2300 V2 is equipped with a number of safety features such as an emergency stop button, interlock protection, a fume detection and filtration machine, and a forced air purge to prevent hazardous gases and aerosols from escaping the process chamber. These features ensure reliable and safe operation of the etcher. 2300 V2 provides a complete etching solution with integrated process control and software. This includes a powerful set of process tools and parameter controls that can be programmed, monitored, and adjusted as needed. This allows users to optimize their process with maximum precision and traceability. The tool is also designed to accommodate a wide variety of customized scripting via the open-source scripting language, allowing users to modify the asset to their specific needs. In conclusion, LAM RESEARCH 2300 V2 is an advanced automated etcher/asher with a wide range of features and capabilities. Its advanced process control and safety features, as well as its open-source scripting language, ensure reliable and accurate operations. Its temperature capability, etching accuracy and throughput make it the ideal choice for mass production and other high-precision fabrication processes.

There are no reviews yet