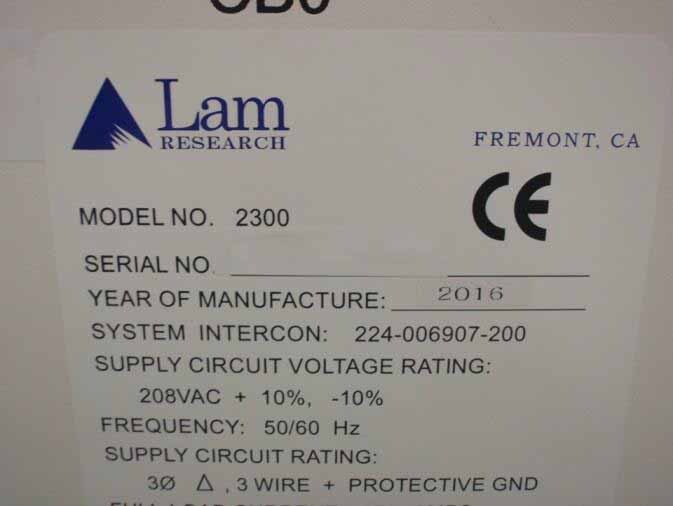

Used LAM RESEARCH 2300 Versys Kiyo #9301851 for sale

URL successfully copied!

Tap to zoom

ID: 9301851

Wafer Size: 12"

Vintage: 2016

Etcher, 12"

Seismic brackets system

SEMI Wafer

Cassette type: 25-Slots

Gas system type: IGS Gas box

Mylar floor template

Manuals electronic CD-ROM

Positions:

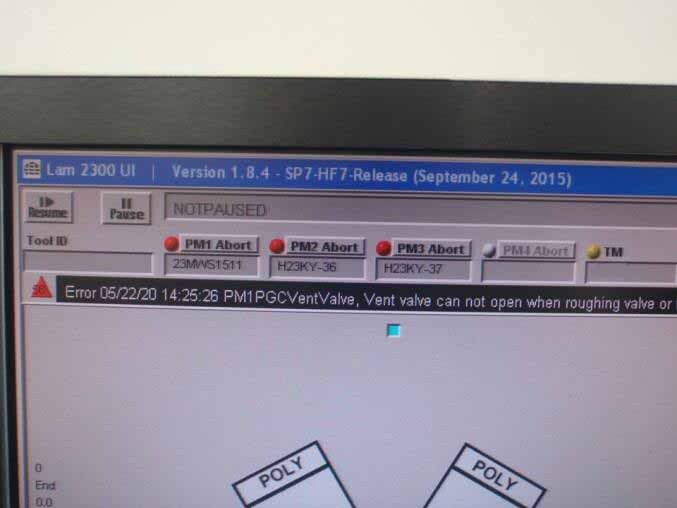

Position 1: 2300 Microwave strip

Position 2 and 3: 2300 Versys Kiyo

Non-standard systems:

NSR300156 Kiyo

NSR301982 RMV Kiyo PM Position-4

Process modules:

(2) Quick clean kits for 2300 Versys Kiyo

(1) Quick clean kit for 2300 MW Strip

Options:

Standard chamber pinnacle (-814)

Tunable ESC Wafer clamping mechanism

Standard fingers RF Ground bracket (-006)

Quartz edge ring

Standard Quartz tunable injector

Standard injector shield

Standard plasma screen (-032)

Gas weldment: Enhanced passivated (-110)

Standard ESC Hose kit

Compression ESC Facility plate

Liner: ACME Coated universal (-838)

Standard chamber manometer

Wafer lift mechanism: Direct drive

Voltage control interface: 800 V

O-rings: Chemraz

Standard TCP Coil

TCP Source dual: 1500 W

300MM Turbo pump: 2200 L/S BOCE (Seiko Seiki)

Heated foreline

Endpoint detection: 2300 LSR with OES 2

Standard chamber viewport window

Chamber isolation valve: Barrier seal door

Viton vacuum valve

Lower isolation valve: Chemraz dry (-006)

Water control passive:

RF PCW Control

Pump to TCU: 25ft

TCU to PM: 50ft

PM to Pump interconnect: 50ft

TCU to RPDB: 25ft

Pump to RPDB: 25ft

Microwave strip options:

O-rings: Fluorosilicon / TEV

Microwave source: Quartz

Baffle: Quartz

Leak check port

Chamber isolation valve: Barrier seal door

Throttle valve (-003)

2-Line on-board gas delivery

PM to Pump interconnect: 50ft

Pump to RPDB: 25ft

Gas box:

Standard gas containment

Top exhaust gas system

Gas box:

Advanced chamber condition control

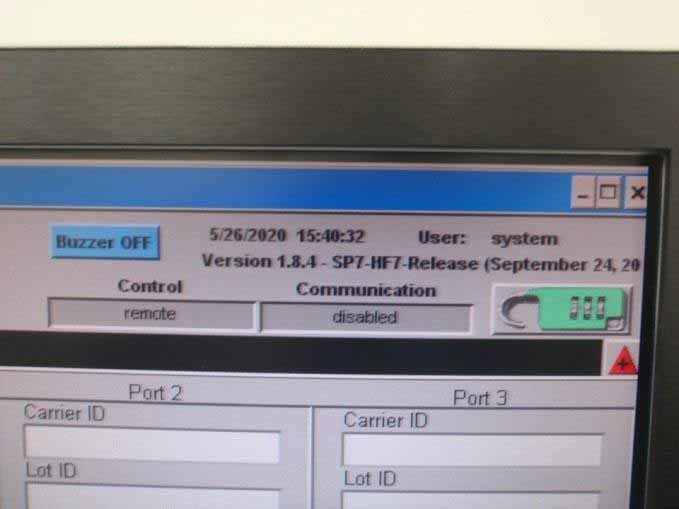

MFC Type: STEC SEC-Z313

No display in transducer

(16) Gas lines

Heated gas lines: Position 1 and 2

Gas box inlet option: Regulated inlet gas panel

Standard gas filter

Non-standard PM/GB Feature:

(2) FUJIKIN NSR 301983 MFC on PM4 IGSGB <PM4>

Line6 : FUJIKIN FCST1005NZFC_4J2, SO2 at 200sccm

Line16 : FUJIKIN FCST1005NZFC_4J2, Ar at 500sccm

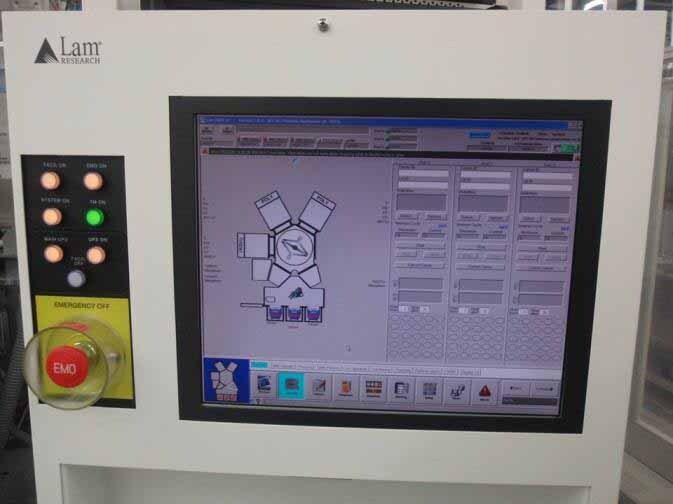

2300 Platform

Standard front fascia

Front end load port cassette: (3) FOUPs

Cassette ID: Keyence BCR Carrier ID

Factory automation: OHT PIO Sensor

Airlock wafer fingers: Stainless wafer pads

EPX Backing pumps for TM

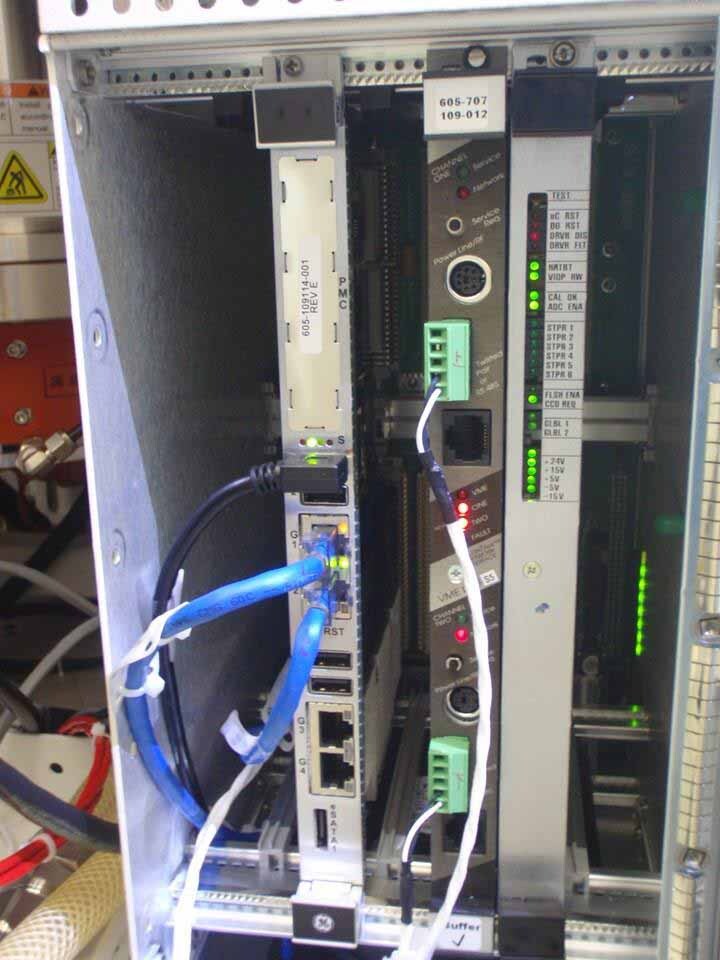

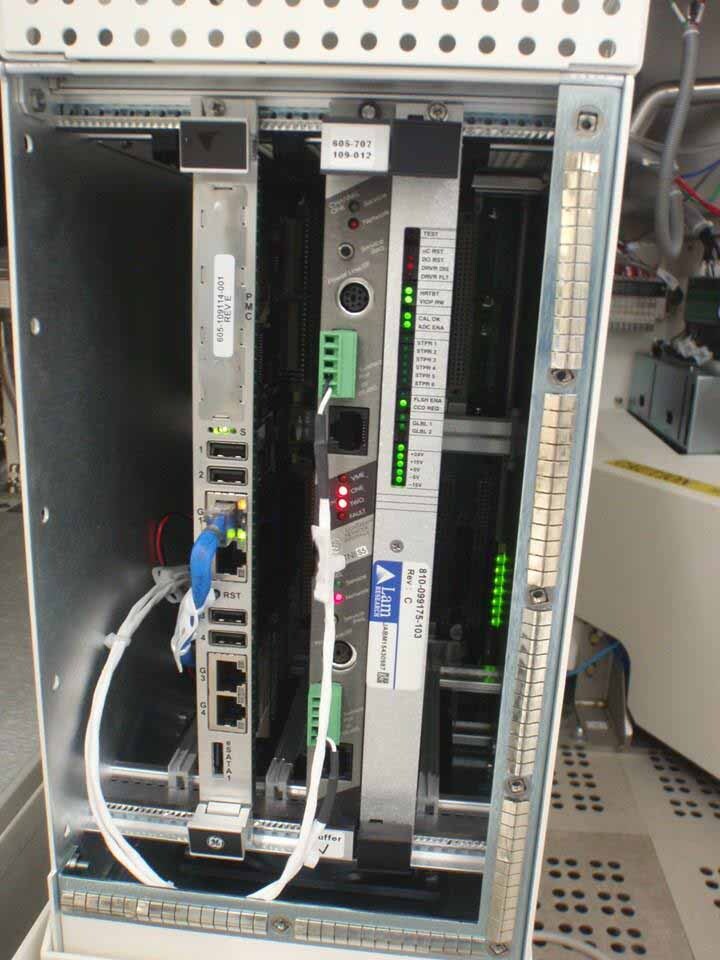

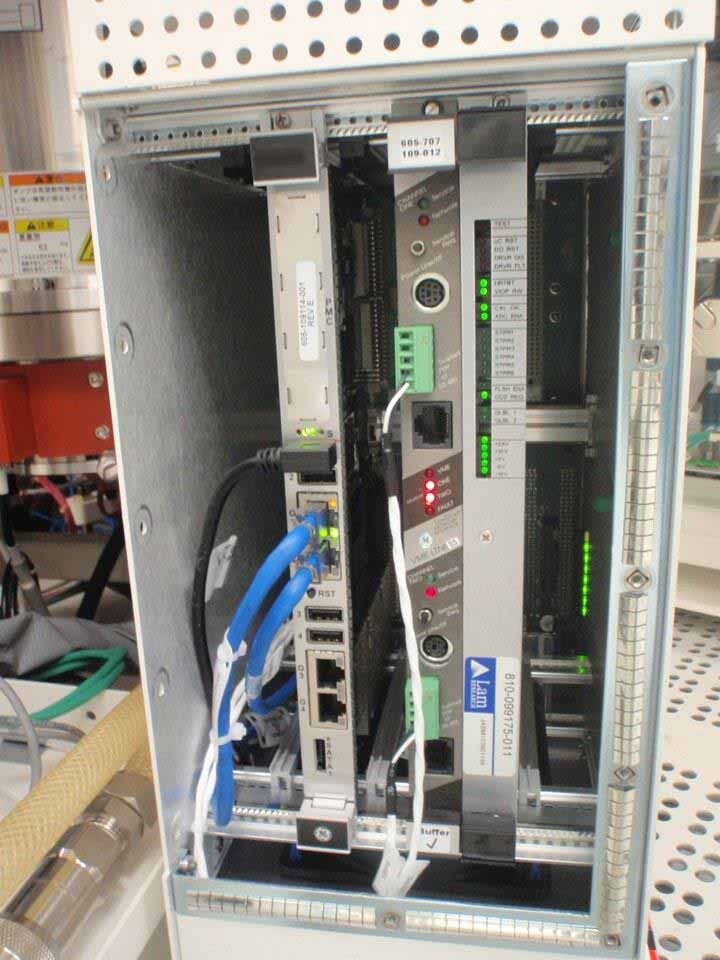

Control rack configuration:

Side monitor user interface

Earth Leakage Breaker (ELB)

RPDB

Interconnect cables: TM to RPDB, 50ft

Signal tower

System options:

System calibration and alignment

Service step for PM

Robot CDM

Non-Standard TM Feature:

NSR6975 Facility IF board kit and SW Key

NSR101080 Vespel endeffector on V2 TM

Gas box configuration:

PM2:

Line / MFC Type / Gas type / Gas Flow

Line 01 / SZ313 / SICL4 / 50

Line 03 / SZ313 / NF3 / 500

Line 04 / SZ313 / CL2 / 200

Line 05 / SZ313 / HBr / 500

Line 06 / SZ313 / SO2 / 200

Line 07 / SZ313 / CH2F2 / 200

Line 09 / SZ313 / O2 / 10

Line 10 / SZ313 / SF6 / 50

Line 11 / SZ313 / O2 / 500

Line 12 / SZ313 / N2 / 100

Line 13 / SZ313 / CF4 / 200

Line 14 / SZ313 / CHF3 / 300

Line 15 / SZ313 / He / 500

Line 16 / SZ313 / Ar / 500

PM3:

Line / MFC Type / Gas type / Gas Flow

Line 01 / SZ313 / SICL4 / 50

Line 03 / SZ313 / NF3 / 500

Line 04 / SZ313 / CL2 / 200

Line 05 / SZ313 / HBr / 500

Line 06 / SZ313 / SO2 / 200

Line 07 / SZ313 / CH2F2 / 200

Line 09 / SZ313 / O2 / 10

Line 10 / SZ313 / SF6 / 50

Line 11 / SZ313 / O2 / 500

Line 12 / SZ313 / N2 / 100

Line 13 / SZ313 / CF4 / 200

Line 14 / SZ313 / CHF3 / 300

Line 15 / SZ313 / He / 500

Line 16 / SZ313 / Ar / 500

PM4:

Line / MFC Type / Gas type / Gas flow

Line 01 / SZ313 / SICL4 / 50

Line 03 / SZ313 / NF3 / 500

Line 04 / SZ313 / CL2 / 200

Line 05 / SZ313 / HBr / 500

Line 06 / SZ313 / SO2 / 200

Line 07 / SZ313 / CH2F2 / 200

Line 09 / SZ313 / O2 / 10

Line 10 / SZ313 / SF6 / 50

Line 11 / SZ313 / O2 / 500

Line 12 / SZ313 / N2 / 100

Line 13 / SZ313 / CF4 / 200

Line 14 / SZ313 / CHF3 / 300

Line 15 / SZ313 / He / 500

Line 16 / SZ313 / Ar / 500

2016 vintage.

LAM RESEARCH 2300 Versys Kiyo is a versatile and efficient etching equipment designed specifically for applications such as silicon single-crystal thin-film deposition, advanced photolithography, and surface scratches repair. This system is a high-end etcher/asher equipped with advanced technologies such as plasma etching, Dry-Oxide deposition, etching, and resist deposition. 2300 Versys Kiyo features a 20kHz plasma input frequency, as well as a wide range of process gases for reliable etching processes. It is a fully automatic machine that takes care of the entire process, from loading the wafer to unloading the results. To ensure accurate and repeatable results, the etcher features an automatic wafer handling unit and a built-in vacuum chamber. LAM RESEARCH 2300 Versys Kiyo also features the latest in-situ imaging and advanced process control, allowing the user to monitor the process and make quick changes on the fly. To ensure consistent, high-precision results, the machine is equipped with a 6-axis tilt and 2-axis yaw positioner. It also offers an optional in-chamber ion source for etching using controlled atmospheric processes. With its advanced features and durable, reliable construction, 2300 Versys Kiyo is an excellent choice for a wide range of demanding etching and ashing applications. The tool is certified to strict safety standards and is equipped with a fail-safe asset that provides an additional layer of protection during the etching process. Additionally, with its high efficiency and fast turnaround, LAM RESEARCH 2300 Versys Kiyo is ideal for rapid prototyping and rapid development in product design.

There are no reviews yet